IOP-60701004 Powered Dock Gate

Looking for a specific replacement part? Ctrl-F (or Command-F for Mac users) brings up your browsers search panel and can search any text on the entire web page. Find parts by searching a part # or part description.

Register your equipment with BHS Optima, BHS's free app.

California Residents: WARNING: This product contains chemicals known to the State of California to cause cancer and/or reproductive harm, and birth defects or other reproductive harm. Learn more here.

Powered Dock Gate (PDG) Parts & Services Manual

GENERAL INFORMATION

Read and understand this manual before installation, use, and maintenance for your gate. Please be sure that no individual is allowed to use this unit unless they have been fully trained and familiarized with the operating instructions of this manual. Also, ensure that at least one person on site is familiar with the maintenance section of this manual and is responsible for performing the defined tasks. If you have any questions regarding operation, service, or the contents of this manual, please contact your dealer or BHS Technical Support 1.877.BHS.4YOU (1.877.247.4968) or visit tech.bhs1.com.

Dock Gates (hereafter referred to as “DG”) provide a safer workplace by protecting personnel, equipment, and property from accidental injury and damage. Dock Gates are available in many standard sizes and capacities to provide a safer work environment. Please consult a dealer or sales representative for application specific needs.

GENERAL SAFETY

- Read and understand all instructions and warnings before using or servicing this equipment

- Keep these instructions for future reference.

- Unit(s) shall only be used indoors in an industrial setting on a hard, nonslip, and level floor without irregularities including but not limited to holes, gouges, cracks, drains or obstacles comprised of concrete or other suitable industrial material.

- Forces required to operate the DG unit will vary with size of the gate, floor conditions, and unit conditions.

- DG units are designed to be operated only when securely mounted to the floor using approved hardware.

- A licensed structural engineer should be consulted prior to installing an DG unit on any building level other than the ground floor.

- A certified electrician should be used to install all electrical components and wiring.

- Perform system and safety checks prior to operating.

- Failure to follow these instructions and warnings may result in property damage, personal injury or death.

WORK AREA

- Keep work area clean and well lit. Cluttered work areas and poor lighting can lead to accidents.

- Clean-up/contain any fluid spills immediately to prevent slips or falls.

- Be aware of potential hazards when performing any service or maintenance to the unit.

SERVICE & MAINTENANCE

Service personnel shall wear Personal Protective Equipment (PPE) appropriate for the task being performed. Use crossbar stands before performing any repairs or maintenance on the unit.

LOCKOUT/TAGOUT

Lockout/tagout the unit if damaged or not functioning properly. Lockout/tagout and de-energize all systems prior to performing any maintenance or service to unit(s).

This unit is not approved for outdoor use. The Dock Gate is not weather resistant and must be stationed indoors at all times.

For custom applications, and modifications please contact BHS directly.

Any instance in which the gate is impacted by a fork truck, transport vehicle, or other equipment, the crossbar should be inspected by the appropriate personnel to ensure structural integrity. For replacement parts, please contact BHS directly.

INSTALLATION

INSTALLATION NOTES

THIS UNIT WAS DESIGNED TO BE INTEGRATED INTO NEW AND EXISTING PASSAGEWAYS. It is the responsibility of the end-user to ensure proper installation by a certified technician. All electrical installation must be completed by a certified electrician. Ensure installation of the unit will not override any safety features or create pinch points with existing equipment or in any way create unsafe working or operating conditions.

Prior to installation of the unit, unpack and remove all shipping materials. A visual inspection should be conducted to check for missing parts or if damage occurred during transit.

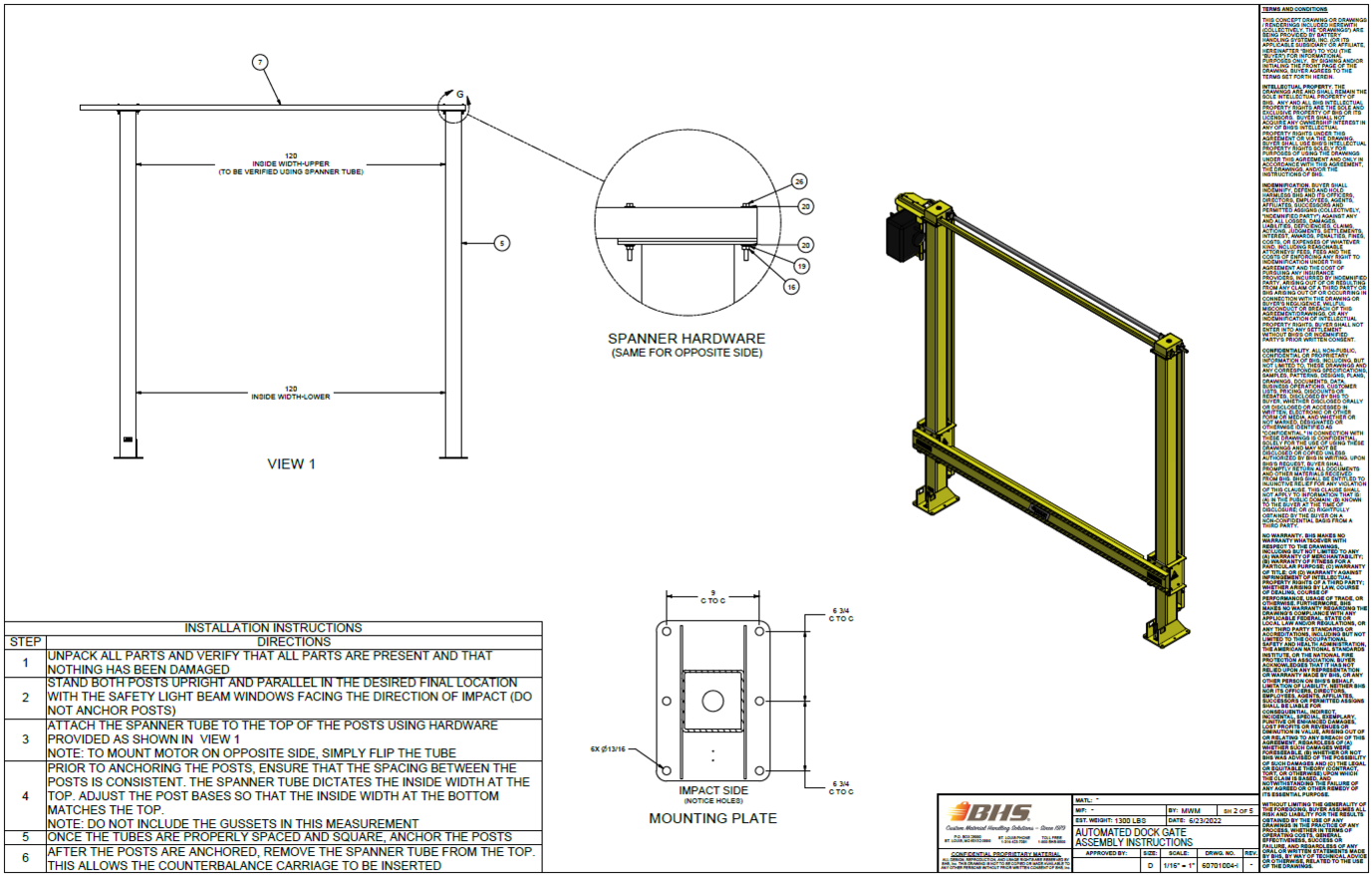

Floor anchors are not provided with the Dock Gate.

Failure to follow proper safety procedures will result in serious personal injury or death.

- Refer to Section D “Service & Maintenance”

- Clear the installation area and inspect the installation surface using a level or straight edge. If the surface is not level, add shims under the base frame around the entire perimeter for proper load distribution.

- Place the unit in the installation area using an approved method such as a forklift, gantry, crane, or other approved lifting devices

- (6) anchor points are required for each vertical post. Anchor the posts in the installation area using appropriately rated hardware or anchors.

- The posts must be parallel to ensure smooth operation and eliminate chance of binding.

FAILURE TO PROPERLY ANCHOR THE UNIT MAY LEAD TO SERIOUS PERSONAL INJURY OR DEATH.

If manual hoist chain is installed, ensure that the chain is restrained to avoid tripping hazard or entanglement. Refer to included motor manual for information regarding switching the drive type to the manual chain hoist.

The 3-button control should be securely wall-mounted at least 48” from unit to eliminate risk of operator entanglement.

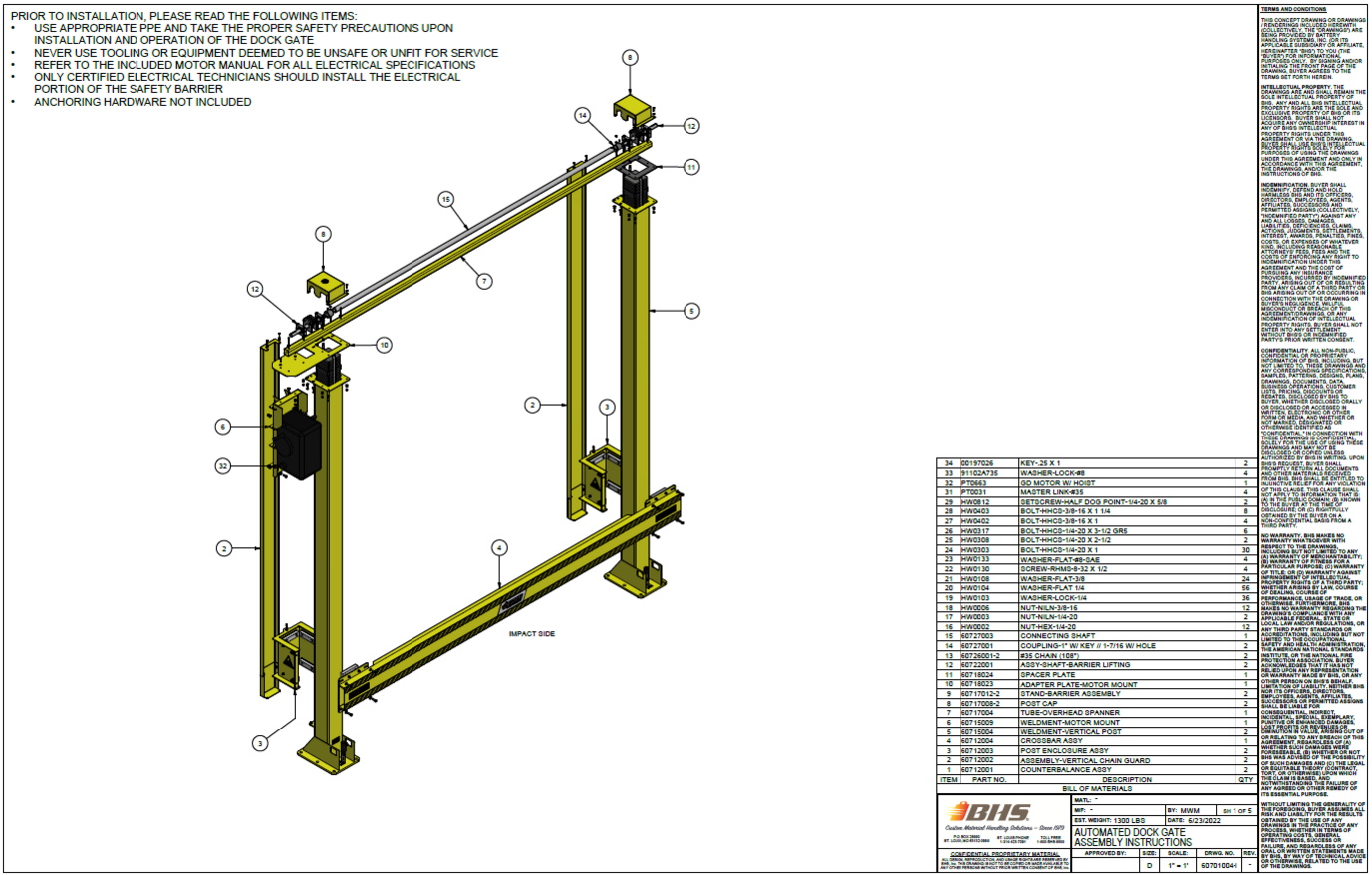

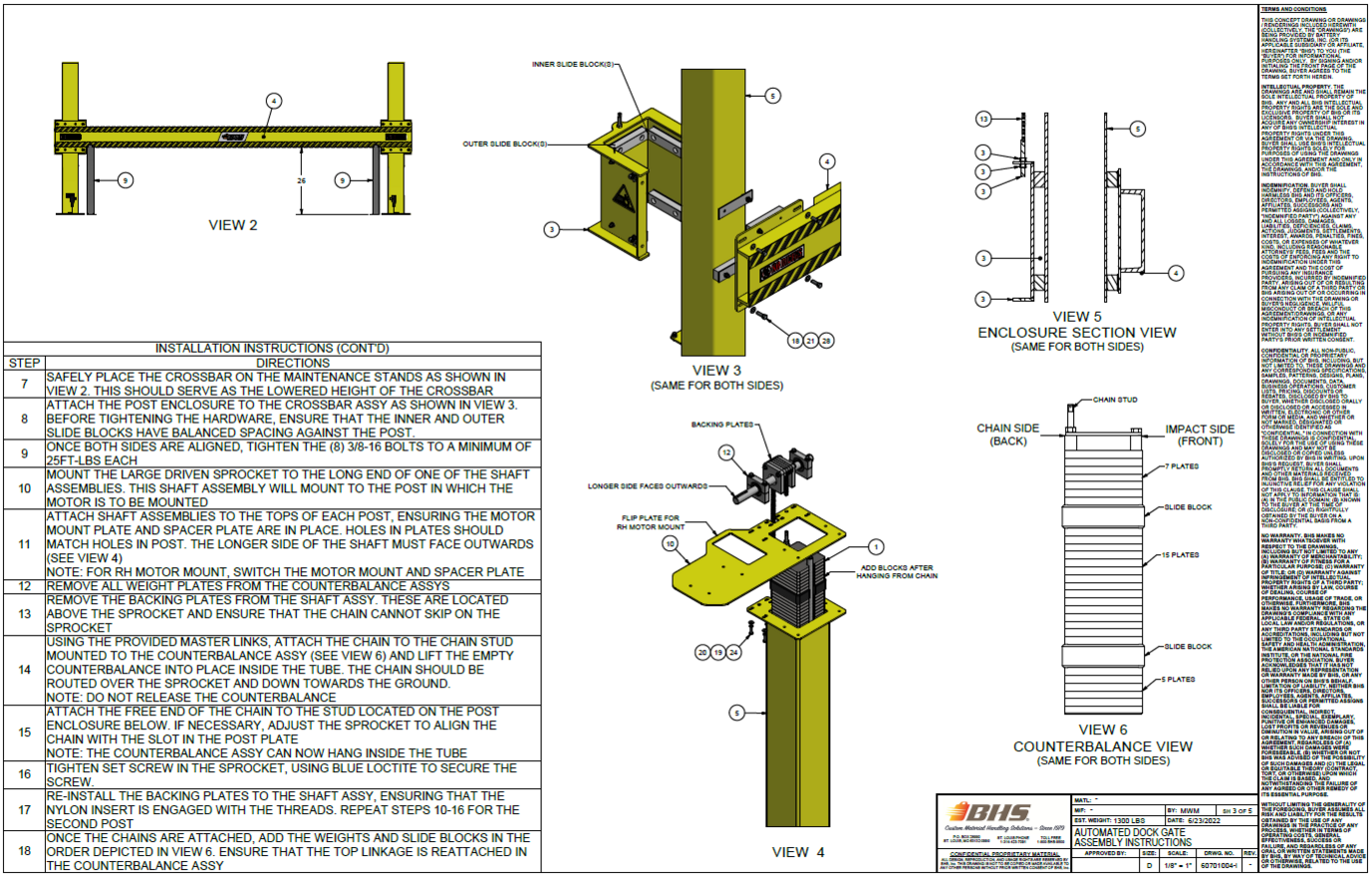

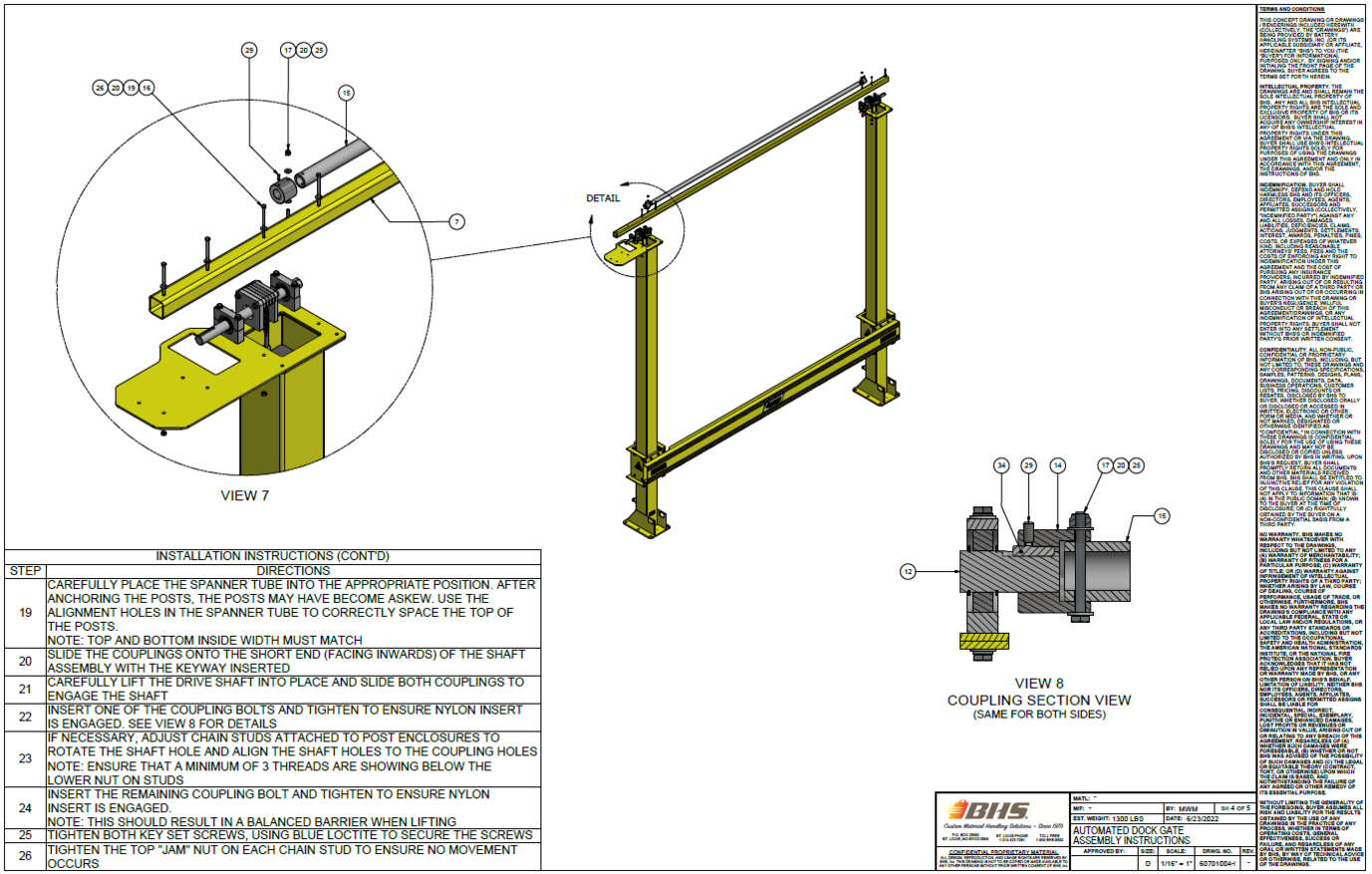

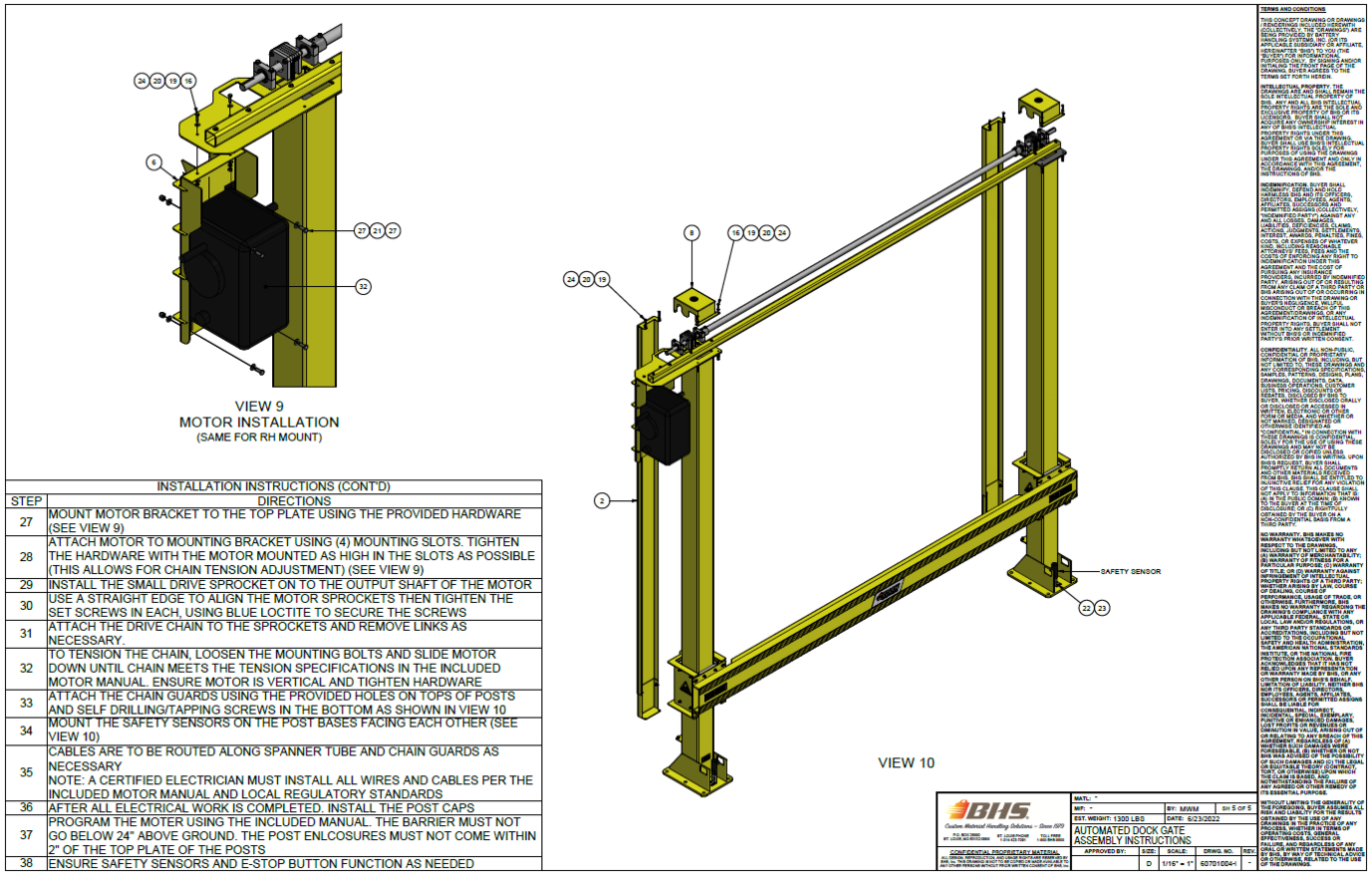

Refer to the included “Installation Instructions” for information pertaining to dimensions, specs, and step-by-step instructions.

Refer to the included motor manual for information pertaining to the installation and set-up of the motor.

OPERATING CONTROLS

The following instructions will guide you through the basic steps necessary to properly and safely operate this unit. Before using the Dock Gate, the operator should:

- Read and understand this manual and the operating instructions.

- Be thoroughly trained on the use and safety of this unit.

- Inspect for proper operating conditions and safety devices.

- Check for and eliminate any obstructions in the travel path.

- Inspect all electrical connections to ensure they are complete and operational.

- Confirm that the safety light beam sensors are operational and cause the device to stop/reset

KEEP HANDS, ARMS, FEET, LEGS, HAIR, CLOTHING, AND JEWELRY OUT OF THE GATE TRAVEL PATH WHILE THE UNIT IS IN OPERATION.

OPERATING THE GATE

Modifications, alterations, and additions to this unit shall not be made without prior written consent from the manufacturer. Customers are responsible for the proper maintenance and upkeep of the unit upon receipt of the product.

- NEVER EXCEED THE CYCLE LIMIT. This unit is rated for a maximum of 15 cycles/hour. Exceeding this limit can result in damage to the unit, shorten the product’s lifespan, and void the unit’s warranty.

- NEVER ALLOW GATE TO CONTACT TOP OF POSTS OR LOWER BELOW 24” HEIGHT. Exceeding these limits can lead to binding, mechanical failure, or damage to product.

- ALWAYS ALLOW DG TO FINISH THE LIFT CYCLE PRIOR TO PASSAGE. Failure to allow DG to complete its cycle can result in damage to unit.

- ALWAYS LEAVE DOCK GATE IN DOWN POSITION. DG is most effective when the Dock Gate is in the down position (24”-28” height).

- ALWAYS KEEP DG TRAVEL PATH CLEAR. The DG travel path must always be kept clear of objects and personnel during operation. Failure to do so may lead to serious personal injury or death.

- NEVER ADD LOAD TO GATE. Do not add additional load to the DG. Adding load could cause the gate to fail, potentially dropping/damaging the gate and causing severe personal injury or death.

- IN CASE OF EMERGENCY, PUSH THE RED STOP BUTTON ON THE CONTROL PENDENT.

CONTROLS

- The Powered Dock Gate includes a 3-button control to be wall mounted (see below)

- Holding the OPEN button will lift the gate to the predetermined maximum height.

- Holding the CLOSE button lowers the gate to the predetermined lowered height.

- The red STOP button will cause the gate to stop immediately.

- Once the OPEN or CLOSE cycle is started, it is best to avoid jerking movement gate, barring emergency situations.

- Hoist includes manual hoist capabilities. To operate in manual mode, refer to the motor manual provided.

KEEP ALL HANDS, ARMS, FEET, LEGS, HAIR, CLOTHING, AND JEWELRY OUTSIDE OF AND AWAY FROM THE PERIMETER OF THE MACHINE AND TRAVEL PATH WHILE UNIT IS IN OPERATION.

OPERATIONAL TEST

After the initial installation has been completed, or any service to the unit has been performed, an operational test should be conducted to ensure proper operation of the DG unit.

- Raise the gate by pressing and holding the OPEN button.

- After reaching the raised height, lower the gate to the lowered position by pressing and holding the CLOSE button.

- Repeat the open and close cycle again. As the gate is lowering, penetrate the safety light beam. Ensure that the gate stops its downward motion once the beam is broken.

- Cycle the lift several times to ensure smooth operation.

- Carefully watch the unit as it raises to ensure proper function of all mechanical components.

- Lockout/Tagout the unit and immediately notify your supervisor or maintenance personnel if the unit is found to be operating abnormally.

All operators should be trained on the contents of this manual prior to operating the Dock Gate. This manual should be made readily available to all interactive personnel.

OPERATIONAL SAFTEY

OPERATIONAL SAFETY

- Only personnel trained in the proper and safe operation of DG units may operate or service the Dock Gate

- All data plates, warning labels, placards, etc. shall be in place and legible at all times. Contact BHS for replacement data plates, warning labels, placards or instructions.

- All users and service personnel shall be familiar with the meaning, significance, and risks associated with all data plates, warning labels, etc.

- All operators and service personnel shall be aware of potential crush and shear points while operating or servicing the DG unit.

- DG units shall be operated in an area with ambient light levels of at least 50 lux.

- Keep hands, arms, feet, legs, hair, clothing and jewelry outside and away from the perimeter of the machine or travel path while operating the DG unit.

- Remove the Dock Gate unit from service if damaged, struck by a vehicle, or operating improperly (or becomes such while operating) until repairs can be made to correct any problem(s).

- When lifting DG components, never exceed the fork truck’s Load Center Rating.

DO'S AND DONT'S

- DO NOT add additional weight/load to the DG unit.

- DO NOT modify or fit the DG unit with attachments without prior, written approval from BHS.

- DO NOT perform any maintenance or service to the DG unit without securing the gate load.

- DO NOT allow anyone to ride in or climb on the DG unit.

- DO NOT continue to use the Dock Gate after impact without first inspecting the structure and insuring no damage occurred.

- Disconnect the DG unit from all power sources before attempting to perform service or maintenance to the unit.

- Mount the DG unit to the floor using approved concrete anchors or bolts prior to assembling crossbar and drive equipment.

- DO NOT service the DG unit without proper personal protective equipment (PPE) or without taking appropriate safety measures.

- DO NOT use the DG unit in a manner for which it is not intended. Some examples of prohibited use are but not limited to:

- As a personnel lift

- As a vehicle jack

- To lift any loads

- Where unintentional movement may occur

- Having direct contact with foodstuffs

- In a potentially explosive atmosphere

- On an uneven floor or surface

- Without being properly anchored to the floor

SERVICE & MAINTENANCE

The following are the basic practices necessary to properly, and safely, service and maintain this unit. It is recommended that a routine maintenance program be enforced to prolong the life of the unit and prevent costly repairs or downtime. Before servicing this unit, the operator should:

- Read and understand this manual as well as the “SERVICE AND MAINTINANCE” instructions.

- Understand mechanical devices and their associated components.

- Be thoroughly trained on the use and safety of this unit.

SAFE SERVICE PRACTICES

Failure to follow proper safety procedures can result in serious personal injury or death.

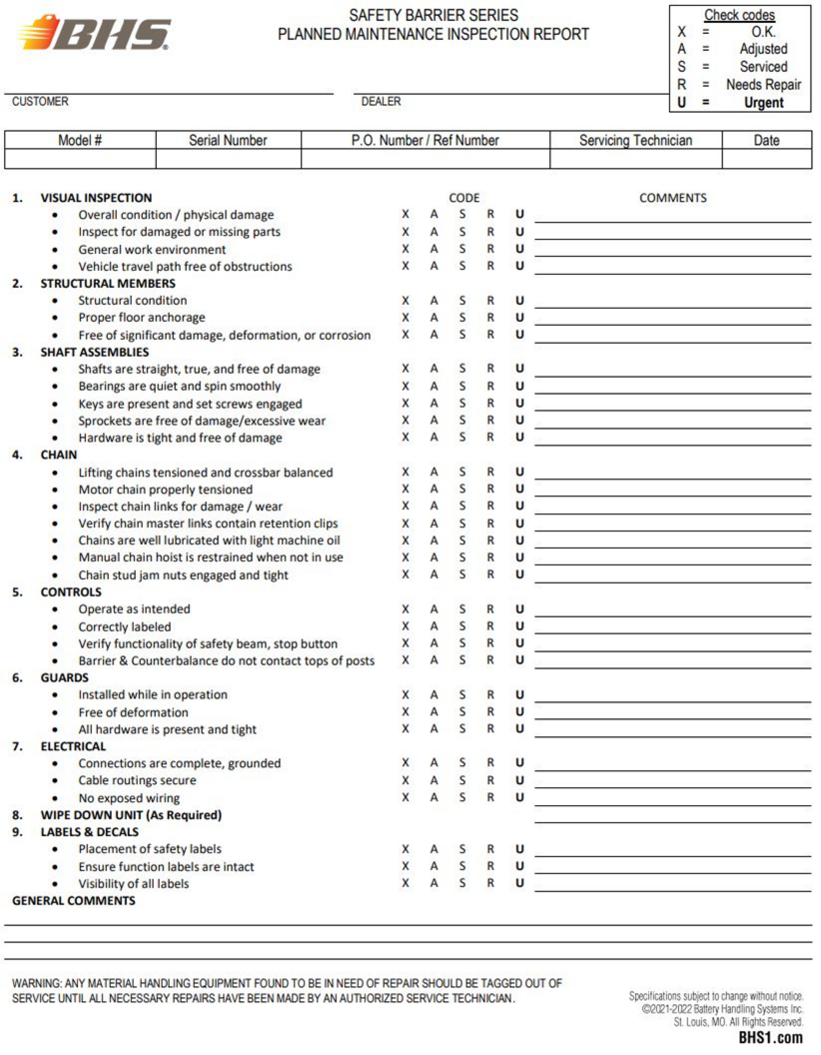

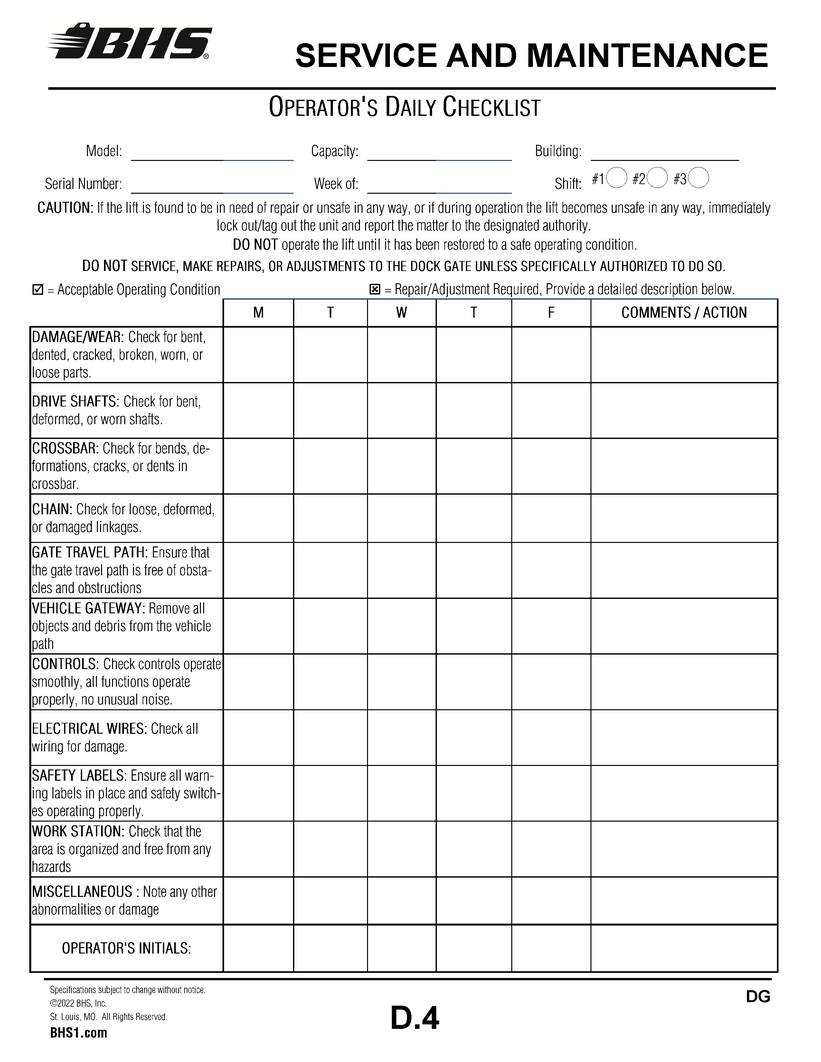

- Inspect the DG in regular intervals: daily, weekly, monthly, and yearly. See pages D.2, D.3, D.4, D.5 of this manual.

- DO NOT ignore a unit in need of repair. A unit in disrepair can be a severe hazard to persons and/or property when left unattended.

- Use only BHS approved replacement parts.

- Observe and identify all potential hazards prior to servicing the unit.

- NEVER attempt to raise or lower the gate unless the base is continuously supported and properly anchored.

NEVER attempt to hold the gate up by lifting one end of the crossbar.

- This can damage lifting components, structural members, and could lead to serious injury or death.

Tilting the gate over center can cause damage to the unit when not anchored.

- NEVER attempt to raise the unit unless the base is properly anchored.

FAILURE TO ANCHOR BASE WILL CAUSE UNIT TO TIP OR FALL RESULTING IN SERIOUS INJURY OR DEATH.

NEVER WORK ON OR UNDER THE DG WITHOUT THE CROSSBAR FULLY RESTRAINED. Failure to follow this safety practice will result in serious personal injury or death.

- NEVER leave the gate unsupported while performing maintenance.

Disconnect the AC power supply. Lockout/Tagout the unit.

Failure to disconnect electrical power to the DG unit could result in electrical shock. Serious personal injury or death will occur.

RECOMMENDED DOCK GATE LUBRICATION INTERVALS

| Task | Number of Places | Intervals |

|---|---|---|

| Lubricate the following areas using light machine oil. | ||

| A. Lifting Chains | 2 places | Monthly |

| B. Motor Transmission Chain | 1 place | Monthly |

| Complete Preventative Maintenance (PM) | - | Quarterly |

These recommendations are based on average use in a typical warehouse environment and may need adjustment based on individual circumstances. Dusty and/or extreme hot/cold environments may require more frequent lubrication.

- DO NOT clean this unit with a high pressure wash.

- DO NOT allow water inside the enclosure as it will cause corrosion.

- Wipe the unit down with a clean, dry cloth when cleaning is required.

SAFETY BARRIER SERIES PLANNED MAINTENANCE REPORT

OPERATOR'S DAILY CHECKLIST

SERVICE & MAINTENANCE WARNINGS

ALWAYS SECURE GATE PRIOR TO PERFORMING MAINTENANCE. Failure to completely secure gate could result in injury due to the following results:

- Unexpected movement of Dock Gate components.

- Component failure

- Ensure that the gate is lowered and secured. The provided stands can support the gate.

- Unplug the Dock Gate from its power source prior to accessing inside components.

- Remove surrounding panels as necessary to access Dock Gate components.

DO NOT perform any maintenance while the gate is in the raised position.

SAFTEY & WARNING LABELS

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ. |

|---|---|---|---|---|---|

| 1 | 00196216 | LABEL— CHAIN ENTANGLEMENT HAZARD | 8 | ||

| 2 | 00196615 | LABEL— DO NOT OPERATE W/ GUARDS REMOVED | 6 | ||

| 3 | 00196709 | SERIAL TAG | 1 | ||

| 4 | 00196701 | DECAL— BHS 12" x 3.875" | 1 | ||

| 5 | 00196424 | LABEL— NO RIDERS ALLOWED | 2 | ||

| 6 | HW1102 | CAUTION TAPE | 23 ft |

1 |

2 |

3 |

|---|---|---|

4 |

5 |

6 |

INSTALLATION INSTRUCTIONS

ELECTRICAL

DISCLAIMER

BHS Inc. requires that the Electrical Installation of the Powered Dock Gate be completed by a Certified Electrical Technician. Refer to the included motor manual for all electrical requirements and troubleshooting. Any motor setup and programming information is retained within the provided motor manual. Please contact BHS Inc. directly for all required part replacement.

STATEMENT OF WARRANTY

Statement of Warranty

Click here for details on BHS' Statement of Warranty.