IOP-407 BE-TSN

Looking for a specific replacement part? Ctrl-F (or Command-F for Mac users) brings up your browsers search panel and can search any text on the entire web page. Find parts by searching a part # or part description.

Register your equipment with BHS Optima, BHS's free app.

California Residents: WARNING: This product contains chemicals known to the State of California to cause cancer and/or reproductive harm, and birth defects or other reproductive harm. Learn more here.

Triple Stack Competitor Replacement Battery Extractors (BE-TSN) Parts & Service Manual

TP-606 - SAFETY AND DE-ENERGIZATION PROCEDURES

GENERAL SAFETY

- Read and understand all instructions and warnings before using or servicing this equipment.

- Keep these instructions for future reference.

- Battery Extractor (BE) units shall only be operated by suitable persons of at least 18 years of age, who have been trained in the proper and safe operation of the BE and expressly certified/charged, in writing, by the user or their representative.

- Only one person is permitted to travel on the BE at any time.

- BE units shall only be used indoors in an industrial setting on a hard, nonslip, and level floor without defects including but not limited to holes, gouges, cracks, drains or obstacles comprised of concrete or other suitable industrial material meeting the minimum requirements specified by BHS as well as any local requirements.

- A licensed structural engineer should be consulted prior to installing a BE on any building level other than the ground floor.

- BE units are not designed to be shipped or transported after initial delivery.

WORK AREA

- Keep work area clean and well lit. Cluttered work areas and poor lighting can lead to accidents.

- Clean up/contain any fluid spills immediately to prevent slips or falls.

- Be aware of potential hazards when performing any service or maintenance to the unit.

SERVICE & MAINTENANCE

Service personnel shall wear Personal Protective Equipment (PPE) appropriate for the task being performed.

LOCKOUT/TAGOUT

Lockout/tagout the BE per your corporate policy, if damaged or not functioning properly. Lockout/tagout and de-energize all systems prior to performing any maintenance or service to unit.

LEAD-ACID BATTERIES-EXPLOSION HAZARD

Do not allow open flames or sparks of any kind near a battery. Highly explosive gas is generated when charging a battery that can remain in battery cells for extended periods of time after charging is complete.

- Always wear appropriate PPE including rubber apron, gloves, boots and full face shield when performing service or maintenance to any lead-acid batteries.

- Do not place metal or other conductive objects on top of battery. Arcing may occur causing damage to the battery and/or serious personal injury or death.

- Use only chargers matching the voltage and amperage of the battery being charged. Overcharging a battery can cause damage to the battery, charger and/or serious personal injury or death.

- Turn off charger before disconnecting battery from charger. Arcing between battery and charger connectors can cause damage to the connectors and/or serious personal injury or death.

HYDRAULIC HAZARDS

AVOID HIGH PRESSURE FLUIDS-Escaping fluid under pressure can penetrate the skin causing serious injury. Relieve pressure before disconnecting hydraulic lines. Tighten all connections before applying pressure. Keep hands and body away from pin holes which eject fluids under high pressure. Use a piece of cardboard or paper to search for leaks. DO NOT use your hand.

Any fluid injected into the skin under high pressure should be considered a serious medical emergency despite an initial normal appearance of the skin. There will be a delayed onset of pain, and serious tissue damage may occur. Medical attention should be sought immediately.

OPERATIONAL SAFETY

OPERATIONAL SAFETY

- Only personnel trained in the proper and safe operation of BE units may operate or service the BE.

- Operators shall wear appropriate PPE suitable for working with industrial lead-acid batteries while operating the BE (see prior page).

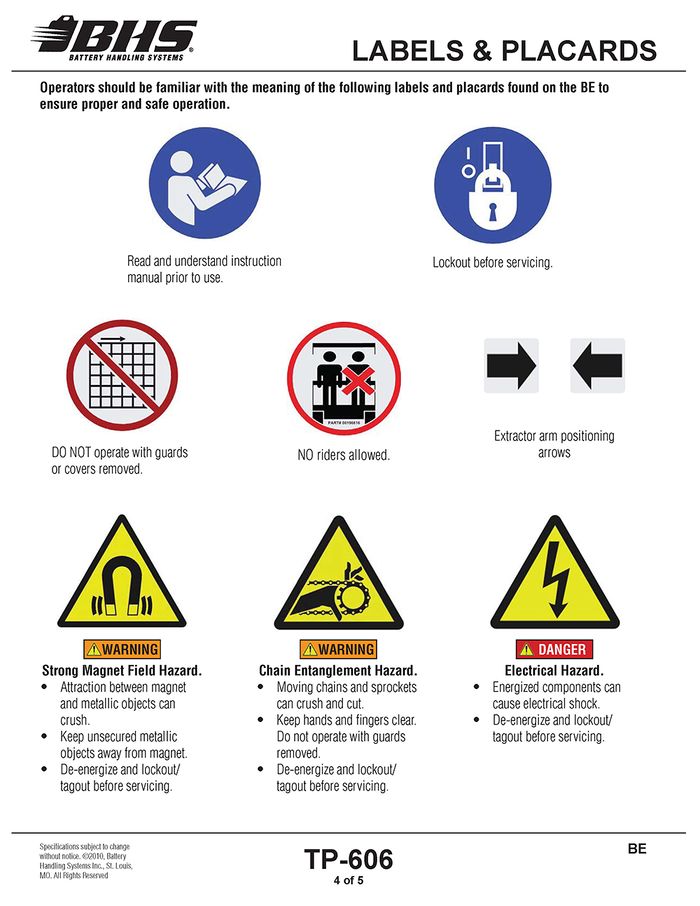

- All data plates, warning labels, placards, etc. shall be in place and legible at all times. Contact BHS for replacement data plates, warning labels, placards or instructions.

- All users and service personnel shall be familiar with the meaning and risks associated with all data plates, warning labels, etc.

- All operators and service personnel shall be aware of potential crush and shear points while operating or servicing the BE.

- Keep hands and arms out of the battery compartment while operating the BE.

- Remove BE from service if damaged, defective, or operating improperly (or becomes such while operating) until repairs can be made to correct any problem(s).

- All operators shall be aware of the location of the end stops in the travel path to prevent driving the BE into the end stops.

DO’s AND DON’T’s

- DO NOT exceed the maximum capacity of the BE.

- DO NOT modify or fit the BE with attachments without prior, written approval from BHS.

- DO NOT perform any maintenance or service to the BE with a battery loaded on the BE.

- DO NOT allow anyone to ride in or on the BE.

- DO NOT operate the BE with any guard or cover removed unless required for maintenance or repair.

- Disconnect the BE from all power sources before attempting to perform service or maintenance to the unit.

- DO NOT drive the BE into the end stops.

- DO NOT operate the BE if disengaged from the guidance track.

- DO NOT allow a battery to exit the BE when a lift truck or battery stand is not present to accept the battery.

- DO NOT rotate the arm onto a battery such that any part of the extractor arm, vacuum cup or magnet contacts the top of the battery.

- DO NOT allow anyone to enter the area under the carriage without the service stands properly installed.

- DO NOT use the BE in a manner for which it is not intended. Some examples of prohibited use are but not limited to:

- To transport people

- As a vehicle jack

- To lift loads greater than its rated load capacity

- Where unintentional movement may exist

- Having direct contact with foodstuff

- In a potentially explosive atmosphere

DE-ENERGIZATION

- Fully lower the BE roller bed or position the roller bed on service stands if service requires the bed be raised. See Figures 1 & 2

- Turn key on dashboard to the “OFF” position. See Figure 3.

- Disconnect power to the extractor or shut off the electrical branch circuit breaker.

- Actuate all hydraulic levers in both directions to release any stored hydraulic pressure. See Figure 4.

- Escaping hydraulic fluid under high pressure (see HYDRAULIC HAZARDS in the GENERAL SAFETY section).

- Unexpected movement of hydraulic components.

Failure to properly support the roller bed when performing service under the BE could result in injury from the roller bed lowering unexpectedly.

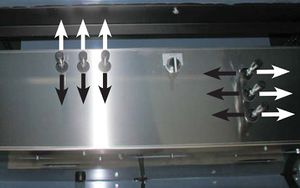

FIGURE 1

FIGURE 2

FIGURE 3

Failure to disconnect electrical power to the BE could result in electrical shock. Serious personal injury or death will occur.

Failure to release any stored hydraulic pressure could result in injury from:

FIGURE 4

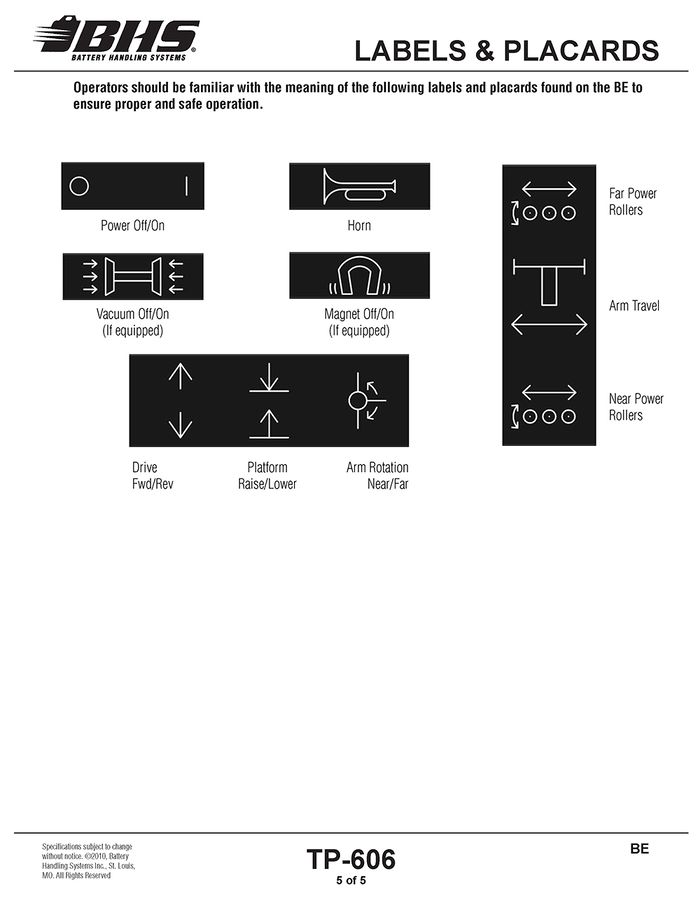

LABELS & PLACARDS

GENERAL INFORMATION

SPECIFICATION DATA

Product Specifications - Imperial / Metric | BE-24-2-SLN | BE-36-2-SLN | BE-24-2-DSN | BE-36-2-DSN | BE-24-2-TSN | BE-36-2-TSN |

Travel Speed | 0-190 FPM / 0-1 mps | 0-190 FPM / 0-1 mps | 0-190 FPM / 0-1 mps | |||

Raise - Lower Speed | 0-10 FPM / 0 -.05 mps | 0-16 FPM / 0-.08 mps | 0-26 FPM / 0-.13 mps | |||

Powered Roller Speed | 0-37 FPM / 0-.18 mps | 0-37 FPM / 0-.18 mps | 0-37 FPM / 0-.18 mps | |||

Arm Traverse Speed | 0-20 FPM / 0-.10 mps | 0-20 FPM / 0-.10 mps | 0-20 FPM / 0-.10 mps | |||

Arm Rotation Time | 6 - 8 Seconds | 6 - 8 Seconds | 6 - 8 Seconds | |||

Draw Bar Pull Vacuum (12” Round Cup) | 1,000 lbs / 450 kg | 1,000 lbs / 450 kg | 1,000 lbs / 450 kg | |||

Vacuum Attach Time / Release Time | < 1 sec / < 1 sec | < 1 sec / < 1 sec | < 1 sec / < 1 sec | |||

Input Voltage | 240/480 VAC/60Hz | 240/480 VAC/60Hz | 240/480 VAC/60Hz | |||

AC Current Draw | 13.6 / 6.8 Amps | 13.6 / 6.8 Amps | 27.2 / 13.6 Amps | |||

Control Circuit Voltage | 120 VAC | 120 VAC | 120 VAC | |||

Hydraulic Power Unit | 5 HP / 3.73 KW | 5 HP / 3.73 KW | 10 HP / 7.46 KW | |||

Hydraulic Pump | 8 GPM / 30 LPM | 8 GPM / 30 LPM | 16 GPM / 60 LPM | |||

Power Unit | Hydraulic, Variable Displacement | Hydraulic, Variable Displacement | Hydraulic, Variable Displacement | |||

Operating Pressure | 1,500 PSI / 103 Bar | 1,500 PSI / 103 Bar | 1,500 PSI / 103 Bar | |||

Vacuum Pump | 1/3 HP / .25 KW | 1/3 HP / .25 KW | 1/3 HP / .25 KW | |||

Vacuum | 21” Hg / 0.73 kg/cm2 | 21” Hg / 0.73 kg/cm2 | 21” Hg / 0.73 kg/cm2 | |||

Full Load Capacity | 10,000 lbs / 4535 kg | 10,000 lbs / 4535 kg | 10,000 lbs / 4535 kg | |||

Weight (Empty) | 5,300 lbs / 2404 kg | 5,700 lbs / 2585 kg | 5,500 lbs / 2495 kg | 6,100 lbs / 2767 kg | 7,500 lbs / 3402 kg | 7,800 lbs / 3538 kg |

Total Compartment Rollers / Powered | 11/5 | 11/5 | 11/5 | |||

Guide Track | 2” x 2.5” Angle / 51 mm x 64 mm | 2” x 2.5” Angle / 51 mm x 64 mm | 3” x 2.5” Angle / 76 mm x 64 mm | |||

Overall Dimensions (L x W x H) | 130” x 67” x 65” / 3302 mm x 1702 mm x 1651 mm | 154” x 67” x 65” / 3912 mm x 1702 mm x 1651 mm | 128” x 67” x 90” / 3252 mm x 1829 mm x 2286 mm | 152” x 67” x 90” / 3861 mm x 1702 mm x 2286 mm | 156 .5” x 67” x 158.06” / 3975 mm x 1702 mm x 4015 mm | 180.5” x 67” x 158.06” / 4585 mm x 1702 mm x 4015 mm |

Vacuum Arm Reach (Stand Side) | 9” / 229 mm | 9” / 229 mm | 9” / 229 mm | |||

Vacuum Arm Reach (Hydraulic Extension) | 5” - 17” / 127 mm - 432 mm | 5” - 17” / 127 mm - 432 mm | 5” - 17” / 127 mm - 432 mm | |||

Wheel Base | 95.75” / 2432 mm | 119.75” / 3042 mm | 95.75” / 2432 mm | 119.75” / 3042 mm | 98” / 2489 mm | 122” / 3099 mm |

Drive Wheel Centerline | 48” / 1219 mm | 48” / 1219 mm | 48” / 1219 mm | |||

Battery Compartment Width | 24” / 610 mm | 36” / 915 mm | 24” / 610 mm | 36” / 915 mm | 24” / 610 mm | 36” / 915 mm |

Maximum Battery Dimensions (L x W x H) | 48” x 23” x 36” / 1220 mm x 580 mm x 910 mm | 48” x 35” x 36” / 1220 mm x 890 mm x 910 mm | 48” x 23” x 36” / 1220 mm x 580 mm x 910 mm | 48” x 35” x 36” / 1220 mm x 890 mm x 910 mm | 48” x 23” x 36” 1220 mm x 580 mm x 910 mm | 48” x 35” x 36” / 1220 mm x 890 mm x 910 mm |

Minimum Battery Width | 12” / 305 mm | 12” / 305 mm | 12” / 305 mm | |||

Minimum Battery Height | 17.75” / 450 mm | 17.75” / 450 mm | 17.75” / 450 mm | |||

Ground Clearance | .625” / 15 mm | .625” / 15 mm | .625” / 15 mm | |||

Roller Height | 6.5” Min - 26.5” Max 165 mm Min - 670 mm Max | 6.5” Min - 56” Max 165 mm Min - 1420 mm Max | 6.5” Min - 96” Max 165 mm Min - 2435 mm Max | |||

Note: Specifications may vary +/- 5% due to temperature, floor considerations and operator efficiency. Values represented under normal operating conditions.

PRE-INSTALLATION CHECK

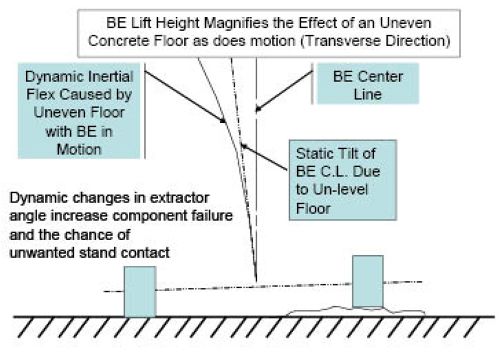

FLOOR CONDITIONS

The floor is the single most critical area of the battery room. A bad floor can cause significant issues with the installation as well as downtime and maintenance problems with the extractor. The floor should be verified as to its minimum thickness and strength with user. As noted on the drawing, the specific requirement of flatness for your particular type of system is listed. Below is a chart stating floor requirements. If possible, especially on double stack and higher systems, a digital level should be used to shoot the grade for compliance with the specification. The floor should also be inspected for severe cracks or excessively wide expansion joints in the travel path of the machine. If floor drains are present, they must not have a grade to the opening that encroaches into the travel path.

F-min is a rating method used to evaluate the flatness and levelness of a floor designated as “defined travel path”. For example, an F-min rating of 60 means that there is no more than .129” of variation in the transverse axis (wheels left to right) and .287” variation in the longitudinal axis (front to back) on the equipment.

To avoid potential damage to drive wheel assemblies, guide track, structural components, guide rollers and issues with the inner frame equalization the “defined travel path” of the Battery Extractor should meet or exceed the recommended F-min specification. See chart below for the model specifications

Model | F-Min | +/- Longitudinal | +/- Transverse | Slope Defect |

SL, DS | 40 | .287” | .192” | .096” |

TS | 60 | .186” | .129” | .066” |

QS | 85 | .131” | .091” | .047” |

OPERATING CONTROLS

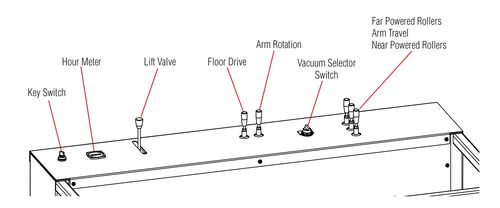

OPERATOR CONSOLE

OPERATION OVERVIEW

- All operators should be familiar with the operator console of the extractor before performing any battery changes. The controls of the console are simple and well marked. It consists of six, manually operated, hydraulic control valves and a three position selector switch which controls the left and right vacuum cups.

- All manual valves are moved in the direction of the function travel which it controls with exception of the lift/ lower valve, which is pulled toward the operator for “up” and pushed away for “down.”

- The extractor arm must be in the center of the carriage or the unit will not travel forward or reverse.

- To ensure smooth operation, all valve movements should be made in a slow, deliberate motion.

OPERATING INSTRUCTIONS

PRE-CHANGE OUT PREPARATION

- Position the lift truck for change out in the designated change out area.

- Remove all battery restraints and disconnect the battery cables following the manufacturer's guidelines. (Be sure to position the battery cables so as not to be damaged by the battery during change out.)

- Board the battery extractor and close the safety gate. (The gate must be fully closed or the unit will not operate.)

- Depress the foot pedal.

- Turn the key switch to the “ON” position.

DISCHARGED BATTERY REMOVAL

- Move the extractor left or right to position the center of compartment with the center of the lift truck battery compartment. (Lead roller of extractor is equipped with a centering groove. Users may find it beneficial to mark center of lift truck compartment to aid in alignment.)

- Align the extractor’s roller compartment height with the lift truck’s battery compartment.

- Rotate extractor arm into battery compartment aligned in Step 2.

- Move the extractor arm toward the battery until the vacuum cup/magnet contacts the battery.

- Energize vacuum by turning selector switch to proper direction, left or right.

- Move extractor arm away from lift truck toward center of extractor roller bed, removing discharged battery. (Battery should be pulled past first three idler rollers onto first or second powered roller.)

- Turn off vacuum and move extractor arm away from battery 1” to 2”.

- Rotate extractor arm out of battery compartment into opposite compartment (if empty) and center arm in carriage.

- Move battery into center of compartment using powered rollers.

DO NOT force cup to battery after initial contact with battery is made.

CHARGED BATTERY RETRIEVAL

- Locate a charged battery for the appropriate type of lift truck being changed.

- Raise battery extractor roller compartment to proper level to gain access as needed to disconnect desired battery from its charger and disengage battery safety stop.

- Move extractor to appropriate rack position and align empty roller compartment with the center of the battery storage rack compartment. (The battery safety stop of each compartment is the center of that compartment and should be used for alignment with the groove in the lead roller of the battery extractor compartment.)

- Rotate arm into empty compartment (if not already positioned there.)

- Move extractor arm toward battery until vacuum cup contacts battery.

- Energize vacuum cup by turning selector switch to proper direction, left or right.

- Move extractor arm away from battery rack toward center of extractor roller bed, removing charged battery. (Battery should be pulled past first three idler rollers onto first or second powered roller.)

- Turn off vacuum and move extractor arm away from battery 1” to 2”.

- Rotate extractor arm out of battery compartment into fully vertical position.

- Move battery into center of compartment using powered rollers.

ALWAYS be sure charging has been completed and the charger is not still charging the battery. Dangerous sparking/arcing can occur if the battery is unplugged from the charger while charging.

DO NOT force cup to battery after initial contact with battery is made.

DISCHARGED BATTERY RETURN

- If required, adjust extractor compartment height to battery rack level with open battery compartment. Drive extractor to align roller compartment containing discharged battery with open battery compartment.

- Return discharged battery to battery rack using powered rollers. NOTE: In most instances, batteries can be deposited into battery racks in one motion using only powered rollers. When this does not work, the battery may need slight assistance from extractor arm. To do this, rotate arm into compartment such as one would if removing battery from rack. If extractor is vacuum equipped, position top edge of cup slightly higher than edge of battery (or over lifting eye if so equipped) to prevent cup from adhering to battery - No vacuum is necessary for pushing. DO NOT activate vacuum switch. Slowly push battery into rack until fully into compartment.

- Engage the battery safety stop and connect the battery to the charger as required.

CHARGED BATTERY INSTALLATION

- Lower extractor to fully lowered position.

- Drive the extractor back to the lift truck and align the roller compartment containing the charged battery as performed in steps 1 and 2 of ”Discharged Battery Removal”.

- Move the charged battery toward the lift truck compartment by moving the extractor arm out, verifying precise battery alignment.

- Adjust the extractor vertically as well as horizontally, if needed.

- Insert battery into lift truck as far as possible using only the powered rollers.

- Rotate extractor arm into compartment and SLOWLY push battery into lift truck. (Be sure to watch battery cables for interference.)

- Return extractor arm to center of roller bed and lower extractor to fully lowered position. Drive extractor out of immediate area.

- Turn off key switch, remove key from switch and carefully exit extractor.

- Secure newly installed battery in lift truck and reconnect battery cables.

- Return lift truck to service.

Many batteries are a tight fit into the lift truck battery compartments. Care MUST be taken to ensure alignment is precise to avoid damage to the battery, lift truck, and/or battery extractor.

DO NOT drive the B.E. into the travel path end stops. The end stops are designed to prevent the B.E. from accidentally traveling beyond its designated travel path. Driving the B.E. into the end stops will cause the B.E. to stop suddenly, possibly causing damage to the end stop, the B.E. and/or personal injury.

MANUAL UNLOADING

Lockout/tagout and de-energize all equipment prior to manually unloading any battery.

In the event of power loss or an operational malfunction of the BE not allowing a battery to be unloaded using normal operating procedures, it is recommended a battery be removed from the BE using certified and approved vertical extraction methods and devices.

Read, understand and observe all safety warnings and procedures related to the vertical extraction device(s) being used.

Should the status of the BE not allow for safe vertical extraction due to position in the battery aisle, only repairs required to safely maneuver the BE to a position allowing for safe vertical extraction should be made. Once any batteries are safely unloaded, any remaining repairs can be made.

Extreme care should be taken when working under or around equipment supporting elevated loads. Unexpected movement of the equipment could cause the load and/or equipment to fall. ALWAYS be sure devices of adequate size and strength are in place to prevent any personnel working under the elevated load from being crushed. Serious personal injury or death will occur.

RECOMMENDED SPARE PARTS

Refer to the Spare Parts Kit (Pt# BE-SPKV-TS) at the beginning of Section 7 for the list of items recommended by the factory to have on hand for BE-TSN models to minimize any downtime due to minor breakdown that may occur under normal operating conditions.

Use only BHS approved replacement parts.

BHS recommends that a full maintenance inspection report similar to the one provided be done at least once a month.

Any parts found to be excessively worn or damaged should promptly be replaced unless said parts pose a safety risk to the operator and/or extractor, in which case the unit should be removed from service until the problem(s) are remedied (See Operator’s Daily Checklist.)

PARTS SECTIONS

CHASSIS

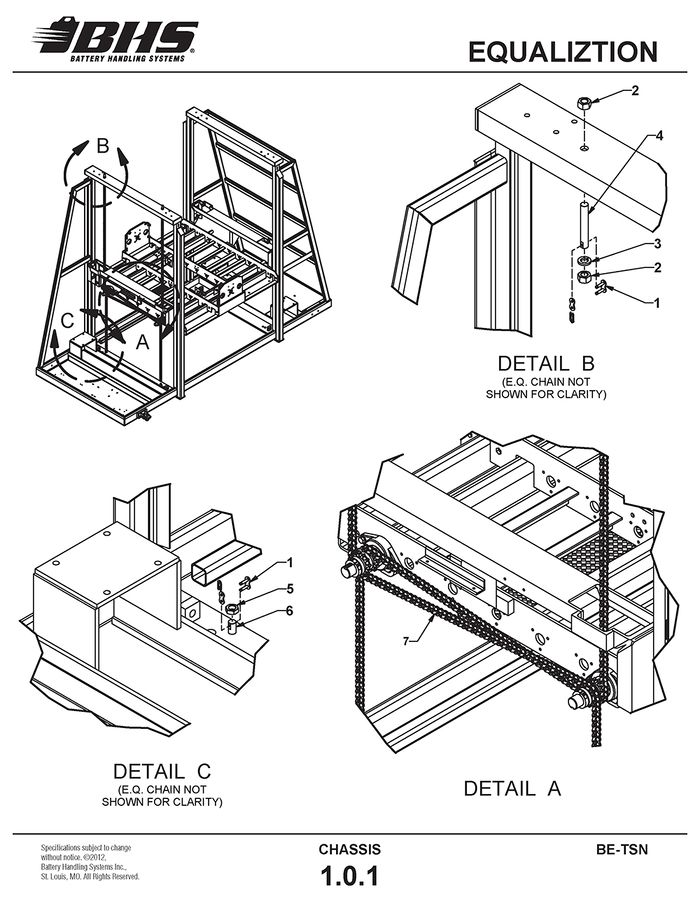

EQUALIZTION

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | PT0222 | LINK-CONNECTING-#60 | 8 | ||

2 | HW0017 | NUT-HEX-3/4-10 | 8 | ||

3 | HW0115 | WASHER-LOCK-3/4 | 4 | ||

4 | 43097001 | STUD-ANCHOR-5” | UPPER | 4 | |

5 | HW0020 | NUT-JAM-3/4-10 | 4 | ||

6 | 43097002 | STUD-ANCHOR-2” | LOWER | 4 | |

7 | 00158001-40 | CHAIN-ROLLER-#60 | 4 |

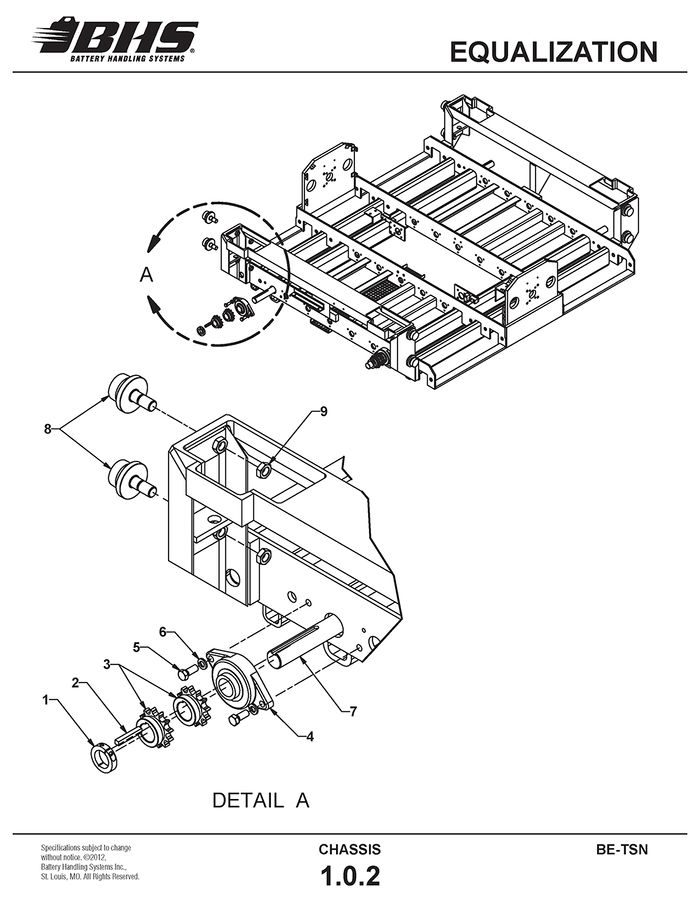

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | PT0416 | COLLAR-SHAFT-1 1/2” | 4 | ||

2 | 43097006 | KEY-3/8” X 2 3/4” | 4 | ||

3 | PT0224 | SPROCKET-60B12 X 1 1/2” | KEYED INLINE | 8 | |

4 | PT0405 | FLANGE BEARING-2 BOLT-1 1/2” | 4 | ||

5 | HW0502 | BOLT-HHCS-1/2-13 X 1 1/4” | 8 | ||

6 | HW0110 | WASHER-LOCK-1/2” | 8 | ||

7 | 43127001 | SHAFT-EQUALIZATION | BE-24-2 | 2 | |

43327001 | SHAFT-EQUALIZATION | BE-36-2 | 2 | ||

8 | PT0503 | BEARING-FLANGED LOAD-2 1/4” | 8 | ||

9 | HW0025 | NUT-JAM-7/8-14 | 8 |

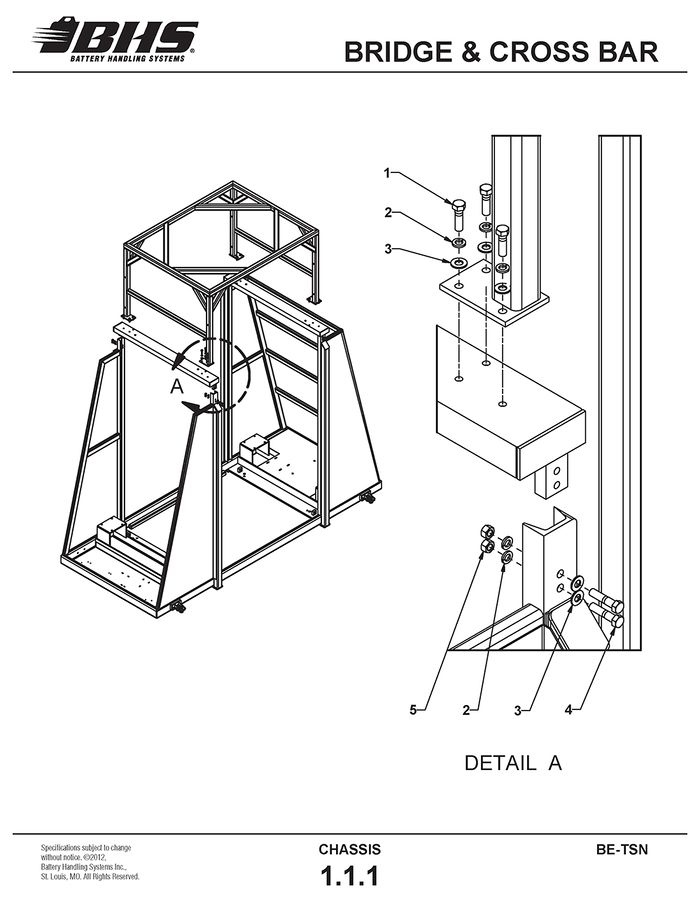

BRIDGE & CROSS BAR

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HW0502 | BOLT-HHCS-1/2-13 X 1 1/4” | 12 | ||

2 | HW0110 | WASHER-LOCK-1/2” | 20 | ||

3 | HW0112 | WASHER-FLAT-1/2”-SAE | 20 | ||

4 | HW0515 | BOLT-HHCS-1/2-13 X 2” | FULLY THREADED | 8 | |

5 | HW0007 | NUT-HEX-1/2-13 | 8 |

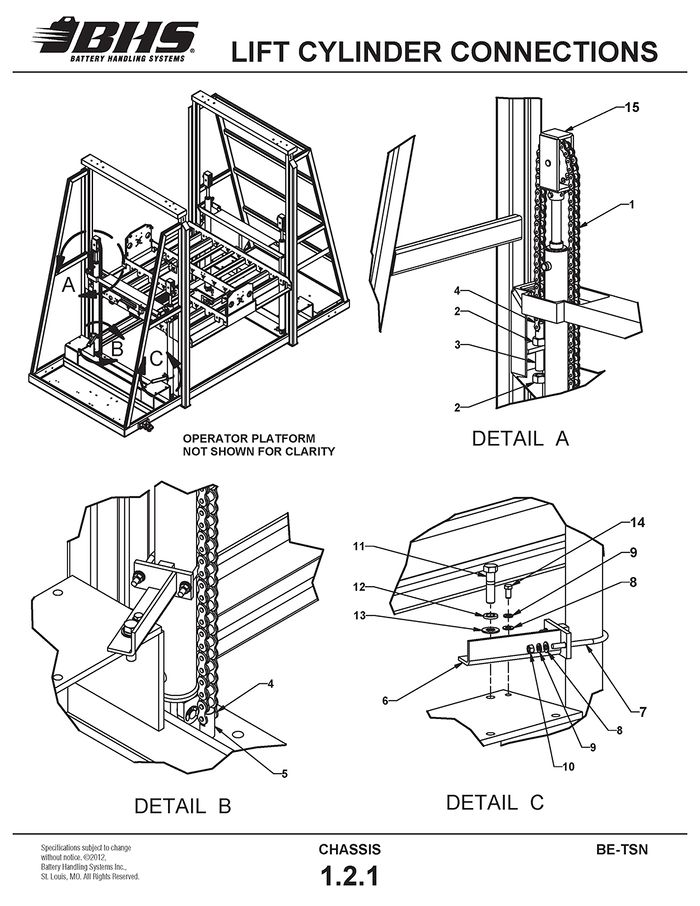

LIFT CYLINDER CONNECTIONS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 00158001-13 | CHAIN-ROLLER-#80 | 4 | ||

2 | HW0014 | NUT-HEX-1-8 | 8 | ||

3 | 43897002 | STUD-LIFT-INNER FRAME | 4 | ||

4 | PT0204 | LINK-CONNECTING-#80 | 8 | ||

5 | 43897001 | STUD-LIFT-OUTER FRAME | 4 | ||

6 | 43815018 | BRACKET-CYLINDER SUPPORT | 4 | ||

7 | SS0761 | U-BOLT-CYLINDER MOUNTING | 4 | ||

8 | HW0108 | WASHER-FLAT-3/8”-SAE | 12 | ||

9 | HW0107 | WASHER-LOCK-3/8” | 12 | ||

10 | HW0005 | NUT-HEX-3/8-16 | 8 | ||

11 | HW0514 | BOLT-HHCS-1/2-13 X 2 1/2” | IDLER CASTER END OF UNIT | 2 | |

HW0504 | BOLT-HHCS-1/2-13 X 2” | DRIVE WHEEL END OF UNIT | 2 | ||

12 | HW0110 | WASHER-LOCK-1/2” | 4 | ||

13 | HW0112 | WASHER-FLAT-1/2”-SAE | 4 | ||

14 | HW0402 | BOLT-HHCS-3/8-16 X 1” | 4 | ||

15 | 43822002 | CLEVIS ASSEMBLY | SOLD AS ASSEMBLY ONLY | 4 |

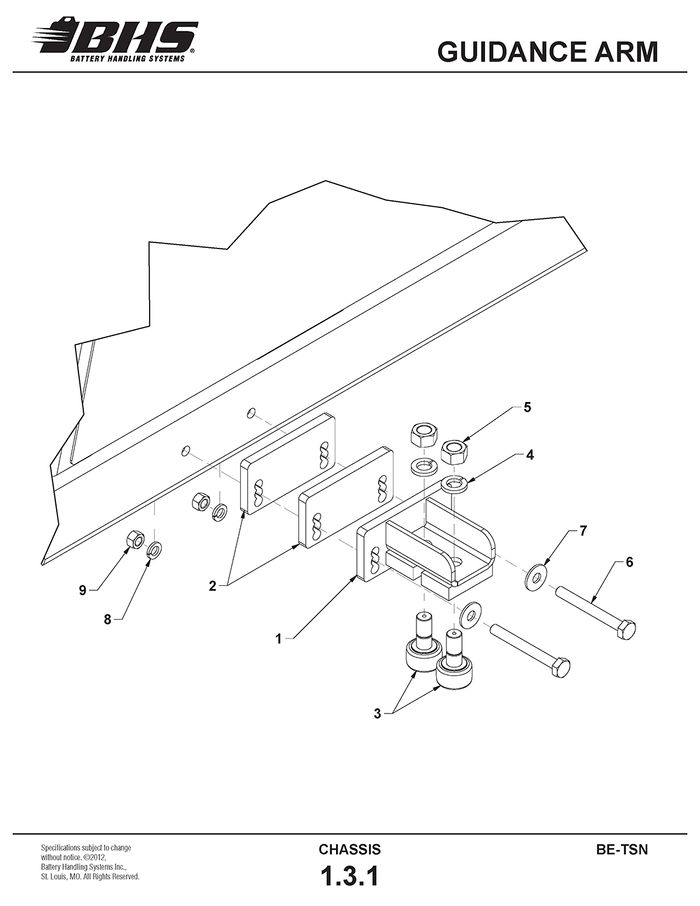

GUIDANCE ARM

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43017021 | GUIDE ARM WELDMENT | 2 | ||

2 | 43017025 | SPACER-GUIDE ARM | 4 | ||

3 | PT0510 | CAM ROLLER-1 3/4” | 4 | ||

4 | HW0115 | WASHER-LOCK-3/4” | 4 | ||

5 | HW0011 | NUT-HEX-3/4-16 | 4 | ||

6 | HW0509 | BOLT-HHCS-1/2-13 X 4 1/2” | 4 | ||

7 | HW0112 | WASHER-FLAT-1/2”-SAE | 4 | ||

8 | HW0110 | WASHER-LOCK-1/2” | 4 | ||

9 | HW0007 | NUT-HEX-1/2-13 | 4 |

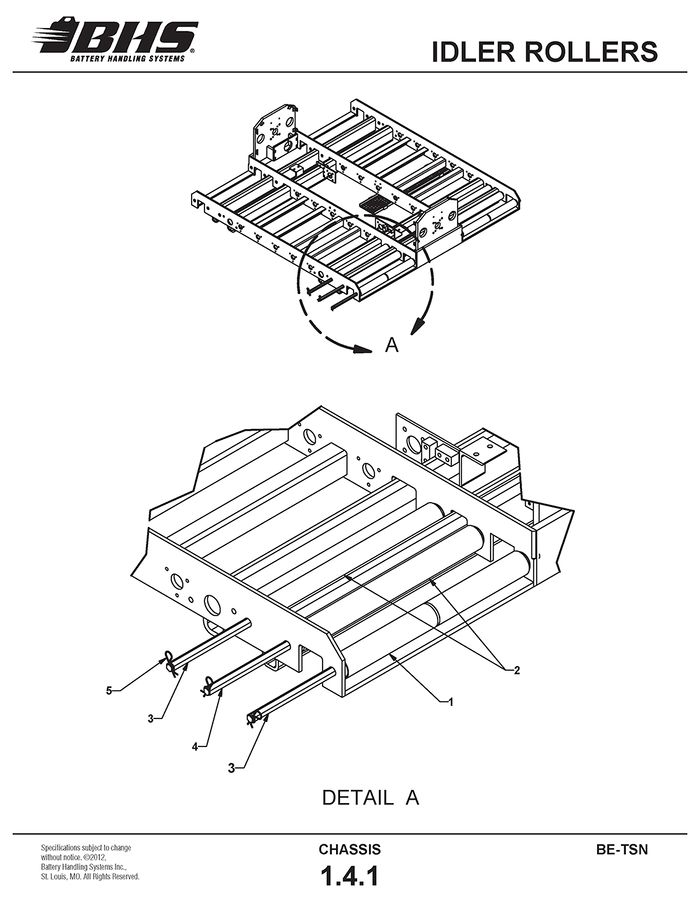

IDLER ROLLERS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43182001 | LEAD ROLLER ASSEMBLY-24” | W/ ALIGNMENT GROOVE | 4 | |

43382001 | LEAD ROLLER ASSEMBLY-36” | W/ ALIGNMENT GROOVE | 4 | ||

2 | 43182002 | IDLER ROLLER ASSEMBLY-24” | 8 | ||

43382002 | IDLER ROLLER ASSEMBLY-36” | 8 | |||

3 | 43187002 | SHAFT-HEX-.75” X 25.75” | 8 | ||

43387002 | SHAFT-HEX-.75” X 37.75” | 8 | |||

4 | 43187003 | SHAFT-HEX-.75” X 27.5” | 4 | ||

43387003 | SHAFT-HEX-.75” X 39.5” | 4 | |||

5 | HW1058 | PIN-HITCH | 24 |

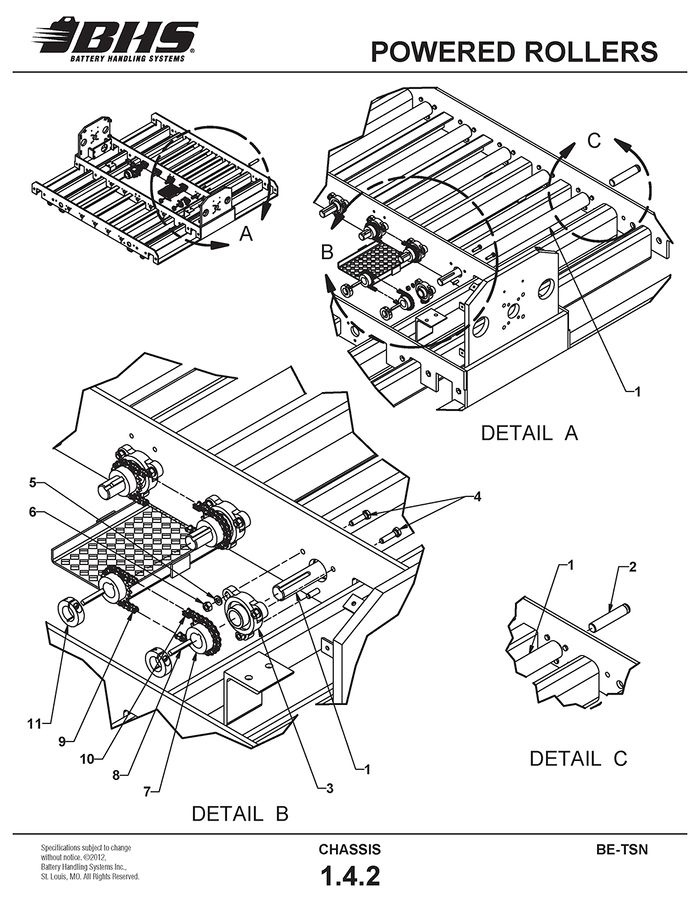

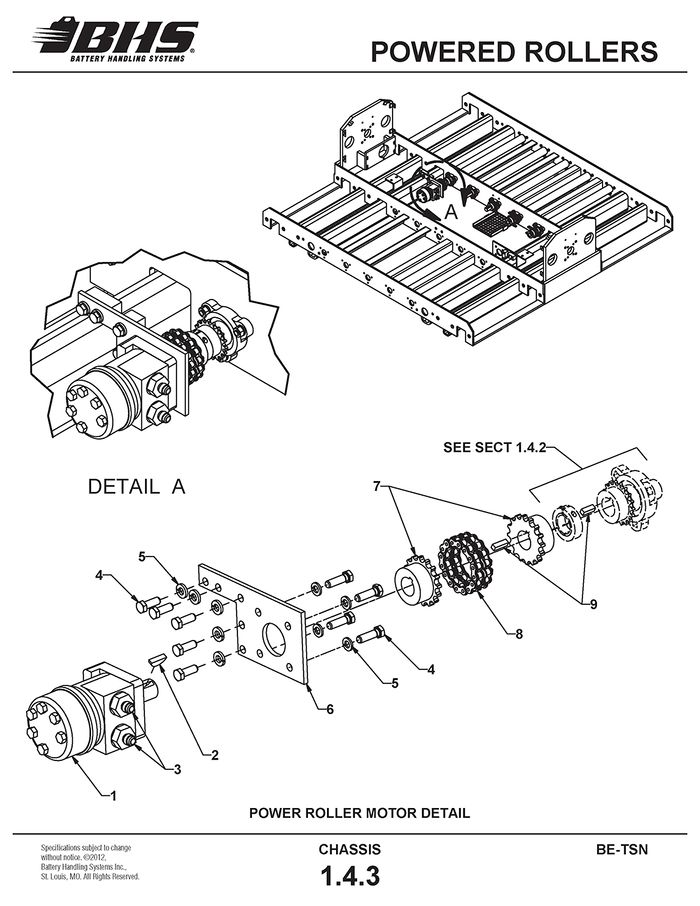

POWERED ROLLERS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43182003 | POWERED ROLLER-24” | 10 | ||

43382003 | POWERED ROLLER-36” | 10 | |||

2 | 43087001 | JOURNAL-POWERED ROLLER | 10 | ||

3 | PT0404 | FLANGE BEARING-3-BOLT-1” | 20 | ||

4 | HW0321 | BOLT-HHCS-5/16-18 X 1 1/4” | 60 | ||

5 | HW0105 | WASHER-LOCK-5/16” | 60 | ||

6 | HW0004 | NUT-HEX-5/16-18 | 60 | ||

7 | PT0033 | SPROCKET-35B18 X 1” | 16 | ||

8 | 00197028 | KEY-1/4” X 1 1/4” | 8 | ||

9 | 00158001-38 | CHAIN-ROLLER-#35 | † 49 PITCH LENGTH | 4 | |

00158001-39 | CHAIN-ROLLER-#35 | 51 PITCH LENGTH | 4 | ||

10 | PT0031 | LINK-CONNECTING-#35 | 8 | ||

11 | PT0418 | COLLAR-SHAFT-1” | 10 | ||

12 | PT0032 | LINK-OFFSET-#35 | † NOT SHOWN | 4 |

† OFFSET LINKS FOR USE WITH 49 PITCH LENGTH CHAINS ONLY.

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0120 | MOTOR-HYDRAULIC-160CC | 2 | ||

2 | HW1071 | KEY-WOODRUFF-#808 STD | SUPPLIED WITH ITEM 1 | A/R | |

3 | H1544 | ADAPTER-#6 JICM X #10 SAEM | 4 | ||

4 | HW0402 | BOLT-HHCS-3/8-16 X 1” | 18 | ||

5 | HW0107 | WASHER-LOCK-3/8” | 18 | ||

6 | 50017005 | PLATE-MOTOR MOUNTING | 2 | ||

7 | PT0302-1 | COUPLING BODY-#40 X 1” | 4 | ||

8 | PT0301 | CHAIN-COUPLING-#40 | INCL. CONNECTING PIN | 2 | |

9 | 00197026 | KEY-1/4” X 1” | 4 |

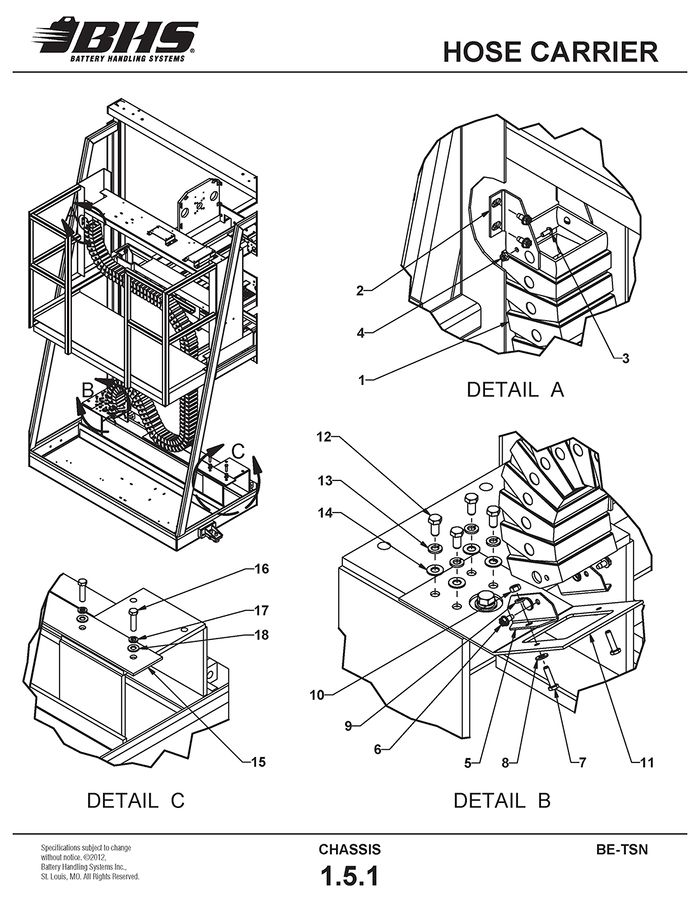

HOSE CARRIER

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | PT0629 | CARRIER TRACK | 81 LINKS REQ’D | 10’ | |

2 | PT0630 | BRACKET-UPPER MOUNTING | SOLD AS SET - INCL. ITEM #5 | 1 | |

3 | HW0212 | SCREW-RHMS-#10-24 X 1/2” | 2 | ||

4 | SS0202 | NUT-NILN-#10-24 | 2 | ||

5 | PT0630 | BRACKET-LOWER MOUNTING | SOLD AS SET - INCL. ITEM #2 | 1 | |

6 | HW0301 | BOLT-SELF TAP “F”-1/4-20 X 1/2” | 6 | ||

7 | HW0303 | BOLT-HHCS-1/4-20 X 1” | 2 | ||

8 | HW0104 | WASHER-FLAT-1/4”-SAE | 2 | ||

9 | HW0103 | WASHER-LOCK-1/4” | 2 | ||

10 | HW0002 | NUT-HEX-1/4-20 | 2 | ||

11 | 43817056-2 | BRACKET-CARRIER TRACK MOUNTING | 1 | ||

12 | HW0401 | BOLT-HHCS-3/8-16 X 3/4” | 4 | ||

13 | HW0107 | WASHER-LOCK-3/8” | 4 | ||

14 | HW0108 | WASHER-FLAT-3/8”-SAE | 4 | ||

15 | 43817057 | PLATE-CARRIER TRACK SUPPORT | 1 | ||

16 | HW0504 | BOLT-HHCS-1/2-13 X 2” | 2 | ||

17 | HW0110 | WASHER-LOCK-1/2” | 2 | ||

18 | HW0112 | WASHER-FLAT-1/2”-SAE | 2 |

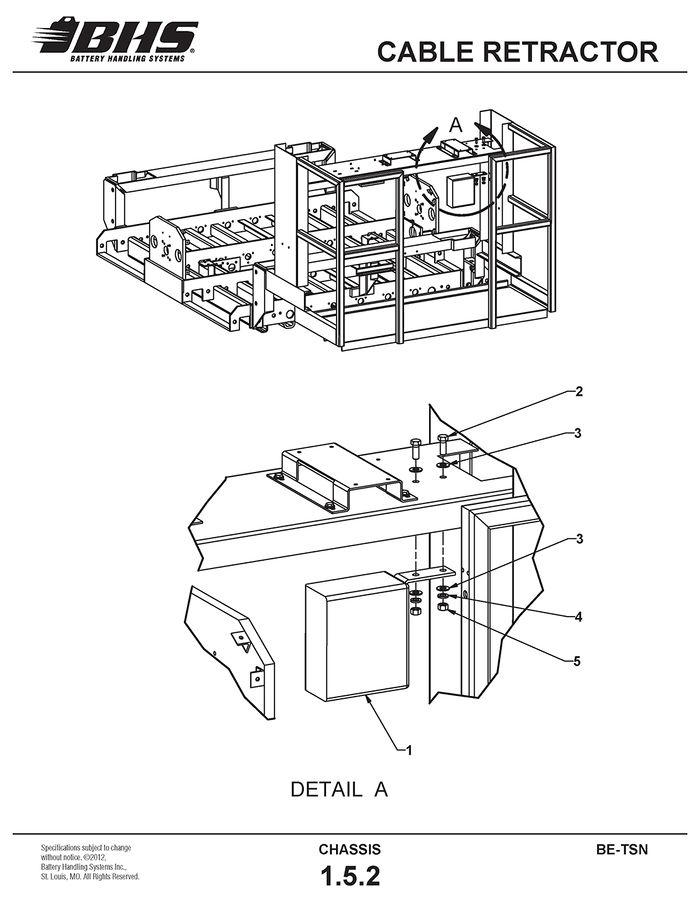

CABLE RETRACTOR

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | CCR-12HD | TAKE UP REEL-CARRIER TRACK | 1 | ||

2 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4” | 2 | ||

3 | HW0108 | WASHER-FLAT-3/8”-SAE | 4 | ||

4 | HW0107 | WASHER-LOCK-3/8” | 2 | ||

5 | HW0005 | NUT-HEX-3/8-16 | 2 |

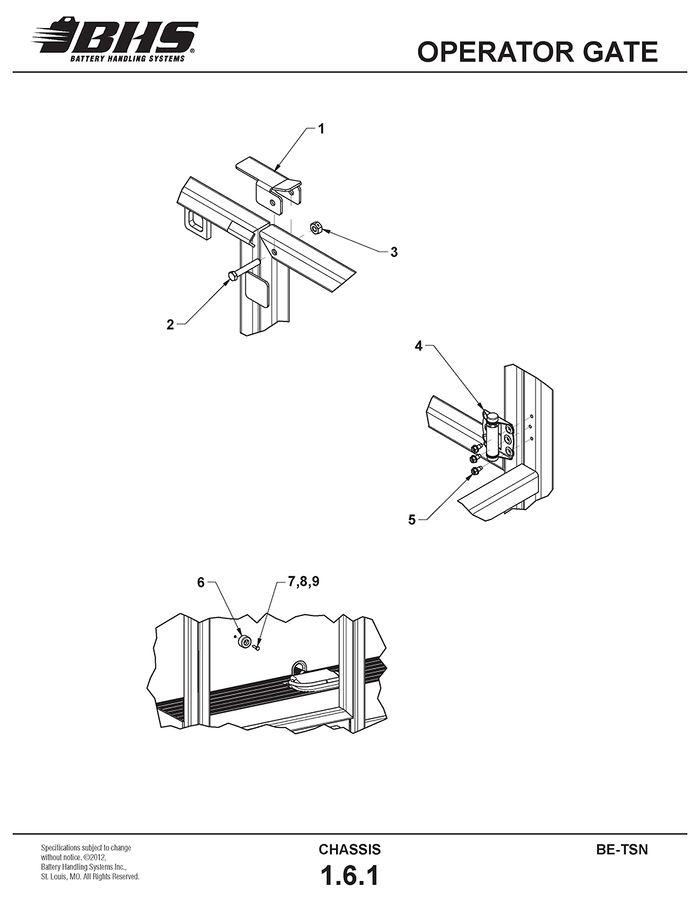

OPERATOR GATE

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43017064-2 | LATCH-SWIING GATE | 1 | ||

2 | HW0030 | BOLT-HHCS-3/8-16 X 2 1/4” | 1 | ||

3 | HW0031 | NUT-LOCK-3/8-16 | 1 | ||

4 | HW9000 | HINGE-SPRING | 1 | ||

5 | HW0301 | BOLT-SELF TAP ”F”-1/4-20 X 1/2” | 3 | ||

6 | HW1037 | STOP-GATE | 80092001 | 1 | |

7 | HW0303 | BOLT-HHCS-1/4-20 X 1” | 80092001 | 1 | |

8 | HW0104 | WASHER-FLAT-1/4”-SAE | 80092001 | (NOT SHOWN) | 1 |

9 | HW0003 | NUT-NILN-1/4-20 | 80092001 | (NOT SHOWN) | 1 |

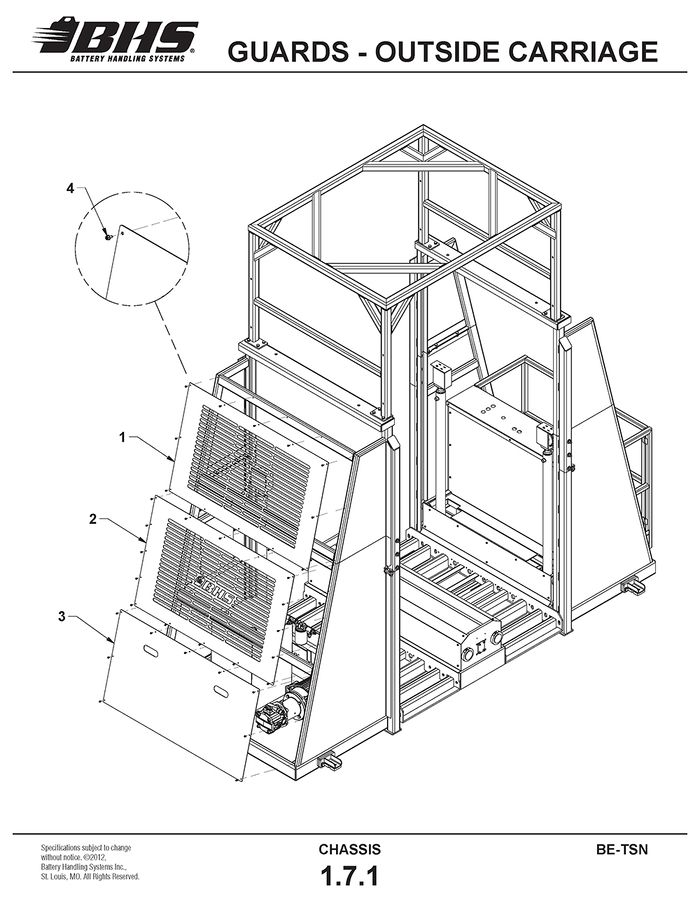

GUARDS - OUTSIDE CARRIAGE

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 53017009 | GUARD-FAR END-TOP | 1 | ||

2 | 53017010 | GUARD-FAR END-MIDDLE | 1 | ||

3 | 53017011 | GUARD-FAR END-BOTTOM | 1 | ||

4 | HW0301 | BOLT-SELF TAP “F”-1/4-20 X 1/2” | 33 |

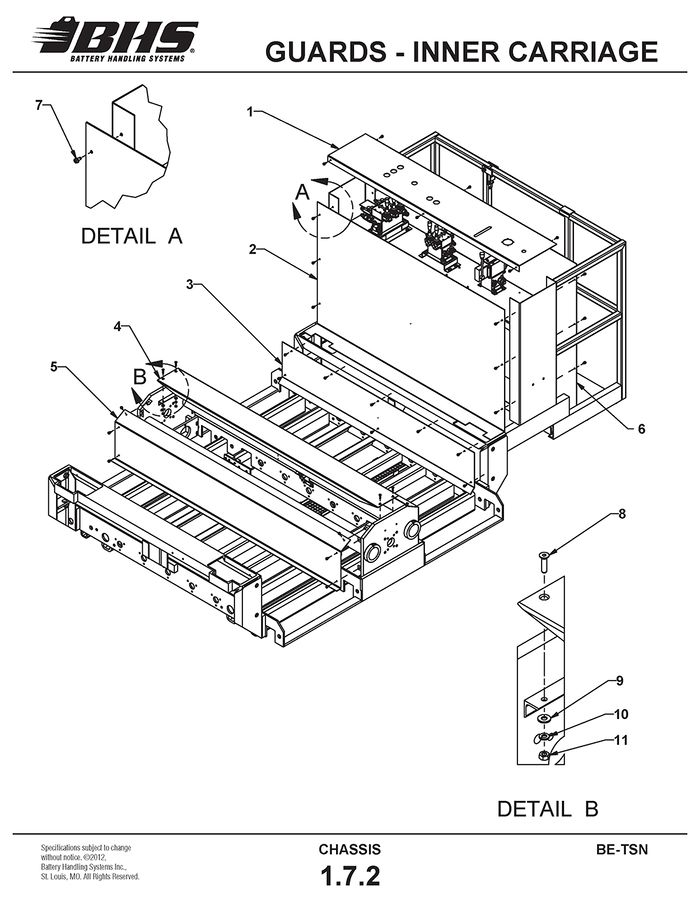

GUARDS - INNER CARRIAGE

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 53017015-2 | DASH BOARD-OPERATOR CONSOLE | 1 | ||

2 | 53017013-2 | GUARD-FRONT-OPERATOR CONSOLE | 1 | ||

3 | 53017012-2 | GUARD-INNER-FRAME | 2 | ||

4 | 50017010-2 | GUARD-LINEAR DRIVE SCREW | 1 | ||

5 | 50017011-2 | GUARD-SIDE-ARM CARRIER SHAFT | 2 | ||

6 | 53017014 | KICK PLATE-OPERATOR CONSOLE | 1 | ||

7 | HW0301 | BOLT-SELF TAP “F”-1/4-20 X 1/2” | 48 | ||

8 | HW0306 | BOLT-FHSCS-1/4-20 X 1” | 4 | ||

9 | HW0104 | WASHER-FLAT-1/4”-SAE | 4 | ||

10 | HW0103 | WASHER-LOCK-1/4” | 4 | ||

11 | HW0002 | NUT-HEX-1/4-20 | 4 | ||

12 | PL0602 | VINYL EDGING | 6’ EA. FOR ITEM #5 - NOT SHOWN | 12’ | |

13 | PL0602 | VINYL EDGING | AT FOOT SWITCH - NOT SHOWN | 1’ |

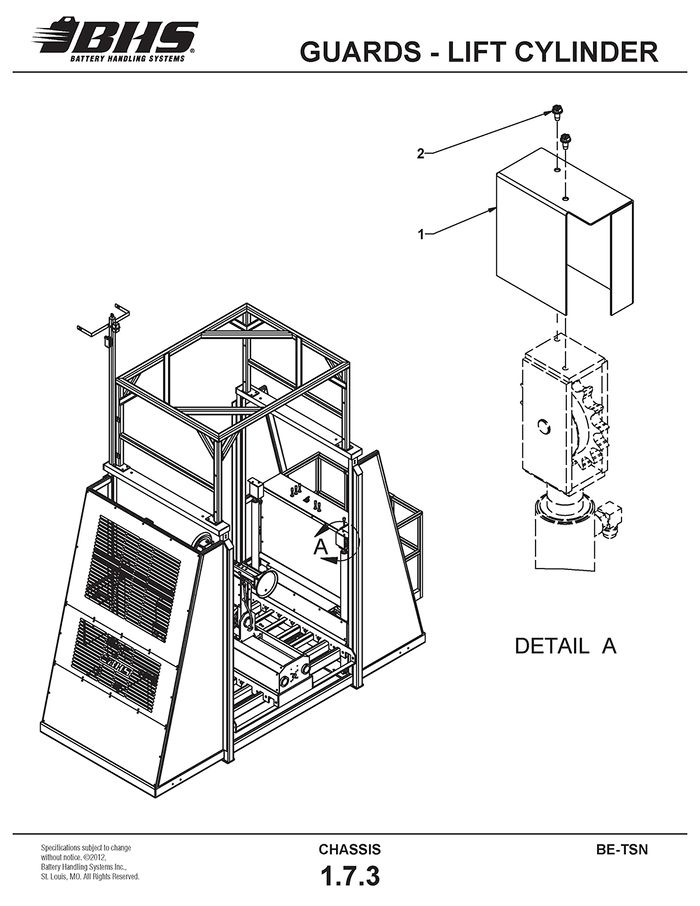

GUARDS - LIFT CYLINDER

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43815016 | GUARD-CLEVIS | OPERATOR RIGHT/FAR LEFT | 2 | |

43815017 | GUARD-CLEVIS | OPERATOR LEFT/FAR RIGHT | 2 | ||

2 | HW0301 | BOLT-SELF TAP “F”-1/4-20 X 1/2” | 8 |

EXTRACTOR ARM

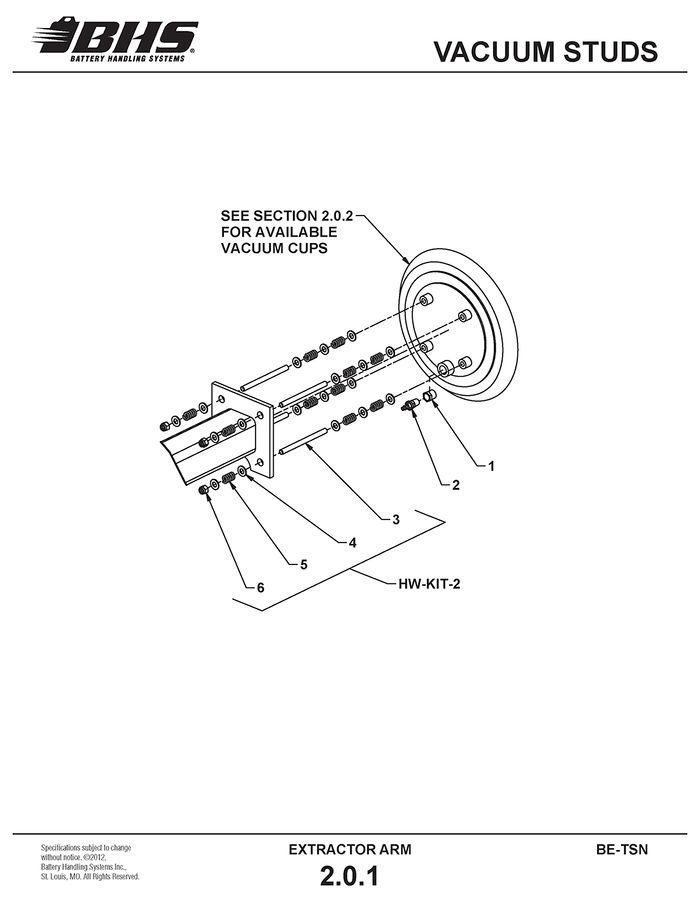

VACUUM STUDS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | P0505 | BUSHING-RED-#6 NPT X #4 NPTF-BRASS | 2 | ||

2 | P0402 | HOSE BARB-1/4 X #4 NPTM-BRASS | FIXED SIDE ONLY | 1 | |

3 | HW0428 | STUD-VACUUM-3/8-16 X 5” | HW-KIT-2 | 8 | |

4 | HW0108 | WASHER-FLAT-3/8”-SAE | HW-KIT-2 | 40 | |

5 | HW1001 | SPRING-3/8” | HW-KIT-2 | 24 | |

6 | HW0006 | NUT-NILN-3/8-16 | HW-KIT-2 | 8 |

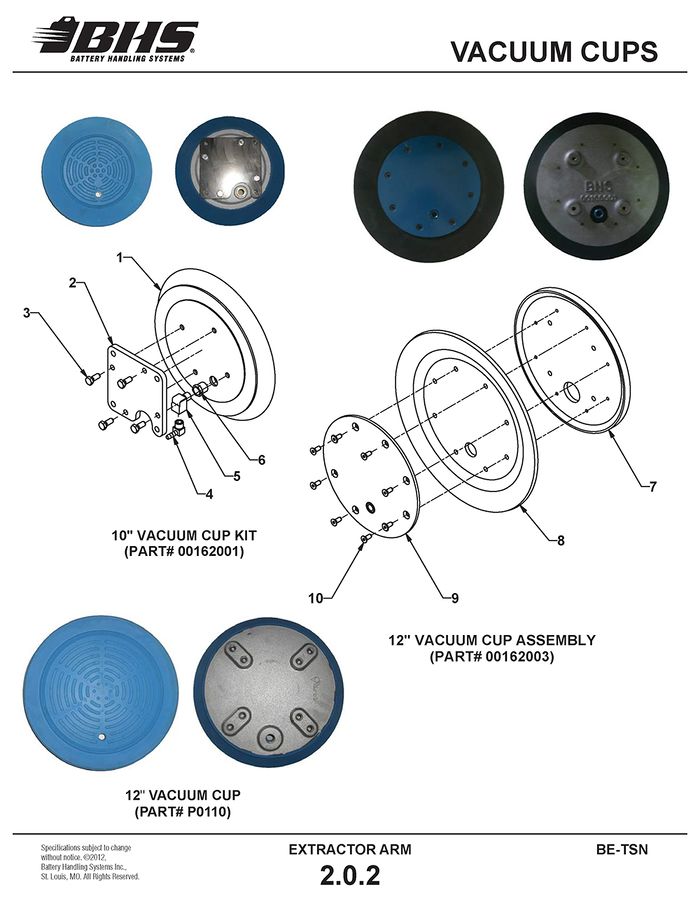

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | P0110 | VACUUM CUP-12” ROUND | † SEE NOTE | 2 | |

N/A | VACUUM CUP-10” ROUND | 00162001 | † AVAILABLE AS KIT ONLY | 2 | |

2 | 00117059 | PLATE-VACUUM CUP ADAPTER | 00162001 | 2 | |

3 | HW0328 | BOLT-HHCS-5/16-18 X 3/4” | 00162001 | 8 | |

4 | P0401 | ELBOW-#4 NPTM X 1/4” BARB-BRASS | 00162001 | 2 | |

5 | P0506 | ELBOW-STR-90 DEG-#4 NPT-BRASS | 00162001 | 2 | |

6 | P0505 | BUSHING-RED-#6 NPT X #4 NPTF-BRASS | 00162001 | 2 | |

7 | 00166001 | CASTING-12” VACUUM CUP | 00162003 | 2 | |

8 | 00164001 | SEAL-RUBBER | 00162003 | 2 | |

9 | 00165001 | PLATE-FRONT | 00162003 | 2 | |

10 | HW0311 | BOLT-FHSCS-1/4-20 X 5/8” | 00162003 | 16 |

† ONE-PIECE CONSTRUCTION

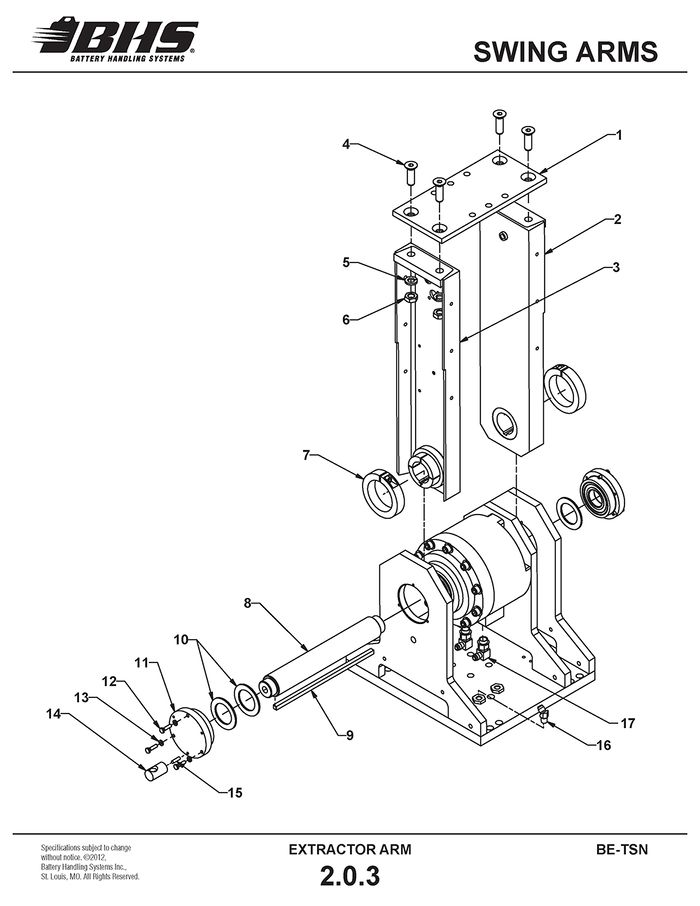

SWING ARMS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 41257014 | TIE PLATE-SWING ARM | 1 | ||

2 | 43055004 | SWING ARM-RHS | † | NOT SOLD INDIVIDUALLY | 1 |

3 | 43055002 | SWING ARM-LHS | † | NOT SOLD INDIVIDUALLY | 1 |

4 | HW0603 | BOLT-FHSCS-5/8-11 X 2” | 4 | ||

5 | HW0113 | WASHER-LOCK-5/8” | 4 | ||

6 | HW0010 | NUT-JAM-5/8-11 | 4 | ||

7 | PT0413 | COLLAR-SHAFT-3” | 80252001 | 2 | |

8 | 43027001 | SHAFT-ROTARY ACTUATOR | 80252001 | 1 | |

9 | HW1013 | KEY-3/8” X 12” | 80252001 | 1 | |

10 | PT0419 | BEARING-SAE 841-2” ID, 3” OD, 1/8” THICK | 80252001 | 3 | |

11 | 43052005 | CAP-BEARING | INCLUDES BEARING | 2 | |

12 | HW0303 | BOLT-HHCS-1/4-20 X 1” | 6 | ||

13 | HW0103 | WASHER-LOCK-1/4” | 6 | ||

14 | 43057014 | STANDOFF-WIRE | 1 | ||

15 | HW0312 | SCREW-SHSS-1/4-20 X 1”-CUP POINT | 1 | ||

16 | H1565 | ADAPTER-45 DEG-#6 JICM X #4 NPTM | 4 | ||

17 | H1600 | ADAPTER-90 DEG-#6 JICM X #8 SAEM | 2 |

† INCLUDED IN MULTIPLE KITS

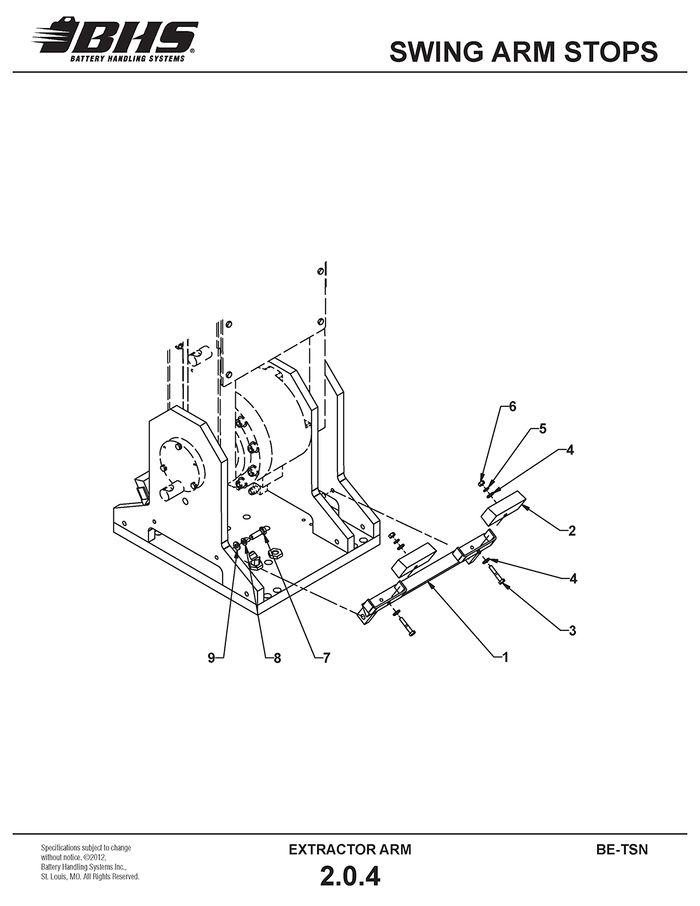

SWING ARM STOPS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43055007 | MOUNT-STOP-SWING ARM | 2 | ||

2 | 43057024 | STOP-SWING ARM | BE-24 | 4 | |

43057023 | STOP-SWING ARM | BE-36 | 4 | ||

3 | HW0304 | BOLT-HHCS-1/4-20 X 1 1/2” | 4 | ||

4 | HW0104 | WASHER-FLAT-1/4”-SAE | 8 | ||

5 | HW0103 | WASHER-LOCK-1/4” | 4 | ||

6 | HW0002 | NUT-HEX-1/4-20 | 4 | ||

7 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4” | 4 | ||

8 | HW0107 | WASHER-LOCK-3/8” | 4 | ||

9 | HW0108 | WASHER-FLAT-3/8”-SAE | 4 |

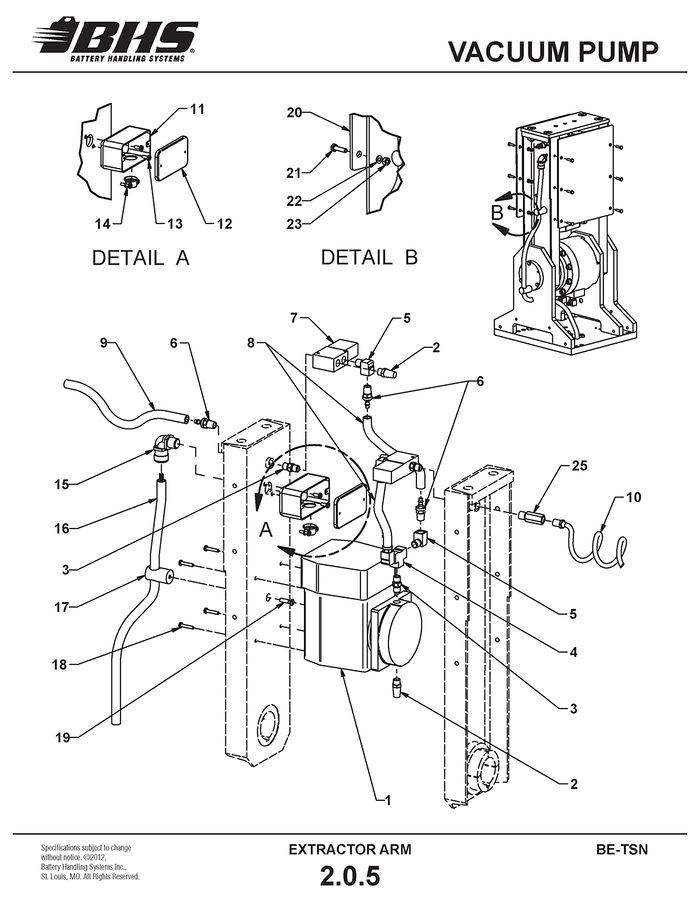

VACUUM PUMP

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | P0005 | PUMP-VACUUM | 1 | ||

2 | P0208 | FILTER-HI FLOW | 3 | ||

3 | P0503 | NIPPLE-#4 NPT-BRASS | 3 | ||

4 | P0502 | TEE-#4 NPTF-BRASS | 1 | ||

5 | P0506 | ELBOW-STR-90 DEG-#4 NPT-BRASS | 4 | ||

6 | P0402 | HOSE BARB-1/4” X #4 NPTM-BRASS | 5 | ||

7 | P0207 | VALVE-VACUUM RELEASE | 2 | ||

8 | P0302 | HOSE-VACUUM-1/4” ID | TWO 6” PIECES | 1’ | |

9 | P0302 | HOSE-VACUUM-1/4” ID | FIXED SIDE | 1’ | |

10 | P0301-1 | HOSE-COIL-VACUUM | 1 | ||

11 | E0611 | JUNCTION BOX-4” X 2” X 2” | 1 | ||

12 | E0612 | COVER-JUNCTION BOX | 1 | ||

13 | HW0212 | SCREW-RHMS-#10-24 X 1/2” | 2 | ||

14 | E0624 | CONNECTOR-1/2” | 1 | ||

15 | E0608-1 | RESTRAINT-1/2”-90 DEG | GRIP SIZE .450 - .560 | 1 | |

15a | E0617 | LOCKNUT-CONDUIT-1/2” | NOT SHOWN | 2 | |

16 | E0501 | CORD-14-4 SW/SOW | 15’ | ||

17 | 43057014 | STANDOFF-CABLE | 1 | ||

18 | HW0206 | SCREW-RHMS-#10-32 X 3/4” | 4 | ||

19 | HW0306 | BOLT-FHSCS-1/4-20 X 1” | 1 | ||

20 | 43057021 | PLATE-STIFFENER | † | 2 | |

21 | HW0402 | BOLT-HHCS-3/8-16 X 1” | † | 12 | |

22 | HW0107 | WASHER-LOCK-3/8” | † | 12 | |

23 | HW0005 | NUT-HEX-3/8-16 | † | 12 | |

24 | HW0108 | WASHER-FLAT-3/8”-SAE | † | NOT SHOWN | 24 |

25 | P0111 | FILTER-VACUUM-IN LINE | 2 |

† INCLUDED IN MULTIPLE KITS

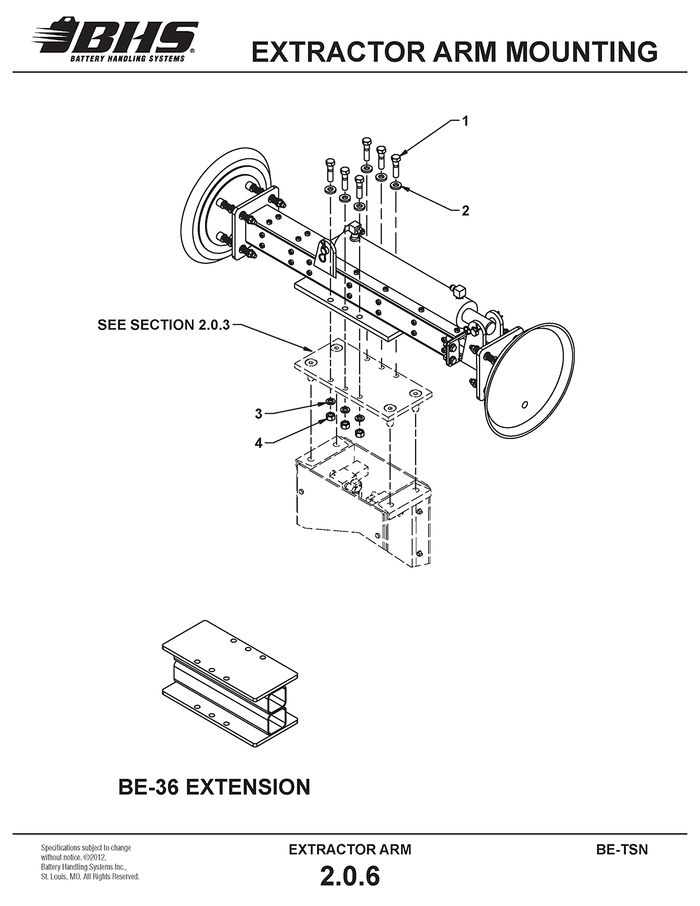

EXTRACTOR ARM MOUNTING

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HW0504 | BOLT-HHCS-1/2-13 X 2” | † SEE NOTE | 6 | |

2 | HW0112 | WASHER-FLAT-1/2”-SAE | 6 | ||

3 | HW0110 | WASHER-LOCK-1/2” | 6 | ||

4 | HW0007 | NUT-HEX-1/2-13 | 6 | ||

5 | 41655008 | EXTENSION-EXTRACTOR ARM | BE-36 | A/R |

† QTY 12 REQUIRED WITH EXTRACTOR ARM EXTENSION.

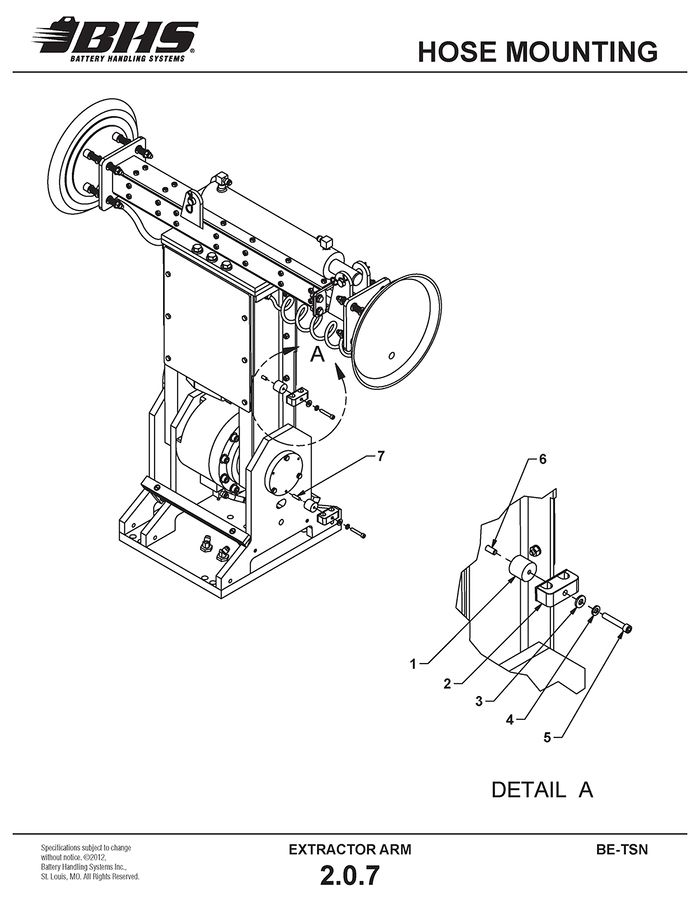

HOSE MOUNTING

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 41257035 | STANDOFF | 2 | ||

2 | HW1072 | RESTRAINT-HOSE | 2 | ||

3 | HW0104 | WASHER-FLAT-1/4”-SAE | 2 | ||

4 | HW0103 | WASHER-LOCK-1/4” | 2 | ||

5 | HW0318 | BOLT-SHCS-1/4-20 X 1 1/2” | 2 | ||

6 | HW0302 | BOLT-HHCS-1/4-20 X 3/4” | 1 | ||

7 | HW0312 | SCREW-SHSS-1/4-20 X 1”-CUP POINT | 1 |

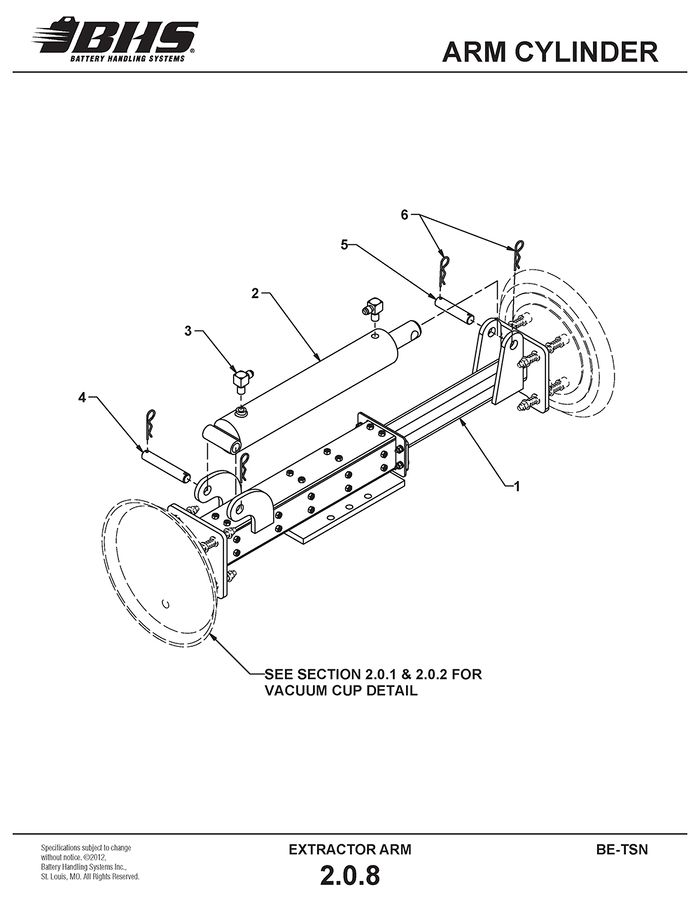

ARM CYLINDER

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 50055002 | ARM-EXTENSION | 1 | ||

2 | HC0416 | CYLINDER-EXTENED REACH | 1 | ||

3 | H1578 | ADAPTER-90 DEG-#6 JICM X #6 NPTM | 2 | ||

4 | 41257031 | PIN-CLEVIS END | 1 | ||

5 | 00197036 | PIN-ROD END | 1 | ||

6 | HW1058 | PIN-HITCH | 4 |

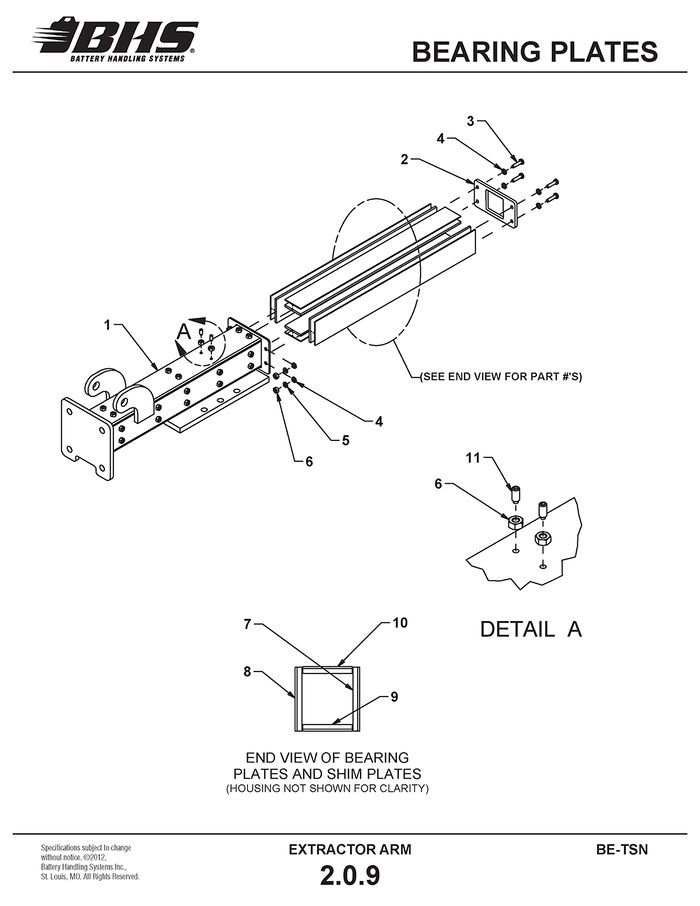

BEARING PLATES

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 50055001 | HOUSING-EXTENDED REACH | 1 | ||

2 | 50057008 | PLATE-END | 1 | ||

3 | HW0303 | BOLT-HHCS-1/4-20 X 1” | 4 | ||

4 | HW0104 | WASHER-FLAT-1/4”-SAE | 8 | ||

5 | HW0103 | WASHER-LOCK-1/4” | 4 | ||

6 | HW0002 | NUT-HEX-1/4-20 | 24 | ||

7 | 50058003 | PLATE-BEARING | SIDE | 2 | |

8 | 50058006 | PLATE-SHIM | SIDE | 2 | |

9 | 50058004 | PLATE-BEARING | UPPER/ LOWER | 2 | |

10 | 50058005 | PLATE-SHIM | UPPER/ LOWER | 2 | |

11 | HW0812 | SCREW-SHSS-1/4-20 X 5/8”-HALF DOG | 20 |

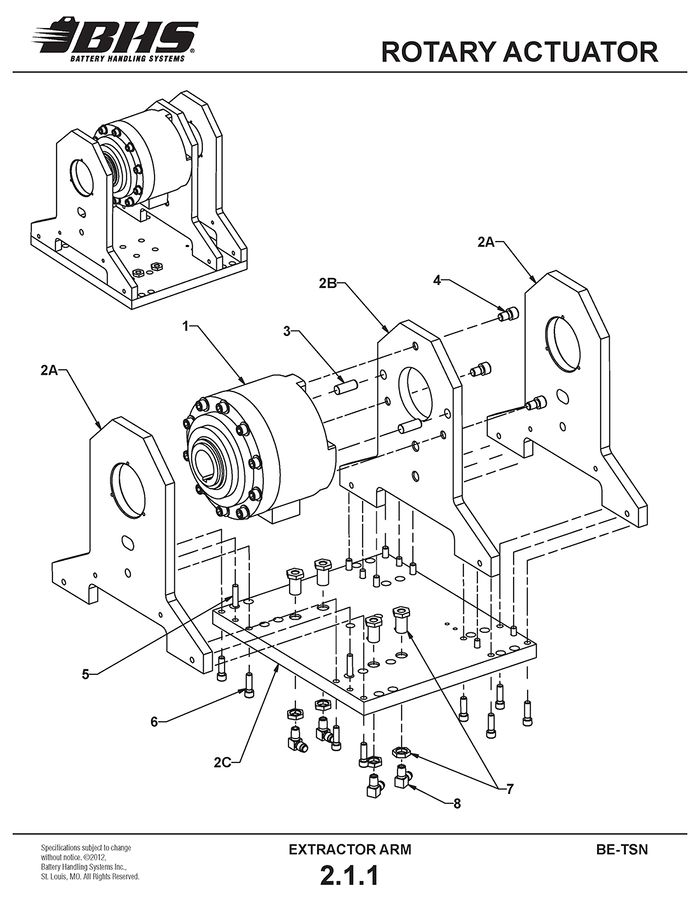

ROTARY ACTUATOR

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43046001 | ROTARY ACTUATOR | 1 | ||

2 | 80000002 | ROTARY ACTUATOR BASE ASSEMBLY | WITHOUT ACTUATOR | 1 | |

2A | N/A | VERTICAL CARRIER PLATE-OUTER | INCL. WITH 80000002 | 2 | |

2B | N/A | VERTICAL CARRIER PLATE-INNER | INCL. WITH 80000002 | 1 | |

2C | N/A | CARRIER BASE PLATE | INCL. WITH 80000002 | 1 | |

3 | HW1070 | PIN-PULL DOWEL-5/8” X 1 1/2” | 2 | ||

4 | HW0508 | BOLT-SHCS-1/2-13 X 3/4” | 3 | ||

5 | HW1045 | PIN-PULL DOWEL-3/8” X 1 1/2” | INCL. WITH 80000002 | 6 | |

6 | HW0412 | BOLT-SHCS-3/8-16 X 1 1/4” | INCL. WITH 80000002 | 12 | |

7 | H0010 | FITTING-BULKHEAD-3/4-16 X #4 NPTF | 4 | ||

8 | H1579 | ADAPTER-90 DEG-#6 JICM X #4 NPTM | 4 |

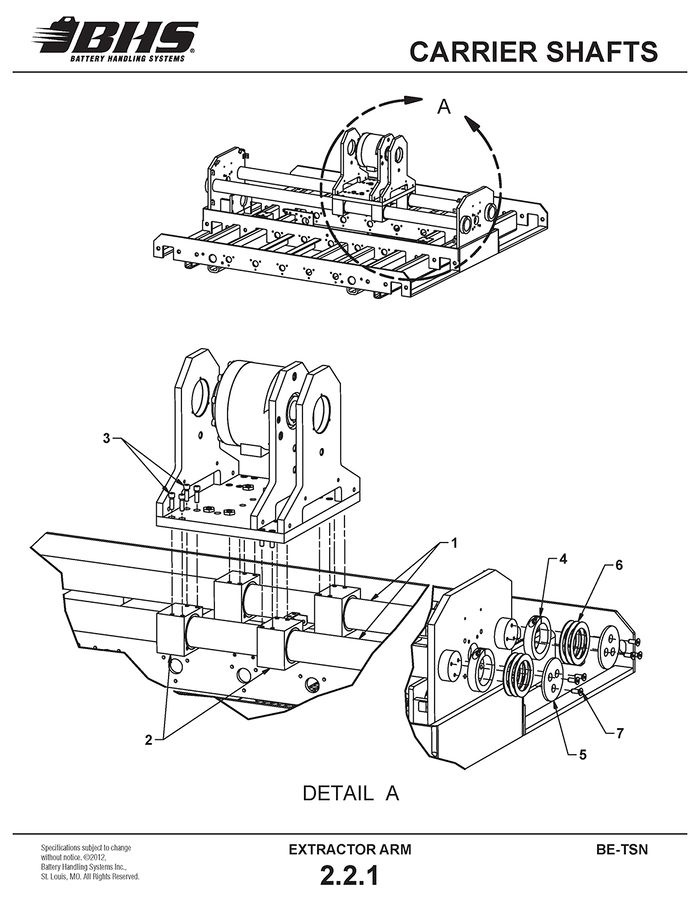

CARRIER SHAFTS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 50057001 | CARRIER SHAFT-EXTRACTOR ARM | 3” DIA. | 2 | |

2 | 43054007 | BEARING-EXTRACTOR ARM CARRIER | 80252002 | 4 | |

3 | HW0412 | BOLT-SHCS-3/8-16 X 1 1/4” | 80252002 | 16 | |

4 | PT0413 | COLLAR-SHAFT-3” | 4 | ||

5 | 50057009 | PLATE-END | 4 | ||

6 | 50057010 | SHIM-END PLATE | A/R | ||

7 | HW1076 | BOLT-FHSCS-3/8-16 X 1” | 12 | ||

PT0624 | FITTING-ZERK | 80252002 | NOT SHOWN | 4 |

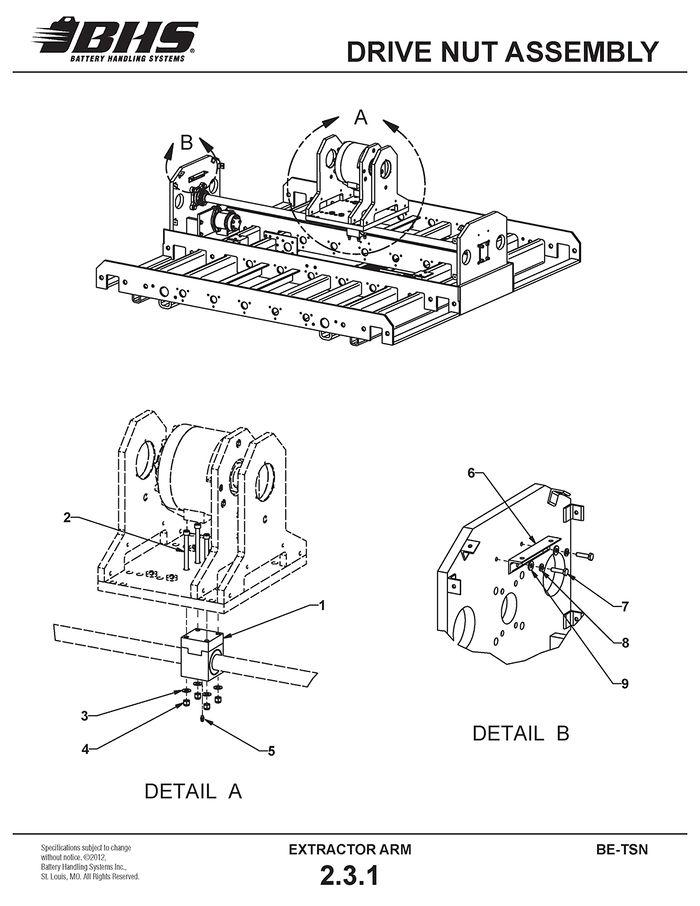

DRIVE NUT ASSEMBLY

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43054006 | DRIVE NUT ASSEMBLY | 80252003 | 1 | |

2 | HW0426 | BOLT-SHCS-3/8-16 X 5 1/2” | 80252003 | † SEE NOTES | 4 |

3 | HW0108 | WASHER-FLAT-3/8”-SAE | 80252003 | † SEE NOTES | 4 |

4 | HW0006 | NUT-NILN-3/8-16 | 80252003 | † SEE NOTES | 4 |

5 | PT0624 | FITTING-ZERK | 80252003 | 1 | |

6 | 43017009-2 | BRACKET-SCREW GUARD MOUNTING | 2 | ||

7 | HW0303 | BOLT-HHCS-1/4-20 X 1” | 4 | ||

8 | HW0103 | WASHER-LOCK-1/4” | 4 | ||

9 | HW0104 | WASHER-FLAT-1/4”-SAE | 4 |

† IT IS RECOMMENDED TO REPLACE MOUNTING HARDWARE WHEN REPLACING DRIVE NUT ASSEMBLY

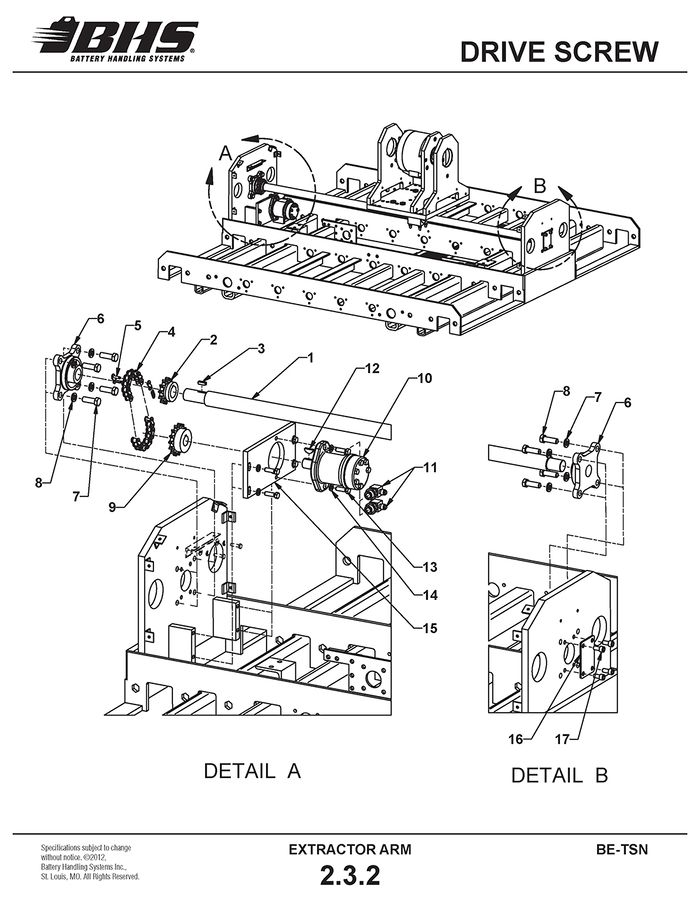

DRIVE SCREW

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 50024001 | SCREW-LINEAR DRIVE | 1 | ||

2 | PT0119 | SPROCKET-50B15 X 1 3/16” | 1 | ||

3 | 43097004 | KEY-1/4” X 7/8” | 1 | ||

4 | 00158001-15 | CHAIN-ROLLER-#50 | 1 | ||

5 | PT0102 | LINK-CONNECTING-#50 | 1 | ||

6 | PT0406 | FLANGE BEARING-4 BOLT-1 3/16” | ALLOY CASTING | 2 | |

7 | HW0503 | BOLT-HHCS-1/2-13 X 1 1/2” | 8 | ||

8 | HW0110 | WASHER-LOCK-1/2” | 8 | ||

9 | PT0107 | SPROCKET-50B15 X 1” | 1 | ||

10 | HC0121 | MOTOR-HYDRAULIC-100CC | SAE 2-BOLT MOUNT | 1 | |

11 | H1605 | ADAPTER-90 DEG-#6 JICM X #10 SAEM | 2 | ||

12 | HW1071 | KEY-WOODRUFF-#808 STD | SUPPLIED WITH ITEM 10 | A/R | |

13 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4” | 6 | ||

14 | HW0107 | WASHER-LOCK-3/8” | 6 | ||

15 | 43017007 | PLATE-MOUNTING-SCREW DRIVE MOTOR | 1 | ||

16 | 43057019 | PLATE-COVER | 2 | ||

17 | HW0415 | BOLT-SHCS-3/8-16 X 3/4” | 8 |

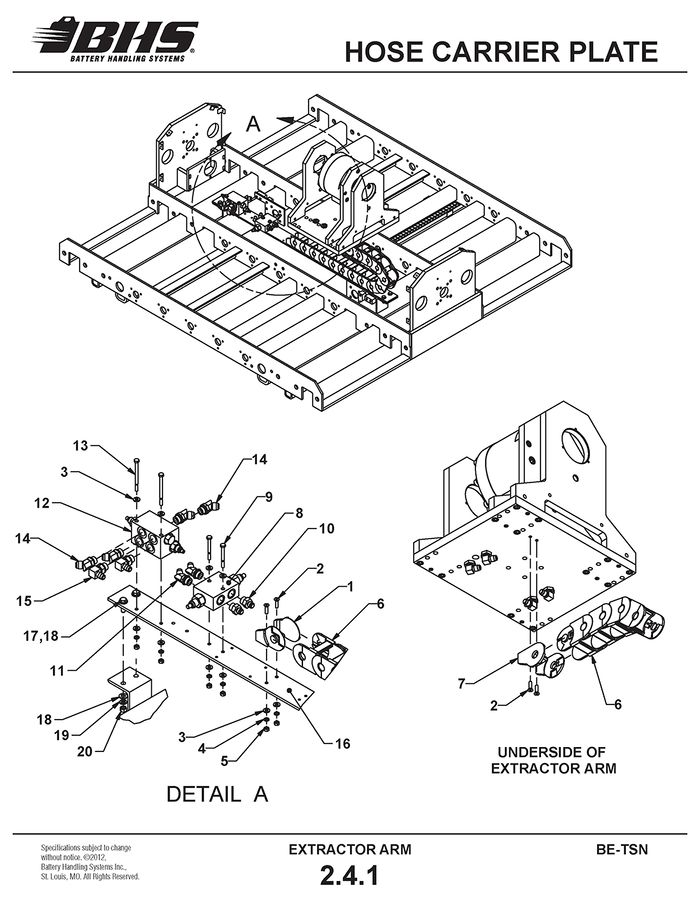

HOSE CARRIER PLATE

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 41696001 | BRACKET-MOVABLE END | 1 | ||

2 | HW0306 | BOLT-FHSCS-1/4-20 X 1” | 4 | ||

3 | HW0104 | WASHER-FLAT-1/4”-SAE | 10 | ||

4 | HW0103 | WASHER-LOCK-1/4” | 6 | ||

5 | HW0002 | NUT-HEX-1/4-20 | 6 | ||

6 | PT0627 | HOSE CARRIER | 12 LINKS REQD. | 34” | |

7 | PT0628 | BRACKET-FIXED END | 1 | ||

8 | HC0262 | VALVE-CROSS PORT RELIEF | 1 | ||

8a | HC0236 | REPLACEMENT CARTRIDGE | † FOR ITEM 8 (NOT SHOWN) | 2 | |

9 | HW0308 | BOLT-HHCS-1/4-20 X 2 1/2” | 2 | ||

10 | H1546 | ADAPTER-#6 JICM X #8 SAEM | 2 | ||

11 | H1617 | ADAPTER-45 DEG-#6 JICM X #8 SAEM | 2 | ||

12 | HC0237 | VALVE-SEQUENCING | 1 | ||

13 | HW0317 | BOLT-HHCS-1/4-20 X 3 1/2” | 2 | ||

14 | H1560 | ADAPTER-45 DEG-#8 JICM X #8 SAEM | 4 | ||

15 | H1600 | ADAPTER-90 DEG-#6 JICM X #8 SAEM | 2 | ||

16 | 50017006 | PLATE-HOSE CARRIER | 1 | ||

17 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4” | 4 | ||

18 | HW0108 | WASHER-FLAT-3/8”-SAE | 8 | ||

19 | HW0107 | WASHER-LOCK-3/8” | 4 | ||

20 | HW0005 | NUT-HEX-3/8-16 | 4 |

† CARTRIDGES ARE FOR REPLACEMENT ONLY

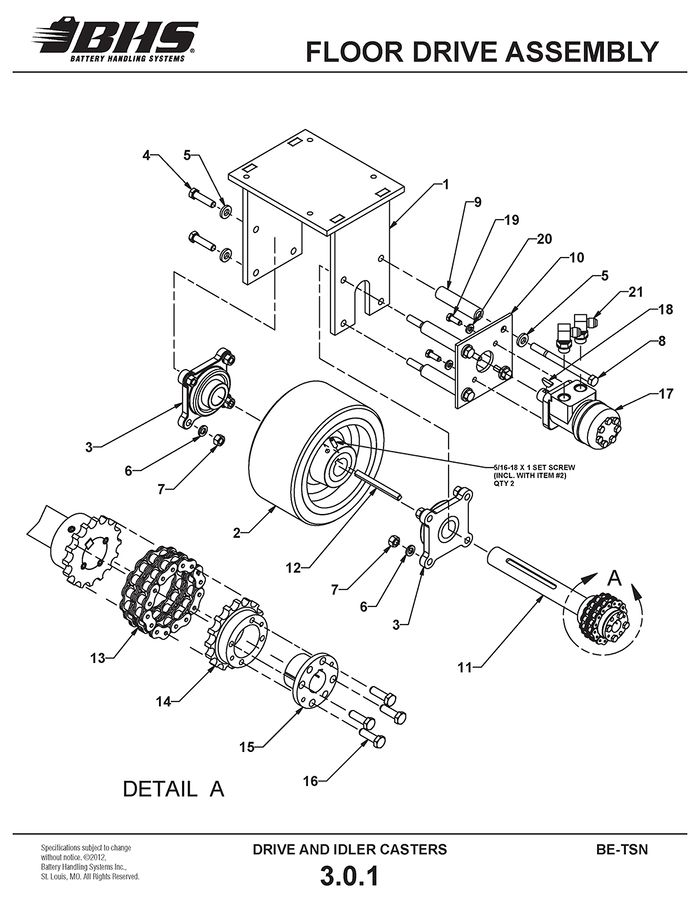

DRIVE AND IDLER CASTERS

FLOOR DRIVE ASSEMBLY

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

REF | 43822004 | FLOOR DRIVE ASSEMBLY | 2 | ||

1 | 43825001 | FRAME-FLOOR DRIVE | 2 | ||

2 | C0510 | WHEEL-10” X 5”-POLY | 80322001 | 2 | |

3 | PT0430 | FLANGE BEARING-4 BOLT-1 1/2” | 80322001 | 4 | |

4 | HW0504 | BOLT-HHCS-1/2-13 X 2” | 8 | ||

5 | HW0112 | WASHER-FLAT-1/2”-SAE | 16 | ||

6 | HW0110 | WASHER-LOCK-1/2” | 16 | ||

7 | HW0007 | NUT-HEX-1/2-13 | 16 | ||

8 | HW0516 | BOLT-HHCS-1/2-13 X 6 1/2” | 8 | ||

9 | 43827006 | SPACER-DRIVE WHEEL | MUST BE ORDERED AS SET OF 4 | 8 | |

10 | 43827004 | PLATE-MOTOR MOUNTING | 2 | ||

11 | 43822003 | SHAFT-WHEEL | 80322001 | INCL. COUPLING BODY | 2 |

12 | 43897004 | KEY-3/8” X 4 3/4” | 80322001 | 2 | |

13 | PT0321 | CHAIN-COUPLING-#50 | INCL. CONNECTING PIN | 2 | |

14 | 43726004 | COUPLING BODY-TAPER BORE-#50 | 2 | ||

15 | 43726002 | BUSHING-TAPER LOCK-1” | 2 | ||

16 | HW0323 | BOLT-HHCS-5/16-18 X 1” | 8 | ||

17 | HC0126 | MOTOR-HYDRAULIC-400CC | 2 | ||

18 | HW1071 | KEY-WOODRUFF-#808 STD | INCL. WITH ITEM 17 | A/R | |

19 | HW0416 | BOLT-SHCS-3/8-16 X 1” | 8 | ||

20 | HW0107 | WASHER-LOCK-3/8” | 8 | ||

21 | H1612 | ADAPTER-90 DEG-#8 JICM X #10 SAEM | 4 |

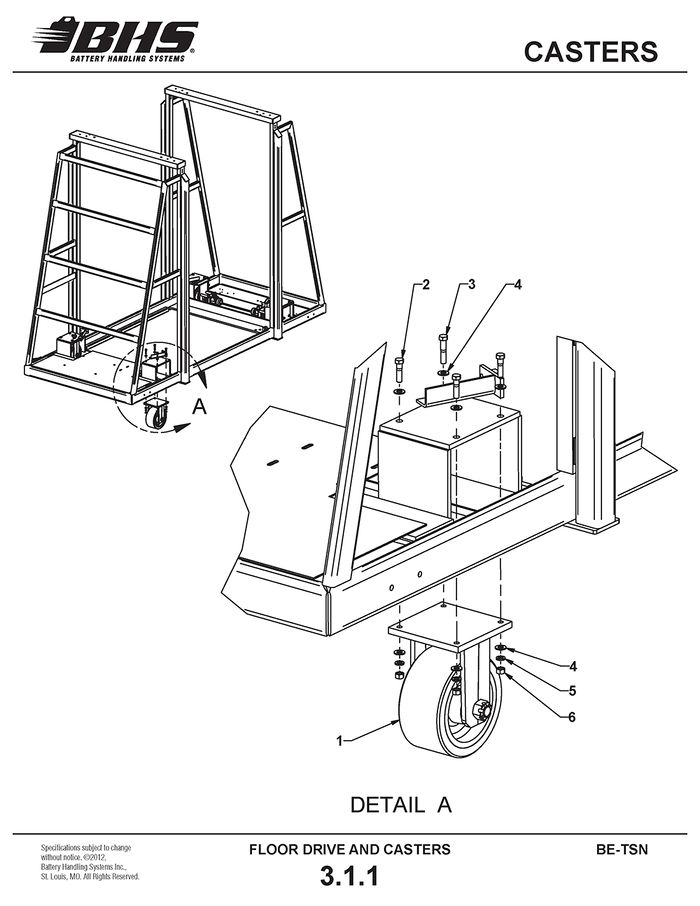

CASTERS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | C0500 | CASTER-RIDGID-10” X 5”-POLY | 2 | ||

2 | HW0504 | BOLT-HHCS-1/2-13 X 2” | 6 | ||

3 | HW0514 | BOLT-HHCS-1/2-13 X 2 1/2” | 2 | ||

4 | HW0112 | WASHER-FLAT-1/2”-SAE | 16 | ||

5 | HW0110 | WASHER-LOCK-1/2” | 8 | ||

6 | HW0007 | NUT-HEX-1/2-13 | 8 |

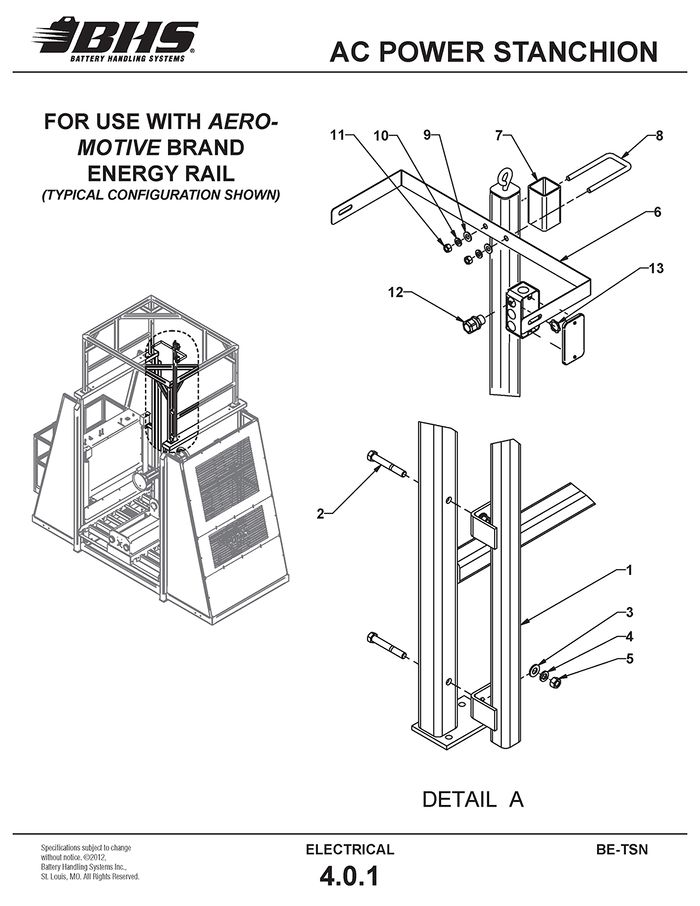

ELECTRICAL

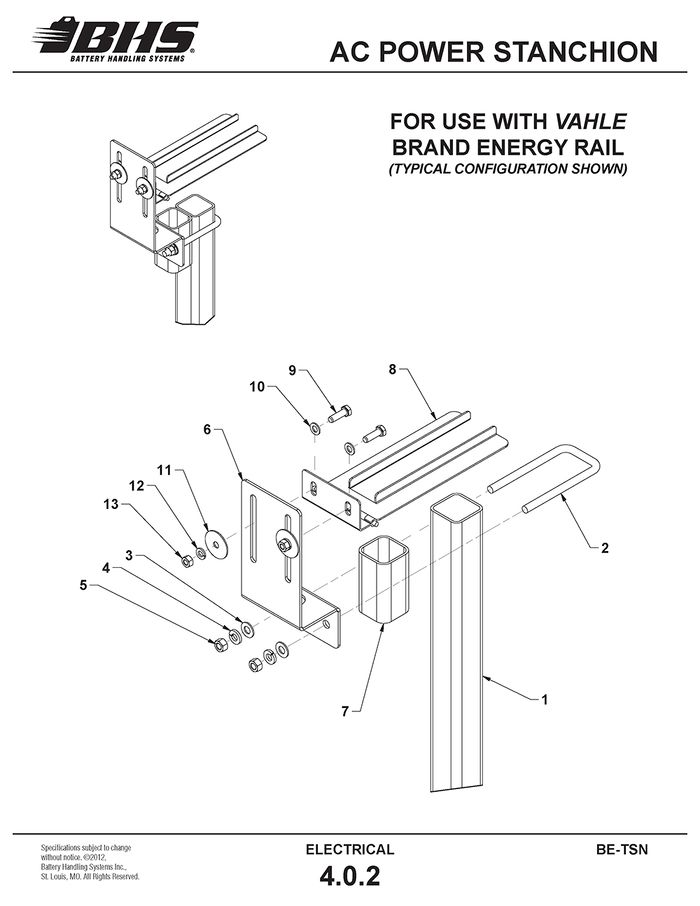

AC POWER STANCHION

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | N/A | STANCHION-POWER | CONSULT FACTORY | 1 | |

2 | HW0511 | BOLT-HHCS-1/2-13 X 3 3/4” | 2 | ||

3 | HW0112 | WASHER-FLAT-1/2”-SAE | 2 | ||

4 | HW0110 | WASHER-LOCK-1/2” | 2 | ||

5 | HW0007 | NUT-HEX-1/2-13 | 2 | ||

6 | 46837014-2 | TOW ARM-COLLECTOR TROLLEY | 1 | ||

7 | 46838015 | SPACER BLOCK-TOW ARM | 1 | ||

8 | HW1030 | U-BOLT-3/8-16 X 2” X 5” | SQUARE BEND | 1 | |

9 | HW0108 | WASHER-FLAT-3/8”-SAE | 2 | ||

10 | HW0107 | WASHER-LOCK-3/8” | 2 | ||

11 | HW0005 | NUT-HEX-3/8-16 | 2 | ||

12 | E0632 | RESTRAINT-3/4” | GRIP RANGE .625” TO .750” | 1 | |

13 | E0618 | LOCKNUT-CONDUIT-3/4” | 1 |

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | N/A | STANCHION-POWER | CONSULT FACTORY | 1 | |

2 | HW1030 | U-BOLT-3/8-16 X 2” X 5” | SQUARE BEND | 1 | |

3 | HW0108 | WASHER-FLAT-3/8”-SAE | 2 | ||

4 | HW0107 | WASHER-LOCK-3/8” | 2 | ||

5 | HW0005 | NUT-HEX-3/8-16” | 2 | ||

6 | 41237056-2 | BRACKET-TOW ARM | 1 | ||

7 | 46838015 | SPACER BLOCK-TOW ARM | 1 | ||

8 | BD0030 | TOW ARM-TROLLEY | 1 | ||

9 | HW0323 | BOLT-HHCS-5/16-18 X 1” | 2 | ||

10 | HW0106 | WASHER-FLAT-5/16”-SAE | 2 | ||

11 | HW0150 | WASHER-FLAT-5/16”-FENDER | 2 | ||

12 | HW0105 | WASHER-LOCK-5/16” | 2 | ||

13 | HW0004 | NUT-HEX-5/16-18 | 2 | ||

14 | HW0511 | BOLT-HHCS-1/2-13 X 3 3/4” | MOUNTING HARDWARE (NOT SHOWN) | 2 | |

15 | HW0112 | WASHER-FLAT-1/2”-SAE | 2 | ||

16 | HW0110 | WASHER-LOCK-1/2” | 2 | ||

17 | HW0007 | NUT-HEX-1/2-13 | 2 |

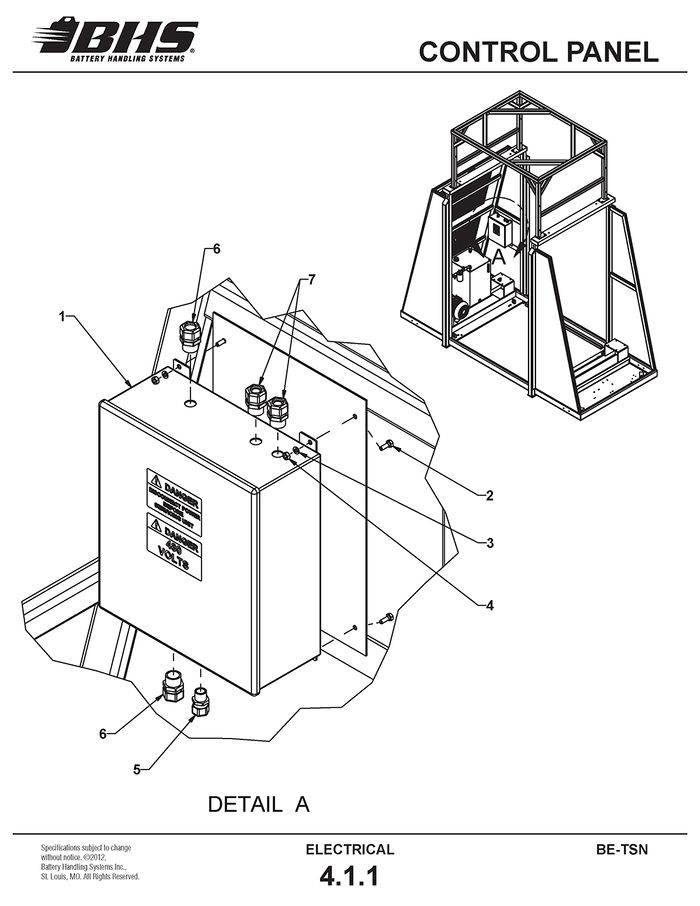

CONTROL PANEL

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E0638 | ENCLOSURE-CONTROL PANEL | 16” X 14” X 6” | 1 | |

2 | HW0303 | BOLT-HHCS-1/4-20 X 1” | 4 | ||

3 | HW0103 | WASHER-LOCK-1/4” | 4 | ||

4 | HW0002 | NUT-HEX1/4-20 | 4 | ||

5 | E0616 | RESTRAINT-1/2” | GRIP RANGE .250” TO .375” | 1 | |

6 | E0632 | RESTRAINT-3/4” | GRIP RANGE .625” TO .750” | 2 | |

7 | E0613 | RESTRAINT-3/4” | GRIP RANGE .500” TO .625” | 2 | |

8 | E0617 | LOCKNUT-CONDUIT-1/2” | NOT SHOWN | 1 | |

9 | E0618 | LOCKNUT-CONDUIT-3/4” | NOT SHOWN | 4 |

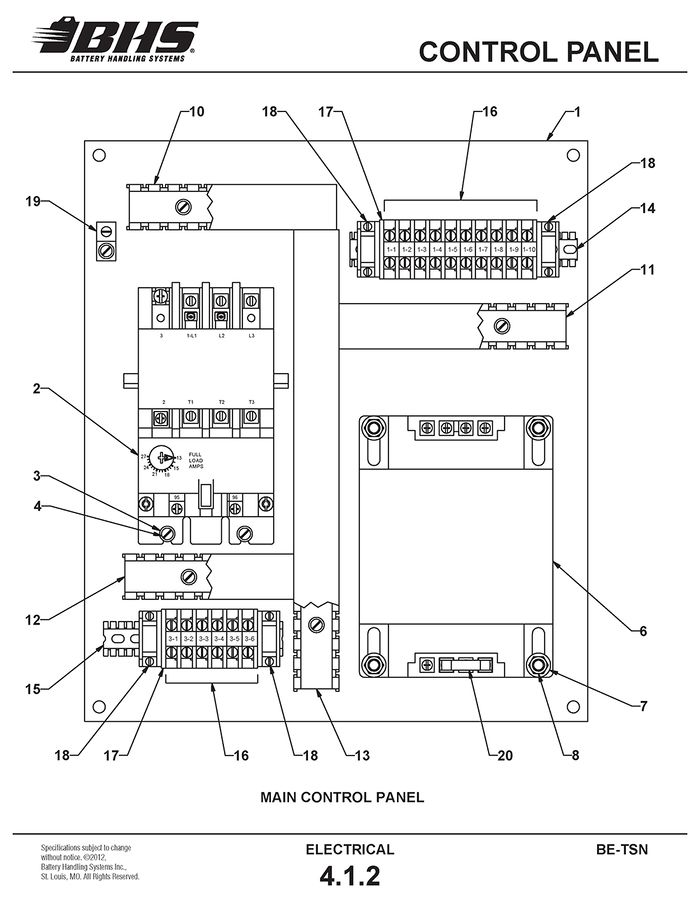

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E0640 | PANEL-COMPONENT MOUNTING | NO HOLES DRILLED | 1 | |

2 | E0120 | MAGNETIC STARTER-NEMA 1 3/4” | WITH OVERLOAD | 1 | |

3 | HW0130 | SCREW-RHMS-#8-32 X 1/2” | 17 | ||

4 | HW0133 | WASHER-FLAT-#8-SAE | 17 | ||

5 | HW0132 | NUT-NILN-#8-32 | NOT SHOWN | 17 | |

6 | E0207-1 | TRANSFORMER | 0.75 Kva | 1 | |

7 | HW0104 | WASHER-FLAT-1/4”-SAE | 4 | ||

8 | HW0003 | NUT-NILN-1/4-20 | 4 | ||

9 | HW0302 | BOLT-HHCS-1/4-20 X 3/4” | NOT SHOWN | 4 | |

10 | E1023 | WIRE WAY | 5 3/8” | ||

11 | E1023 | WIRE WAY | 5 3/4” | ||

12 | E1023 | WIRE WAY | 4 3/8” | ||

13 | E1023 | WIRE WAY | 11 3/4” | ||

14 | E1024 | TRACK-TERMINAL BLOCK | 5 7/8” | ||

15 | E1024 | TRACK-TERMINAL BLOCK | 4 5/8” | ||

16 | E1020 | TERMINAL BLOCK | 16 | ||

17 | E1040 | END BARRIER | 2 | ||

18 | E1330 | END ANCHOR | 4 | ||

19 | E0341 | GROUND LUG | 1 | ||

20 | E0902 | FUSE | FLM6 | 1 |

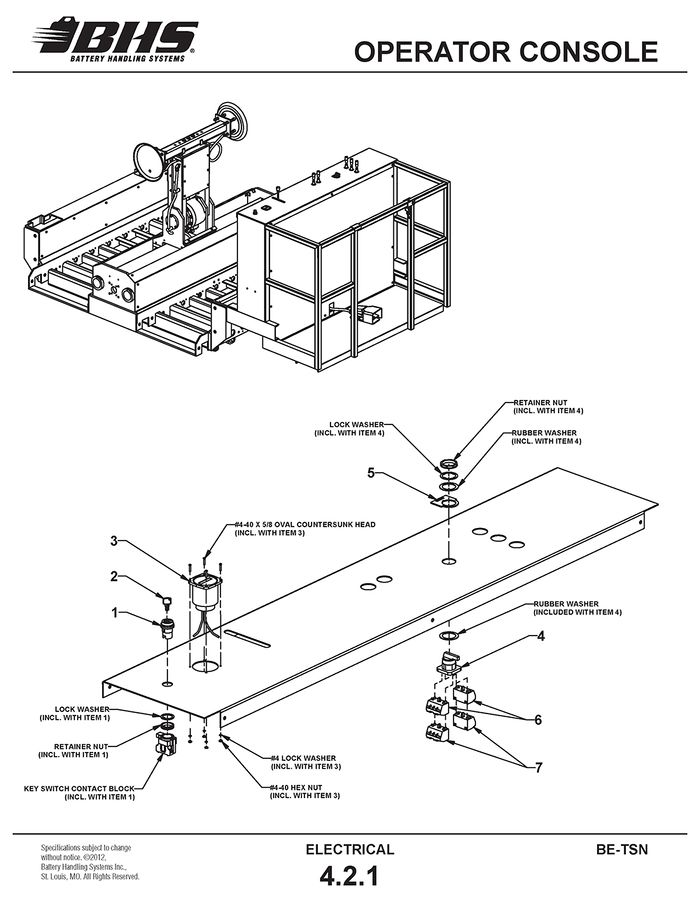

OPERATOR CONSOLE

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E0327 | KEYED ACTUATOR ASSEMBLY | INCL. 2 KEYS & CONTACT BLOCK | 1 | |

2 | E0351 | KEY-REPLACEMENT | SET OF 2 KEYS | A/R | |

3 | E0309 | HOUR METER | INCL. MOUNTING HARDWARE | 1 | |

4 | E0315 | SWITCH-SELECTOR-3 POSITION | 80232001 | ON-OFF-ON | 1 |

5 | E0812 | LEGEND PLATE-VACUUM | 1 | ||

6 | E1006 | CONTACT BLOCK-N/O | 80232001 | 2 | |

7 | E1007 | CONTACT BLOCK-N/C | 80232001 | 2 |

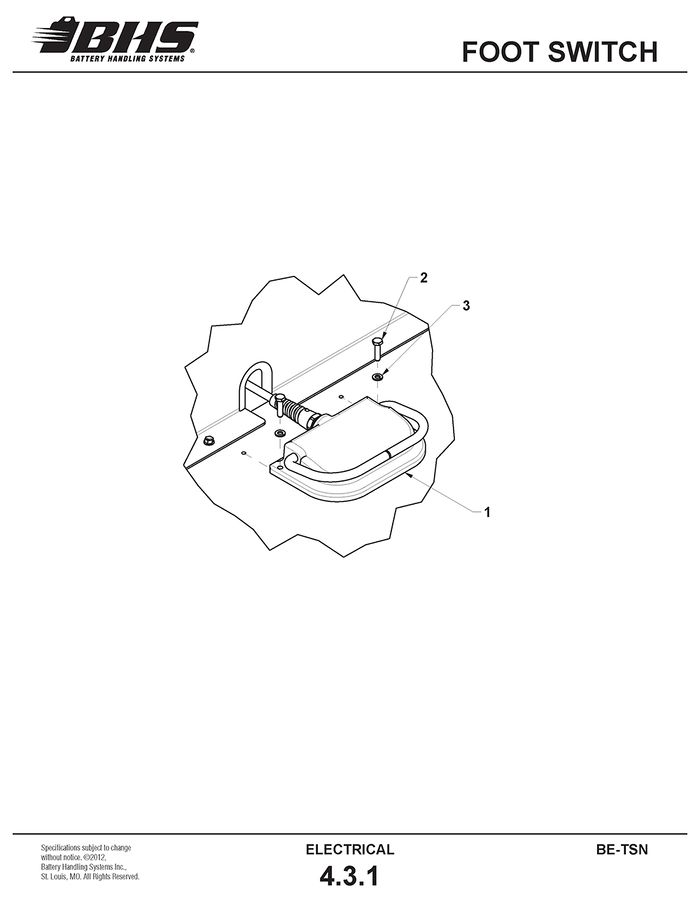

FOOT SWITCH

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E0301-1 | SWITCH-FOOT OPERATED | † SEE NOTES | 1 | |

2 | HC0303 | BOLT-HHCS-1/4-20 X 1” | IF EQUIPPED | 2 | |

3 | HC0103 | WASHER-1/4”-LOCK | IF EQUIPPED | 2 |

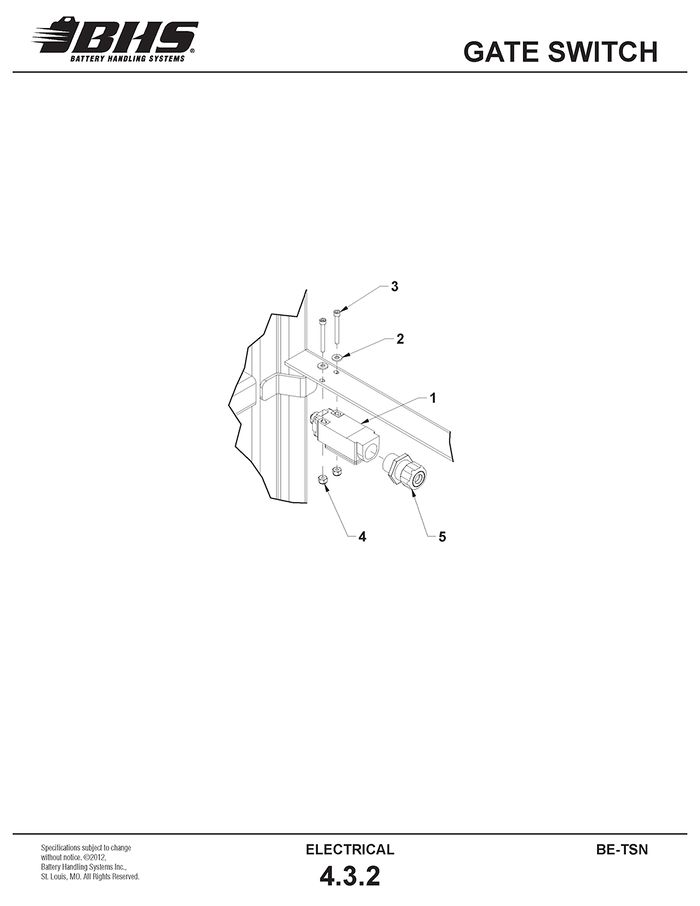

GATE SWITCH

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | YE0305 | SWITCH-ROLLER | 1 | ||

2 | SS0303 | WASHER-FLAT-#8 | 2 | ||

3 | SS0111 | SCREW-SHCS-#8-32 X 1 1/2” | 2 | ||

4 | SS0203 | NUT-NILN-#8-32 | 2 | ||

5 | E0616 | RESTRAINT-1/2” | GRIP SIZE .250” TO .375” | 1 |

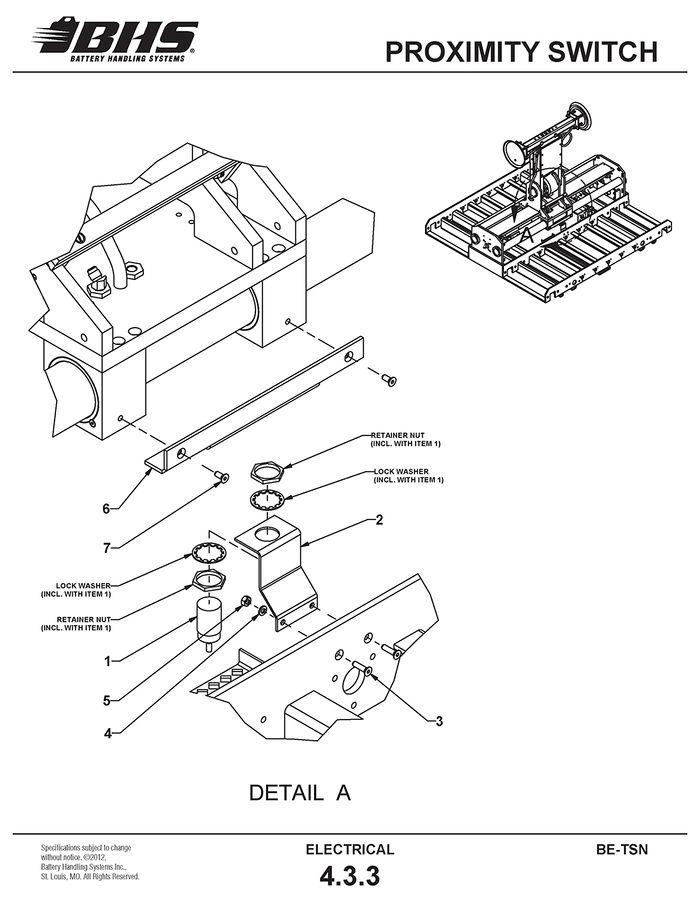

PROXIMITY SWITCH

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E0314 | SENSOR-PROXIMITY-30MM | 1 | ||

2 | 43017027-2 | BRACKET-PROXIMITY SENSOR | 1 | ||

3 | HW0306 | BOLT-FHSCS-1/4-20 X 1” | 2 | ||

4 | HW0103 | WASHER-LOCK-1/4” | 2 | ||

5 | HW0002 | NUT-HEX-1/4-20 | 2 | ||

6 | 43017037-2 | ANGLE-PROXIMITY SENSOR TARGET | 1 | ||

7 | HW0311 | BOLT-FHSCS-1/4-20 X 5/8” | 2 |

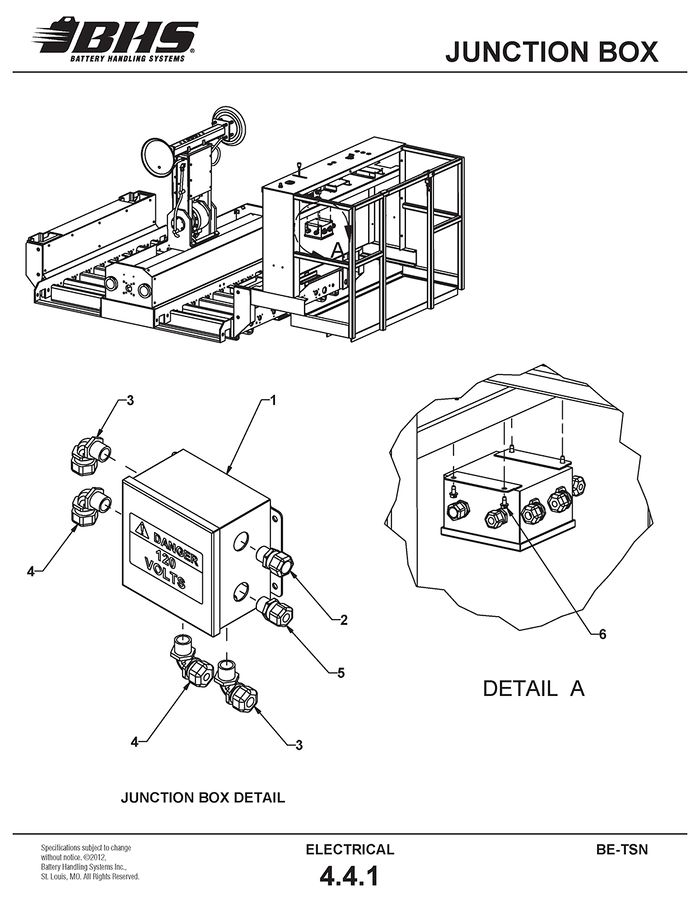

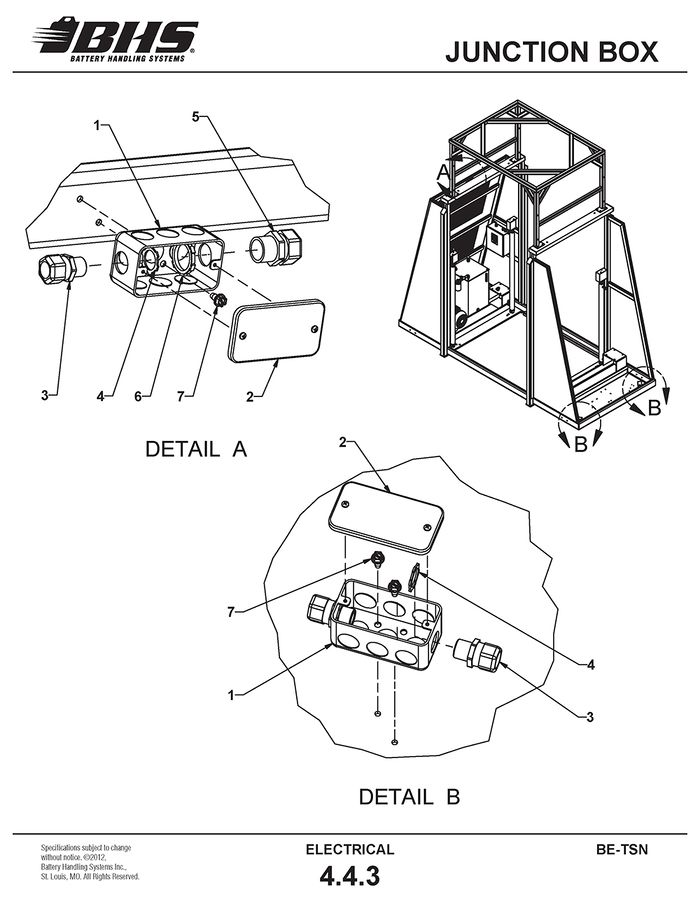

JUNCTION BOX

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E1342 | ENCLOSURE-6” X 6” X 4” | NO HOLES DRILLED | 1 | |

2 | E0622 | RESTRAINT-1/2” | GRIP SIZE .450” TO .500” | 1 | |

3 | E0608-1 | RESTRAINT-1/2”-90 DEG | GRIP SIZE .450” TO .500” | 2 | |

4 | E0623 | RESTRAINT-1/2”-90 DEG | GRIP SIZE .250” TO .375” | 2 | |

5 | E0616 | RESTRAINT-1/2” | GRIP SIZE .250” TO .375” | 1 | |

6 | HW0301 | BOLT-SELF TAP “F”-1/4-20 X 1/2” | 4 | ||

7 | E0617 | LOCKNUT-CONDUIT-1/2” | NOT SHOWN | 6 |

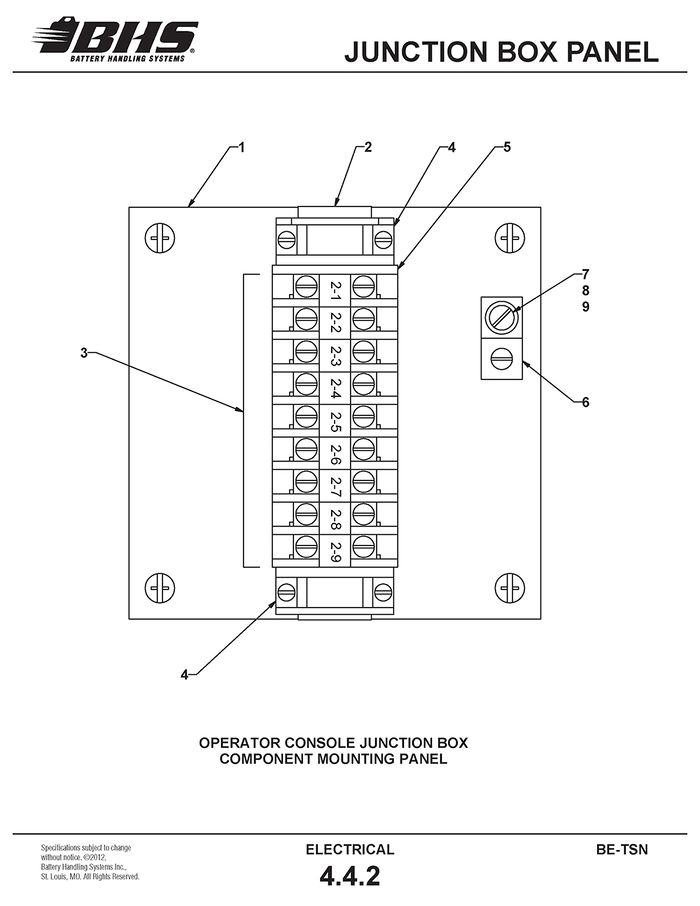

JUNCTION BOX PANEL

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E0639 | PANEL-COMPONENT MOUNTING | WITHOUT HOLES | 1 | |

2 | E1024 | TRACK-TERMINAL BLOCK | 4 7/8” | 1 | |

3 | E1020 | TERMINAL BLOCK | 9 | ||

4 | E1330 | END ANCHOR | 2 | ||

5 | E1040 | END BARRIER | 1 | ||

6 | E0341 | GROUND LUG | 1 | ||

7 | HW0130 | SCREW-RHMS-#8-32 X 1/2” | 2 FOR TRACK MOUNTING | 3 | |

8 | HW0132 | NUT-NILN-#8-32 | 2 FOR TRACK MOUNTING | 3 | |

9 | HW0133 | WASHER-FLAT-#8-SAE | 2 FOR TRACK MOUNTING | 3 |

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E0611 | JUNCTION BOX-4” X 2” X 2” | 3 | ||

2 | E0612 | COVER-JUNCTION BOX | 3 | ||

3 | E0622 | RESTRAINT-1/2” | GRIP SIZE .450” TO .500” | 5 | |

4 | E0617 | LOCKNUT-CONDUIT-1/2” | 5 | ||

5 | E0632 | RESTRAINT-3/4” | GRIP SIZE .625” TO .750” | 1 | |

6 | E0618 | LOCKNUT-CONDUIT-3/4” | 1 | ||

7 | HW0301 | BOLT-SELF TAP “F”-1/4-20 X 1/2” | 6 |

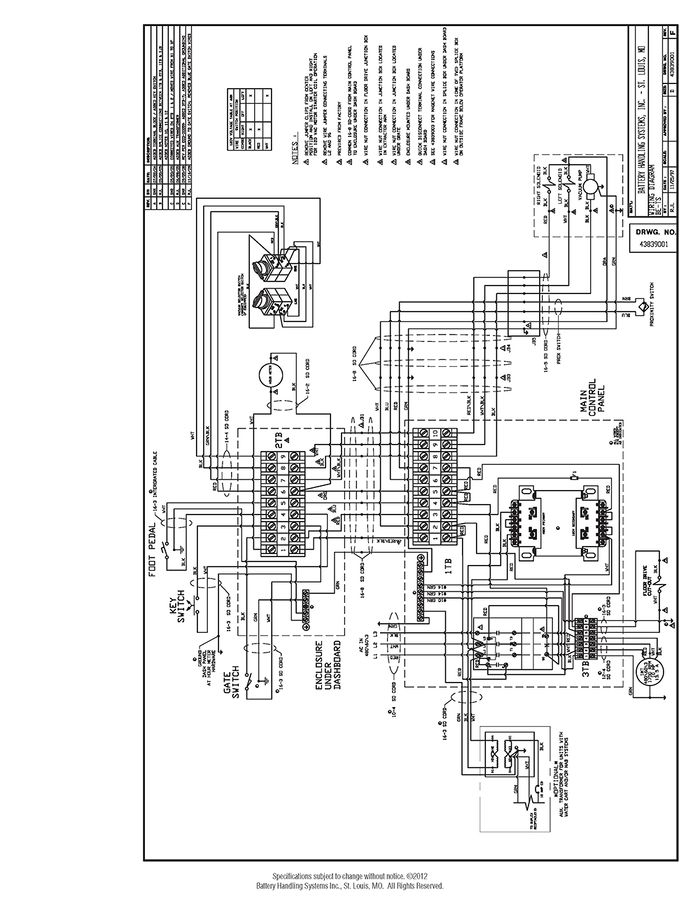

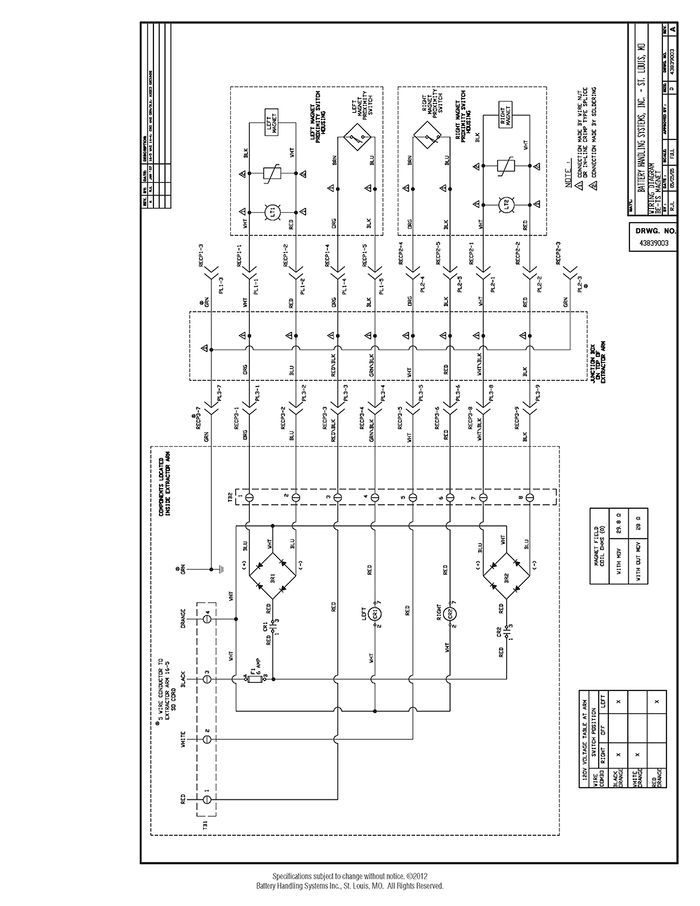

WIRING DIAGRAMS

HYDRAULICS

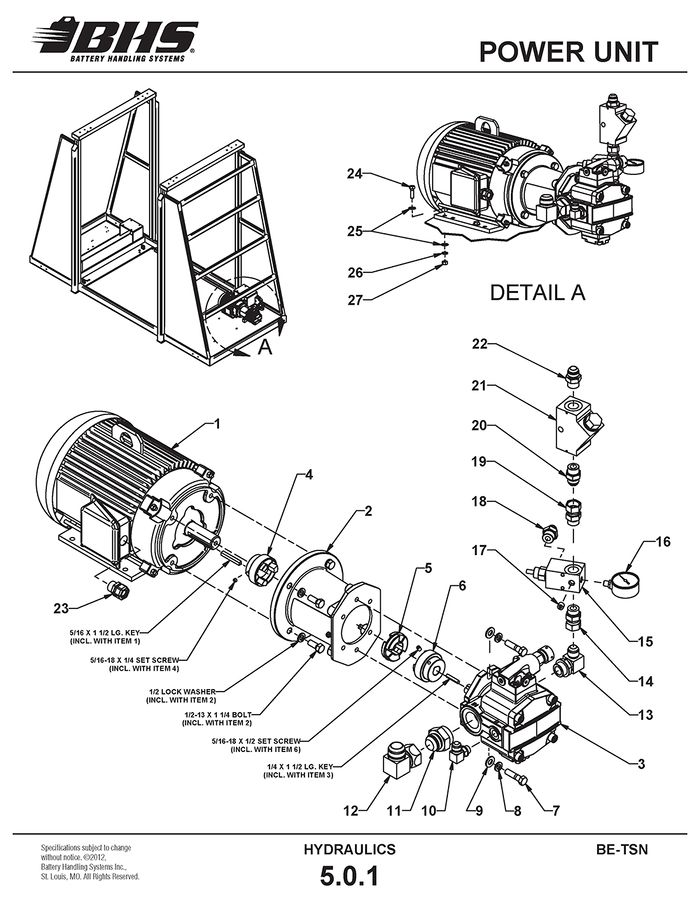

POWER UNITS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E0011 | MOTOR-ELECTRIC-10HP | 1 | ||

2 | HC0326 | ADAPTER-PUMP TO MOTOR | 1 | ||

3 | HC0325 | PUMP-16 GPM-VARIABLE DISP.-VANE TYPE | 1 | ||

4 | HC0327 | COUPLING BODY-1 3/8” | MOTOR END | 1 | |

5 | HC0329 | SPIDER-COUPLING INSERT | 1 | ||

6 | HC0328 | COUPLING BODY-7/8” | PUMP END | 1 | |

7 | HW0502 | BOLT-HHCS-1/2-13 X 1 1/4” | 2 | ||

8 | HW0110 | WASHER-LOCK-1/2” | 2 | ||

9 | HW0112 | WASHER-FLAT-1/2”-SAE | 2 | ||

10 | H1606 | ADAPTER-90 DEG-#8 JICM X #8 SAEM | 1 | ||

11 | H1549 | ADAPTER-#20 JICM X #24 SAEM | 1 | ||

12 | H1595 | ADAPTER-90 DEG-#20 JICM X #20 JICSW | 1 | ||

13 | H1609 | ADAPTER-90 DEG-#12 JICM X #16 SAEM | 1 | ||

14 | H1522 | ADAPTER-#12 JICSW X #12 SAEM | 1 | ||

15 | HC0260 | VALVE-MAIN SYSTEM RELIEF | 1 | ||

15a | HC0236 | REPLACEMENT CARTRIGE | † FOR ITEM 15 (NOT SHOWN) | A/R | |

16 | HC0318 | GAUGE-PRESSURE | 1 | ||

17 | H0206 | PLUG-#4 NPT | 1 | ||

18 | H1547 | ADAPTER-#8 JICM X #10 SAEM | 1 | ||

19 | H1522 | ADAPTER-#12 JICSW X #12 SAEM | 1 | ||

20 | H1542 | ADAPTER-#12 JICM X #12 SAEM | 1 | ||

21 | HC0280 | VALVE-CHECK | 1 | ||

22 | H1542 | ADAPTER-#12 JICM X #12 SAEM | 1 | ||

23 | E0613 | RESTRAINT-3/4” | GRIP RANGE .500” TO .625” | 1 | |

23a | E0618 | LOCKNUT-CONDUIT-3/4” | FOR ITEM 23 - NOT SHOWN | 1 | |

24 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4” | 4 | ||

25 | HW0108 | WASHER-FLAT-3/8”-SAE | 8 | ||

26 | HW0107 | WASHER-LOCK-3/8” | 4 | ||

27 | HW0005 | NUT-HEX-3/8-16 | 4 |

† CARTRIDGE FOR REPLACEMENT ONLY.

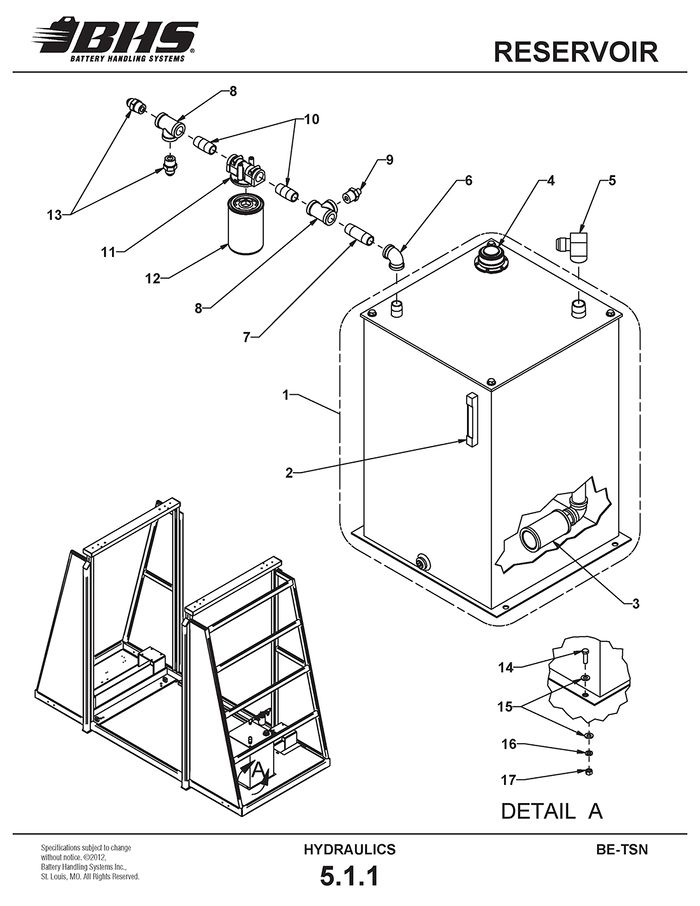

RESERVOIR

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0330-1 | TANK-VERITCAL-30 GAL | INCL. ITEMS 1 THRU 4 | 1 | |

2 | HC0340 | GAUGE-SIGHT | W/ THERMOMETER | 1 | |

3 | HC0306 | STRAINER-SUCTION | 1 | ||

4 | HC0308 | FILLER/BREATHER ASSEMBLY | 1 | ||

5 | H1590 | ADAPTER-90 DEG-#16 JICM X #16 NPTF | 1 | ||

6 | BI0102 | ELBOW-#12 NPTF | 1 | ||

7 | BI0020 | NIPPLE-#12 NPT X 3 | 1 | ||

8 | BI0301 | TEE-#12 NPTF | 2 | ||

9 | H1502 | ADAPTER-#8 JICM X #12 NPTM | 1 | ||

10 | BI0002 | NIPPLE-CLOSE-#12 NPT | 2 | ||

11 | HC0307 | RETURN LINE FILTER ASSEMBLY | HOUSING AND FILTER | 1 | |

12 | HC0317 | FILTER-RETURN LINE | REPLACEMENT FILTER | 1 | |

13 | H1509 | ADAPTER-#10 JICM X #12 NPTM | 2 | ||

14 | HW0402 | BOLT-HHCS-3/8-16 X 1” | 4 | ||

15 | HW0108 | WASHER-FLAT-3/8”-SAE | 8 | ||

16 | HW0107 | WASHER-LOCK-3/8” | 4 | ||

17 | HW0005 | NUT-HEX-3/8-16 | 4 |

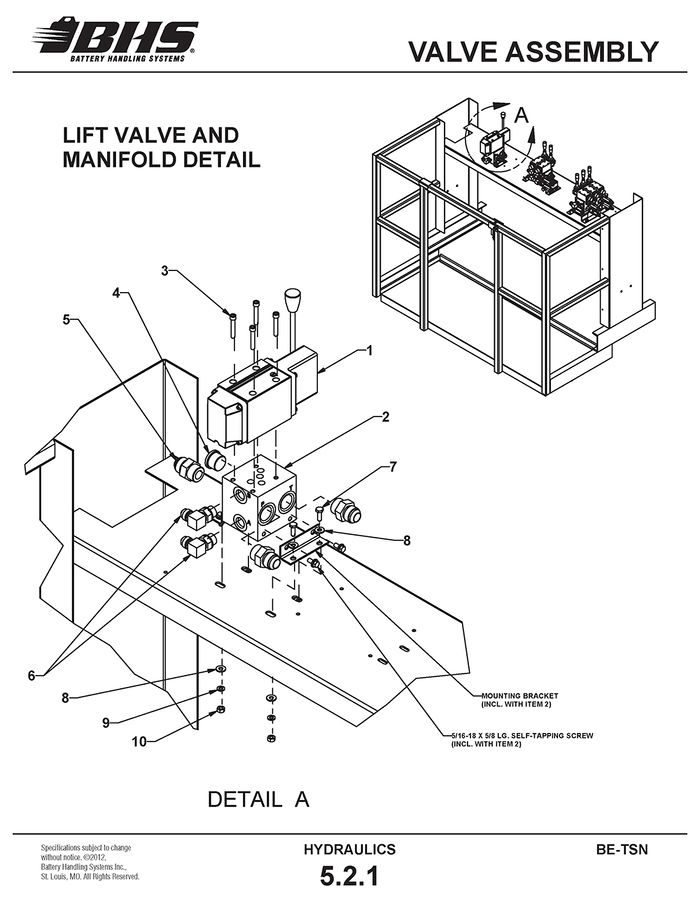

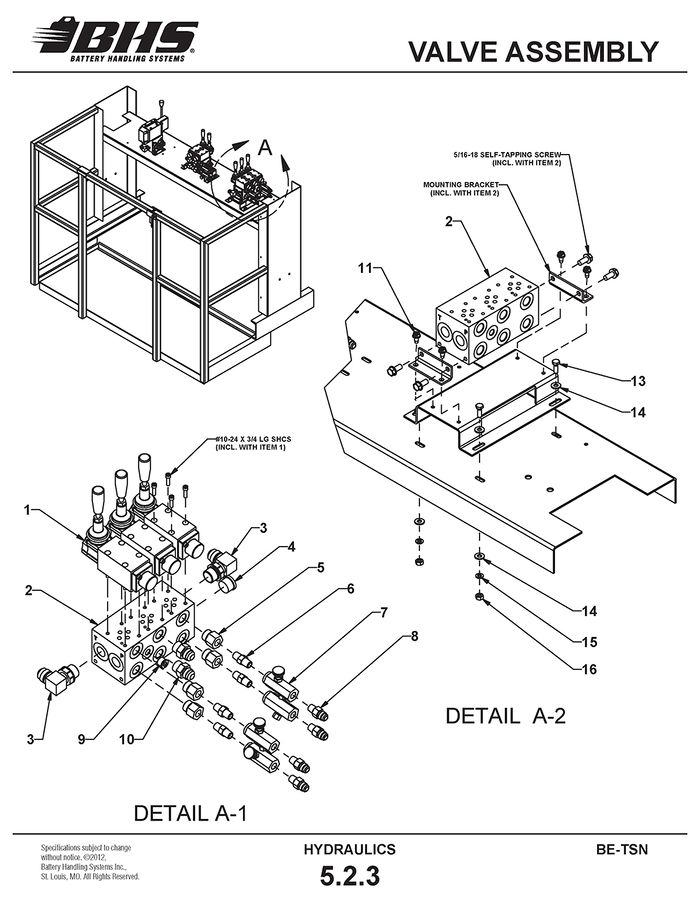

VALVE ASSEMBLY

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0257 | VALVE-LEVER | 1 | ||

2 | HC0252 | MANIFOLD-D05-1 BANK | 1 | ||

3 | HW0318 | BOLT-SHCS-1/4-20 X 1 1/2” | 4 | ||

4 | H1642 | PLUG-#12 SAE | 1 | ||

5 | H1542 | ADAPTER-#12 JICM X #12 SAEM | 3 | ||

6 | H1606 | ADAPTER-90 DEG-#8 JICM X #8 SAEM | 2 | ||

7 | HW0303 | BOLT-HHCS-1/4-20 X 1” | 4 | ||

8 | HW0104 | WASHER-FLAT-1/4”-SAE | 8 | ||

9 | HW0103 | WASHER-LOCK-1/4 | 4 | ||

10 | HW0002 | NUT-HEX-1/4-20 | 4 | ||

11 | 43817085 | PLATE-ADAPTER-VALVE | † NOT SHOWN | 1 | |

12 | SS0104 | BOLT-SHCS-1/4-20 X 5/8”-SST | † NOT SHOWN | 4 | |

13 | SS0300 | WASHER-FLAT-1/4”-SAE-SST | † NOT SHOWN | 4 |

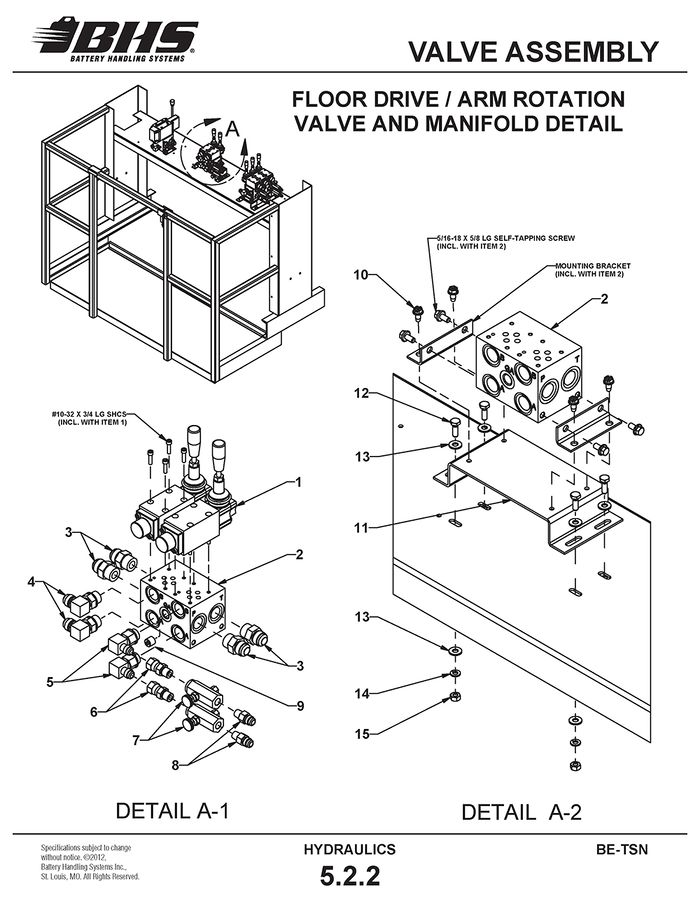

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0233 | VALVE-LEVER | 2 | ||

2 | HC0251 | MANIFOLD-D03-2 BANK | 1 | ||

3 | H1545 | ADAPTER-#10 JICM X #10 SAEM | 4 | ||

4 | H1606 | ADAPTER-90 DEG-#8 JICM X #8 SAEM | 2 | ||

5 | H1600 | ADAPTER-90 DEG-#6 JICM X #8 SAEM | 2 | ||

6 | H1587 | ADAPTER-#6 JICSW X #4 NPTM | 2 | ||

7 | HC0211 | VALVE-ADJUSTABLE FLOW CONTROL | 2 | ||

8 | H1504 | ADAPTER-#6 JICM X #4 NPTM | 2 | ||

9 | H1640 | PLUG-#6 SAE | 1 | ||

10 | HW0301 | BOLT-SELF TAP “F”-1/4-20 X 1/2” | 4 | ||

11 | 43817033-2 | RISER PLATE | 1 | ||

12 | HW0303 | BOLT-HHCS-1/4-20 X 1” | 4 | ||

13 | HW0104 | WASHER-FLAT-1/4”-SAE | 8 | ||

14 | HW0103 | WASHER-LOCK-1/4” | 4 | ||

15 | HW0002 | NUT-HEX-1/4-20 | 4 | ||

16 | HC0233-SK | SEAL KIT | FOR ITEM 1 (NOT SHOWN) | A/R |

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0233 | VALVE-LEVER | 3 | ||

2 | HC0250 | MANIFOLD-D03-3 BANK | 1 | ||

3 | H1610 | ADAPTER-90 DEG-#10 JICM X #10 SAEM | 2 | ||

4 | H1641 | PLUG-#10 SAE | 1 | ||

5 | H1000 | ADAPTER-#8 SAEM X #4 NPTF | 4 | ||

6 | H0001 | NIPPLE-#4 NPT | 4 | ||

7 | HC0211 | VALVE-ADJUSTABLE FLOW CONTROL | 4 | ||

8 | H1504 | ADAPTER-#6 JICM X #4 NPTM | 4 | ||

9 | H1640 | PLUG-#6 SAE | 1 | ||

10 | H1540 | ADAPTER-#8 JICM X #8 SAEM | 2 | ||

11 | HW0301 | BOLT-SELF TAP “F”-1/4-20 X 1/2” | 4 | ||

12 | 43817034-2 | RISER PLATE | 1 | ||

13 | HW0303 | BOLT-HHCS-1/4-20 X 1” | 4 | ||

14 | HW0104 | WASHER-FLAT-1/4”-SAE | 8 | ||

15 | HW0103 | WASHER-LOCK-1/4” | 4 | ||

16 | HW0002 | NUT-HEX-1/4-20 | 4 | ||

17 | HC0233-SK | SEAL KIT | FOR ITEM 1 (NOT SHOWN) | A/R |

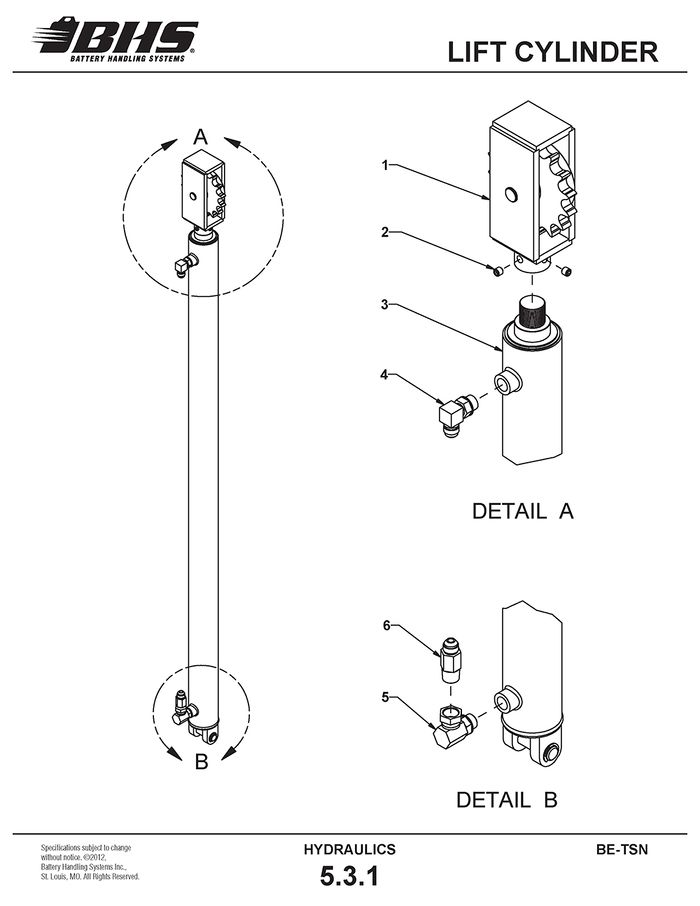

LIFT CYLINDER

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43822002 | CLEVIS ASSEMBLY | SOLD AS ASSEMBLY ONLY | 4 | |

2 | HW0813 | SCREW-SHSS-3/8-16 X 1/2” | NYLON TIPPED | 8 | |

3 | HC0420 | CYLINDER-LIFT | 4 | ||

4 | H1606 | ADAPTER-90 DEG-#8 JICM X #8 SAEM | 4 | ||

5 | H1107 | ADAPTER-90 DEG-#8 SAEM X #8 NPTSW | 4 | ||

6 | HC0425 | VELOCITY FUSE | 4 | ||

7 | HC0420-SK | SEAL KIT | NOT SHOWN | A/R |

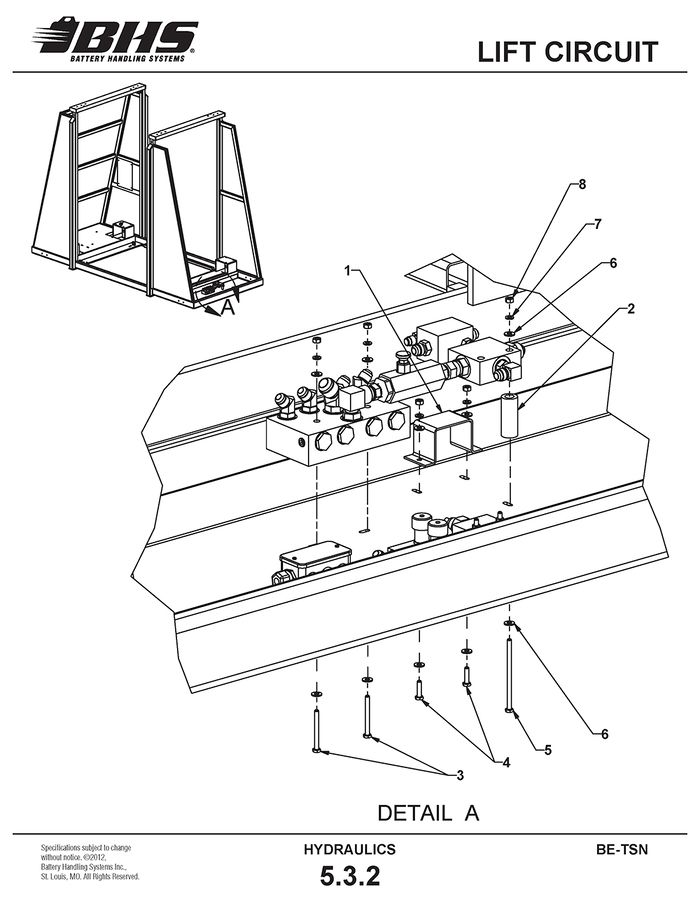

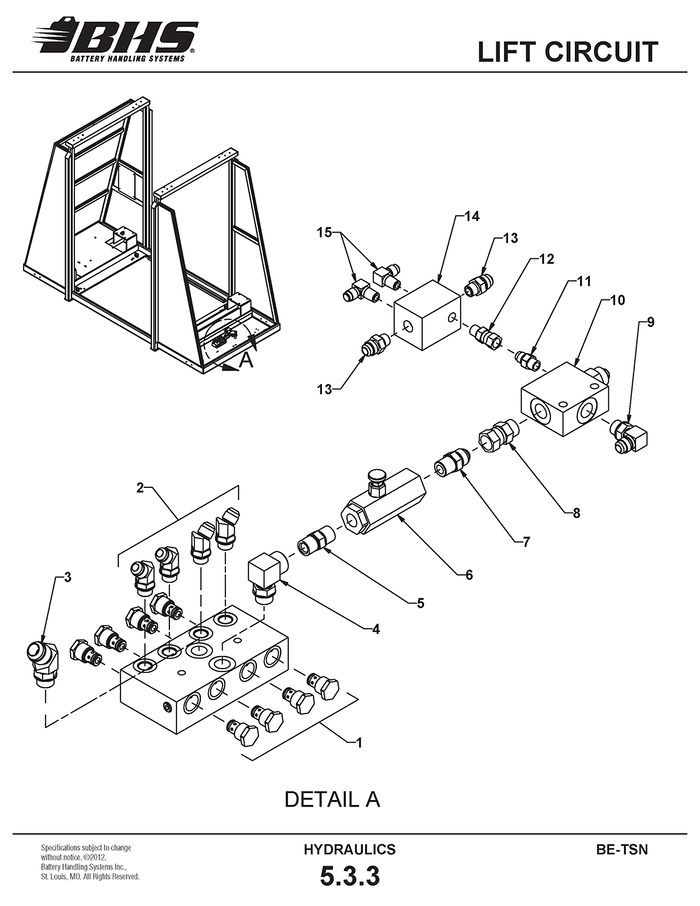

LIFT CIRCUIT

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43017014-2 | SUPPORT-PILOT DOWN MANIFOLD | 1 | ||

2 | 43718008 | STANDOFF | 1 | ||

3 | HW0308 | BOLT-HHCS-1/4-20 X 2 1/2” | 2 | ||

4 | HW0303 | BOLT-HHCS-1/4-20 X 1” | 2 | ||

5 | HW0315 | BOLT-HHCS-1/4-20 X 4 1/2” | 1 | ||

6 | HW0104 | WASHER-FLAT-1/4”-SAE | 10 | ||

7 | HW0103 | WASHER-LOCK-1/4 | 5 | ||

8 | HW0002 | NUT-HEX-1/4-20 | 5 |

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0215 | VALVE-CHECK-CARTRIDGE | 8 | ||

2 | H1560 | ADAPTER-45 DEG-#8 JICM X #8 SAEM | 4 | ||

3 | H1670 | ADAPTER-45 DEG-#12 JICM X #10 SAEM | 1 | ||

4 | H1647 | ADAPTER-90 DEG-#10 SAEM X #8 NPTF | 1 | ||

5 | H0007 | NIPPLE-#8 NPT | 1 | ||

6 | HC0270 | VALVE-ADJUSTABLE FLOW CONTROL | PRESSURE COMPENSATED | 1 | |

7 | H1680 | ADAPTER-#10 JICM X #8 NPTM | 1 | ||

8 | H1690 | ADAPTER-#10 JICSW X #10 SAEM | 1 | ||

9 | H1612 | ADAPTER-90 DEG-#8 JICM X #10 SAEM | 1 | ||

10 | HC0283 | VALVE-COUNTER BALANCE | 1 | ||

11 | H1552 | ADAPTER-#6 JICM X #6 SAEM | 1 | ||

12 | H1587 | ADAPTER-#6 JICSW X #4 NPTM | 1 | ||

13 | H1501 | ADAPTER-#8 JICM X #6 NPTM | 2 | ||

14 | 43047002 | MANIFOLD-PILOT DOWN | 1 | ||

15 | H1579 | ADAPTER-90 DEG-#6 JICM X #4 NPTM | 2 |

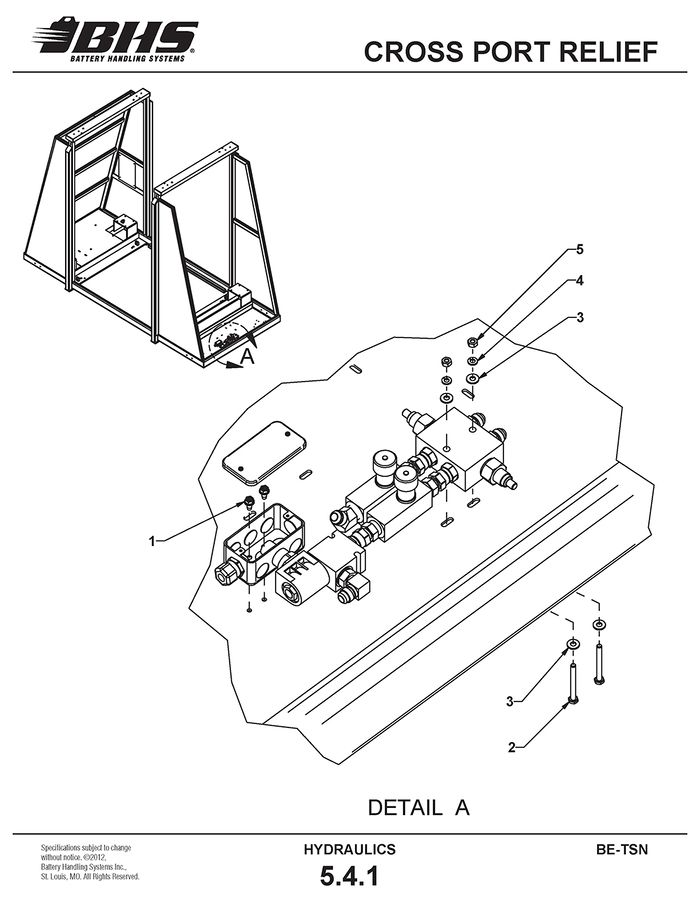

CROSS PORT RELIEF

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HW0301 | BOLT-SELF TAP “F”-1/4-20 X 1/2” | 2 | ||

2 | HW0308 | BOLT-HHCS-1/4-20 X 2 1/2” | 2 | ||

3 | HW0104 | WASHER-FLAT-1/4”-SAE | 4 | ||

4 | HW0103 | WASHER-LOCK-1/4” | 2 | ||

5 | HW0002 | NUT-HEX-1/4-20 | 2 |

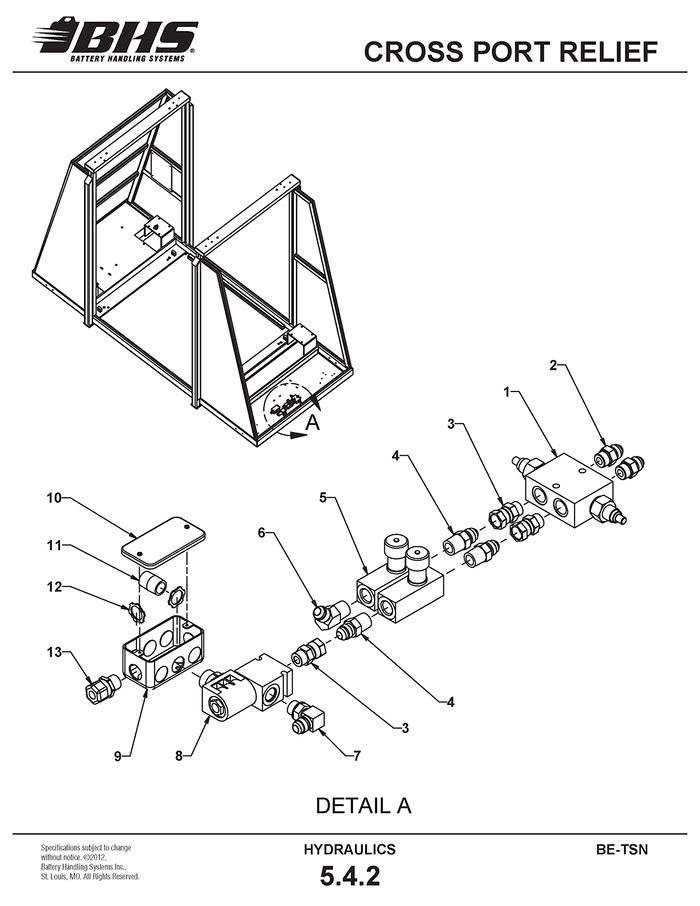

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0262 | VALVE-CROSS PORT RELIEF | 1 | ||

1a | HC0236 | REPLACEMENT CARTRIDGE | † FOR ITEM 1 (NOT SHOWN) | A/R | |

2 | H1540 | ADAPTER-#8 JICM X #8 SAEM | 2 | ||

3 | H1521 | ADAPTER-#8 JICSW X #8 SAEM | 3 | ||

4 | H1507 | ADAPTER-#8 JICM X #8 NPTM | 3 | ||

5 | 1A043 | VALVE-ADJUSTABLE FLOW CONTROL | 2 | ||

6 | H1568 | ADAPTER-45 DEG-#8 JICM X #8 NPTM | 1 | ||

7 | H1606 | ADAPTER-90 DEG-#8 JICM X #8 SAEM | 1 | ||

8 | HC0265-1 | SOLENOID-FLOOR DRIVE CUT OUT | 1 | ||

9 | E0611 | JUNCTION BOX-4” X 2” X 2” | 1 | ||

10 | E0612 | COVER-JUNCTION BOX | 1 | ||

11 | BI0001 | NIPPLE-CLOSE-#8 NPT | 1 | ||

12 | E0617 | LOCKNUT-CONDUIT-1/2” | 2 | ||

13 | E0616 | RESTRAINT-1/2” | GRIP SIZE .250” TO .375” | 1 |

† CARTRIDGES ARE FOR REPLACEMENT ONLY

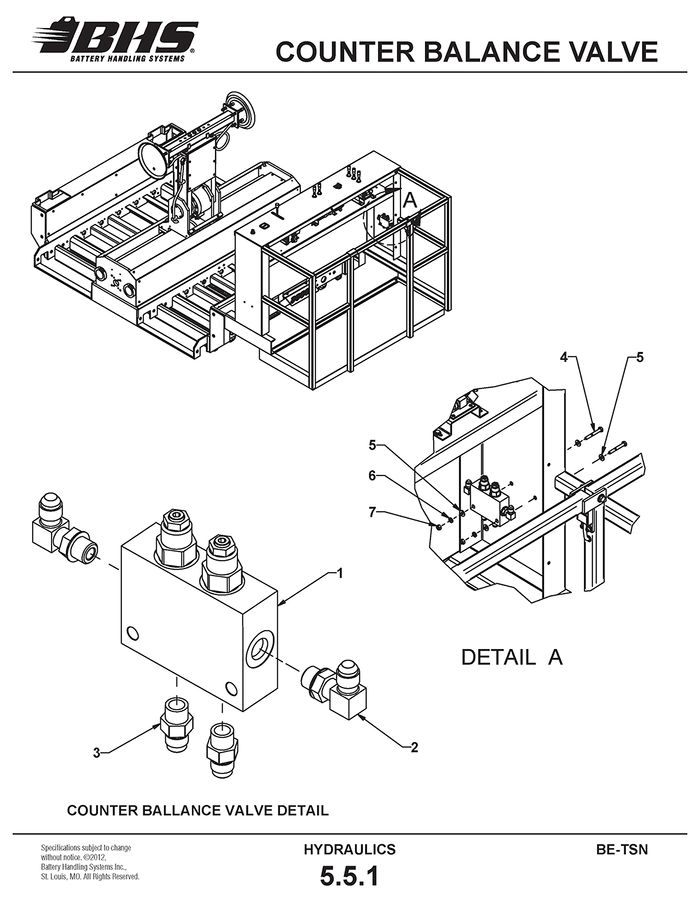

COUNTER BALANCE VALVE

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0263 | VALVE-COUNTER BALANCE | 1 | ||

2 | H1615 | ADAPTER-90 DEG-#6 JICM X #6 SAEM | 2 | ||

3 | H1552 | ADAPTER-#6 JICM X #6 SAEM | 2 | ||

4 | HW0305 | BOLT-HHCS-1/4-20 X 2” | 2 | ||

5 | HW0104 | WASHER-FLAT-1/4”-SAE | 4 | ||

6 | HW0103 | WASHER-LOCK-1/4” | 2 | ||

7 | HW0002 | NUT-HEX-1/4-20 | 2 |

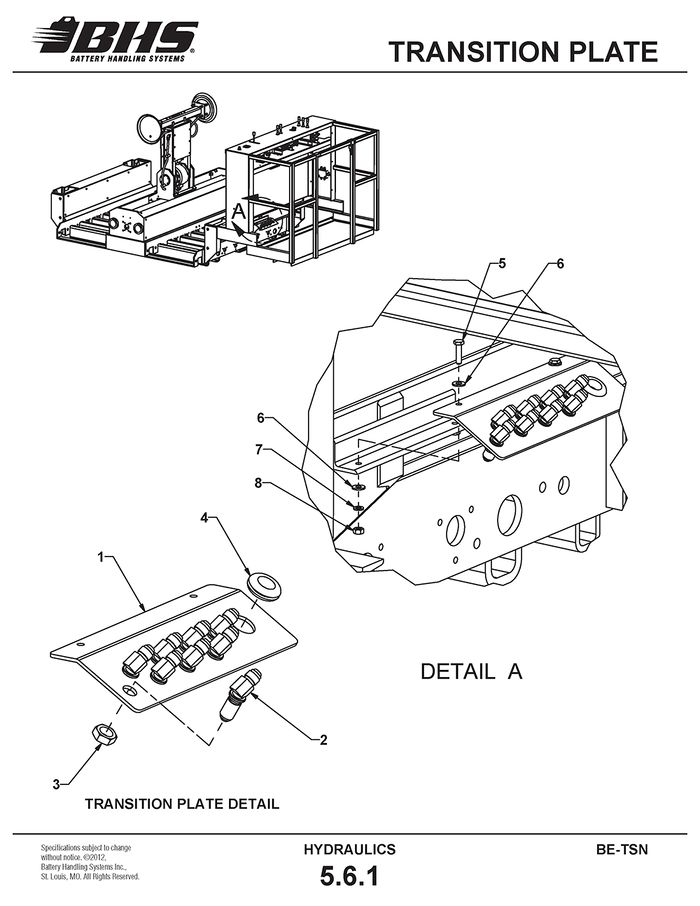

TRANSITION PLATE

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43817067-2 | PLATE-TRANSITION | 1 | ||

2 | H0020 | UNION-BULKHEAD-45 DEG-#6 JICM | 8 | ||

3 | H0021 | NUT-BULKHEAD-#6 JIC | 8 | ||

4 | PL0501 | GROMMET-1/2 | 1 | ||

5 | HW0303 | BOLT-HHCS-1/4-20 X 1” | 2 | ||

6 | HW0104 | WASHER-FLAT-1/4”-SAE | 4 | ||

7 | HW0103 | WASHER-LOCK-1/4” | 2 | ||

8 | HW0002 | NUT-HEX-1/4-20 | 2 |

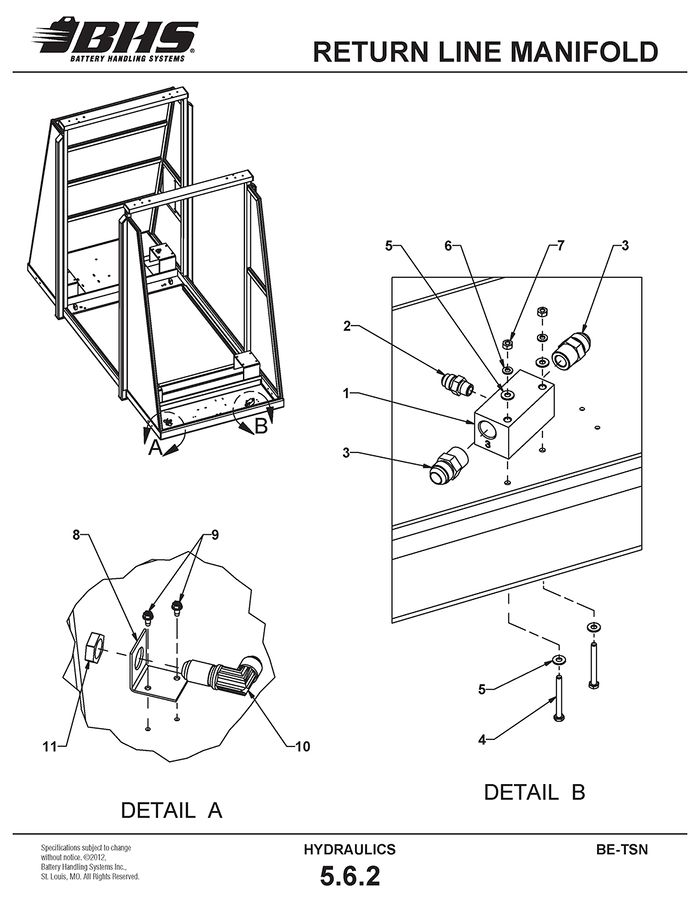

RETURN LINE MANIFOLD

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 43847001 | MANIFOLD-RETURN LINE | 1 | ||

2 | H1501 | ADAPTER-#8 JICM X #6 NPTM | 1 | ||

3 | H1503 | ADAPTER-#12 JICM X #12 NPTM | 2 | ||

4 | HW0308 | BOLT-HHCS-1/4-20 X 2 1/2 | 2 | ||

5 | HW0104 | WASHER-FLAT-1/4”-SAE | 4 | ||

6 | HW0103 | WASHER-LOCK-1/4” | 2 | ||

7 | HW0002 | NUT-HEX-1/4-20 | 2 | ||

8 | 43817069-2 | BRACKET-BULKHEAD | 1 | ||

9 | HW0301 | BOLT-SELF TAP “F”-1/4-20 X 1/2” | 2 | ||

10 | H0015 | UNION-BULKHEAD-90 DEG-#12 JICM | 1 | ||

11 | H0016 | NUT-BULKHEAD-#12 JIC | 1 |

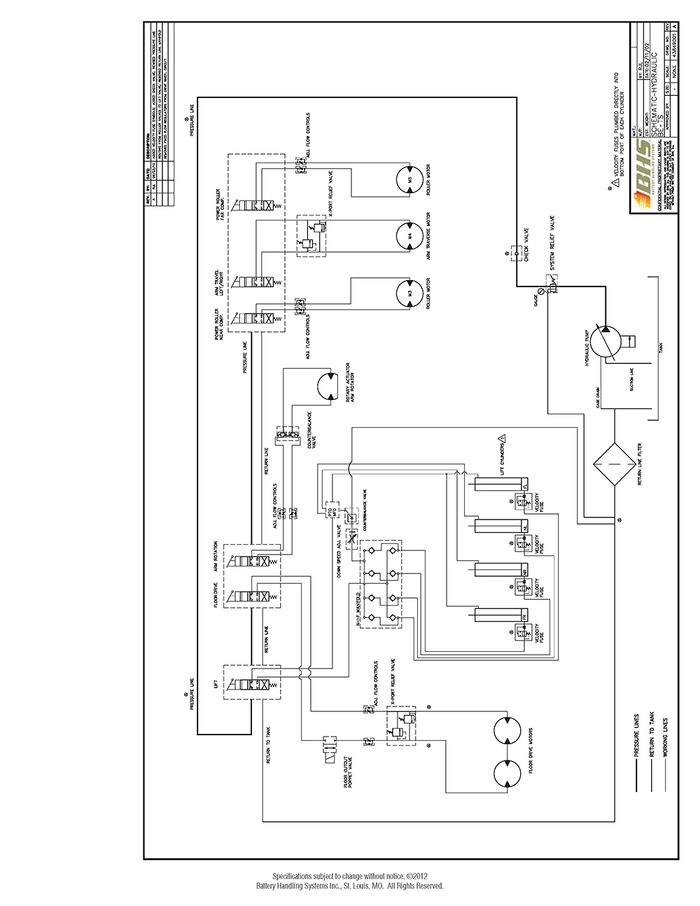

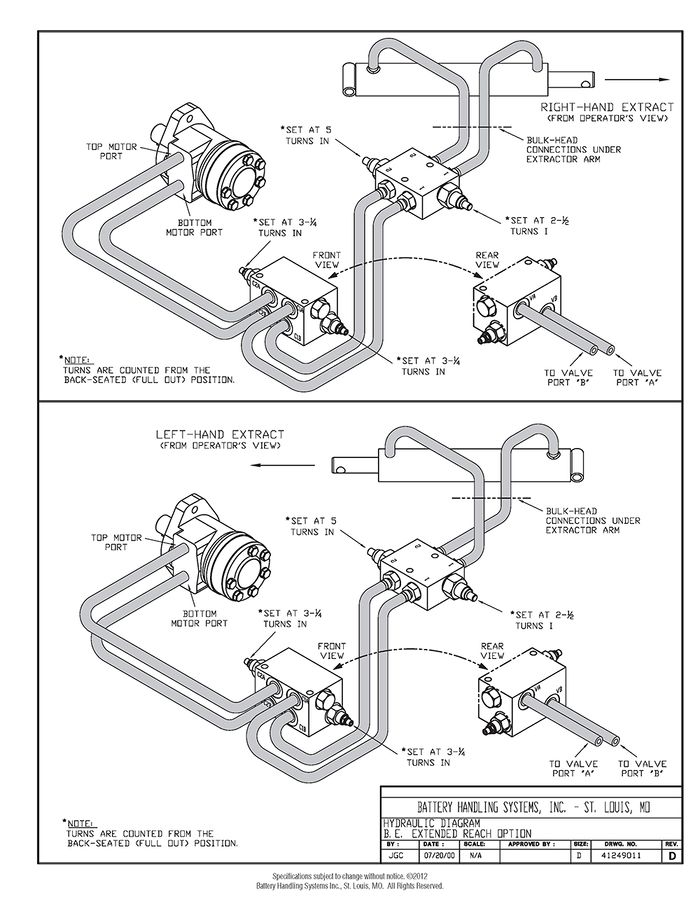

HYDRAULIC SCHEMATICS

SERVICE AND MAINTENANCE

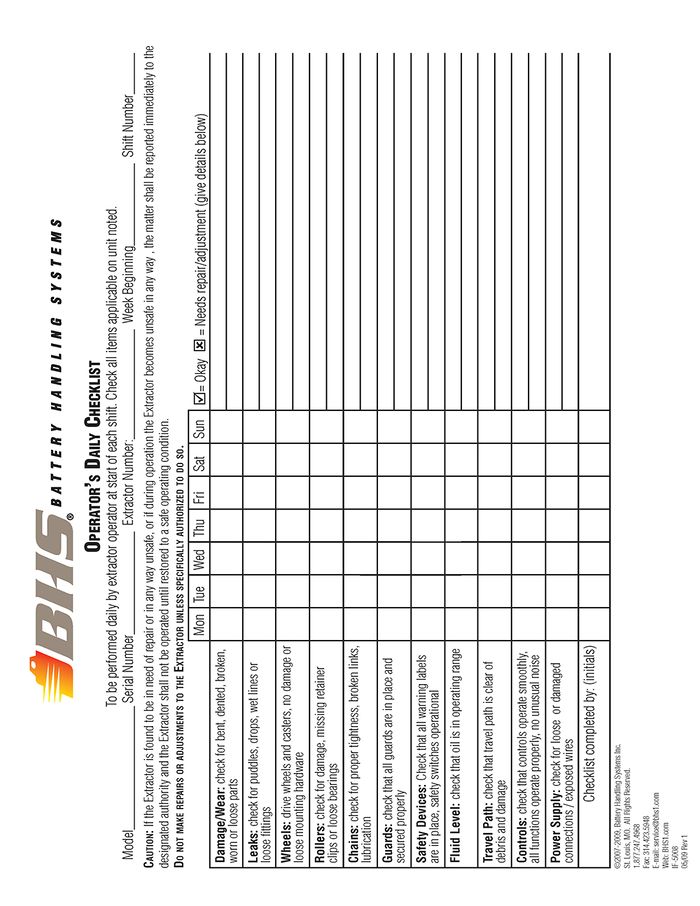

DAILY INSPECTION LIST

The points listed below should be visually inspected daily prior to initial start up of the Battery Extractor to ensure safe and proper operation of the unit and to help avoid unnecessary down time.

1. Walk around unit and inspect for any physical damage to machine not previously noted.

2. Verify all guards are in place.

3. Inspect the AC power feed for any damage.

4. Inspect vacuum cups for damage to cup sealing surface, backup casting, and vacuum hoses.

5. Inspect travel path and area around unit for any hydraulic oil that could be a potential repair/maintenance issue and/or safety hazard.

6. Check oil level in hydraulic reservoir at fill level gauge.

7. Check that operator safety gate and all safety switches are in proper working order.

8. Verify extractor path is free of obstructions.

9. Check roller beds for any debris and clean as required.

10. Board unit, engage system and verify all functions are operating properly and that no abnormal or unusual noises are present.

USE FORM IF-5008 WHEN PREFORMING DAILY INSPECTIONS.

OPERATOR'S DAILY CHECKLIST

RECOMMENDED LUBRICATION INTERVALS

| # OF PLACES | INTERVALS | |

|---|---|---|

| 1. Lubricate grease fittings using #2 lithium based grease A. Extractor arm drive nut and carrier bearings B. Idler casters |

5 places 2 places |

50 hrs/Weekly 500 hrs/Weekly |

| 2. Wipe off and lubricate chains using light machine oil A. #80 Lift chains (Not applicable to BE-SL units) B. #60 Equalization chains C. #35 Powered roller chains |

4 places 4 places 8 places |

500 hrs/Monthly 500 hrs/Monthly 500 hrs/Monthly |

| 3. Change return line hydraulic fluid filter (Oil filtration of at least 20 microns is recommended) |

1 place | 500 hrs/Twice quarterly |

| 4. Change/Test hydraulic fluid | - | 500 hrs/Quarterly |

| 5. Complete preventative maintenance (PM) (Use form IF-5029 for Vacuum equipped units Use form IF-5028 for Magnet equipped units) |

- | 500 hrs/Quarterly * |

These recommendations are based on average use in a typical warehouse environment and may be adjusted based on individual circumstances. Dusty and/or extreme hot/cold environments may require more frequent lubrication.

- BHS recommends implementing an oil sampling and analysis program to monitor hydraulic fluid condition and determine when hydraulic fluid changes are required. The fluid analysis program should be a continuous process and all results should be evaluated. Changes in the condition of the hydraulic system may indicate component wear, fluid deterioration and contamination.

- The mounted bearings used on the power rollers, equalization shafts, drive wheels, and drive screw are are sealed and shielded bearings. Lubrication may breach the seals of these bearings, therefore these bearings should not be lubricated unless the machine has been cleaned with a high pressure wash on a regular basis (not recommended).

- Hydraulic fluid should not exceed 140° F (60° C) for extended periods.

| INTERVALSRESERVOIR | CAPACITIES (APPROX.) |

|---|---|

| »BE-SL | 18 gal (68 L) |

| »BE-DS | 18 gal (68 L) |

| »BE-TS | 30 gal (114 L) pre 2014 45 gal (170 L) post 2014 |

| »BE-QS | 60 gal (227 L) |

The reservoir should be filled so fluid level is within a half inch (1/2") of the top of sight glass. Use Chevron AW 68 or equivalent ISO 68 grade hydraulic oil with anti-wear additives and foam suppressant.

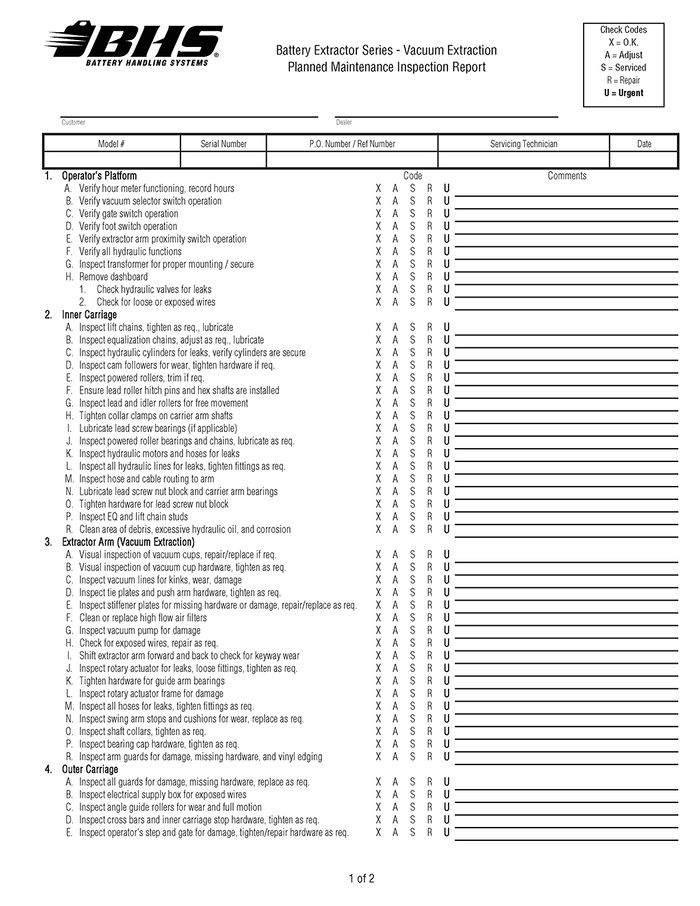

Battery Extractor Series - Vacuum Extraction Planned Maintenance Inspection Report

EQUALIZATION CHAIN

Installation / Resetting Procedures

P/N: 80292002-I

E.Q. CHAIN RESETTING

These instructions outline the procedures for replacing or resetting the equalization chains on single, double, and triple stack battery extractors.

Tools Required:

1 - Large standard screw driver 1 - 1/8” Allen key

1 - 5/32” Allen key 2 - 1 1/8” End wrenches

1 - 3/16” Allen key 1 - Needle nose pliers

1 - Steel ruler 1 - 80292002 EQ. adjustment stop kit

Step 1)

You will need to remove the inner and outer frame guards to access the lower studs to ease the adjustment process. The next step is to level the inner frame of the extractor using the 80292002 equalization adjustment stop kit.

NOTE: THIS PROCESS REQUIRES THE EXTRACTOR TO BE FULLY UNLOADED. BE SURE TO POSITION THE BATTERY EXTRACTOR IN A LEVEL AREA OF THE FLOOR.

Installation of the equalization adjustment stop kit requires (4) persons plus a trained battery extractor operator to raise and lower the extractor from the operator platform.

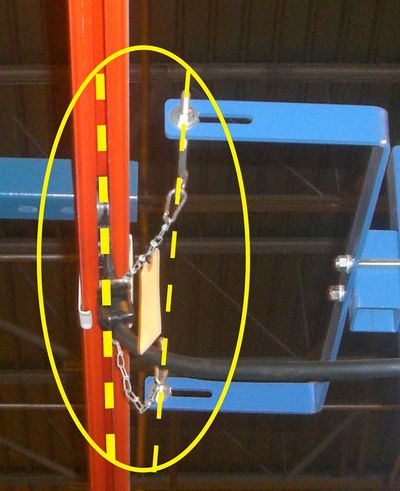

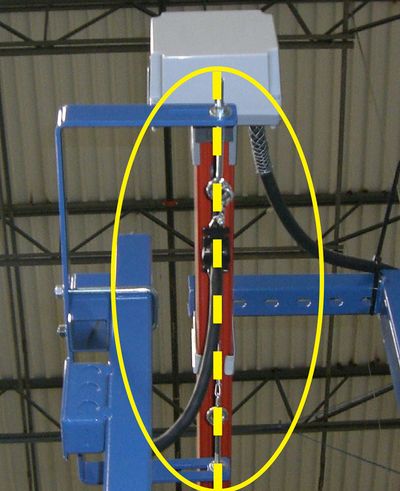

First, have the operator raise the extractor approximately 30” from the fully lowered position. Next, have (4) persons install a service stop in each corner of the roller beds as shown in the following photos.

Be sure that the word “UP” and the etched arrow are pointing toward the top of the machine.

Once all four stops have been installed as shown, have the operator slowly lower the platform until the roller bed is firmly seated against all (4) stops.

BE SURE ALL STOPS ARE CORRECTLY SEATED AS SHOWN HERE

Step 2) If you are replacing or adjusting existing EQ chains at this point you will need to remove the hex nuts and lock washers from the upper EQ chain studs and lower the chains. Retain the hex nuts and lock washers for reassembly. Remove and discard the master links from the upper and lower EQ chain studs and remove the chain from the studs.

NOTE: If the equalization chains are being reset due to a master link failure, it is recommended that the stud where the master link failed be replaced at this time.

Step 3) Thread the lower EQ chain studs into the frame until they are flush with the bottom of the frame then turn an additional one half turn with the holes aligned front to back. (See figure 2)

FIGURE 2

Step 4) Attach the # 60 EQ chains to the upper and lower studs using the new #60 master links and lay chains in the frame until all 4 chains are reattached. Be sure the hex nut is threaded down near the master link. (See Figure 3)

FIGURE 3

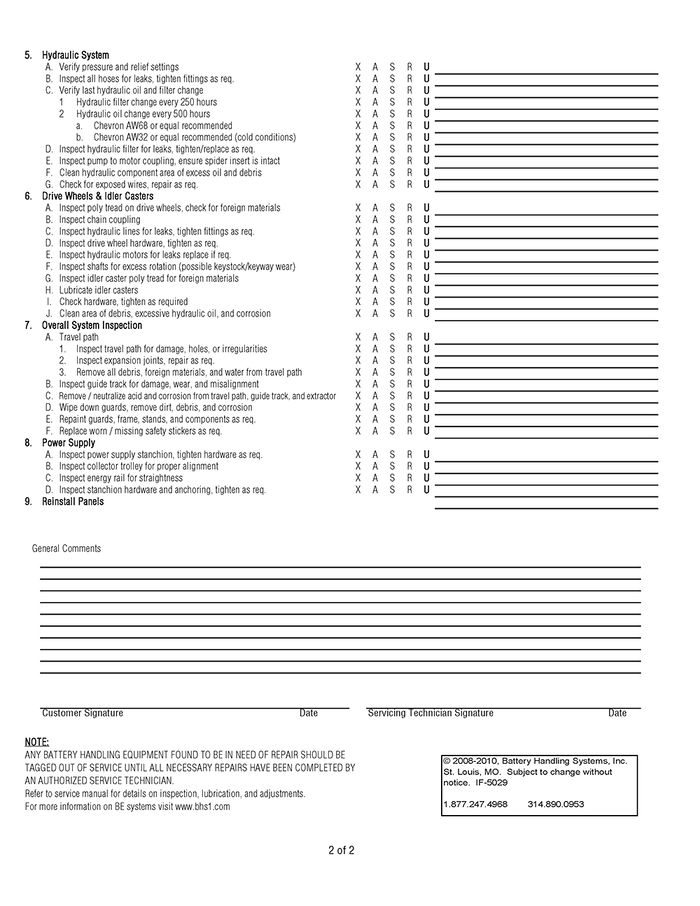

Step 5) Align the EQ shafts so that the key stocks are in the 2 o’clock position. This will bring the set screws on the sprockets to the top of the sprocket when the inner frame is lowered. (See Figure 4)

FIGURE 4

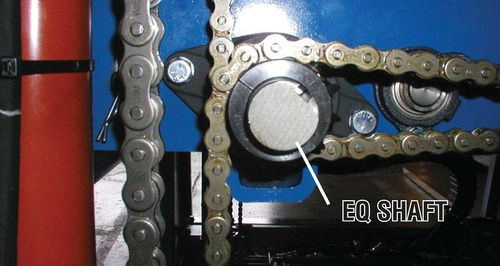

Starting with the inside #60 EQ chain, route the chain over the sprocket directly above the lower EQ chain stud and then under the inside sprocket on the opposite EQ shaft. (See Figures 4 & 5) Be sure to take out as much slack as possible between the sprockets. Then attach the upper EQ Chain Stud to the top cross bar. (See Figure 6)

FIGURE 5

FIGURE 6

Next route the outer chain over the outer EQ sprocket and under the outer sprocket on the opposite EQ shaft and attach the upper stud to the top cross bar. Repeat this process for the opposite side of the extractor. Do not tighten the upper EQ stud adjusting nuts at this time. Be sure a lock washer is installed between the top cross bar and lower hex nut. (See figure 6)

Adjust the lower stud up or down to take the slack out of the equalization chain between the lower stud and the sprocket. It will probably be necessary to use a large standard screwdriver to get the fi nal chain over the sprocket. NOTE: It is recommended that the operator end is done fi rst since it has more obstacles hindering complete and easy access.

Step 6) Once all the chains have been installed you should now tighten the upper hex nuts on the upper studs until it takes about 10 pounds of force to produce ¼” deflection in the middle of the vertical section of the EQ chain. Tighten the lower hex nut on the upper cross bar studs to lock the studs in position.

Step 7)

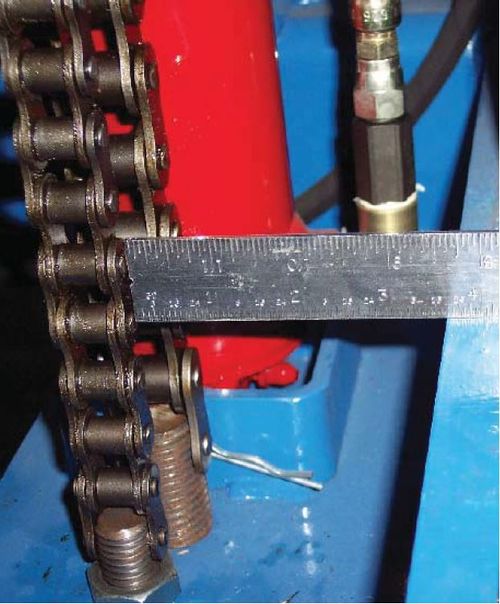

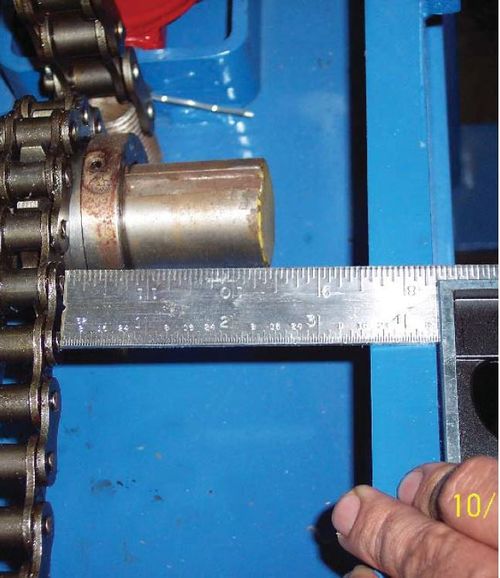

Using a steel ruler measure the distance of the chain at the lower stud to the inside frame and set the distance of the corresponding sprocket to that distance. (See figures 7 and 8) Repeat this process for the remaining 3 sprockets. Raise and lower the inner frame several times and listen for any chain popping noise to confirm the sprockets are in line with the lower studs. If there is no popping noise then tighten the set screws on the sprockets and slide the clamp collars against the outside sprocket and tighten the clamp collars.

FIGURE 7

FIGURE 8

80292001-I

BATTERY EXTRACTOR SERVICE STAND INSTALLATION INSTRUCTIONS

THESE INSTRUCTIONS REFER TO BHS PARTS KITS 80292001 & 80392001

REMOVE ALL BATTERIES FROM EXTRACTOR PRIOR TO INSTALLATION

Tools required:

- None

Procedure:

- Three (3) persons are required to perform the installation of the service stands. DO NOT ATTEMPT INSTALLATION WITH LESS THAN (3) PERSONS.

- Begin by having a qualified operator enter the operator platform and raise the roller compartment platform of the extractor to the required height. (For single level applications, the required height will be approximately 25 inches from the fully lowered position. For double & triple stack applications, the required height will be approximately 55 inches from the fully lowered position.

- Once the required platform height is achieved, the stands can be installed as shown in the following photographs. Installation is accomplished by engaging the top of the stand before the bottom. The top flanges of each stand have been tapered to aid in proper alignment of the stand with the roller compartment divider weldments Be sure that the tabs on the top of the stand are properly engaged with the roller compartment divider weldments as shown.

- The bottom of the stand can now be slid over the lower frame rail as shown.

- Once BOTH stands have been properly fitted, have the battery extractor operator SLOWLY lower the roller compartment platform while the other (2) persons are holding the stands in place.

- Once the roller compartment platform is firmly seated against the service stands, carefully check the top and bottom of both stands for proper fitment. The stands should not move when pulled on during inspection.

- Remember to disconnect power prior to the battery extractor and follow all applicable OSHA lockout / tag-out procedures prior to performing service.

- On double & triple stack battery extractors; the operator on the operator platform either must remain on the operator platform during service or be provided egress by an approved OSHA method. (The above does not apply to single level battery extractors as the operator platform is fi xed from vertical movement.)

SINGLE LEVEL STAND PROPERLY INSTALLED

DOUBLE, TRIPLE, & QUAD LEVEL STAND PROPERLY INSTALLED

TROUBLE SHOOTING GUIDE

PROBLEM SYMPTOM | PROBABLE CAUSE | SOLUTION |

Hydraulic power Unit does not operate. No electric to power unit motor. |

|

|

Power unit runs but no pressure reading at gauge also no functions move. |

|

|

Magnetic starter contact chatters-at startup. Contact chatters while traveling. |

|

|

No floor travel empty or loaded-all other func- tions work properly. |

|

|

Floor travel moves but is sluggish and stalls with a load at certain points. |

|

|

Inner cartridge bounces while lifting under load but not when empty. | 1. Down speed adjustment valve open too far. | 1. Adjust as needed to eliminate carriage bounce. |

Inner carriage does not lift evenly. Four corners do not land evenly against outer frame tube. |

|

|

TECH TIPS

Vacuum Cup Replacement

Tech Tip TT-901

Models Effected: All Vacuum Equipped Extractors

Subject:

Vacuum Cup Replacement for Battery Extractor Systems.

Description:

Vacuum cups are the most frequently replaced items on a battery extractor. This is due to damage of the cup by way of tearing the sealing edge of the cup, separation of the rubber from the metal backing plate, or bending/breaking the metal backing plate.

Recommendation:

When extracting a lift truck battery from either a lift truck or a charging stand, DO NOT change the elevation of the roller bed, or rotate the extractor arm while engaged on a battery case. This causes the cup to slide along the battery case leading to the edge of the cup curling or rolling under and eventually leading to the damage of the cup assembly. To eliminate this from happening, verification of the roller bed height and extractor arm position is critical prior to engaging the cup to the battery case. To help reduce the problem of the cup edge curling under, we recommend a silicone type lubricant applied on the face of the cup to help the cup slide on the battery case.

Repair:

If the vacuum cup has been torn or separated from the metal backing plate, the cup will need to be replaced. BHS offers three cup options with a standard mounting layout. All three options are available for use on any BHS vacuum equipped extractor.

10" REPLACEMENT CUP

P/N: 00162001

STANDARD ON ATC-24 UNITS WITH VACUUM EXTRACTION.

12" REPLACEMENT CUP

P/N: P0110

STANDARD ON ATC UNITS 30" AND ABOVE

3 PIECE, 12" REPLACEMENT CUP

P/N: 00162003

CURRENT STANDARD ON BE UNITS. ALLOWS REPLACEMENT OF RUBBER PAD ONLY.

Moving an Inoperable Battery Extractor

Tech Tip TT-902

Models Effected: All Man-on-Board Extractors

Subject:

Proper procedure for moving a Battery Extractor without AC power to energize the machine.

Description:

It may be necessary to move the Battery Extractor when AC power is unavailable. This could be due to a lack of AC power at the time of install, a problem with the AC power feed, or other such instances. Regardless of the circumstances, special precautions must be taken in order to ensure no damage occurs to the drive wheel motors. DO NOT push the Battery Extractor once it is removed from the shipping skid. Pushing the battery extractor may damage the drive motor seals; thus voiding the warranty.

Recommendation:

Raise the drive wheels so that they do not contact the floor. The drive wheels are typically located at the operator’s end of the machine. Using a forklift to raise this end of the machine while moving the Battery Extractor, will prevent damage to the drive wheel motors. If the machine was moved improperly and damage has occurred, replacement of the hydraulic motors may be necessary.

INCORRECT

Pushing Extractor

CORRECT

Raising Extractor

Hydraulic Systems and Temperature Extremes

Tech Tip TT-903

Models Effected: All Hydraulic Systems

Subject:

Operating temperatures of a hydraulic system have a direct effect on oil, components, and the overall performance of the system. Temperature extremes, whether high or low, can create conditions that will break down the oil and cause component failure well before their anticipated life span.

Description:

Low Temperature increases the viscosity, or thickness, of the oil; this forces the pump to work harder pulling the oil on the inlet side. In some instances, the air dissolved in the oil will desorb and form air bubbles. These bubbles can implode violently inside the pump as it tries to compress this bubbly oil on the high-pressure side causing vibration and sounding as if marbles are inside the pump (cavitation). These implosions actually destroy the internal parts of the pump and the micro-particles are then carried throughout the system to cause additional damage to components downstream.

High Temperature decreases oil viscosity. This thinner oil causes excess wear on moving components. As the oil thins, it loses its lubricating value, which increases friction and creates more heat. This cycle continues until the oil becomes burnt and oxidized, giving it a brown color and burnt smell. At this point the oil is of no value and only damages the system. As long as the system remains below 140° F, the breakdown rate of the oil is minimized. Every 15°F over 140° F decreases the life of the oil by 50%. If the oil has an expected life of 1000 hours and the system runs at 170°F, even intermittently, the oil life is reduced to 250 hours.

Recommendation: BHS systems are shipped from the factory with Chevron AW-68 oil. This provides low temperature performance when ambient temperatures are as low as 60° F. For applications where the temperature may be consistently lower than that, we offer AW-32 oil for ambient temperatures down to 40° F. This application may be found in a refrigerated warehouse.

Be aware of your oil temperature. High temperature extremes are typically caused by a problem within the system that must be addressed as soon as possible to avoid further damage to the oil and components.

BHS recommends hydraulic oil be changed every 500 hours under normal conditions and filters be changed at least every 250 hours of operation. Oil sampling and testing can be very helpful in determining a proper maintenance schedule for your application and environment, or if a change in viscosity is needed.

Hydraulic Oil Cleanliness

Tech Tip TT-904

Models Effected: All Hydraulic Systems

Subject:

One of the most common factors of poor performance and damage to a hydraulic system is also one of the easiest to avoid - dirty hydraulic fluid. Although invisible to the naked eye, germ size particles at high counts are detrimental to the performance of close tolerance valves and system components. A single large particle or an accumulation of small particles may cause valve control to become erratic. The presence of many small particles also leads to shortened pump, motor, and actuator life by causing accelerated wear to seals and bearings.

Description:

Contamination enters a system in many ways. The following are some of the most common:

- Built In Contamination – Typical built-in contaminants include metal burrs, dust, lint from rags, and sealant which can be introduced into the system during the assembly process.

- New Oil – New oil is not necessarily clean oil and should be pre-filtered before it is put into the machine. Improperly cleaned reservoirs contain contaminants that mix with the new oil and are recirculated into the system.

- Environmental Contamination – Dust, dirt, and other airborne contaminants typically found in manufacturing environments can enter a system through exposed cylinder rods. Removal of any cap, cover, plug or line connection will expose a system to environmental contaminants.

- Generated Contamination – Even the best maintained machine in the cleanest environment will have contamination introduced from the normal wear of components and degradation of oil. Exposure to the sources described above will accelerate the generation of contaminants.

Recommendation:

Proper monitoring and maintenance of system fluids can improve operating performance more than any other single factor. BHS recommends to change oil filters (20 micron or better) at least every 250 hours of operation and to change hydraulic oil every 500 hours under normal conditions. Oil sampling and testing can be very helpful in determining a proper maintenance schedule for your application and environment.

Trimming Powered Rollers

Tech Tip TT-905

Models Affected: BE-SL,DS,TS & QS Models

Subject:

Trimming the plastic coating on powered rollers for battery extractors.

Description: