IOSM-240 BLB

Looking for a specific replacement part? Ctrl-F (or Command-F for Mac users) brings up your browsers search panel and can search any text on the entire web page. Find parts by searching a part # or part description.

Register your equipment with BHS Optima, BHS's free app.

California Residents: WARNING: This product contains chemicals known to the State of California to cause cancer and/or reproductive harm, and birth defects or other reproductive harm. Learn more here.

Battery Lifting Beam (BLB) System Parts & Service Manual

SAFETY

GENERAL SAFETY PRACTICES WHEN HANDLING SUSPENDED LOADS

GENERAL SAFETY PRACTICES WHEN HANDLING SUSPENDED LOADS

- Always lock your elbow and stay at least an arm's length away from the load.

- Position hand at rear of lifting beam to help guide battery.

- Never use your body or limbs to stop a swinging load.

- Be sure feet are not under the battery and are out of the primary danger zone.

- The operator, as required by your company's safety policy and/or O.S.H.A, SHALL wear the proper safety equipment.

- All lifting apparatus SHALL be inspected at the beginning of each shift to ensure no damage or defects are present that could pose a safety hazard.

- Areas of travel SHALL be clear of any trip hazards and obstacles.

- Only trained and authorized personnel SHALL operate overhead lifting equipment and this battery below-the- hook device.

- The operator SHALL verity that any load slings or below-the-hook devices are properly secured to the load prior to lifting or moving the load.

- No other persons SHALL be in the work area or travel path of the load or empty below-the-hook device.

- The operator SHALL NOT place hands or fingers on hooks.

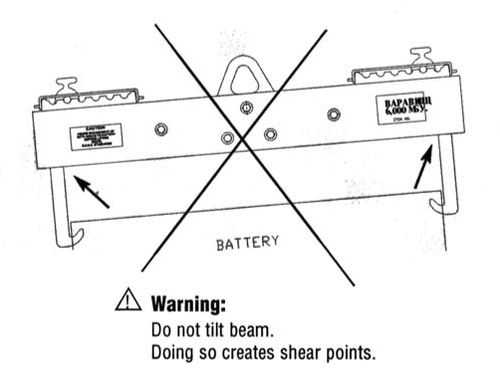

- The operator SHALL NOT tilt the below-the-hook device causing the hooks to hang outside the lines of the below-the-hook device.

BATTERY LIFTING BEAM DAILY INSPECTION

BATTERY LIFTING BEAM DAILY INSPECTION

Inspections are to be performed: " At the beginning of each shift and/or before first use." Using a lifting device that is worn or damaged can cause loss of load and possible personal injury or death.

- Inspect the wood laminate load members for any cracks, splits, indentions, or delamination.

- Inspect all attaching hardware for tightness and wear.

- Inspect hook adjusting trunnions for wear or damage.

- Inspect load pins on battery lift hooks for wear or damage.

- Inspect battery hook engaging throat for excessive wear or damage.

- -Minimum throat height - 5/8" at center of throat.

- Inspect lift "A" plate for excessive wear.

- -Minimum height - 3/4" at engagement point to hoist.

If any of the above conditions do not meet wear and/or dimensional specifications, this device should be removed from service and replaced immediately.

PROPER HOOK ENGAGEMENT OPERATION

PROPER HOOK ENGAGEMENT OPERATION

Lower the lifting beam horizontally until the hooks are slightly above the battery eyelets.

Push the beam forward a few inches to allow the hook farthest from you to pass the outside edge of the battery eyelet.

Lower the beam until the hook inserts into the eyelet.

Push down slightly on the heal of the beam closest to you and lower it until the hook can be inserted into the battery eyelet closest to you .

Lift the beam slightly to engage the hooks completely in the eyelets of the battery.

Insure both hooks are fully engaged in the battery eyelet.

Continue to lift and move battery

PROPER HOOK POSITION FOR THE BHS BLB-6000 BATTERY LIFTING BEAM

PROPER HOOK POSITION FOR THE BHS BLB-6000 BATTERY LIFTING BEAM BASIC OPERATION NOTES

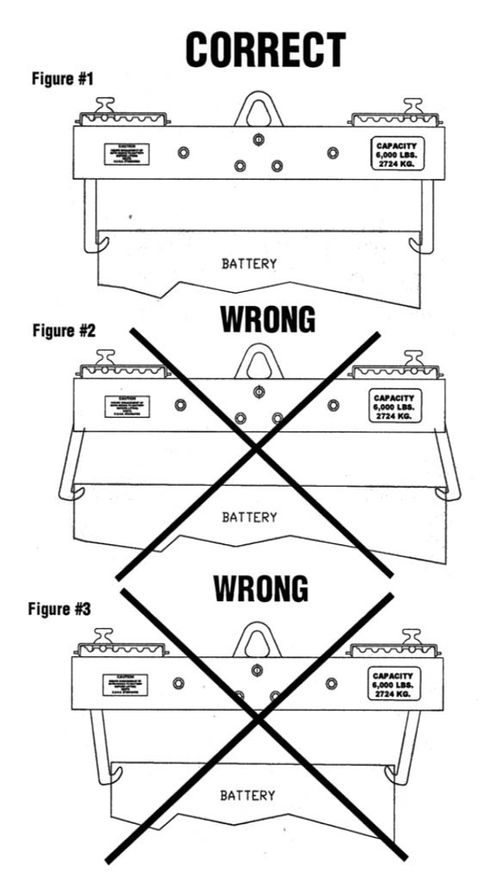

Make sure hooks are fully engaged in battery lifting eyelet prior to lifting the battery. Hooks SHALL be fully inserted into the battery holes as shown in Figure #1

Hooks SHALL be spaced equally around the center line of the below-the-hook device and be properly placed in the scalloped adjusting trunnions. Correct positioning of the hooks will allow the battery to be level when lifted.

Hooks SHALL be hanging in a vertical position as shown in Figure #1. Do not allow hooks to be tilted inward or outward as in Figures #2 and #3.

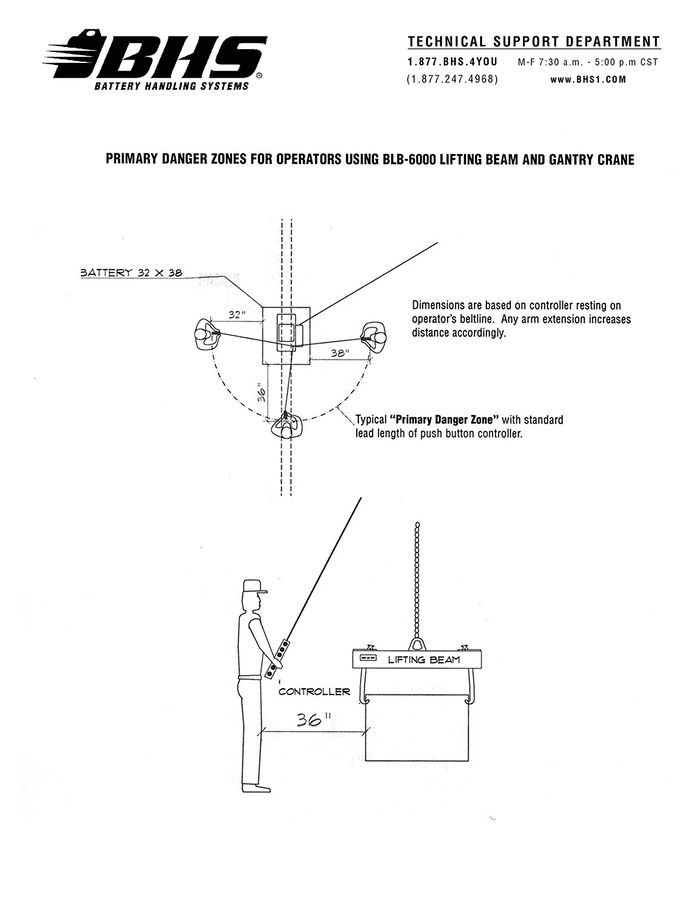

PRIMARY DANGER ZONES FOR OPERATORS USING BLB-6000 LIFTING BEAM AND GANTRY CRANE

BLB-6000

BLB-6000

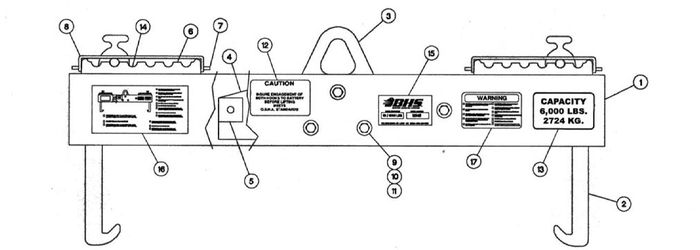

Item | PPart No. | Description | Qty |

1 | 24016003 | Wood BLB-6000 Beam | 2 |

2 | 24015001 | Hook Standard | 2 |

3 | 24016001 | Lift Plate - Hook | 1 |

4 | 24017002 | Plate Spanner | 2 |

5 | 24017005 | Spacer - Block | 2 |

6 | 24096001 | Trunnion - Aluminum | 4 |

7 | LB0080 | Pin - Spring 1/4" x 1 1/2" | 8 |

8 | LB0060 | Straps - Tie | 4 |

9 | LB0090 | Bolt 1/2 x 5 NCGR5 | 5 |

10 | HW0111 | Washer 1/2 Flat - Zinc | 10 |

11 | LB0100 | Nut- Lock - Cone 1/2" x 13 | 5 |

12 | 00196411 | Label Danger - Insure Engagement | 2 |

13 | 00196703 | Label - Capacity 6000 Lbs. | 2 |

14 | LB0070 | Screw Wood #10 x 2 FHWS | 12 |

15 | LB0130 | Tag Serial # - BLB-6000 | 1 |

16 | LB-Inspection Label | Label - Caution - Inspection - BLB-6000 | 1 |

17 | 00196213 | Warning Label | 1 |

SP-2400 | Parts & Service Instructions | 1 |

LOAD CAPACITY STATEMENT MODEL BLB-6000 BATTERY LIFTING BEAM AND BUILT TO STANDARDS

LOAD CAPACITY STATEMENT MODEL BLB-6OOO

BATTERY LIFTING BEAM

The battery lifting beam model number BLB-6000 has a stated load capacity of 6000# (six thousand). It is designed and tested to meet or exceed any governing rules and regulations pertaining to sufficient factors of safety as well as safety features when used according to its original intent.

Any misuse, abuse or modification to said unit voids all factory warranties. As with any lifting device, units should be visually inspected before each use for any signs of damage or wear.

Built To Standards

The BLB-6000 was designed and built to current industry and government standards and guidelines. For more information see the following.

- American National Standards Institute (ASME) B30.20

- American National Standards Institute (ASME) B30.20

- Occupational Safety and Health ACT (OSHA) (Standards 29 CFR)

STATEMENT OF WARRANTY

Statement of Warranty

Click here for details on BHS' Statement of Warranty.