IOP-425 RNS-1

Looking for a specific replacement part? Ctrl-F (or Command-F for Mac users) brings up your browsers search panel and can search any text on the entire web page. Find parts by searching a part # or part description.

Register your equipment with BHS Optima, BHS's free app.

California Residents: WARNING: This product contains chemicals known to the State of California to cause cancer and/or reproductive harm, and birth defects or other reproductive harm. Learn more here.

Recirculation/Neutralization System, 125 Galleon (RNS-1) Parts & Service Manual

TP-601 - SAFETY AND DE-ENERGIZATION PROCEDURES

GENERAL SAFETY

- Read and understand all instructions and warnings before using or servicing this equipment.

- Keep these instructions for future reference.

- Follow all federal, state and local requirements for handling and treatment of battery wash cabinet effluent.

- Recirculation/Neutralization System (RNS) units are not designed to be shipped or transported after initial delivery.

- A licensed structural engineer should be consulted prior to installing a RNS on any building level other than the ground floor.

- Perform system and safety check before operating.

- Failure to follow these instructions and warnings may result in property damage, personal injury or death.

WORK AREA

- Keep work area clean and well lit. Cluttered work areas and poor lighting can lead to accidents.

- Clean up/contain any fluid spills immediately to prevent slips or falls.

- Be aware of potential hazards when performing any service or maintenance to the unit.

SERVICE & MAINTENANCE

Service personnel shall wear Personal Protective Equipment (PPE) appropriate for the task being performed.

LOCKOUT/TAGOUT

Lockout/tagout the RNS per your corporate policy, if damaged or not functioning properly. Lockout/tagout and deenergize all systems prior to performing any maintenance or service to unit.

LEAD-ACID BATTERIES-EXPLOSION HAZARD

Do not allow open flames or sparks of any kind near a battery. Highly explosive gas is generated when charging a battery that can remain in battery cells for extended periods of time after charging is complete.

- Always wear appropriate PPE including rubber apron, gloves, boots and full face shield when performing service or maintenance to any lead-acid batteries.

- Do not place metal or other conductive objects on top of battery. Arcing may occur causing damage to the battery and/or serious personal injury or death.

- Use only chargers matching the voltage and amperage of the battery being charged. Overcharging a battery can cause damage to the battery, charger and/or serious personal injury or death.

- Turn off charger before disconnecting battery from charger. Arcing between battery and charger connectors can cause damage to the connectors and/or serious personal injury or death.

BATTERY WASH WATER HAZARDS

HEAVY METALS:

Battery wash water contains heavy metals including (but not limited to) lead and antimony, which through prolonged exposure can lead to serious, long-term, adverse health conditions.

EXTREME pH LEVELS:

Highly acidic (low pH) as well as highly alkaline/ basic (high pH) solutions can cause severe burns, release toxic fumes, and cause violent chemical reactions when mixed with water or when mixed together.

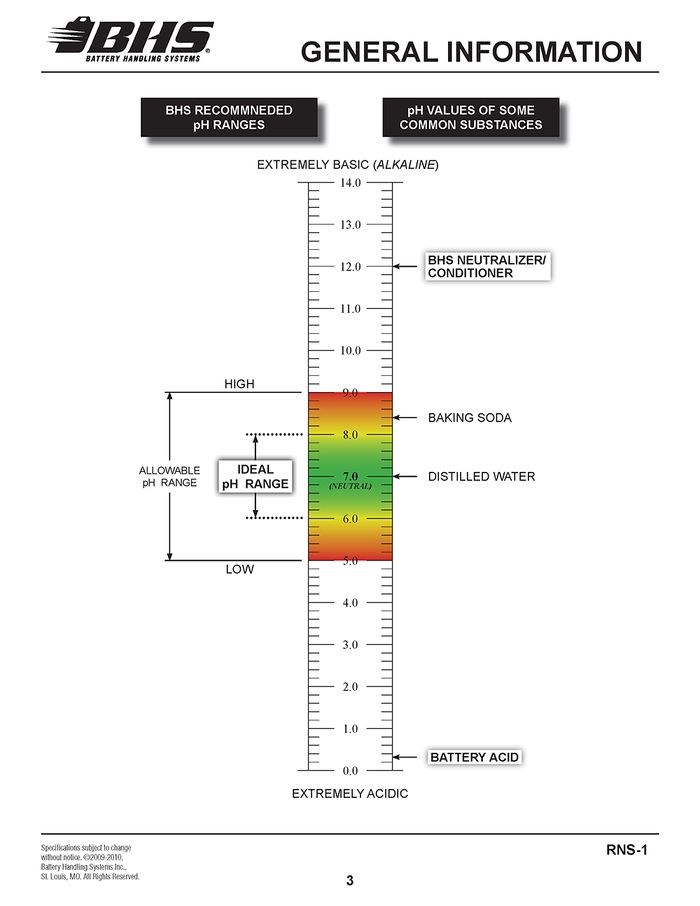

- pH values outside of the BHS allowable range of 5 to 9 should be treated as “extreme” and caution should be taken to avoid direct contact with such solutions.

- Always wear appropriate PPE including rubber apron, gloves, boots and full face shield when working in contact with any battery wash water.

TREATMENT CHEMICALS:

Use of chemicals not approved by BHS to treat wash water may result in the release of toxic fumes.

OPERATIONAL SAFETY

OPERATIONAL SAFETY

- Only personnel trained in the proper and safe operation of RNS units may operate or service the RNS.

- Operators shall wear appropriate PPE suitable for working with industrial lead-acid batteries while operating the RNS (see prior page).

- All data plates, warning labels, placards, etc shall be in place and legible at all times. Contact BHS for replacement data plates, warning labels, placards or instructions.

- All users and service personnel shall be familiar with the meaning and risks associated with all data plates, warning labels, etc.

- Remove the RNS from service if damaged, defective, or operating improperly (or becomes such while operating) until repairs can be made to correct any problem(s).

- Only use BHS approved chemicals in the RNS. Severe chemical and/or toxic reactions may result.

DO’s AND DON’T’s

- DO NOT overfill the RNS reservoir.

- DO NOT operate the RNS when reservoir is empty.

- DO NOT modify or fit the RNS with attachments without prior, written approval from BHS.

- DO NOT operate the RNS with any guard or cover removed unless required for maintenance or repair.

- Disconnect RNS from all power sources before attempting to perform service or maintenance to the unit.

- DO NOT attempt to move the RNS using a pallet or lift truck with a capacity of less than 2,000 pounds.

- DO NOT immerse any body part into the RNS holding tank water.

- DO NOT use any chemicals in the RNS that are not approved by BHS.

- DO NOT use the RNS to wash anything other than industrial lead-acid batteries.

- DO NOT use foaming type detergents in conjunction with the RNS.

- DO NOT use soda ash or similar types of neutralizers.

- Use only liquid neutralizers.

- DO NOT spray personnel or electrical components with spray wand (if equipped).

- DO NOT use the RNS in a manner for which it is not intended. Some examples of prohibited use are but not limited to:

- As an emergency wash station

- As a parts washer

- As a battery room wash-down device

- As a battery acid disposal device

DE-ENERGIZATION

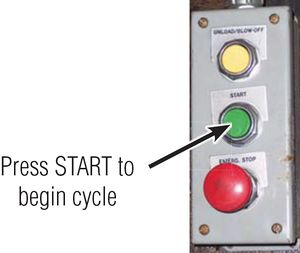

- Place the RNS power switch into the center or “OFF” position. See Figure 1

- Place the pump circulation valve in the recirculate position. Units built prior to 09/01/03:

- Rotate the valve handle to the “R” position and move the handle to the horizontal position. See Figures 2.1 & 2.2.

- Rotate the valve handle clockwise to the vertical position. See Figure 3.

- Rotate the valve on the intake strainer counter 3. clockwise to the closed position. See Figure 4.

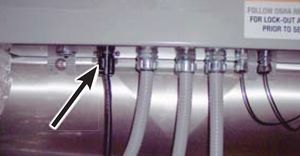

- If connected to a BWC, unplug the RNS auto start cable from the BWC. See Figure 5.

- If equipped with a spray wand, hold the trigger on the wand to release any residual pressure. If connected to a BWC, cycle the BWC through one complete wash to release residual water pressure. See Figures 6 & 7.

- Disconnect electrical power to the RNS.

FIGURE 1

FIGURE 2.1

FIGURE 2.2

Units built from to 09/01/03 to present:

FIGURE 3

FIGURE 4

FIGURE 5

Failure to release any stored water pressure could result in an unexpected spray of wash water.

FIGURE 6

FIGURE 7

Failure to disconnect electrical power to the RNS could result in electrical shock.

GENERAL INFORMATION

INTRODUCTION

The RNS-1 is a closed loop system to supply and recycle the water used in cleaning forklift batteries.

The main objective of the RNS-1 is to:

1.) Remove contaminants associated with lead/acid batteries.

2.) Filter and reclaim water for multiple cycles.

3.) Keep contaminants contained until proper disposal method is obtained.

The basic mechanical operation includes: pumping water from the reservoir through the filters, into a battery wash unit, through the sump assembly, and back into the reservoir.

FUNCTIONAL DESCRIPTION

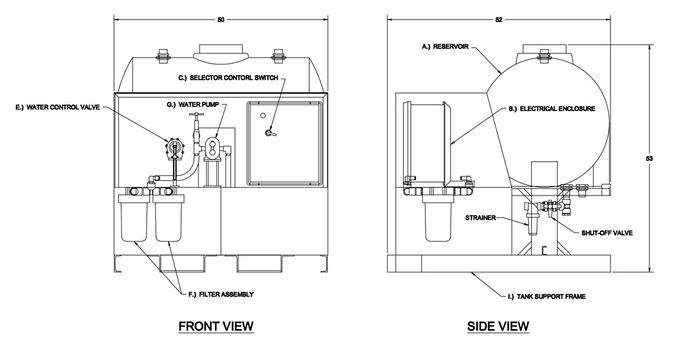

The following paragraphs provide the functional description of the RNS-1 system’s major components and assemblies. (See Figure 1-1, page 4)

A.)Reservoir - The reservoir is a 125 gallon polyethylene container that stores the battery cleaning water.

B.) Electrical Enclosure Assembly - The electrical enclosure houses the electrical control components and assemblies. The enclosure cover holds the Selector Control Switch and green power indicator lamp.

C.) Selector Control Switch - The Selector Control Switch provides “OFF”, “ON” and “AUTO” switch positions.

D.) Manually Operated pH Probe - The hand-held pH meter is used to monitor pH level of the water in the RNS unit. (See Section 1-3)

E.) Water Control Valve - The Water Control Valve directs the system’s water flow from the 5 micron filters to either the battery wash unit or back to the reservoir.

F.) Filters - There are two 5 micron filter cartridges, connected in parallel, to filter water contaminates in the system.

G.) Water Pump - The water pump circulates the water through the system.

H.) Sump Assembly - The sump assembly is located in the wash unit. The sump assembly receives the drained water from the battery wash unit and returns it to the RNS-1 reservoir. When the water in the sump pan reaches a certain level, the fl oat switch turns on the sump pump and water is pumped back to the reservoir.

I.) Reservoir Support - In addition to supporting the reservoir, the reservoir support also supports the water control valve, water pump, 5 micron filters, and the electrical enclosure.

pH LEVEL MONITORING

Consistent monitoring of pH levels in recirculation and neutralization systems is the single most important step in preventing part failures, insuring smooth operation and extending the life of the system. Failures due to improper pH levels will not be covered under warranty.

The pH level should never drop below 5.0 or rise above 9.0. Allowing the pH levels outside these parameters will result in premature failure of the sump pump and float switch in the battery wash cabinet. Left unchecked, further damage may be done to the relief valve and the system pump in the RNS.

It is recommended that pH levels are checked at least daily under normal conditions. If a large number of batteries are going to be washed or if batteries that have not been well maintained are going to be washed for the first time, it is recommended that the pH be checked after every second or third battery and neutralizer added accordingly. Refer to Section 3-2C for neutralizing procedures. After several pH tests, adjust the frequency of testing accordingly.

The pH level should be checked at the start of each shift as a part of the daily checklist of the entire battery handling system.

pH LEVEL MONITORING PROCEDURE

pH Meter should be checked and calibrated (if required) prior to each test. Refer to Section 4-3 for calibration procedures.

1.) Remove a water sample from the reservoir for testing.

2.) Switch pH meter on and set selector switch to “pH”.

3.) Immerse the probe end of pH meter into the water sample. Allow the pH probe to sit in the water for approximately one minute to allow the reading to stabilize prior to recording the reading.

DO NOT immerse pH meter past line marked on meter or damage to the meter will result.

4.) If pH is between 5.0 and 9.0, the RNS can be used to wash batteries. If pH is out of range, refer to Section 3-2C for neutralizing procedures.

LEADING PARTICULARS

| POWER REQUIREMENTS: | |

|---|---|

| Voltage: | 120 Volt, 1Ph, 60Hz or 240/480 Volt, 3Ph, 60Hz |

| Current: | 15.2 Amps @ 120V 4.8 Amps @ 240V 2.4 Amps @ 480V |

| Water Pump Capacity: | 12 gal/min @ 50 PSI |

| Water Pump Motor: | 1.5 Hp, 1725 RPM |

| Sump Pump Capacity: | Up to 25 gal/min |

| Reservoir Capacity: | 125 gallons |

| Weight (Shipping): | 500 lbs |

| Dimensions (See Figure 1-1 1-1): | |

| Description Width Depth Height |

Inches 50” 52” 53” |

INSTALLATION

GENERAL

The following paragraphs provide installation instructions for the RNS-1 Instructions provided include: unpacking, positioning, power and water installation.

The following tools and materials will be required for system installation:

Channel-Lock Pliers

Screw Driver (Standard, 1/4” Blade)

Adjustable Wrench (12”)

Measuring Tape (12’ min)

Level (12”)

Water Hose (length as required)

Liquid Neutralizing Conditioner (LNC) - one gallon supplied

Optional:

Heat Gun (to aid in hose attachment)

UNPACKING

A.) Place package system in general area of its operating location. Location considerations should be: within proximity to water supply, electrical power supply, vehicle entrance, and battery station locations.

B.) Cut wrapping bands and unstrap the system. Be careful not to scratch, cut or bend any components on system while unpacking.

C.) Inspect the system components for any signs of damage. Take particular note of any evidence of rough handling in transit. Immediately report any damage to shipping agent.

D.) Utilizing plant’s best technique, lift RNS-1 from its shipping skids and remove the skids from the area.

POSITIONING

The RNS-1 should be positioned where it will not interfere with the battery washing operation. Also, the distance from the battery wash unit should accommodate the interconnections between the system and the battery wash unit. The following paragraphs provide instructions for positioning of the system assemblies.

A.) Move RNS-1 into a position not further than 10 feet from the battery wash unit.

B.) Ensure the unit is relatively level.

POWER CABLE CONNECTION

A power line must be connected to the unit’s electrical enclosure assembly. The connection should be made by a certified electrician and any installed wiring shall meet all local electrical codes and requirements. See Section 1-4 for RNS-1 power requirements.

WASH CYCLE CONTROL CABLE CONNECTION

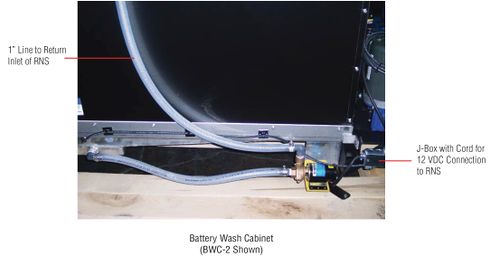

When the RNS-1 is connected to a Battery Wash Cabinet (Typical BHS model BWC-2), a wash cycle control cable from the RNS-1 must be connected to the BWC-2 control panel. See Figure 2-1.

INNER CONNECTION TO WASH CABINET

There are 3 connections from the RNS-1 to a battery wash cabinet. (Typical BHS unit model BWC-2).

A.) Attach the 3/4” I.D. hose from the water outlet of the RNS-1 to the water inlet of the BWC-2.

Note: This connection should be made AFTER completing procedures in Section 2-8.

B.) Attach the 1” I.D. hose from the sump pump outlet to the return inlet of the RNS-1.

C.) Connect the DC line cord from the sump pump of the wash unit to the 12 volt DC power outlet of the RNS-1.

SEE FIGURE 2-1

WATER INSTALLATION

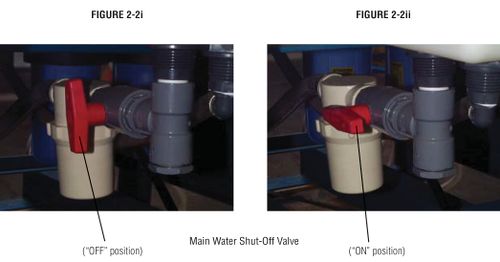

Water can be hard piped to the reservoir or the unit can simply be filled using a water hose. The reservoir support is constructed to Water can be hard piped to the reservoir or the unit can simply be filled using a water hose. The reservoir support is constructed to facilitate usage of forklift or pallet truck to transport the unit to a water source. ( facilitate usage of forklift or pallet truck to transport the unit to a water source. (Note: Be sure to disconnect all hoses and electrical Note: Be sure to disconnect all hoses and electrical cables to wash unit prior to transporting RNS-1. cables to wash unit prior to transporting RNS-1.) ) Check that filter bowls are tight. Once filter bowls have been checked, open shut-off Check that filter bowls are tight. Once filter bowls have been checked, open shut-off valve beneath tank and partially fill. See Figure 2-2. Check for leaks under the tank. If no leaks are found, finish filling the tank with valve beneath tank and partially fill. See Figure 2-2. Check for leaks under the tank. If no leaks are found, finish filling the tank with approximately 110 gallons of water. approximately 110 gallons of water.

INITIAL START UP PROCEDURE

A.) Prior to final hook up of the 3/4” pressure line to the wash cabinet, take the end of the hose and route it to the inside of the wash cabinet or to a drain.

B.) Move the selector switch to the “ON” position. The unit should start pumping immediately.

3-Phase units are “phase sensitive”. If wired out of phase, the pump will run in reverse and must be corrected immediately or damage to the pump will occur.

C.) Run the unit until all air is purged from the water circuit then turn the selector switch to the “OFF” position.

D.) Proceed with the connection of the pressure line to the wash cabinet.

The RNS-1 is now ready for normal operation.

NOTE: If the RNS is being used with a manual wash unit, follow all the instructions above except the pressure line will have a spray wand attached. Air purging can be done by depressing the trigger of the wand while powering up the RNS-1 as described above

OPERATION

CONTROLS

The RNS-1 system is controlled by a Selector Control Switch and a Water Control valve. The Selector Control Switch is located on the electrical enclosure assembly and provides the switch positions ON/OFF/AUTO. The Water Control valve is located above the two 5 micron filters and provides valve positions “C” and “R”. The following steps describe the operation of the controls:

A.) Selector Control Switch

The Selector Control Switch provides “OFF”, “ON” and “AUTO” switch positions. Functional descriptions for each of these three switch positions are as follows:

OFF In this position all functions are off.

ON The “ON” position allows continuous operation of the water pump. It is normally used when the battery wash unit is connected to a hand-held spray nozzle to clean batteries. This position also allows continuous operation of the water-pump motor to circulate the water when adding liquid neutralizing conditioner or when draining the reservoir. ( NOTE: This position may be marked as “MAN” for Manual on older units.)

AUTO The “AUTO” position is normally used when a BWC wash cabinet is used as the battery wash unit. It allows the wash cycle to be controlled by the wash cabinet timer.

B.) Water Control Valve

The Water Control Valve directs the system’s water flow from the 5 micron filters to either the battery wash unit or back to the reservoir. The valve has a gauge plumbed to it to indicate its internal water pressure.

Units built prior to 09/01/03

Units built prior to 09/01/03 are equipped with a multi-position valve with seven indexed positions. Only “C” and “R” positions are used in the system’s operation. Water will only fl ow through the valve when its handle is in the horizontal position. See Figure 3-2-iii. The operational description for each of the usable positions is provided below.

“C” Position - This position is referred to as the “WASH” position. In this position, water flows to either the wand or the BWC (if equipped.) See Figure 3-2i.

“R” Position - This position is referred to as the “RECIRCULATE” position. In this position, water flows from the reservoir, through the 5 micron filters and back to the reservoir. See Figure 3-2ii.

NOTE: Water Control Valve positions not used are: L, LC, LCR, LR and RC.

FIGURE 3-2i

FIGURE 3-2ii

FIGURE 3-2iii

Units built after 09/01/03 to present

Units built after 09/01/03 to present are equipped with a 3-way ball valve. The operational description for two handle positions is provided below.

Horizontal - This position is referred to as the “WASH” position. In this position, water flows to either the wand or the BWC (if equipped.) See Figure 3-3i.

Vertical - This position is referred to as the “RECIRCULATE” position. In this position, water flows from the reservoir, through the 5 micron filters and back to the reservoir. See Figure 3-3ii

FIGURE 3-3i

FIGURE 3-3ii

OPERATING INSTRUCTIONS

Generally, operation of the RNS-1 consists of: setting the Selector Control switch and Water Control valve, washing batteries and neutralizing the battery wash water. The following procedures provide the system operating instructions.

A.) Start-Up Procedure The start-up procedure for the RNS-1 is provided in the following paragraphs. Consult the technical manual of the battery wash unit (if being used) with the RNS for its start-up procedure.

Pre 09/01/03 Units

1.) Verify the green indicator lamp is illuminated indicating there is power to the unit.

2.) Place the Water Control valve handle in the “CHANGE” position. See figure 3-2ii.

3.) Place the Water Control valve in the “C” position.

NOTE: Set the Selector Control Switch to “AUTO” when an automatic battery wash unit is in use. Set the Selector Control switch to “ON” when a manually operated wash unit is in use. The green indicator lamp must be illuminated indicating there is power to the unit.

If a manual operated battery wash unit is in use, ensure that water spray nozzle is connected and in its “OFF” position before setting selector control switch to the “ON” position.

4.) Set the Selector Control Switch to the “ON” position.

5.) Place the Water Control valve handle in the “FLOW” position. See figure 3-2iii.

6.) Wash the battery. If the wash system fails to operate, see the Maintenance Section included in this manual and/or see the battery wash unit’s operating instructions.

09/01/03 to Present Units

1.) Verify the green indicator lamp is illuminated indicating there is power to the unit.

2.) Place the Water Control valve handle in the “WASH” position. See figure 3-3i.

NOTE: Set the Selector Control Switch to “AUTO” when an automatic battery wash unit is in use. Set the Selector Control switch to “ON” when a manually operated wash unit is in use. The green indicator lamp must be illuminated indicating there is power to the unit.

If a manual operated battery wash unit is in use, ensure that water spray nozzle is connected and in its “OFF” position before setting selector control switch to the “ON” position.

4.) Set the Selector Control Switch to the “ON” position.

5.) Wash the battery. If the wash system fails to operate, see the Maintenance Section included in this manual and/ or see the battery wash unit’s operating instructions.

B.) Operating Procedure

The RNS-1 may become hazardous to equipment and personnel if proper operation is not followed. Therefore, operation shall be performed in conformance with the following practices.

1.) The operator shall wear a face shield, rubber gloves, rubber apron and rubber boots and follow all plant safety regulations.

2.) Occasionally check the pressure gauges at the Water Control valve and at the 5 Micron filter inlet. If valve gauge indicates 5 PSI or lower and the filter gauge indicates 40 PSI or higher, replace the 5 Micron filter cartridges at the earliest convenience.

3.) Occasionally check the water level in the sump area of the wash cabinet. If the water level is higher than 3 inches, check the operation of the sump pump and or fl oat switch. Perform any maintenance to sump pump and/or float switch as necessary.

4.) Continuously check the battery wash system for leaks or overflowing conditions. If either of these conditions is noticed, immediately turn of the wash system and perform necessary maintenance.

5.) After several batteries have been washed, the pH level may drop below the specified safe working limits. Before attempting to restart the system, neutralize the reservoir water (See Neutralizing Procedure that follows.) After neutralizing the reservoir water, restart the system in accordance with the Start-Up Procedure only with the Water Control valve in the “RECIRCULATE” position.

C.) Neutralizing Procedure

The neutralization procedure includes adding the proper amount of Liquid Neutralizing Conditioner (LNC) to the water in the reservoir. The following steps provide the neutralizing procedure.

1.) Place the Water Control valve handle in the “CHANGE” position (for units built prior to 09/01/03 only).

2.) Place the Water Control valve in the “RECIRCULATE” position.

3.) Set the Selector Control Switch to the “ON” position. The water in the RNS system will begin circulating.

4.) Remove the access hole cover on top of the reservoir.

5.) Measure 4 to 6 ounces of LNC solution.

6.) Pour the measured LNC solution into the reservoir through the access hole.

7.) Circulate the water for a minimum of 15 - 20 minutes before using the RNS-1.

8.) Test the reservoir water to verify the pH is within the specified safe working limits. If the pH is lower than this limit, repeat steps 5 - 7 as necessary.

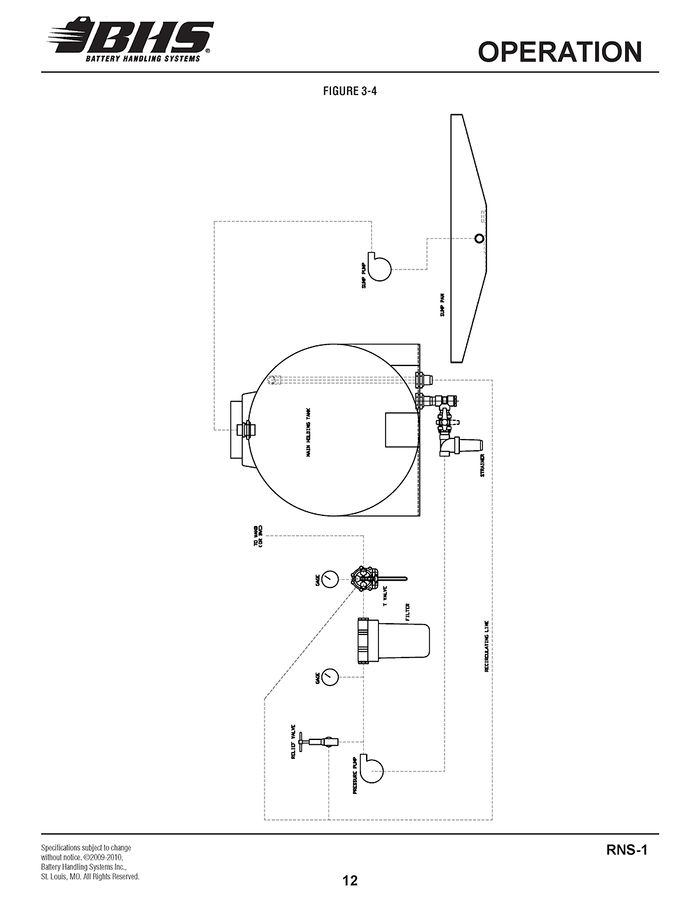

PLUMBING CIRCUIT THEORY OF OPERATION

REFERENCE FIGURE 3-4

Water is pulled from the bottom outlet port of water reservoir through the shut off valve and a 100 mesh strainer to the pump inlet.

The water from the pressure side (outlet side) of the pump flows past the main system relief valve and gauge. The relief valve is activated if there is a failure in the pump that could cause over pressurization to occur.

Water is then pushed through the dual 5 micron filter assembly.

Under normal operating conditions, the T-valve to the wash cabinet/wand is open and the recirculate mode is closed.

As demand/flow is required at the wash cabinet, the output water goes into the sump area of the wash cabinet base where a fl oat switch is located.

When the water in the sump reaches a depth adequate to engage the fl oat switch, it then energizes the sump pump mounted on the back of the wash cabinet that pumps the spent water back to the RNS return inlet.

The water is held in storage for recycling through the system.

MAINTENANCE

It is imperative all equipment be inspected and maintained on a regular basis to ensure a long dependable life from your investment. The following information is a rule of thumb only and should be adjusted based on; environment, amount of run time, condition of batteries to be cleaned, etc. As you first start a battery cleaning program, you may fi nd it necessary to have increased inspection and maintenance requirements. But if a good regimen is followed and batteries are kept in a cleaner state, these increases should subside and you will be able to get a better feel for your own individual scheduling of maintenance.

PERIODIC INSPECTIONS

On the following page is an operator/maintenance spread sheet for daily and weekly inspections. Copies should be made and stored in an area of your battery room or maintenance department for accessibility by authorized personnel. Some of the inspections noted may require the removal of a particular access panel to accomplish. Refer to the parts/component location figures further back in this manual.

Monday | Tuesday | Wednesday | Thursday | Friday | Saturday | Sunday | |

Inspection Item | OK | OK | OK | OK | OK | OK | OK |

YES/NO | YES/NO | YES/NO | YES/NO | YES/NO | YES/NO | YES/NO | |

Water level within limits | |||||||

pH levels normal | |||||||

Strainer clear of debris | |||||||

Water pump belt condition/tension O.K. (pre 09/03 untis only) | |||||||

Check for leaks | |||||||

Sump area in wash cabinet clear of debris | |||||||

All electrical conductors in good condition | |||||||

At least one 20 minute recirc. cycle completed (Weekly) | |||||||

DATE | |||||||

Inspector's initials | |||||||

SPECIAL COMMENTS OR NOTES: | |||||||

CAUTION: If any problem or discrepancies are found, follow you company's procedures and policies for notifying the proper authority. Use all appropriate lock out/tag out procedures until the problem(s) can be rectified and the unit is placed back into normal service | |||||||

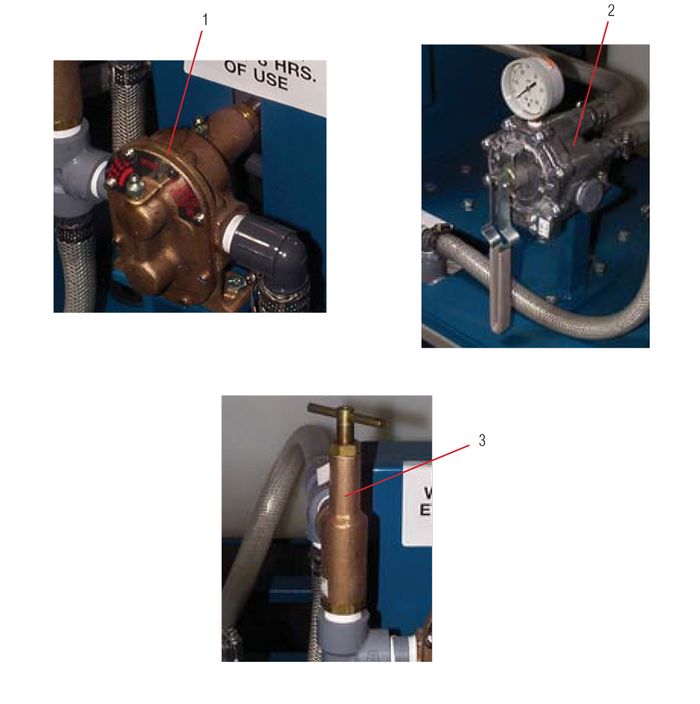

PERIODIC MAINTENANCE

A.) Inlet strainer screen

The inlet strainer screen should be inspected and cleaned at regular intervals. A good starting point would be monthly until such time as you can validate the correct time frame for your application.

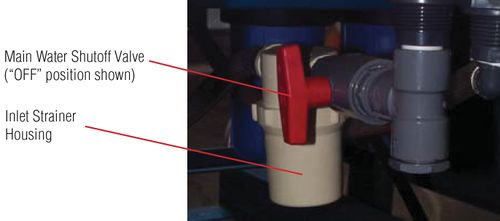

PROCEDURE: REFERENCE FIGURE 4-1

1.) Locate the strainer assembly positioned under the water reservoir. Turn the main water shut off valve to the “OFF” position.

2.) Place a container under the strainer housing to capture the water when the bowl is loosened.

3.) Unscrew the strainer bowl until flow of water starts. Allow to drain until flow has diminished.

4.) Remove the bowl to access the filter screen and remove the screen from body.

5.) Flush as required to remove any solid debris that may be captured in screen.

6.) Replace screen into body and re-attach bowl to hand tight only.

7.) Turn the main water shut off valve to the “ON” position.

8.) Allow to stand a few minutes and inspect for leaks. Correct as needed.

9.) Return power switch to the “ON” position, and move the Water Control valve to the “RECIRCULATE” position to allow the unit to cycle and remove the air from the system.

10.) Normal operation can now be resumed.

B.) 5 Micron Filter Cartridge Replacement

The filter cartridges should be changed on a regular basis in order to keep down any restrictions of flow in the system. This may be required more frequently as you first start your new battery cleaning program. A symptom of a restricted filter is reduced fl ow to the wash cabinet or wand.

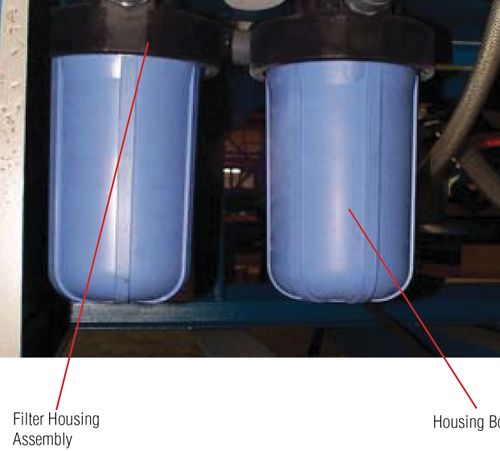

PROCEDURE: REFERENCE FIGURE 4-2

1.) Remove the front panels to access the plumbing compartment (**See SAFETY WARNING #5 from page ii). Turn the main water shut off valve to the “OFF” position.

2.) Place a container under the filter housing to capture the water when the bowl is loosened.

3.) Unscrew the filter housing bowl by turning it COUNTER CLOCKWISE until flow of water starts. Allow to drain until flow has diminished.

4.) Remove the bowl to access the filter cartridge and remove the cartridge from bowl.

5.) Place the new cartridge into the bowl.

6.) Verify the large O-ring is in the groove of the bowl and re-attach. Tighten by hand, then apply 1/4-turn more with a strap wrench.

7.) Turn the main water shut off valve to the “ON” position.

8.) Allow to stand a few minutes and inspect for leaks. Correct as needed.

9.) Return power switch to the “ON” position, and move the Water Control valve to the “RECIRCULATE” position to allow the unit to cycle and remove the air from the system.

10.) Re-install front panels.

11.) Normal operation can now be resumed.

NOTE: Dispose of waste water, filter cartridge and any rags used in accordance with all applicable codes and regulations pertaining to heavy metals removal.

C.) Water Pump Belt Adjustment/Replacement (pre 09/01/03 units only)

PROCEDURE: REFERENCE FIGURE 4-3

1.) Loosen (4) motor mounting bolts.

2.) Move motor away from pump to tighten the belt or towards the pump to remove the belt.

3.) Position motor so as to achieve 3/16” movement in both directions (3/8” total movement) of the belt and re-tighten the (4) motor mounting bolts.

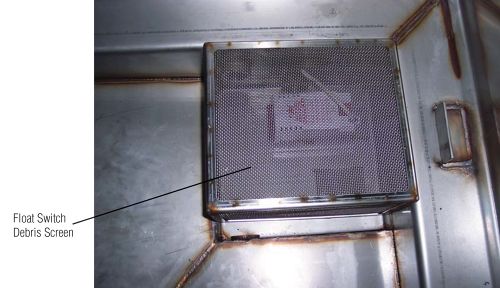

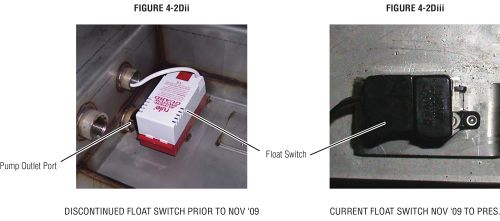

D.) Sump Area Screen & Float Switch

As noted on the inspection sheet previously in this manual, the sump area should be inspected and cleaned as needed.

Refer to the manual for the wash cabinet or manual wash rack you are using in conjunction with the RNS-1 for the sump area location and access.

FIGURE 4-4i

pH METER STORAGE AND CALIBRATION

It is important that the pH meter sent with the RNS-1 is properly maintained and calibrated in order to ensure that correct pH readings are displayed when testing the water in the RNS-1 tank.

BHS provides 2 different bottles of pH solution used to calibrate the pH meter. One bottle contains solution at 7.0 pH and the other bottle contains solution at 4.0 pH. To calibrate the unit, first immerse the probe end of the unit in to the 7.0 pH solution and use the screwdriver provided with the unit (or a very small standard screwdriver) to turn the screw inside of the hole below the display until the display reads 7.0. Then immerse the probe end of the unit into the 4.0 pH solution and confirm the reading goes down to 4.0 pH +/- 0.1. If the unit reads properly when switched between the 2 solutions, the unit is properly calibrated. If the reading in the display does not go down to 4.0 pH the bulb on the probe end of the pH meter may be dried out and will not obtain a true reading. At this point you can try soaking the probe end of the unit for a couple of hours in the 7.0 pH solution to see if the meter will re-hydrate. If it will not, the meter will need to be replaced.

To prevent the bulb from drying out you will need to keep a small amount of the 7.0 pH solution in the cap of the pH meter. When the meter is not in use, it must be stored standing upright and not laying on its side.

These procedures are outlined in the instructions that come with the pH meter and are available from the BHS Tech support group.

pH MONITORING ACCESSORIES | |||

ITEM # | DESCRIPTION | PART NUMBER | QTY |

1 | pH METER | PB0803 | 1 |

2 | SOLUTION-BUFFER-pH 4.0 | PB0804 | 1 |

3 | SOLUTION-BUFFER-pH 7.0 | PB0805 | 1 |

TROUBLESHOOTING

TROUBLESHOOTING GUIDE | ||

SYMPTOM | PROBABLE CAUSE(S) | SOLUTION(S) |

- NO WATER | 1. WATER CONTROL VALVE HANDLE IN “CHANGE” POSITION (09/01/03 AND OLDER UNITS ONLY) | 1. PLACE WATER CONTROL VALVE HANDLE IN “FLOW” POSITION |

- LOW WATER PRESSURE |

|

|

- DRIVE BELT SQUEAL (09/01/03 AND OLDER UNITS ONLY) | 1. LOOSE BELT | 1. TIGHTEN OR REPLACE BELT |

- SUMP AREA IN WASH CABINET NOT BEING DRAINED OF WASTE WATER |

|

|

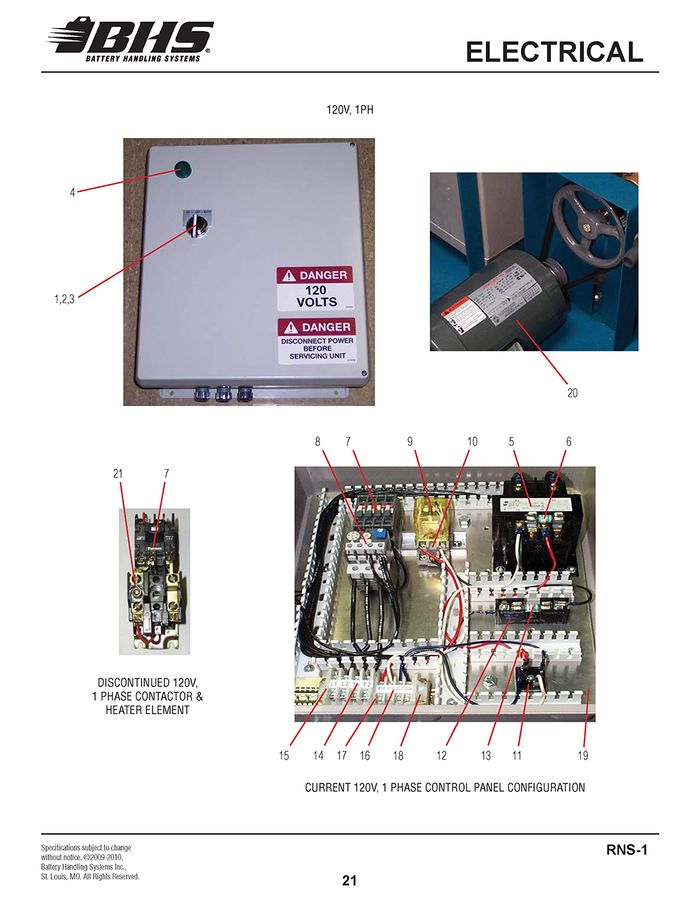

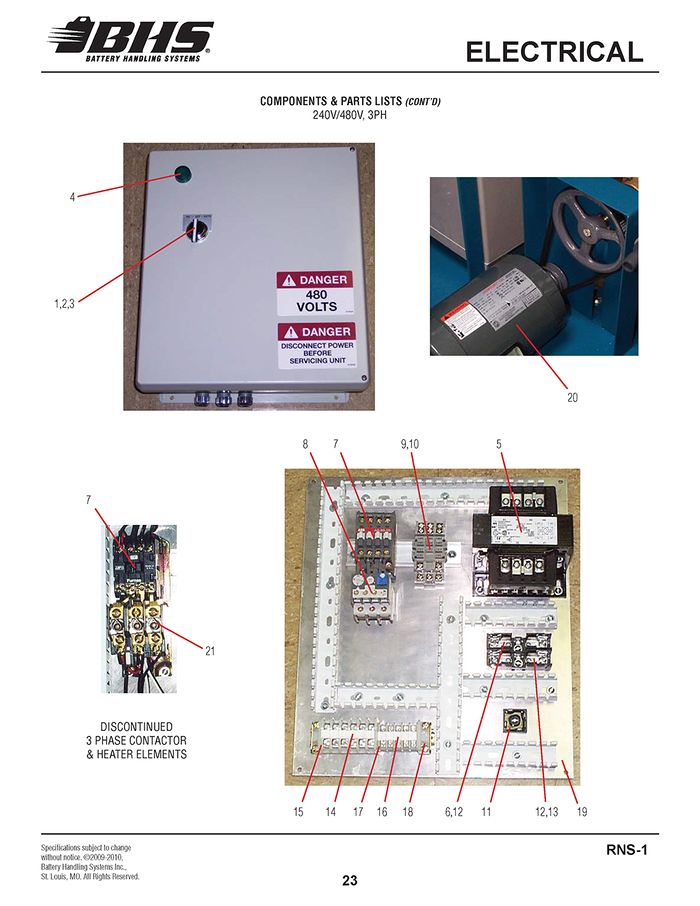

ELECTRICAL

COMPONENTS & PARTS LISTS

ELECTRICAL PARTS LIST 120V, 1PH | |||||

ITEM # | DESCRIPTION | PART NUMBER | VOLTAGE | NOTES | QTY |

1 | SELECTOR SWITCH | E0315 | 1 | ||

2 | CONTACT BLOCK-N/O | E1006 | 1 | ||

3 | CONTACT BLOCK-N/C | E1007 | 1 | ||

4 | INDICATOR LIGHT | E1008-1 | 1 | ||

5 | TRANSFORMER | E1004 | 120V TO 12V | 1 | |

6 | FUSE-3.5A | E0904 | 1 | ||

7 | MAIN CONTACTOR | E1002-1 | JAN ‘00 - PRES | 1 | |

MAIN CONTACTOR | N/A | † PRE JAN ‘00 | 1 | ||

8 | THERMAL OVERLOAD | E1015-1 | JAN ‘00 - PRES | 1 | |

9 | 11-BLADE SOCKET RELAY | E1311 | 24V | 1 | |

10 | 11-BLADE SOCKET RELAY BASE | E1013 | 1 | ||

11 | RECTIFIER (AC TO DC) | E1009 | 12V | 1 | |

12 | FUSE BLOCK | E1016 | 1 | ||

13 | FUSE-12A | E0903 | 1 | ||

14 | TERMINAL BLOCK-LARGE | E1020 | 4 | ||

15 | END BARRIER-LARGE | E1040 | 1 | ||

16 | TERMINAL BLOCK-SMALL | E1022 | 4 | ||

17 | END BARRIER-SMALL | E1021 | 1 | ||

18 | END BARRIER ANCHOR | E1330 | 2 | ||

19 | MOUNTING PANEL | E1305 | 1 | ||

20 | MOTOR | E0021 | 120V, 1PH | SEPT ‘03 - PRES | 1 |

MOTOR | E0004 | PRE SEPT ‘03 | 1 | ||

21 | HEATER ELEMENT | E1015 | 120V, 1PH | †† PRE JAN ‘00 | 1 |

22 | RECEPTACLE-SUMP PUMP (NOT SHOWN) | E1010 | 1 | ||

23 | PLUG-SUMP PUMP (NOT SHOWN) | E1011 | 1 | ||

† NO LONGER AVAILABLE. MUST REPLACE WITH CURRENT CONTACTOR AND THERMAL OVERLOAD.

† † AVAILABLE AS REPLACEMENT ONLY.

ELECTRICAL PARTS LIST 240/480V, 3PH | ||||||

ITEM # | DESCRIPTION | PART NUMBER | VOLTAGE | NOTES | QTY | |

1 | SELECTOR SWITCH | E0315 | 1 | |||

2 | CONTACT BLOCK-N/O | E1006 | 1 | |||

3 | CONTACT BLOCK-N/C | E1007 | 1 | |||

4 | INDICATOR LIGHT | E1008-1 | 1 | |||

5 | TRANSFORMER-240/480V TO 12/24V | E1318 | 1 | |||

6 | FUSE-3.5A | (NOT SHOWN) | E0904 | 1 | ||

7 | MAIN CONTACTOR | E1001-2 | JAN ‘00 - PRES | 1 | ||

MAIN CONTACTOR | N/A | † PRE JAN ‘00 | 1 | |||

8 | THERMAL OVERLOAD | E1055 | 240V, 3PH | JAN ‘00 - PRES | 1 | |

THERMAL OVERLOAD | E1014-1 | 480V, 3PH | 1 | |||

9 | 11-BLADE SOCKET RELAY | (NOT SHOWN) | E1311 | 24V | 1 | |

10 | 11-BLADE SOCKET RELAY BASE | E1013 | 1 | |||

11 | RECTIFIER (AC TO DC) | E1009 | 12V | 1 | ||

12 | FUSE BLOCK | E1016 | 2 | |||

13 | FUSE-12A | (NOT SHOWN) | E0903 | 1 | ||

14 | TERMINAL BLOCK-LARGE | E1020 | 6 | |||

15 | END BARRIER-LARGE | E1040 | 1 | |||

16 | TERMINAL BLOCK-SMALL | E1022 | 5 | |||

17 | END BARRIER-SMALL | E1021 | 1 | |||

18 | END BARRIER ANCHOR | E1330 | 2 | |||

19 | MOUNTING PANEL | E1305 | 1 | |||

20 | MOTOR | E0022 | 240/480V, 3PH | SEPT ‘03 - PRES | 1 | |

MOTOR | E0005 | PRE SEPT ‘03 | 1 | |||

21 | HEATER ELEMENT | E1014 | 240/480V, 3PH | † † PRE JAN ‘00 | 3 | |

22 | FLOAT SWITCH | (NOT SHOWN) | - | 12V | SEE PLUMBING | 1 |

23 | RECEPTACLE-SUMP PUMP | (NOT SHOWN) | E1010 | 1 | ||

24 | PLUG-SUMP PUMP | (NOT SHOWN) | E1011 | 1 | ||

† NO LONGER AVAILABLE. MUST REPLACE WITH CURRENT CONTACTOR AND THERMAL OVERLOAD.

† † AVAILABLE AS REPLACEMENT ONLY.

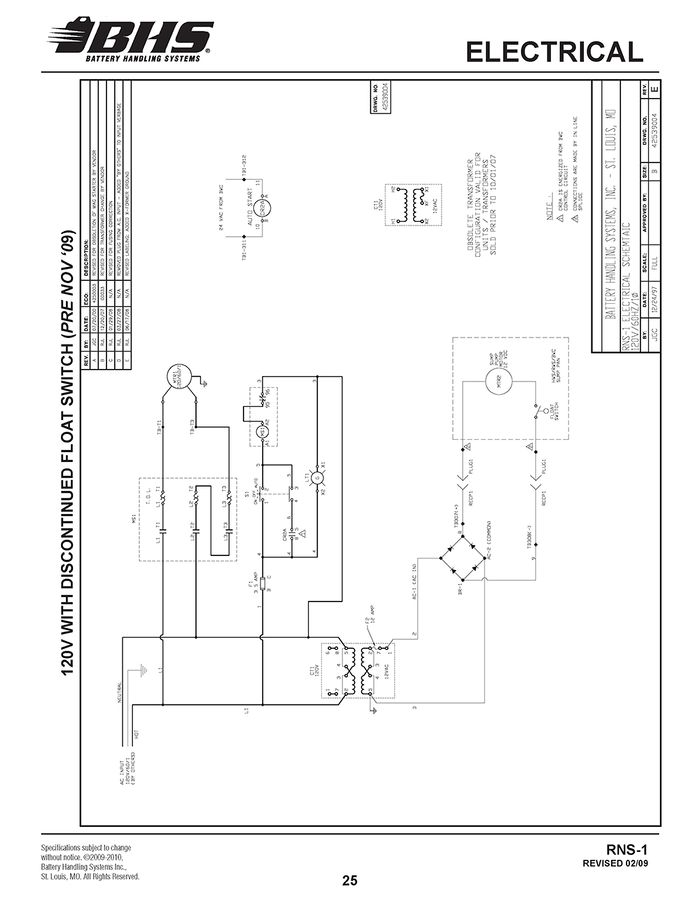

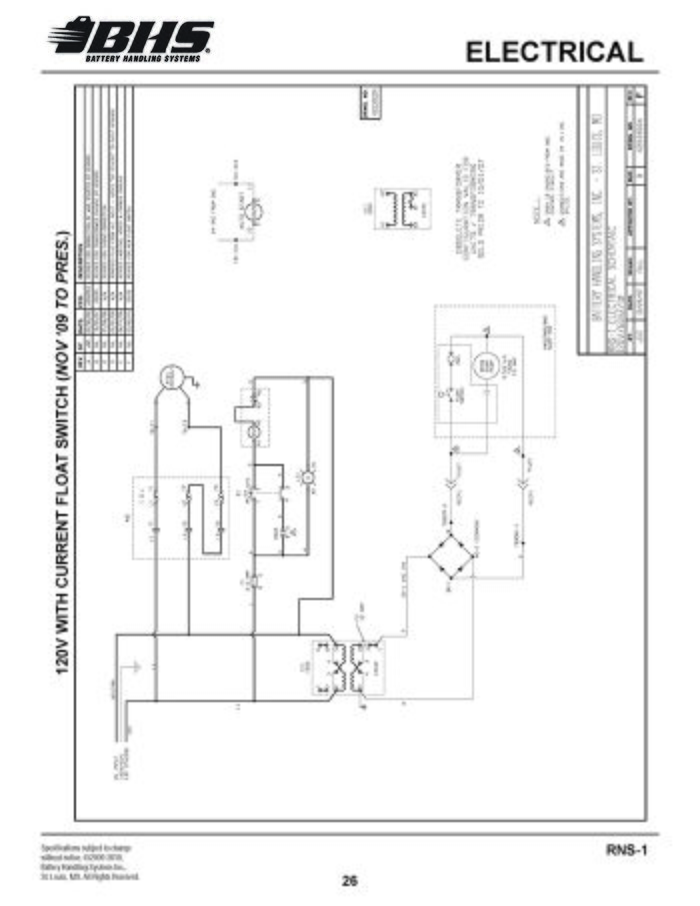

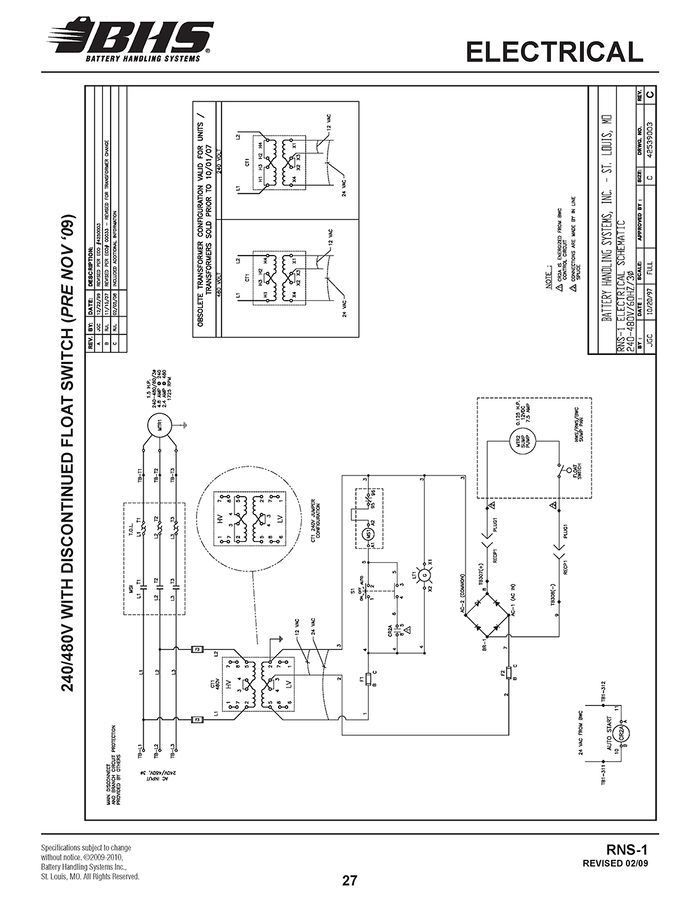

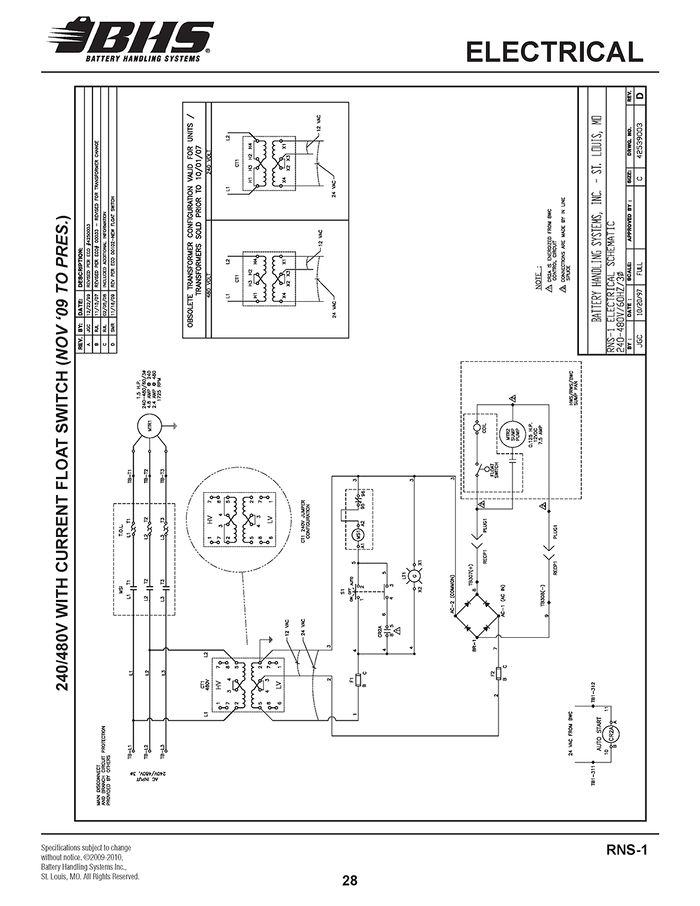

ELECTRICAL SCHEMATICS

POWER TRANSMISSION

POWER TRANSMISSION PARTS LIST | |||

ITEM # | DESCRIPTION | PART NUMBER | QTY |

1 | V-BELT | PT0612 | 1 |

2 | PUMP PULLEY | PT0613 | 1 |

3a | MOTOR PULLEY-240/480V, 3PH | PT0614 | 1 |

3b | MOTOR PULLEY-120/240V, 1PH | PT0615 | 1 |

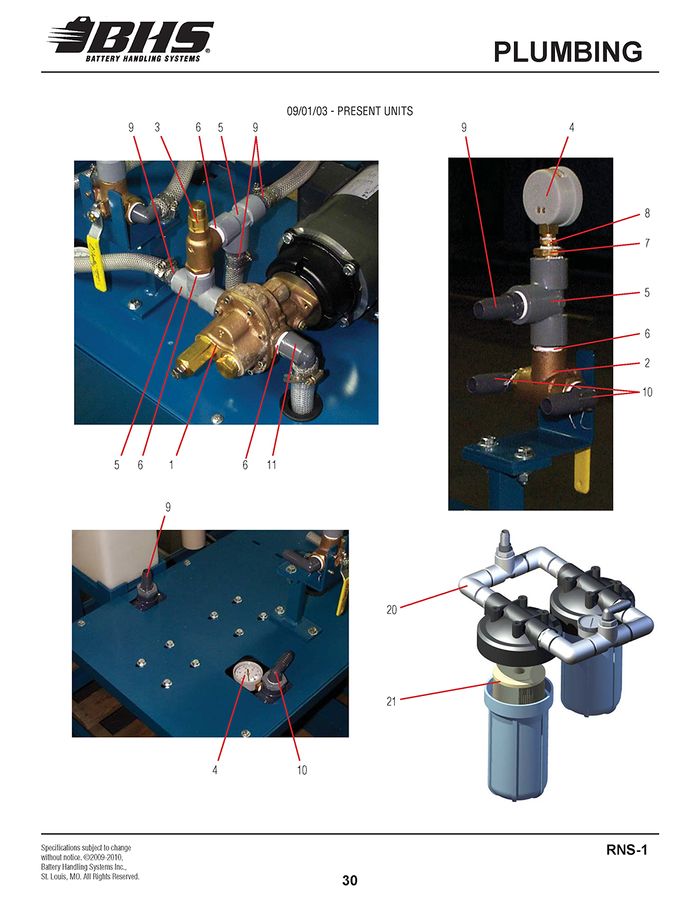

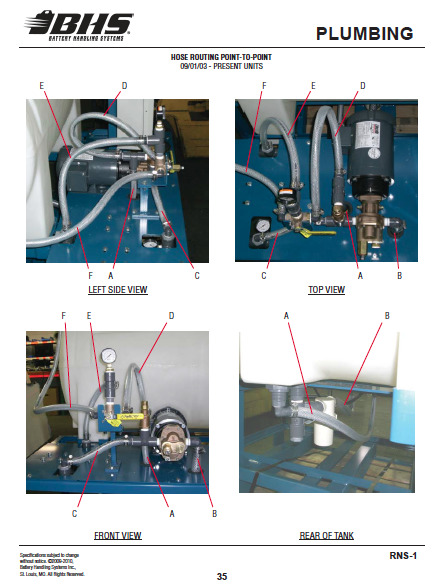

PLUMBING

PLUMBING COMPONENTS 09/01/03 - PRESENT UNITS | |||

ITEM # | DESCRIPTION | PART NUMBER | QTY |

1 | WATER PUMP | PB0120 | 1 |

2 | T-VALVE | PB0201-1 | 1 |

3 | RELIEF VALVE | PB0203-1 | 1 |

4 | PRESSURE GAUGE | PB0802 | 1 |

5 | TEE-THREADED-3/4”-BRASS | PB0504-1 | 4 |

6 | NIPPLE-CLOSE-3/4”-BRASS | PB0310-1 | 5 |

7 | BUSHING-REDUCER-3/4” X 3/8” | P0515 | 1 |

8 | BUSHING-REDUCER-3/8” X 1/4” | P0505 | 1 |

9 | HOSE BARB-3/4” X 3/4” NPT | PB0603 | 3 |

10 | ELBOW-90 DEG-3/4” NPT X 3/4” BARB | PB0605 | 4 |

11 | ELBOW-90 DEG-3/4” NPTF X 1” BARB | PB0703 | 2 |

12 | FILTER/STRAINER | PB0005 | 1 |

13 | SHUT-OFF VALVE | PB0202 | 1 |

14 | TANK ADAPTER-3/4” | PB0401 | 2 |

15 | PLUG-THREADED-1” | PB0303 | 1 |

16 | TEE-THREADED-1” | PB0503 | 1 |

17 | NIPPLE-CLOSE-1” X 1” | PB0312 | 2 |

18 | HOSE BARB-1” X 1” NPT | PB0606 | 1 |

19 | TANK ADAPTER-1” | PB0402 | 1 |

20 | FILTER HOUSING ASSEMBLY | 42572001 | 1 |

21 | FILTER | PB0002 | 2 |

22 | O-RING-FILTER HOUSING (NOT SHOWN) | 80000001 | A/R |

23 | NIPPLE-CLOSE-1” X 2” | PB0314 | 1 |

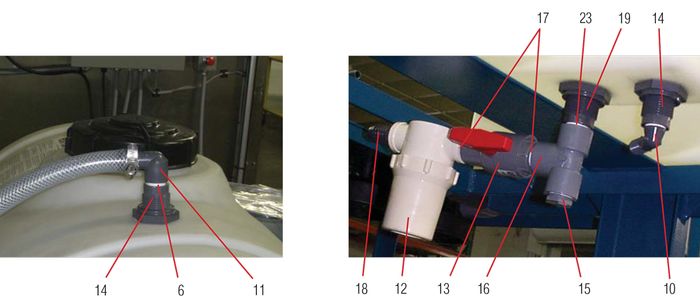

PLUMBING COMPONENTS UNITS PRIOR TO 09/01/03 | ||||

ITEM # | DESCRIPTION | PART NUMBER | NOTES | QTY |

1 | PUMP-PULLEY DRIVE | PB0101 | 1 | |

2 | T-VALVE | PB0201 | 1 | |

3 | VALVE-RELIEF | N/A | † OBSOLETE | 1 |

† REPLACE WITH CURRENT STYLE RELIEF VALVE.

† † REFER TO PREVIOUS PARTS LIST FOR ALL OTHER PLUMBING COMPONENTS NOT SHOWN HERE.

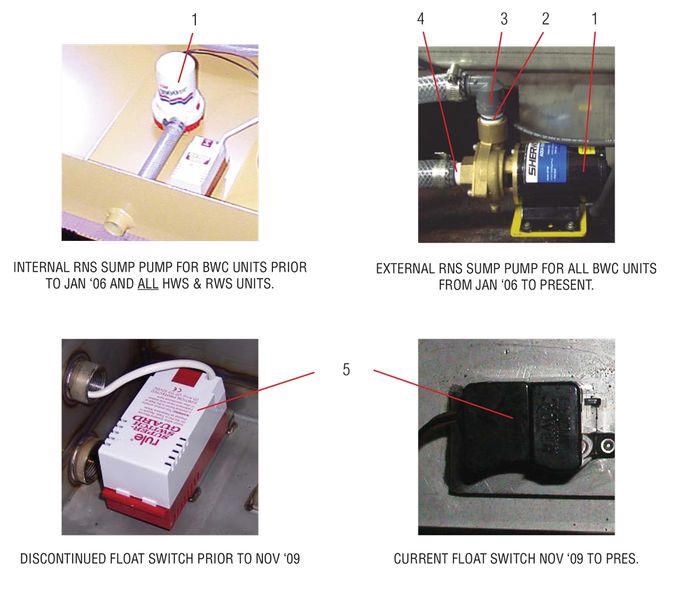

SUMP PUMP | ||||

ITEM # | DESCRIPTION | PART NUMBER | NOTES | QTY |

1 | SUMP PUMP-INTERNAL | PB0103 | 1 | |

SUMP PUMP-EXTERNAL | PB1012 | 1 | ||

2 | NIPPLE-CLOSE-3/4”-BRASS | PB0310-1 | 1 | |

3 | ELBOW-90 DEG-3/4” NPTF X 1” BARB | PB0703 | 1 | |

4 | ADAPTER-3/4” NPT X 1” BARB | PB0709 | 1 | |

5 | FLOAT SWITCH | N/A | † PRE NOV ‘09 | 1 |

FLOAT SWITCH REPLACEMENT KIT | 80672001 | NOV ‘09 TO PRES | 1 | |

† NO LONGER AVAILABLE. MUST REPLACE WITH CURRENT REPLACEMENT KIT.

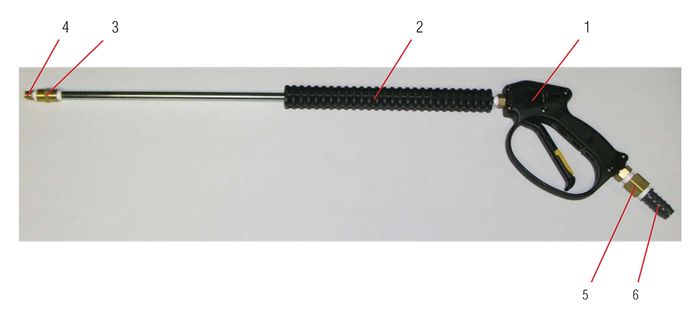

SPRAY WAND (IF EQUIPPED) | ||||

ITEM # | DESCRIPTION | PART NUMBER | NOTES | QTY |

REF | SPRAY WAND ASSEMBLY | 42512001 | INCL. ITEMS 1 - 6 | A/R |

1 | SPRAY GUN | PB0807 | 1 | |

2 | LANCE | PB0808 | 1 | |

3 | COUPLING-1/4” NPT | P0522 | 1 | |

4 | SPRAY NOZZLE | PB1002 | 1 | |

5 | ADAPTER-3/8” NPT X 1/2” NPTM | PB0505 | 1 | |

6 | HOSE BARB-3/4” X 1/2” NPT | PB0607 | 1 | |

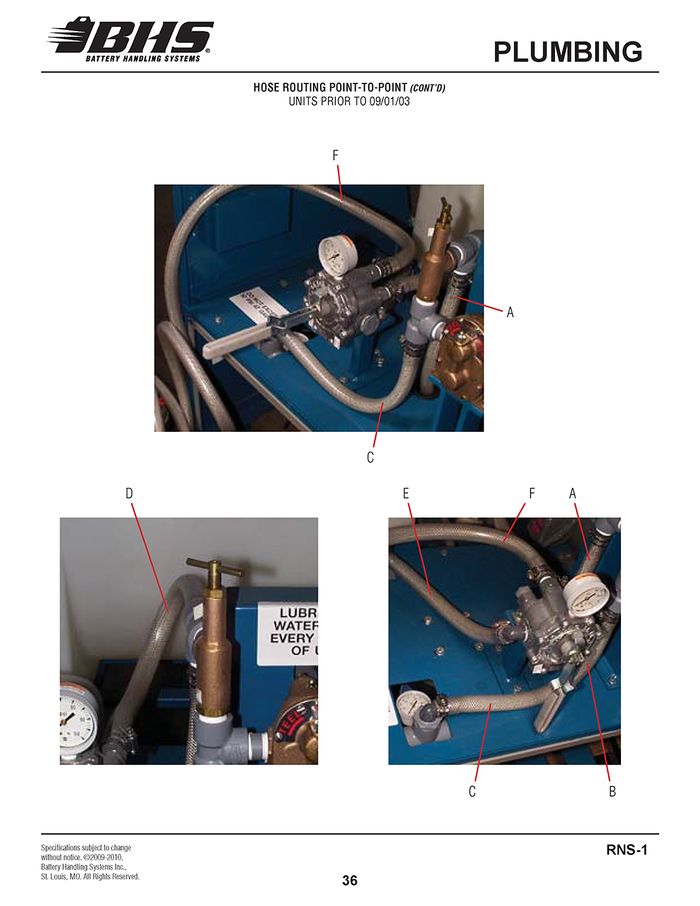

HOSE ROUTING POINT-TO-POINT | |||||

HOSE | STARTING LOCATION | MFG. DATE | TERMINATING LOCATION | HOSE DIA. | LENGTH |

A | BOTTOM OF PVC “T” @ RELIEF VALVE | CURRENT | RETURN LINE TO TANK (REAR PORT) | 3/4” | 46” |

† PRE 09/03 | 50” | ||||

B | PUMP INLET | CURRENT | TANK OUTLET PORT (FROM STRAINER) | 1” | 31” |

† PRE 09/03 | 38 1/4” | ||||

C | PUMP OUTLET | CURRENT | FILTER INLET (FRONT GAUGE PORT) | 3/4” | 10” |

† PRE 09/03 | 17 1/2” | ||||

D | REAR OF PVC “T” @ RELIEF VALVE | CURRENT | CONTROL VALVE INLET (RHS) | 3/4” | 27” |

† PRE 09/03 | REAR RHS CONTROL VALVE PORT | 24 1/4” | |||

E | FILTER OUTLET (REAR PORT) | CURRENT | REAR PVC “T” @ PRESSURE GAUGE | 3/4” | 22” |

† PRE 09/03 | LHS CONTROL VALVE PORT | 15 1/4” | |||

F | CONTROL VALVE OUTLET | CURRENT | BWC INLET (OR SPRAY WAND) | 3/4” | 17’ |

REAR LHS CONTROL VALVE PORT | † PRE 09/03 | ||||

G | HWS / RWS SUMP PUMP (INTERNAL) | ALL | WASH CABINET SUMP PAN | 1” | 8 1/2” |

BWC SUMP PUMP (INTERNAL) | - | 1” | 1 @ 3 1/4” 1 @ 6 5/8” | ||

BWC SUMP PUMP (EXTERNAL) | 1” | 24” | |||

H | WASH CABINET SUMP PUMP | ALL | TOP OF RNS TANK | 1” | 17’ |

† PRE 09/03 UNITS ARE EQUIPPED WITH BELT DRIVEN WATER PUMP (SEE PAGE 27)

HOSE DATA | |

DESCRIPTION | PART NUMBER |

3/4” I.D. HOSE | PB0902 |

1” I.D. HOSE | PB0901 |

3/4” HOSE CLAMP | HW1018 |

1” HOSE CLAMP | HW1019 |

STATEMENT OF WARRANTY

Statement of Warranty

Click here for details on BHS' Statement of Warranty.