IOP-050 BTC

Looking for a specific replacement part? Ctrl-F (or Command-F for Mac users) brings up your browsers search panel and can search any text on the entire web page. Find parts by searching a part # or part description.

Register your equipment with BHS Optima, BHS's free app.

California Residents: WARNING: This product contains chemicals known to the State of California to cause cancer and/or reproductive harm, and birth defects or other reproductive harm. Learn more here.

Battery Transfer Carriage (BTC) Parts & Service Manual

TP-619 - SAFETY AND DE-ENERGIZATION PROCEDURES

GENERAL INFORMATION

The Battery Transfer Carriage (BTC) is used to remove large batteries from electric industrial trucks.

The BTC is either freely maneuvered on casters by a person at the rear of the BTC by pushing/pulling on the handles of the unit or sideways along a designated travel path by a person at either side of the unit pushing/pulling on a handle of the unit.

The BTC can be one of a possible three operating types / options:

- Fully Mechanical Unit - The unit is raised and lowered using a manual, hydraulic jack located at the rear of the unit. The battery is manipulated by either A) a hand winch located at the rear of the unit that is attached to the battery and retracted, pulling the battery onto the unit while physically pushing the battery by hand off of the unit or B) an extractor arm that moves inward and outward using a hand wheel located on the left, rear of the unit to push or pull the battery on and off the unit.

- Fully Electric Unit - The unit has a fully enclosed, self contained, electrically powered, hydraulic power unit located on the right, rear of the unit. Power is supplied by a 12VDC battery located on the left, rear of the unit. The power unit provides power to raise the unit using a hydraulic cylinder and power to move the extractor arm inward and outward using a hydraulic motor. The lift and extraction functions are controlled by individual manual lever valves located within the power unit housing. This unit may be equipped with an optional vacuum extraction which has a vacuum pump located between the push handles at the rear of the unit powered by the DC battery.

- Partially Electric Unit - The unit is a combination of either mechanical extraction and electric lift or electric extraction and mechanical lift. Operation of this unit is a combination of each type listed above.

GENERAL SAFETY

- Read and understand all instructions and warnings before using or servicing this equipment.

- Keep these instructions for future reference.

- Battery Transfer Carriage (BTC) units shall only be used indoors in an industrial setting on a hard, nonslip, and level floor without defects including but not limited to holes, gouges, cracks, drains or obstacles comprised of concrete or other suitable industrial material.

- Forces required to operate the BTC vary with weight of the load, floor conditions, and carriage conditions.

- BTC units are not designed to be shipped or transported after initial delivery.

- A licensed structural engineer should be consulted prior to installing a BTC on any building level other than the ground floor.

- Perform system and safety check before operating.

- Failure to follow these instructions and warnings may result in property damage, personal injury or death.

WORK AREA

- Keep work area clean and well lit. Cluttered work areas and poor lighting can lead to accidents.

- Clean up/contain any fl uid spills immediately to prevent slips or falls.

- Be aware of potential hazards when performing any service or maintenance to the unit.

SERVICE & MAINTENANCE

Service personnel shall wear Personal Protective Equipment (PPE) appropriate for the task being performed.

LOCKOUT/TAGOUT

Lockout/tagout the BTC per your corporate policy, if damaged or not functioning properly. Lockout/tagout and de-energize all systems prior to performing any maintenance or service to unit.

LEAD-ACID BATTERIES-EXPLOSION HAZARD

Do not allow open flames or sparks of any kind near a battery. Highly explosive gas is generated when charging a battery that can remain in battery cells for extended periods of time after charging is complete.

- Always wear appropriate PPE including rubber apron, gloves, boots and full face shield when performing service or maintenance to any lead-acid batteries.

- Do not place metal or other conductive objects on top of battery. Arcing may occur causing damage to the battery and/or serious personal injury or death.

- Use only chargers matching the voltage and amperage of the battery being charged. Overcharging a battery can cause damage to the battery, charger and/or serious personal injury or death.

- Turn off charger before disconnecting battery from charger. Arcing between battery and charger connectors can cause damage to the connectors and/or serious personal injury or death.

HYDRAULIC HAZARD

AVOID HIGH PRESSURE FLUIDS-Escaping fluid under pressure can penetrate the skin causing serious injury. Relieve pressure before disconnecting hydraulic lines. Tighten all connections before applying pressure. Keep hands and body away from pin holes which eject fluids under high pressure. Use a piece of cardboard or paper to search for leaks. DO NOT use your hand.

Any fluid injected into the skin under high pressure should be considered a serious medical emergency despite an initial normal appearance of the skin. There will be a delayed onset of pain, and serious tissue damage may occur. Medical attention should be sought immediately.

OPERATIONAL SAFETY

OPERATIONAL SAFETY

- Only personnel trained in the proper and safe operation of BTC units may operate or service the BTC.

- Operators shall wear appropriate PPE suitable for working with industrial lead-acid batteries while operating the BTC (see prior page).

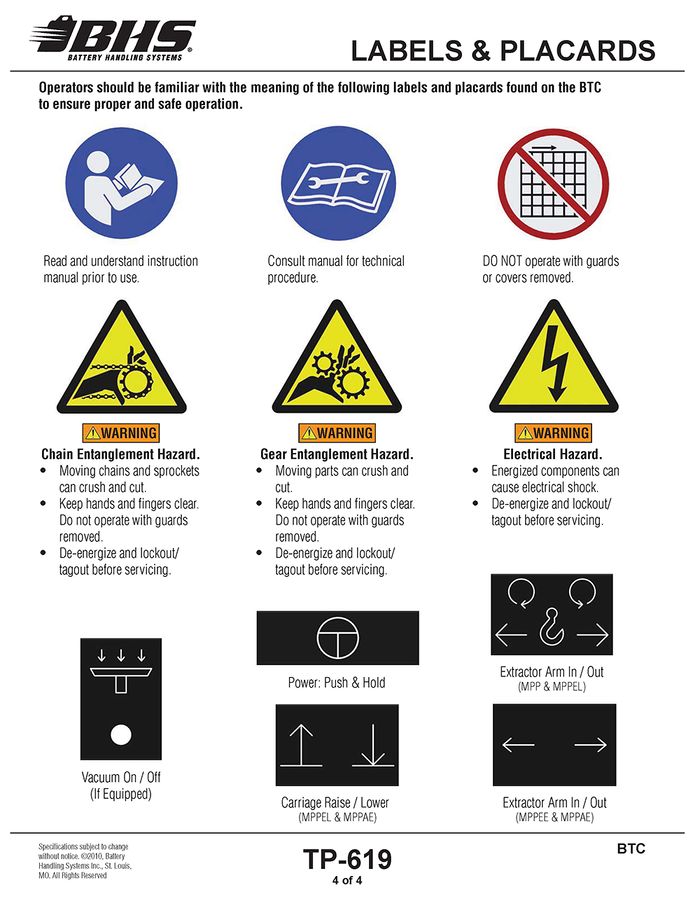

- All data plates, warning labels, placards, etc. shall be in place and legible at all times. Contact BHS for replacement data plates, warning labels, placards or instructions.

- All users and service personnel shall be familiar with the meaning and risks associated with all data plates, warning labels, etc.

- All operators and service personnel shall be aware of potential crush and shear points while operating or servicing the BTC, including the casters and brakes.

- BTC should be operated in an area with ambient light levels of at least 50 lux.

- Keep hands and arms out of the battery compartment while operating the BTC.

- Engage the battery stop(s) and properly secure the battery prior to transporting the battery.

- Attach the hook and chain (if equipped) to the battery prior to transporting the battery.

- Avoid abrupt changes in direction when transporting a battery in the BTC to prevent loss of the battery and/or loss of control of the BTC.

- Remove BTC from service if damaged, defective, or operating improperly (or becomes such while operating) until repairs can be made to correct any problem(s).

DO’s AND DON’T’s

- DO NOT exceed the maximum capacity of the BTC.

- DO NOT modify or fit the BTC with attachments without prior, written approval from BHS.

- DO NOT perform any maintenance or service to the BTC with a battery loaded on the BTC.

- DO NOT allow anyone to ride in or on the BTC.

- DO NOT operate the BTC with any guard or cover removed unless required for maintenance or repair.

- DO NOT travel with the stop bar in the raised position.

- DO NOT lower the inside frame on any person or object.

- Disconnect the battery (if equipped) before attempting to perform service or maintenance to the BTC.

- DO NOT use the BTC in a manner for which it is not intended. Some examples of prohibited use are but not limited to:

- As a scooter or to transport people

- As a vehicle jack

- To lift loads greater than its rated load capacity

- Where unintentional movement may exist

- Having direct contact with foodstuff

- In a potentially explosive atmosphere

DE-ENERGIZATION

BTC/BTC-MPP:

- Turn the pump release handle counterclockwise to lower the inner carriage and release hydraulic pressure. See Figure 1

Failure to lower the inner carriage when performing service to the BTC could result in injury from the roller bed lowering unexpectedly.

FIGURE 1

BTC-MPPEL/MPPEE/MPPAE:

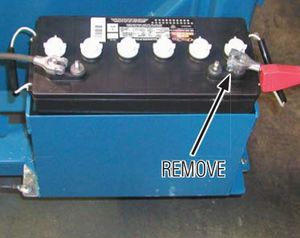

- Unplug the battery charger (if equipped).

- Disconnect the positive cable from the battery post. Secure the positive cable so it cannot contact the positive battery post. See Figure 2.

- Cycle the manual valves several times to relieve stored hydraulic pressure. See Figure 3.

Failure to disconnect electrical power to the BTC could result in electrical shock.

FIGURE 2

Failure to release any stored hydraulic pressure could result in injury from: Escaping hydraulic fluid under high pressure (see HYDRAULIC HAZARDS in the GENERAL SAFETY section). Unexpected movement of hydraulic components.

FIGURE 3

LABELS & PLACARDS

GENERAL INFORMATION

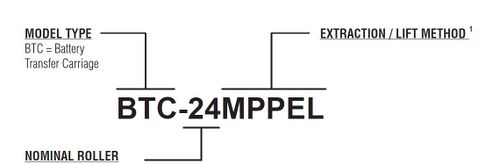

MODEL NUMBER & OPTIONS

NOMINAL ROLLER COMPARTMENT WIDTH

18 = 18" Wide Compartment

24 = 24" Wide Compartment

30 = 30" Wide Compartment

EXTRACTION / LIFT METHOD 1

MPP = Mechanical Push/Pull - Mechanical Lift MPPEL = Mechanical Push/Pull - Electric Lift MPPEE = Electric Push/Pull - Mechanical Lift

MPPAE = Electric Push/Pull - Electric Lift (All Electric)

CANTILEVER / ROLLER BED EXTENSION 2

CAN-7 = 7" Extension At Top, No Roller Bed Extension CAN-7-6 = 7" Extension At Top, 6" Roller Bed Extension CAN-14-6 = 14" Extension At Top, 6" Roller Bed Extension

ADDITIONAL OPTIONS

RB-OPT = Rubber Bumpers

TM = Track Mount (used in conjunction with optional guidance track) PA = Push Arm Extension (Hook and chain models only)

VAC = Vacuum Extraction

CHGR = Self Contained Charger (Electric models only) RGD = Rubber Guard Kit

EC = Extra Capacity (Increases capacity to 3400 lbs) 3

NS = Non-Standard Option 3

1 If no extraction / lift method is listed (e.g. MPP, MPPAE, etc.) the unit is equipped with hand winch extraction and mechanical lift.

2 If no cantilever option is listed (e.g. CAN-7) the unit is considered to be "standard" with no arm travel extension or roller bed extension.

3 Consult factory for units with EC or NS options as components may be completely unique to the particular unit.

Specifications subject to change without notice. ©2009-2010, Battery Handling Systems Inc., St. Louis, MO. All Rights Reserved.

SPECIFICATIONS

Product Specifications - Imperial / Metric

MPPAE | MPPEL | MPPEE | MPP | |

Max. Load Capacity 1 | 3,000 lb / 1360 kg | 3,000 lb / 1360 kg | 3,000 lb / 1360 kg | 3,000 lb / 1360 kg |

Voltage Requirement | 12 VDC | 12 VDC | 12 VDC | N/A |

Hydraulic Pump | 1.3 GPM / 4.6 LPM | 1.3 GPM / 4.6 LPM | 1.3 GPM / 4.6 LPM | N/A |

Extractor Arm Travel Speed | 0 - 20 FPM / 0-.10 m/s | N/A | 0 - 20 FPM / 0-.10 m/s | N/A |

Battery Attachment | Hook & Chain | Hook & Chain | Hook & Chain | Hook & Chain |

Optional Vacuum | Yes | N/A | Yes | N/A |

Primary Drive Reduction | N/A | 4.5 to 1 | N/A | 4.5 to 1 |

Primary Drive Chain Size | #50 | #50 | #50 | # 50 |

Roller Diameter | 2.4” / 61 mm | 2.4” / 61 mm | 2.4” / 61 mm | 2.4” / 61 mm |

Roller Shaft Size | 7/16” / 11 mm Hex (Model 18) 7/16” / 11 mm Hex (Model 24) 3/4” / 19 mm Hex (Model 30) | 7/16” / 11 mm Hex (Model 18) 7/16” / 11 mm Hex (Model 24) 3/4” / 19 mm Hex (Model 30) | 7/16” / 11 mm Hex (Model 18) 7/16” / 11 mm Hex (Model 24) 3/4” / 19 mm Hex (Model 30) | 7/16” / 11 mm Hex (Model 18) 7/16” / 11 mm Hex (Model 24) 3/4” / 19 mm Hex (Model 30) |

Maximum Battery Width | 17” / 430 mm 23” / 580 mm 29” / 735 mm | 17” / 430 mm 23” / 580 mm 29” / 735 mm | 17” / 430 mm 23” / 580 mm 29” / 735 mm | 17” / 430 mm 23” / 580 mm 29” / 735 mm |

Battery Length | 25” to 39.75” 635 to 1010 mm | 25” to 39.75” 635 to 1010 mm | 25” to 39.75” 635 to 1010 mm | 25” to 39.75” 635 to 1010 mm |

Min. Battery Height | 20” / 500 mm | 20” / 500 mm | 20” / 500 mm | 20” / 500 mm |

Overall Length2 | 67” / 1700 mm | 67” / 1700 mm | 67” / 1700 mm | 67” / 1700 mm |

Overall Width | 46.5” / 1180 mm (Model 18) 52.5” / 1335 mm (Model 24) 58.5” / 1485 mm (Model 30) | 46.5” / 1180 mm (Model 18) 52.5” / 1335 mm (Model 24) 58.5” / 1485 mm (Model 30) | 46.5” / 1180 mm (Model 18) 52.5” / 1335 mm (Model 24) 58.5” / 1485 mm (Model 30) | 38.5” / 975 mm (Model 18) 44.5” / 1130 mm (Model 24) 50.5” / 1280 mm (Model 30) |

Overall Height | 65.5” / 1665 mm | 65.5” / 1665 mm | 65.5” / 1665 mm | 65.5” / 1665 mm |

Roller Height Service Range | 5.5” - 21.5” 140 - 545 mm | 5.5” - 21.5” 140 - 545 mm | 5.5” - 23.5” 140 - 595 mm | 5.5” - 23.5” 140 - 595 mm |

Roller Width (Nominal) | 18” / 445 mm (Model 18) 24” / 610 mm (Model 24) 30” / 760 mm (Model 30) | 18” / 445 mm (Model 18) 24” / 610 mm (Model 24) 30” / 760 mm (Model 30) | 18” / 445 mm (Model 18) 24” / 610 mm (Model 24) 30” / 760 mm (Model 30) | 18” / 445 mm (Model 18) 24” / 610 mm (Model 24) 30” / 760 mm (Model 30) |

Extended Arm Reach3 (Beyond Roller Bed) | 6” / 152 mm | 6” / 152 mm | 6” / 152 mm | 6” / 152 mm |

Service Weight (unloaded) | 1050 lb / 480 kg (Model 18) 1128 lb / 515 kg (Model 24) 1135 lb / 520 kg (Model 30) | 945 lb / 430 kg (Model 18) 960 lb / 440 kg (Model 24) 1090 lb / 500 kg (Model 30) | 850 lb / 390 kg (Model 18) 934 lb / 425 kg Model 24) 1060 lb / 485 kg (Model 30) | 718 lb / 330 kg (Model 18) 748 lb / 340 kg (Model 24) 960 lb / 440 kg (Model 30) |

Maximum Load Capacity based on 39” Battery Length

Not including cantilever or roller bed extension options

Not including any roller bed extension options

Specifications are subject to change without notice.

©2009, Battery Handling Systems Inc. St. Louis, MO

Data Sheet: SF-500 07/09

INSTALLATION

The following describes the basic installation procedures for the BTC battery transfer carriage.

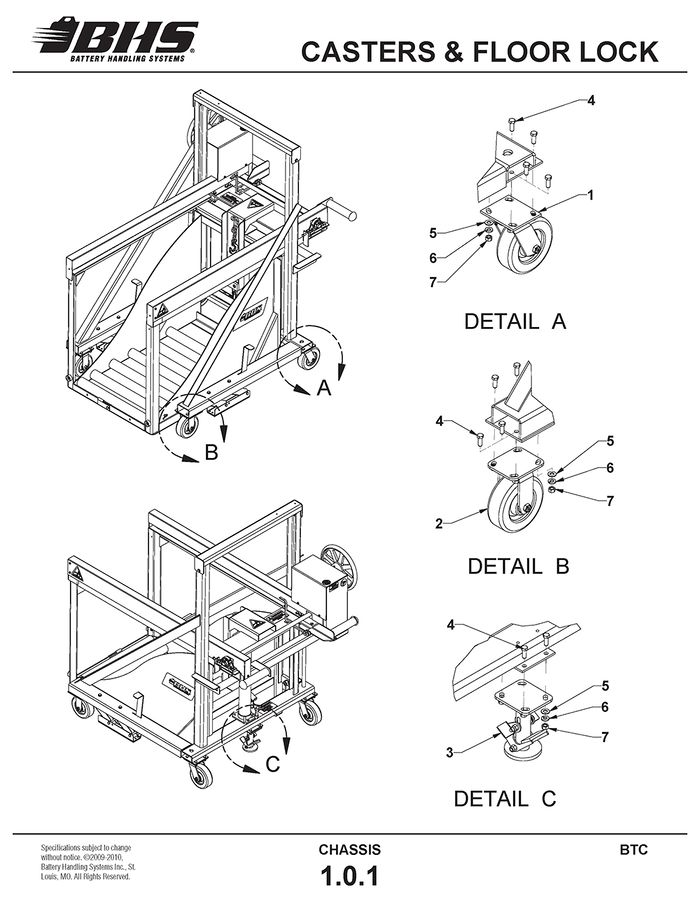

- Once the carriage has been removed from the shipping 1. pallet, the floor lock(s) must be attached. The floor lock is attached to the lower frame on the operator side below the lift cylinder with the supplied hardware. See Figures 1 - 3. Notes: BTC-30 units have two floor locks. The floor lock is only to be used when parking the carriage when not in use.

- Ensure that the lift cylinder is properly aligned with the hole located on the underside of the inner frame. This will ensure safe, even lifting. See Figure 4.

- Winch units only: Unbolt the winch support and reposition it toward the rear of the unit. See Figure 5.

- Electric units only: Connect the positive cable to the positive terminal of the battery. See Figure 6. Note: The battery must be disconnected prior to charging.

- The carriage is now ready for use.

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

FIGURE 5

FIGURE 6

OPERATING CONTROLS

The following is a brief operational overview of the BTC.

-

EXTRACTION CONTROLS

- Winch Extraction - Rotate the winch handle counterclockwise to extend the winch strap and rotate the winch handle clockwise to retract the winch strap. Winch direction is changed by switching the lever at the rear of the winch. See Figure 7

- Mechanical Extraction - Turn the hand wheel counterclockwise to extend the extractor arm toward the lift truck or battery stand and clockwise to retract the extractor arm. See Figure 8. Note: The extractor arm latch must be raised to move the arm when fully retracted. See Figure 9.

- Electric Extraction - With the green power button depressed, push the extraction valve handle to the right to extend the extractor arm toward the lift truck or battery stand and push the valve handle to the left to retract the extractor arm. See Figure 10.

- Vacuum (if equipped) - Pull up the vacuum switch to energize the vacuum pump and push down to de-energize the vacuum pump. LIFT CONTROLS

- Mechanical Lift - Insert the jack handle into the jack handle socket and pump the jack handle up and down to raise the inner carriage. To lower the inner carriage, slowly turn the release handle located at the base of the manual jack counterclockwise. Turn the release handle clockwise to stop lowering the inner carriage. See Figures 11 & 12.

- Electric Lift - With the green power button depressed, push the lift valve handle to the left to raise the inner carriage and push the valve handle to the right to lower the inner carriage. See Figure 13.

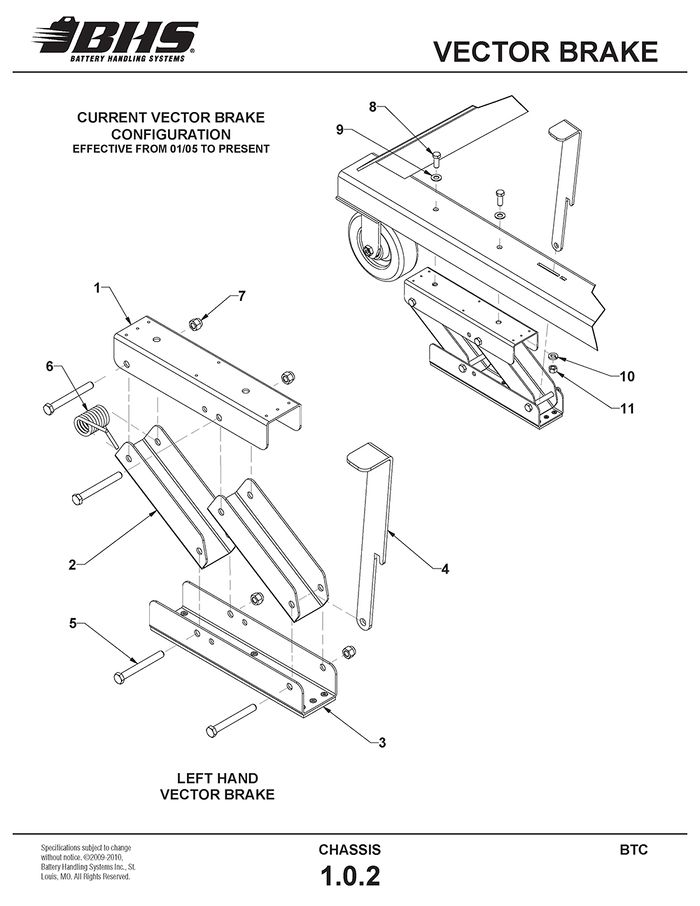

- Vector Brakes - The vector brakes are used when transferring batteries from the BTC to the industrial truck or battery stand. To engage the vector brake, lift the release handle up and slide it forward allowing the vector brake to lower to the floor. To disengage, lift the release handle up until the notch in the release handle is allowed to move rearward, locking the brake in the raised position. See Figures 14 & 15.

- Floor Lock - The floor lock is to be used any time the BTC is left unattended. DO NOT use the floor lock during the change out process. To engage the floor lock, press down on the pedal with your foot. To disengage, press either of the two release tabs on the side of the floor lock with your foot. See Figure 16.

- Extractor Arm - Verify proper arm travel by slowly moving the extractor arm fully in and out of the battery compartment.

- Lift - Verify proper lift by slowly raising and lowering the inner carriage through the entire lift range.

- Vector Brakes - Verify operation by engaging and disengaging the vector brake to ensure smooth operation and verify complete contact of the brake pad with the floor. While engaged, carefully pull rearward on the cart to ensure proper engagement of the vector brakes. Note: When unloaded, it is normal for the front casters of the carriage to lift off the floor as the vector brakes engage.

- Floor Lock - Verify operation by engaging the floor lock and ensure the carriage cannot move when pushed or pulled with moderate force.

- Vacuum (if equipped) - Verify the vacuum pump energizes and there is suction at the vacuum port of the vacuum cup.

FIGURE 7

FIGURE 8

FIGURE 9

FIGURE 10

FIGURE 11

FIGURE 12

FIGURE 13

BRAKES

FIGURE 14

FIGURE 15

FIGURE 16

OPERATIONAL TEST

After the initial installation has been completed or any service to the unit has been performed, an operational test should be conducted to ensure proper functions of the unit prior to returning the BTC back into service.

OPERATING INSTRUCTIONS

The following instructions will guide you through the basic steps necessary to operate and change batteries with a BTC.

Operators must be equipped with all necessary PPE and be properly trained in handling industrial lead-acid lift truck batteries.

- If not already in place, position industrial truck (pallet or lift truck) which requires a battery change in the appropriate staging area.

- Disconnect the battery leads and remove any battery restraints.

- Move the BTC into position such that the roller compartment of the BTC is aligned with the battery compartment of the industrial truck.

- Verify the battery safety stop at the end of the BTC roller bed is in the down position.

- Adjust the vertical height of the BTC battery compartment to the battery compartment of the industrial truck or slightly higher. [DO NOT exceed 1/4" difference.].

- Once the proper height is achieved, the extractor arm can be moved toward the lift truck battery.

Hook and Chain - Stop the extractor arm approximately 3" - 4" from the battery.

Vacuum Extraction - Bring the vacuum cup in contact with the battery. DO NOT force the extractor arm into the battery once contact is made. - For hook and chain units, attach the hook securely through the lifting eye of the battery and ensure full engagement. See Figure 17. For vacuum units, energize the vacuum.

- Slowly begin removing the battery from the industrial truck battery compartment while inspecting the vertical alignment of both battery compartments. If vertical adjustment is required, disengage the vacuum cup (if equipped) prior to adjusting the height of the BTC.

- Once the battery is entirely inside the BTC battery compartment, move the battery safety stop to the upright position. For electric units, secure the battery for transport by moving the battery forward using the extractor arm to “pin” the battery between the extractor arm and battery stop to prevent the battery from rocking front to back. If equipped, turn off the vacuum.

- The battery may now be transported to the charging area.

Note: When possible, always push carriage so as to not create a hazard should you slip while pulling the carriage. Batteries are heavy and could cause personal injury under such conditions. - Align the BTC with an open roller compartment in the battery charging area.

- Adjust the vertical height as needed for alignment with the battery stand.

- Engage both vector brakes.

- Lower the battery safety stop at the front of the carriage.

- Slowly move the battery from the BTC into the battery stand. For vacuum equipped units, it is not necessary to energize the vacuum for this step.

- After transfer, raise the battery stop on the stand and disconnect the hook from the battery. DO NOT force the extractor arm into the battery after the battery is completely in the stand.

- Reposition the BTC at the location of the newly charged battery to be installed in the lift truck.

- The above process can be used to remove a battery from the roller stand to be installed into the industrial truck.

- After completing battery changes, the floor lock(s) should be engaged prior to leaving the BTC unattended. As with all material handling equipment, the transfer carriage should be inspected prior to each use for any visual damage. It should also undergo a routine inspection by trained maintenance personnel to verify and maintain the load capacity of the unit.

FIGURE 17

MANUAL UNLOADING

Lockout/tagout and de-energize all equipment prior to manually unloading any battery.

In the event of power loss or an operational malfunction of the BTC not allowing the battery to be unloaded using normal operating procedures, it is recommended the battery be removed from the BTC using certified and approved vertical extraction methods and devices.

Read, understand and observe all safety warnings and procedures related to the vertical extraction device(s) being used.

If certified and approved vertical extraction methods and/or devices are not available and the unit’s casters and lift/lower functions operate normally, the battery may be unloaded by hand as follows:

1. Move the BTC into position such that the roller compartment of the BTC is aligned with an empty battery stand roller compartment. Verify the battery safety stop(s) of the empty roller compartment is in the down position.

2. Engage the vector brakes on both sides of the BTC.

3. Adjust the vertical height of the BTC roller compartment with the empty roller compartment or slightly higher. DO NOT exceed 1/4” difference. Verify the battery safety stop(s) at the end of the BTC roller bed is in the down position.

4. Carefully push the battery by hand from the BTC into the battery stand. Move the battery safety stop(s) of the battery stand to the up position.

Hand position should be carefully selected to prevent accidental crushing. Maintain a secure footing to prevent slips, trips or falls.

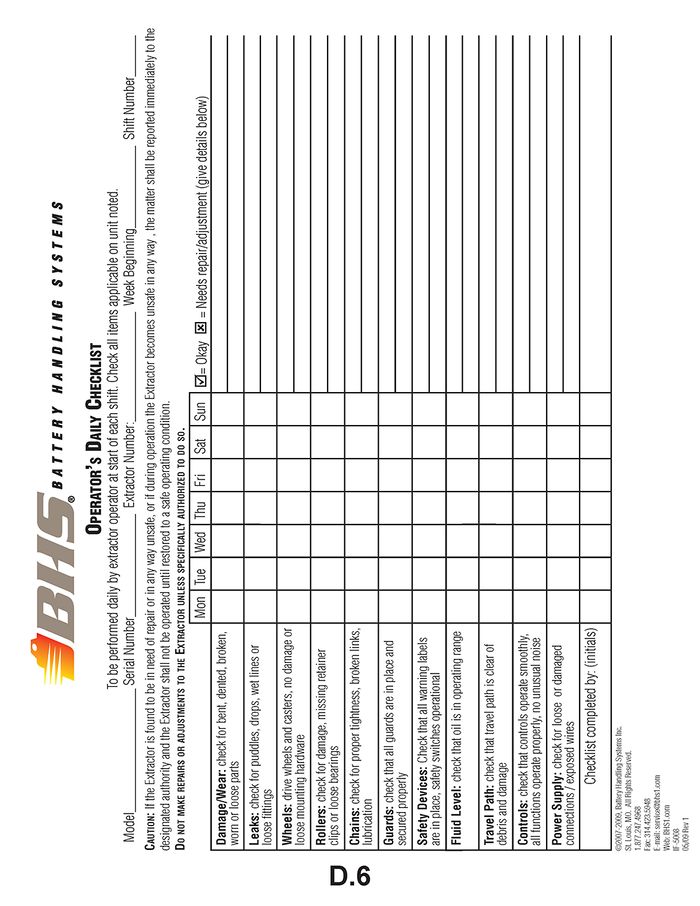

OPERATOR’S DAILY CHECKLIST

SERVICE & MAINTENANCE

The following items are recommended by the factory to have on hand for BTC models to minimize any downtime due to minor breakdown that may occur under normal operating conditions.

BHS PART NUMBER | DESCRIPTION | QTY | REFERENCE SECTION | NOTES |

80122001 | CASTER KIT | 1 | 1.0.1 | BTC-18 & 24 UNITS |

80122002 | CASTER KIT | 1 | 1.0.1 | BTC-30 UNITS |

80152002 | HAND WHEEL KIT | 1 | 1.1.1 | |

80052005 | SLIDE BLOCK KIT | 1 | 1.1.3 | |

80812001 | BATTERY STOP KIT | 1 | 1.2.1 | |

08092001 | HOOK AND CHAIN ASSEMBLY | 1 | 2.0.1 | |

E0009-2 | SOLENOID-12VDC | 1 | 3.0.1 | ELECTRIC UNITS ONLY |

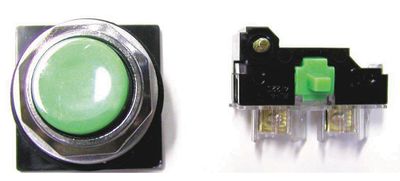

80032001 | PUSH BUTTON ASSEMBLY | 1 | 4.1.1 | |

E0302 | SWITCH-PULL | 1 | 5.5.1 | VACUUM UNITS ONLY |

00162001 | VACUUM CUP-10" | 1 | 5.5.3 | |

HW-KIT-1 | STUD KIT-VACUUM | 1 | 5.5.3 | |

P0301-1 | HOSE-COIL-VACUUM | 1 | 5.5.3 |

Use only BHS approved replacement parts.

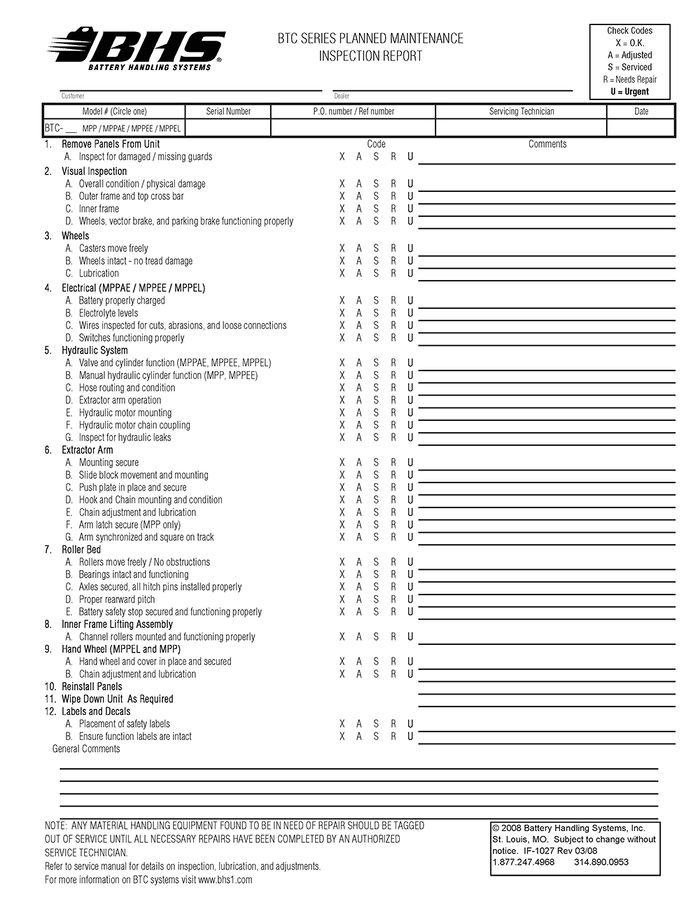

BHS recommends that a full maintenance inspection report similar to the one provided be done at least once a month.

Any parts found to be excessively worn or damaged should promptly be replaced unless said parts pose a safety risk to the operator and/or extractor, in which case the unit should be removed from service until the problem(s) are remedied (See Operator’s Daily Checklist.)

“READY” STATUS INDICATOR LIGHT

BTC electric motors are protected by an internal thermal switch. If the motor gets too hot, the switch will open so the motor will not operate. When this happens the green light will not be lit. This switch will reset automatically and the light will be lit again when the motor has cooled sufficiently.

The unit is “Ready” for use when the green light is lit. If the light is not lit, check the following:

1. Verify the battery voltage is the same as listed on the serial plate.

2. Verify the correct polarity at the light terminals.

If both these items are correct, then the thermal switch may have opened. Let the motor cool for about 30 minutes and check the green light again. If the green light does not come on, call for service.

HYDRAULIC SYSTEM

For electric units, the reservoir should be filled within 1" of the top of the reservoir with approximately 0.8 Gal / 3.0 L of Chevron hydraulic oil AW ISO 32 or equivalent ISO 32 grade hydraulic oil with anti-wear additives and foam suppressant.

NOTE: It is not necessary to bleed the system after filling the unit.

DISPOSAL OF WASTE MATERIAL

Dispose of all fluids and waste according to local regulations.

BTC SERIES PLANNED MAINTENANCE INSPECTION REPORT

PARTS SECTIONS

CHASSIS

CASTERS & FLOOR LOCK

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | C0020 | CASTER-6" X 2"-SWIVEL | † | 2 | |

2 | C0015 | CASTER-6" X 2"-RIGID | † | 2 | |

3 | C0010-1 | FLOOR LOCK | † | BTC-18 & 24 | 1 |

BTC-30 ONLY | 2 | ||||

4 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | † | BTC-18 & 24 | 20 |

BTC-30 ONLY | 24 | ||||

5 | HW0108 | WASHER-FLAT-3/8"-SAE | † | BTC-18 & 24 | 20 |

BTC-30 ONLY | 24 | ||||

6 | HW0107 | WASHER-LOCK-3/8" | † | BTC-18 & 24 | 20 |

BTC-30 ONLY | 24 | ||||

7 | HW0005 | NUT-HEX-3/8-16 | † | BTC-18 & 24 | 20 |

BTC-30 ONLY | 24 |

† INCLUDED IN MULTIPLE KITS

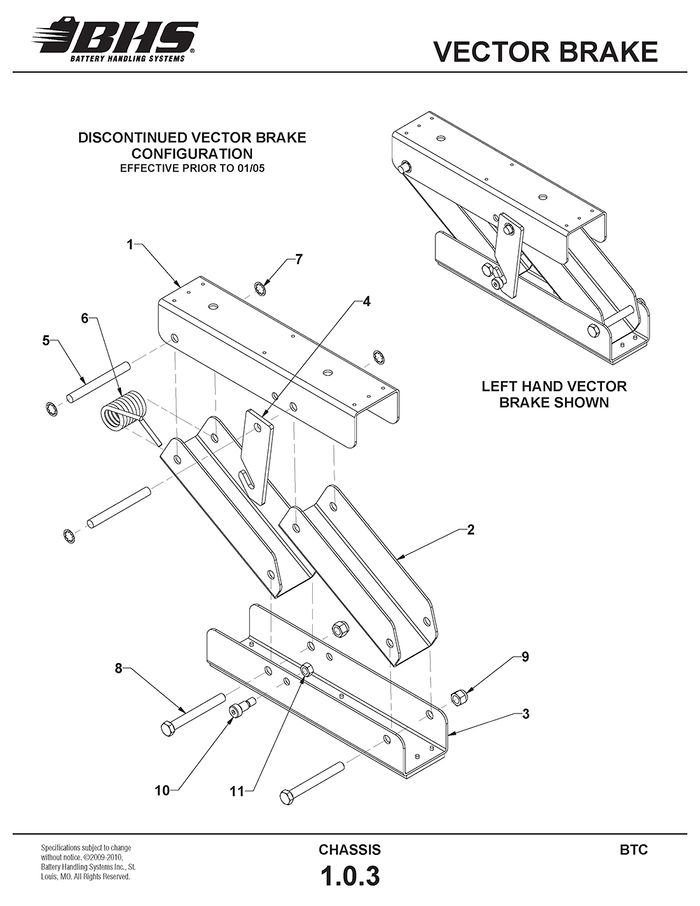

VECTOR BRAKE

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

REF | VB | VECTOR BRAKE ASSEMBLY | HANDLE SOLD SEPARATELY | 2 | |

1 | 05017023-2 | MOUNT-VECTOR BRAKE | 2 | ||

2 | 05017025-2 | ARM-VECTOR BRAKE | 4 | ||

3 | 05012004-B | BRAKE PAD ASSEMBLY | LOWER SHOE W/ RUBBER PAD | 2 | |

4 | 05017085-3 | HANDLE-LHS | 1 | ||

05017085-4 | HANDLE-RHS | 1 | |||

5 | HW0423 | BOLT-HHCS-3/8-16 X 3 1/2" | 8 | ||

6 | HW1003 | SPRING-TORSION | 2 | ||

7 | HW0006 | NUT-NILN-3/8-16 | 8 | ||

8 | HW0402 | BOLT-HHCS-3/8-16 X 1" | 4 | ||

9 | HW0108 | WASHER-FLAT-3/8"-SAE | 4 | ||

10 | HW0107 | WASHER-LOCK-3/8" | 4 | ||

11 | HW0005 | NUT-HEX-3/8-16 | 4 |

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

REF | 80112001 | VECTOR BRAKE KIT | INCL. ITEMS 1-11 | A/R | |

1 | 05017023-2 | MOUNT-VECTOR BRAKE | 80112001 | 2 | |

2 | 05017025-2 | ARM-VECTOR BRAKE | 80112001 | 4 | |

3 | 05012004-B | BRAKE PAD ASSEMBLY | 80112001 | LOWER SHOE W/ RUBBER PAD | 2 |

4 | 05017026 | CLASP-VECTOR BRAKE | 80112001 | 2 | |

5 | 05018010 | PIN-PIVOT | 80112001 | 4 | |

6 | HW1003 | SPRING-TORSION | 80112001 | 2 | |

7 | HW1007 | CLIP RING-STAR-3/8" | 80112001 | 8 | |

8 | HW0423 | BOLT-HHCS-3/8-16 X 3 1/2" | 80112001 | 4 | |

9 | HW0006 | NUT-NILN-3/8-16 | 80112001 | 4 | |

10 | HW1008 | BOLT-SHOULDER-5/16-18 X 1/2" | 80112001 | 3/8" DIA. SHOULDER | 2 |

11 | HW0004 | NUT-HEX-5/16-18 | 80112001 | 2 |

NOTE: VECTOR BRAKES REPLACEMENT KITS SHIPPED ASSEMBLED FOR ONE SIDE ONLY. TO MOUNT ON OPPOSITE SIDE OF UNIT, MOVE CLASP TO OPPOSITE SIDE OF VECTOR BRAKE ASSEMBLY (CLASP SHOULD BE ON OUTER SIDE OF VECTOR BRAKE ASSEMBLY ONCE INSTALLED.)

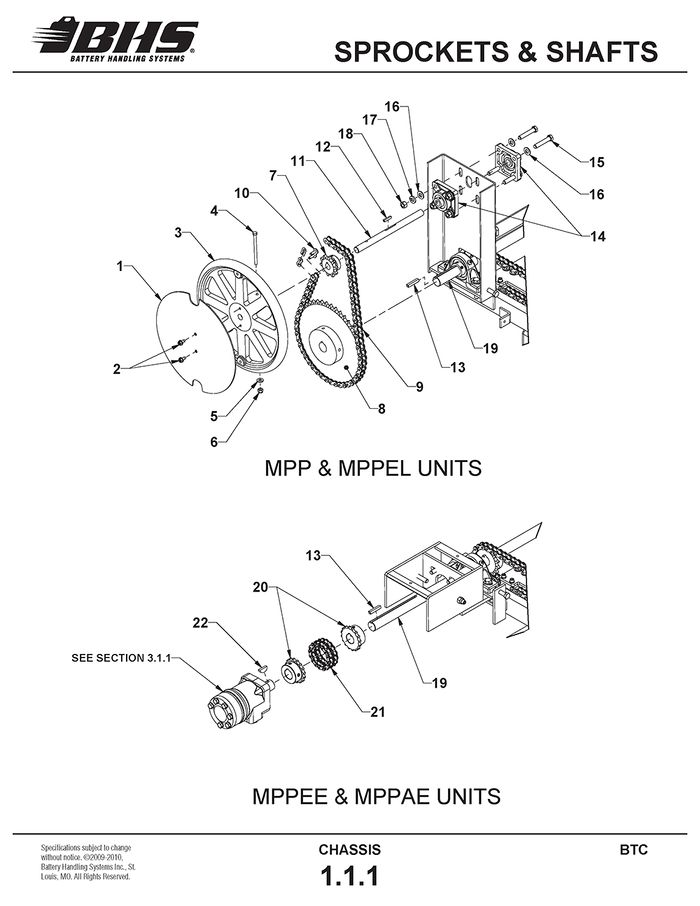

SPROCKETS & SHAFTS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 05017045 | COVER-HAND WHEEL | 80152002 | 1 | |

2 | HW0301 | BOLT-SELF-TAP "F"-1/4-20 X 1/2" | 80152002 | 2 | |

3 | 05026001 | HAND WHEEL | 80152002 | 1 | |

4 | HW0317 | BOLT-HHCS-1/4-20 X 3 1/2" | 80152002 | 1 | |

5 | HW0104 | WASHER-FLAT-1/4"-SAE | 80152002 | 1 | |

6 | HW0003 | NUT-NILN-1/4-20 | 80152002 | 1 | |

7 | PT0105 | SPROCKET-5010 X 5/8" | INCLUDES SET SCREWS | 1 | |

8 | PT0109 | SPROCKET-5045 X 1" | INCLUDES SET SCREWS | 1 | |

9 | 00158001-6 | CHAIN-ROLLER-#50 | 1 | ||

10 | PT0102 | LINK-CONNECTING-#50 | 1 | ||

11 | 05027002 | SHAFT-HAND WHEEL | 80152002 | 1 | |

12 | 00197017 | KEY-3/16" X 1" | 80152002 | 1 | |

13 | 00197018 | KEY-1/4" X 1 1/2" | ONE EACH SIDE | 2 | |

14 | PT0403 | FLANGE BEARING-4 BOLT-5/8" | 2 | ||

15 | HW0405 | BOLT-HHCS-3/8-16 X 2" | 4 | ||

16 | HW0108 | WASHER-FLAT-3/8"-SAE | 8 | ||

17 | HW0107 | WASHER-LOCK-3/8" | 4 | ||

18 | HW0005 | NUT-HEX-3/8-16 | 4 | ||

19 | 05027001 | SHAFT-DRIVE-BTC-18 | MPP & MPPEL (MECHANICAL EXTRACT) | 1 | |

05127001 | SHAFT-DRIVE-BTC-24 | ||||

05227001 | SHAFT-DRIVE-BTC-30 | ||||

05027003 | SHAFT-DRIVE-BTC-18 | MPPEE & MPPAE (ELECTRIC EXTRACT) | |||

05127002 | SHAFT-DRIVE-BTC-24 | ||||

05227003 | SHAFT-DRIVE-BTC-30 | ||||

20 | PT0302-1 | COUPLING BODY-#40 X 1" | 2 | ||

21 | PT0301 | CHAIN-COUPLING | INCL. CONNECTING PIN | 1 | |

22 | HW1071 | KEY-WOODRUFF-#808 STD | INCL. WITH MOTOR | A/R |

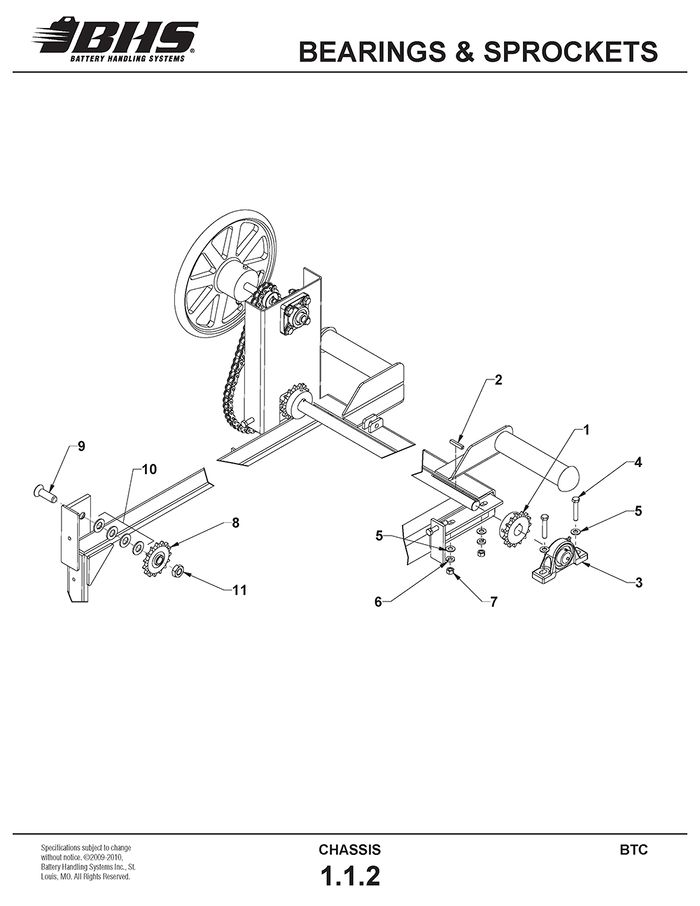

BEARINGS & SPROCKETS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | PT0107 | SPROCKET-5015 X1" | 2 | ||

2 | 00197018 | KEY-1/4" X 1 1/2" | ONE EACH SIDE | 2 | |

3 | PT0401 | BEARING-PILLOW BLOCK-1" | 2 | ||

4 | HW0405 | BOLT-HHCS-3/8-16 X 2" | 4 | ||

5 | HW0108 | WASHER-FLAT-3/8"-SAE | 8 | ||

6 | HW0107 | WASHER-LOCK-3/8" | 4 | ||

7 | HW0005 | NUT-HEX-3/8-16 | 4 | ||

8 | PT0111 | SPROCKET-IDLER-50A15 X 5/8" | 2 | ||

9 | HW0603 | BOLT-FHSCS-5/8-11 X 2" | 2 | ||

10 | HW0114 | WASHER-FLAT-5/8"-SAE | 8 | ||

11 | HW0010 | NUT-JAM-5/8-11 | 2 |

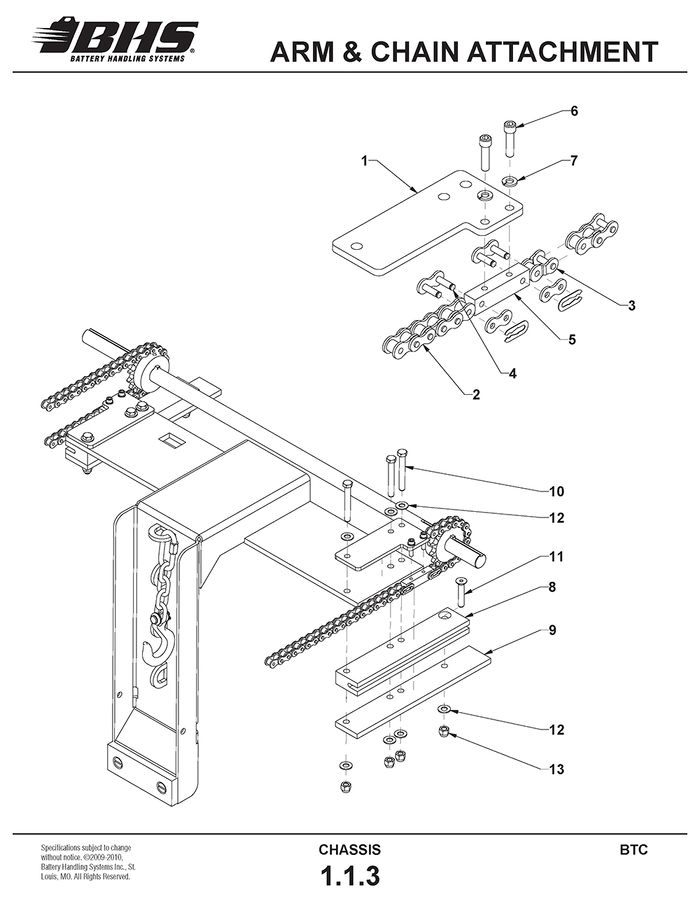

ARM & CHAIN ATTACHMENT

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 05057006 | PLATE-TOP | 2 | ||

2 | 00158001-7 | CHAIN-ROLLER-#50 | STANDARD BTC | 2 | |

00158001-8 | CHAIN-ROLLER-#50 | BTC-CAN-7 | |||

00158001-9 | CHAIN-ROLLER-#50 | BTC-CAN-14 | |||

3 | PT0104 | LINK-OFFSET-#50 | 2 | ||

4 | PT0102 | LINK-CONNECTING-#50 | 4 | ||

5 | 05057005 | BLOCK-PULL | 80052002 | 2 | |

6 | HW0307 | BOLT-SHCS-1/4-20 X 1" | 80052002 | 4 | |

7 | HW0103 | WASHER-LOCK-1/4" | 80052002 | 4 | |

8 | 05056002 | BLOCK-SLIDE | 80052005 | 2 | |

9 | 05057004 | PLATE-BOTTOM | 80052005 | 2 | |

10 | HW0407 | BOLT-HHCS-3/8-16 X 2 3/4" | 80052005 | 6 | |

11 | HW0409 | BOLT-FHSCS-3/8-16 X 2" | 80052005 | 2 | |

12 | HW0108 | WASHER-FLAT-3/8"-SAE | 80052005 | 14 | |

13 | HW0006 | NUT-NILN-3/8-16 | 80052005 | 8 |

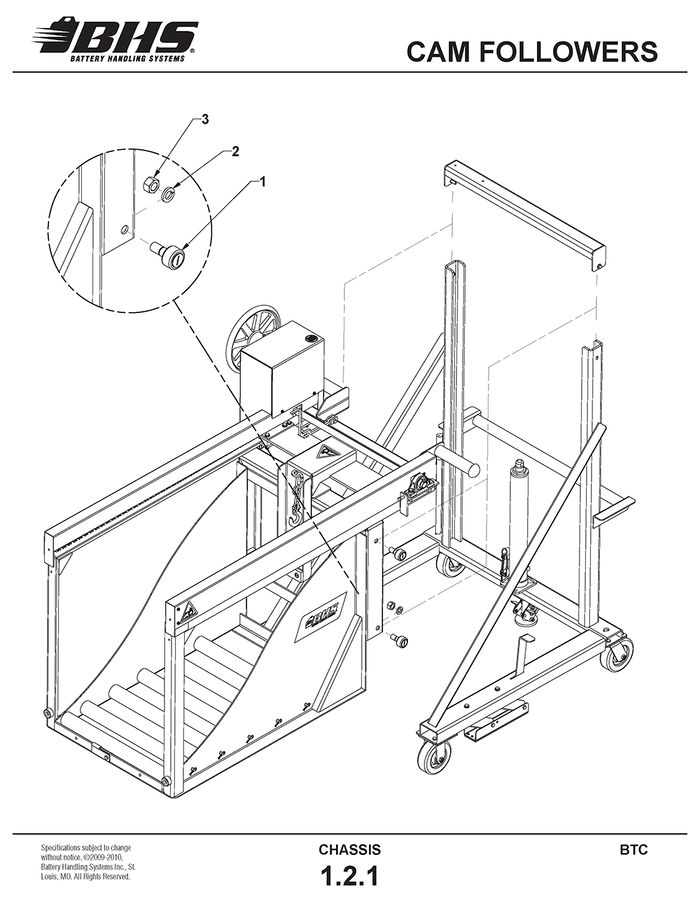

CAM FOLLOWERS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | PT0501 | CAM FOLLOWER | 4 | ||

2 | HW0115 | WASHER-LOCK-3/4" | 4 | ||

3 | HW0011 | NUT-HEX-3/4-16 | 4 |

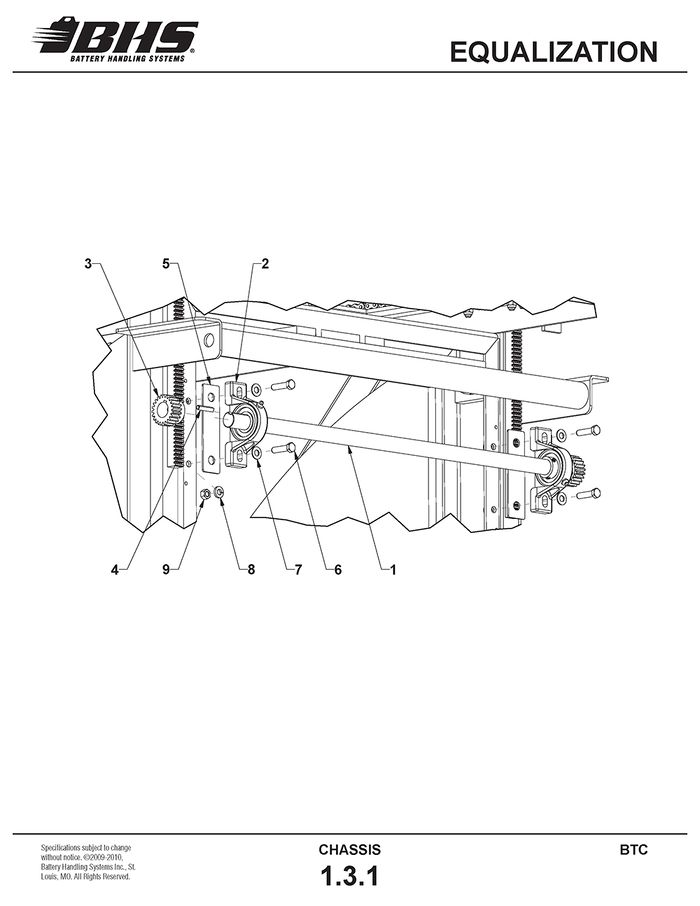

EQUALIZATION

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 05127003 | SHAFT-LIFT EQUALIZATION | BTC-24 | 1 | |

05227002 | SHAFT-LIFT EQUALIZATION | BTC-30 | |||

2 | PT0401 | BEARING-PILLOW BLOCK-1" | 2 | ||

3 | PT0606 | SPUR GEAR-1" | 22 TOOTH | 2 | |

4 | 00197019 | KEY-1/4" X 1 3/8" | 2 | ||

5 | 00197022 | SHIM-BEARING | 2 | ||

6 | HW0404 | BOLT-HHCS-3/8-16 X 1 1/2" | 4 | ||

7 | HW0108 | WASHER-FLAT-3/8"-SAE | 4 | ||

8 | HW0107 | WASHER-LOCK-3/8" | 4 | ||

9 | HW0005 | NUT-HEX-3/8-16 | 4 |

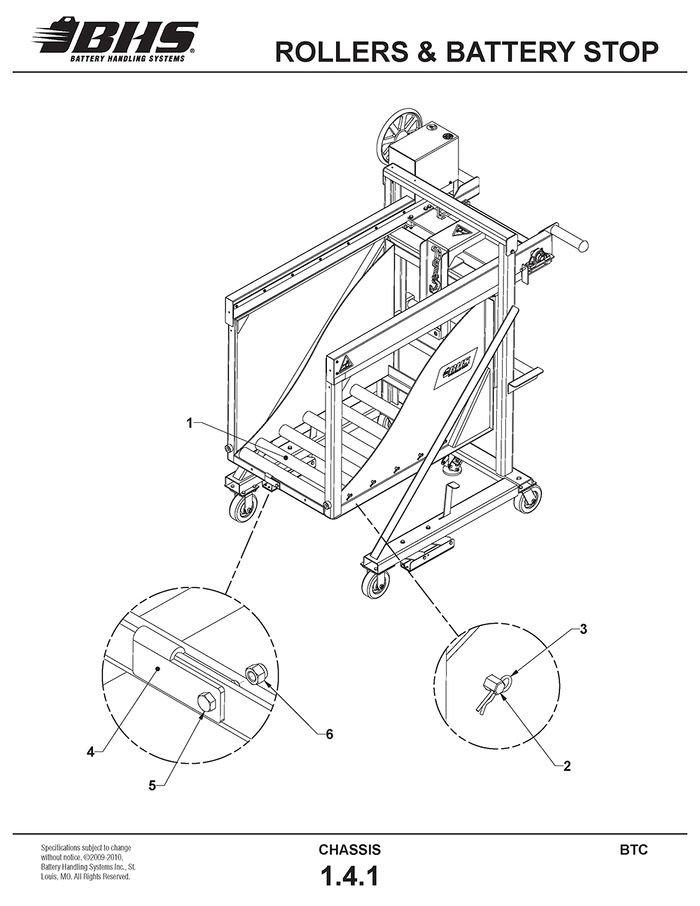

ROLLERS & BATTERY STOP

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 00182003 | ROLLER ASSEMBLY-BTC-18 | 6 | ||

00182005 | ROLLER ASSEMBLY-BTC-24 | ||||

05282001 | ROLLER ASSEMBLY-BTC-30 | ||||

2 | 00187044 | SHAFT-HEX-.438" X 20" | BTC-18 | 6 | |

00187045 | SHAFT-HEX-.438" X 26" | BTC-24 | |||

05287001 | SHAFT-HEX-.75" X 32" | BTC-30 | |||

3 | HW1014-1 | PIN-HITCH | FOR USE WITH .438" HEX SHAFT | 12 | |

HW1058 | PIN-HITCH | FOR USE WITH .75" HEX SHAFT | |||

4 | 00194001 | STOP-BATTERY | 80812001 | 1 | |

5 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | 80812001 | 1 | |

6 | HW0006 | NUT-NILN-3/8-16 | 80812001 | 1 |

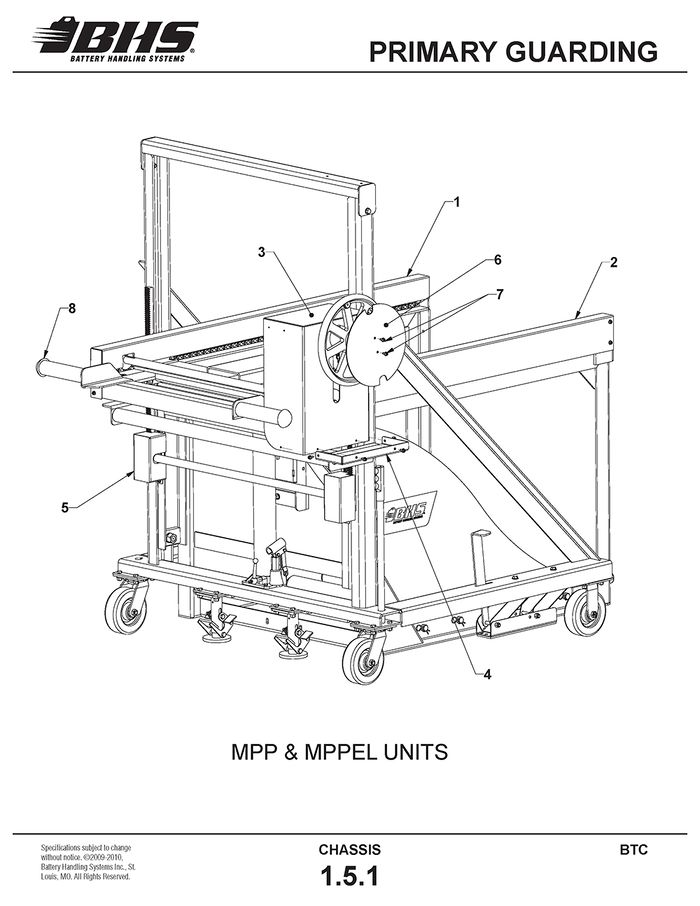

PRIMARY GUARDING

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 05017087-2 | GUARD-CHAIN-LHS | STANDARD BTC | 1 | |

05017097-2 | GUARD-CHAIN-LHS | BTC-CAN-7 | |||

05017098-2 | GUARD-CHAIN-LHS | BTC-CAN-14 | |||

2 | 05015011-2 | GUARD-CHAIN-RHS | STANDARD BTC | 1 | |

05015021-2 | GUARD-CHAIN-RHS | BTC-CAN-7 | |||

05115013-2 | GUARD-CHAIN-RHS | BTC-CAN-14 | |||

3 | 05015009 | GUARD-HAND WHEEL-PRIMARY | 1 | ||

4 | 05017086-2 | GUARD-HAND WHEEL-LOWER | 1 | ||

5 | 05115018 | GUARD-EQUALIZATION SHAFT | 2 | ||

6 | 05017045 | COVER-HAND WHEEL | 1 | ||

7 | HW0301 | BOLT-SELF-TAP "F"-1/4-20 X 1/2" | 21 | ||

8 | PL0401 | CAP-END | 2 |

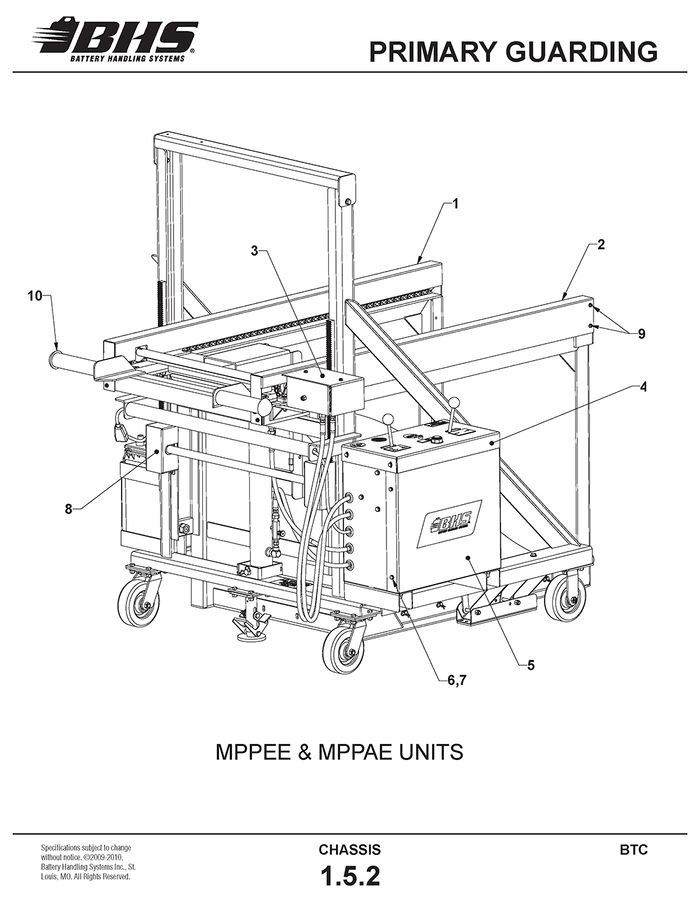

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 05017087-2 | GUARD-CHAIN-LHS | STANDARD BTC | 1 | |

05017097-2 | GUARD-CHAIN-LHS | BTC-CAN-7 | |||

05017098-2 | GUARD-CHAIN-LHS | BTC-CAN-14 | |||

2 | 05015010-2 | GUARD-CHAIN-RHS | STANDARD BTC | 1 | |

05015020-2 | GUARD-CHAIN-RHS | BTC-CAN-7 | |||

05115012-2 | GUARD-CHAIN-RHS | BTC-CAN-14 | |||

3 | 05017077-2 | GUARD-MOTOR | 1 | ||

4 | 05017070-2 | COVER-POWER UNIT | 1 | ||

5 | 05017067-2 | GUARD-POWER UNIT | 1 | ||

6 | HW0303 | BOLT-HHCS-1/4-20 X 1" | 8 | ||

7 | HW0104 | WASHER-LOCK-1/4" | 8 | ||

8 | 05115018 | GUARD-EQUALIZATION SHAFT | 2 | ||

9 | HW0301 | BOLT-SELF-TAP "F"-1/4-20 X 1/2" | 14 | ||

10 | PL0401 | CAP-END | 2 |

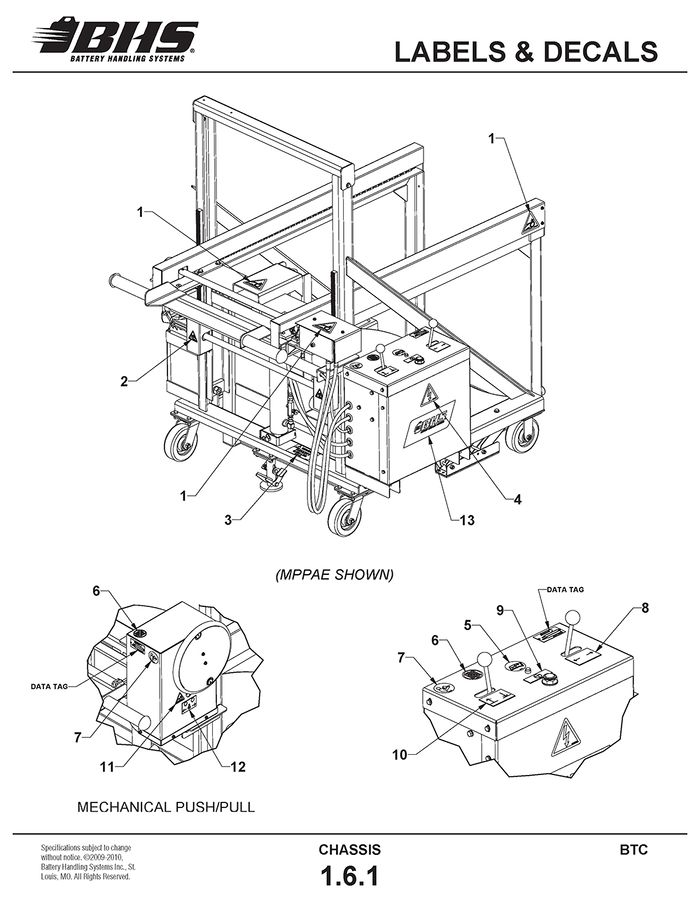

LABELS & DECALS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 00196216 | LABEL-WARNING-"CHAIN ENTANGLEMENT HAZARD" | LARGE | 4 | |

2 | 00196217 | LABEL-WARNING-"GEAR ENTANGLEMENT HAZARD" | 2 | ||

3 | 00196724 | LABEL-CAPACITY-”CAPACITY 3,000 LBS” | 1 | ||

4 | 00196219 | LABEL-WARNING-"ELECTRICAL VOLTAGE HAZARD" | 1 | ||

5 | 00196613 | LABEL-"CONSULT MANUAL FOR TECHNI- CAL PROCEDURE" | 1 | ||

6 | 00196615 | LABEL-"DO NOT OPERATE WITH GUARDS REMOVED" | 1 | ||

7 | 00196612 | LABEL-"READ INSTRUCTION MANUAL PRIOR TO USE" | 1 | ||

8 | 08096007 | PLACARD-EXTRACTOR ARM IN/OUT | ELECTRIC EXTRACTION UNITS | 1 | |

9 | 08096008 | PLACARD-POWER: PUSH & HOLD | 1 | ||

10 | 05096006 | PLACARD-CARRIAGE RAISE/LOWER | 1 | ||

11 | 00196215 | LABEL-WARNING-"CHAIN ENTANGLEMENT HAZARD" | SMALL | 1 | |

12 | 05096007 | PLACARD-EXTRACTOR ARM IN/OUT | MECHANICAL PUSH/PULL UNITS | 1 | |

13 | 00196701 | DECAL-BHS-12" X 3.875" | 2 |

EXTRACTOR ARM

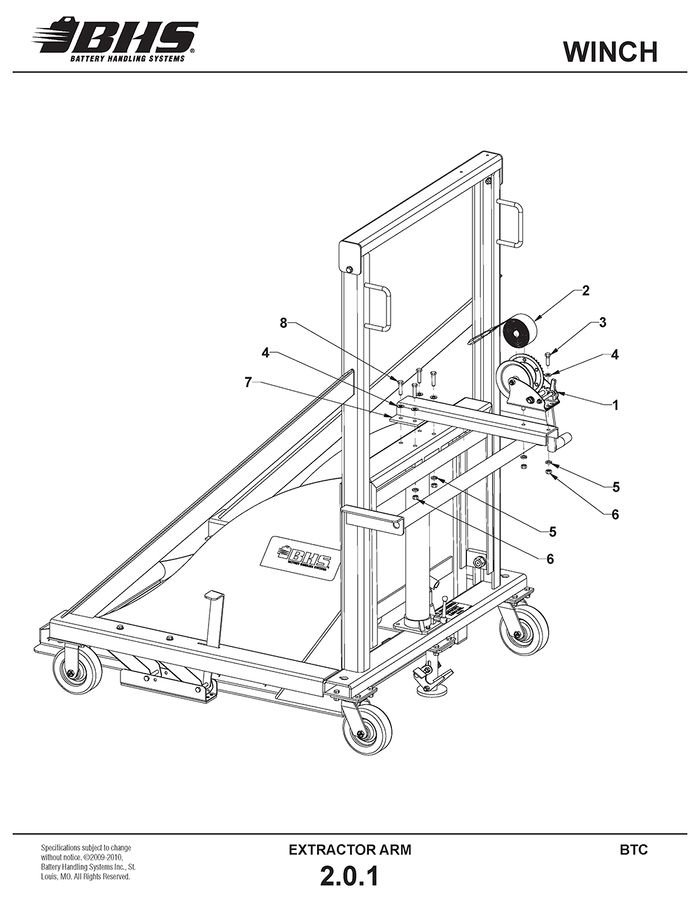

WINCH

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | PT0601 | WINCH | 1 | ||

2 | PT0602 | STRAP-WINCH | INCLUDES HOOK | 1 | |

3 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | 2 | ||

4 | HW0108 | WASHER-FLAT-3/8"-SAE | 6 | ||

5 | HW0107 | WASHER-LOCK-3/8" | 6 | ||

6 | HW0005 | NUT-HEX-3/8-16 | 6 | ||

7 | 05015006 | MOUNT-WINCH | 1 | ||

8 | HW0404 | BOLT-HHCS-3/8-16 X 1 1/2" | 4 |

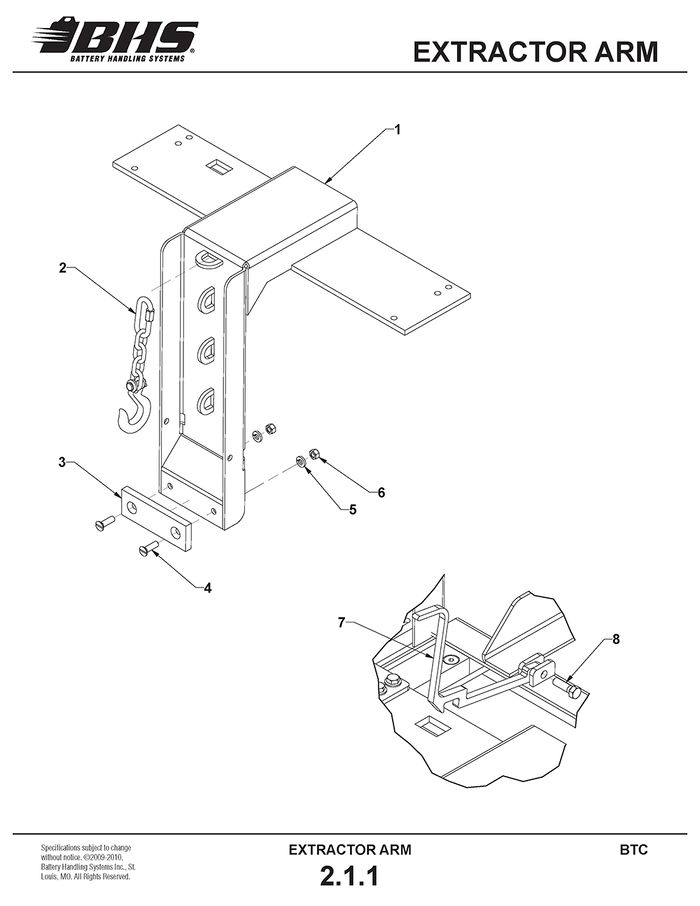

EXTRACTOR ARM

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 05055001 | EXTRACTOR ARM-BTC-18 | 1 | ||

05155001 | EXTRACTOR ARM-BTC-24 | ||||

08155001 | EXTRACTOR ARM-BTC-30 | ||||

2 | 08092001 | HOOK AND CHAIN ASSEMBLY | 1 | ||

3 | 05057007 | PAD-PUSH | 1 | ||

4 | HW0413 | BOLT-FHSMS-3/8-16 X 1 1/4" | 2 | ||

5 | HW0107 | WASHER-LOCK-3/8" | 2 | ||

6 | HW0005 | NUT-HEX-3/8-16 | 2 | ||

7 | 08617006 | LATCH-EXTRACTOR ARM | MECHANICAL PUSH/PULL UNITS ONLY | 1 | |

8 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | 1 |

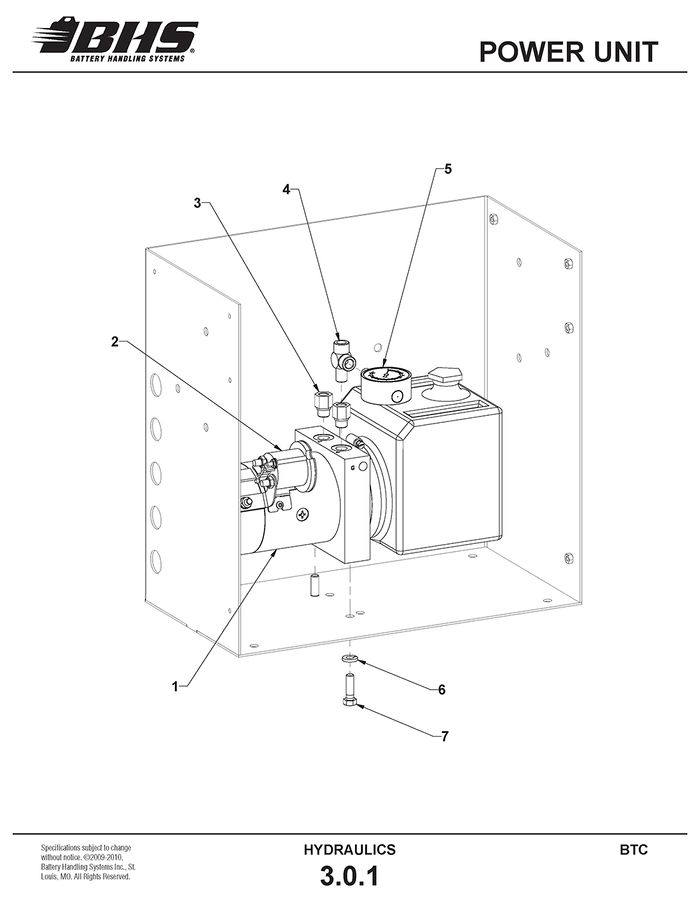

HYDRAULICS

POWER UNIT

MONARCH POWER UNITS - EFFECTIVE: 03/06 TO PRESENT

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

REF | HC0002-4 | POWER UNIT ASSEMBLY-12VDC | 1 | ||

1 | E0029 | MOTOR-12VDC-ISKRA | † SEE NOTES | 1 | |

2 | E0009-2 | SOLENOID | 1 | ||

3 | H1008 | ADAPTER-RED-#6 SAEM X #4 FNPT | 2 | ||

4 | H0600 | TEE-MALE RUN-#4 NPT | 1 | ||

5 | HC0318 | GAUGE-PRESSURE | INCL. WITH POWER UNIT ASSY | 1 | |

6 | HW0107 | WASHER-LOCK-3/8" | 2 | ||

7 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | 2 | ||

8 | E0030 | BRUSH KIT (ISKRA MOTOR) | NOT SHOWN | 1 | |

HC0534 | BRUSH KIT (BOSCH MOTOR) | 1 | |||

9 | - | THERMAL SWITCH | †† SEE NOTES | 1 |

NOTE:

† BOSCH MOTOR NO LONGER AVAILABLE. ISKRA MOTOR IS DIRECT REPLACEMENT FOR BOSCH MOTOR.

††INTERNAL OF MOTOR. CONSULT FACTORY

BARNES POWER UNIT - EFFECTIVE: 02/02 TO 03/06

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

REF | N/A | POWER UNIT ASSEMBLY-12VDC | ††† SEE NOTES | - | |

1 | N/A | MOTOR-12VDC-HALDEX | ††† SEE NOTES | - | |

2 | E0009-2 | SOLENOID | 1 | ||

8 | HC0512 | BRUSH KIT (HALDEX MOTOR) | NOT SHOWN | 1 |

FENNER POWER UNIT - EFFECTIVE PRIOR TO 02/02

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

REF | N/A | POWER UNIT ASSEMBLY-12VDC | ††† SEE NOTES | - | |

1 | N/A | MOTOR-12VDC | ††† SEE NOTES | - | |

2 | E0009-2 | SOLENOID-12VDC | 1 | ||

8 | N/A | BRUSH KIT-12VDC | ††† SEE NOTES | - |

††† MUST ORDER NEW MONARCH POWER UNIT TO REPLACE BARNES OR FENNER POWER UNIT.

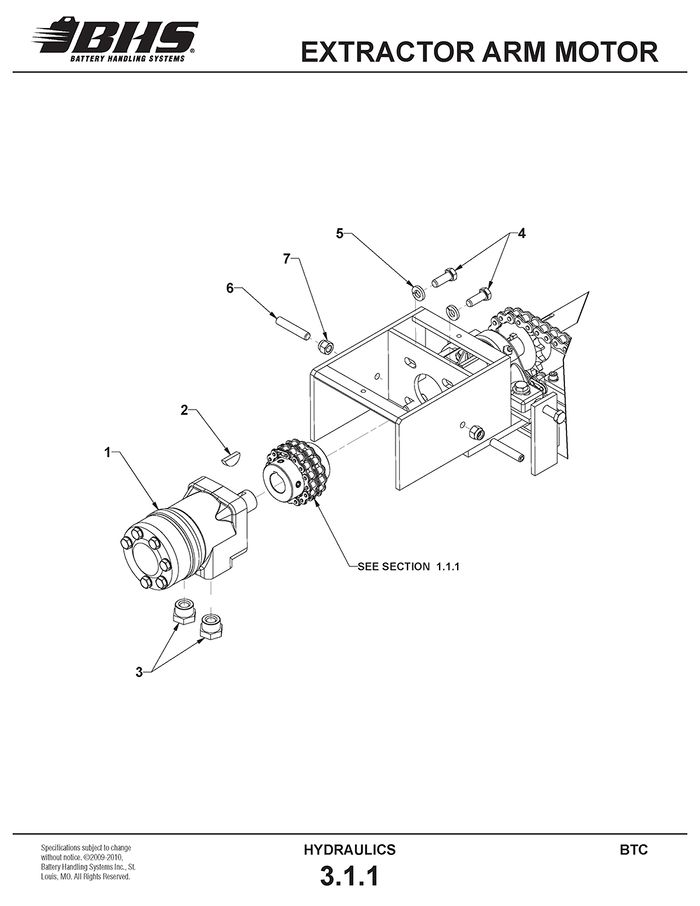

EXTRACTOR ARM MOTOR

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0120 | MOTOR-HYDRAULIC-160CC | 1 | ||

2 | HW1071 | KEY-WOODRUFF-#808 STD | INCL. WITH MOTOR | A/R | |

3 | H1002 | BUSHING-RED-#10 SAEM X #4 FNPT | 2 | ||

4 | HW0402 | BOLT-HHCS-3/8-16 X 1" | 4 | ||

5 | HW0107 | WASHER-LOCK-3/8" | 4 | ||

6 | HW0806 | SCREW-SHSS-3/8-16 X 2" | 2 | ||

7 | HW0006 | NUT-NILN-3/8-16 | 2 |

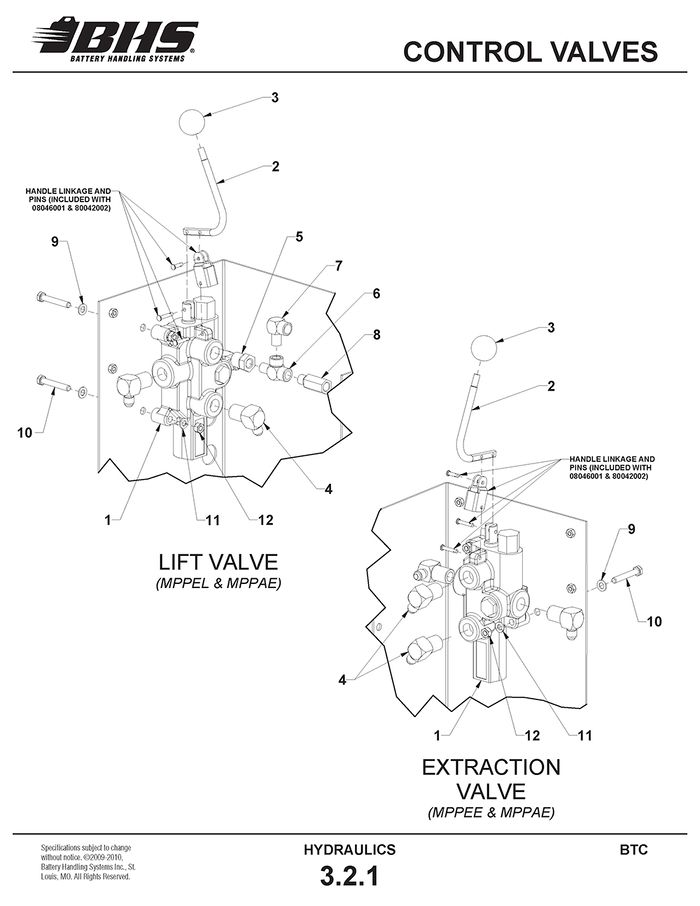

CONTROL VALVES

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0201 | MANUAL VALVE | 80042002 | 1 | |

REF | 08046001 | MODIFIED VALVE HANDLE ASSEMBLY | 80042002 | INCL. ITEMS 2 & 3 | 1 |

2 | N/A | VALVE HANDLE-MODIFIED | † | 1 | |

3 | N/A | BALL-HANDLE | † | 1 | |

4 | H1303 | ADAPTER-90 DEG-#6 JICM X #8 NPTM | 80042002 | 4 | |

5 | H0201 | BUSHING-RED-#8 NPTM X #4 FNPT | 1 | ||

6 | H0600 | TEE-MALE RUN-#4 NPT | 1 | ||

7 | H0300 | ELBOW-STR-90 DEG-#4 NPT | 1 | ||

8 | HC0218 | VALVE-CHECK | 1 | ||

9 | HW0106 | WASHER-FLAT-5/16"-SAE | 3 | ||

10 | HW0322 | BOLT-HHCS-5/16-18 X 2" | 3 | ||

11 | HW0105 | WASHER-LOCK-5/16" | 3 | ||

12 | HW0004 | NUT-HEX-5/16-18 | 3 |

† INCLUDED IN MULTIPLE KITS

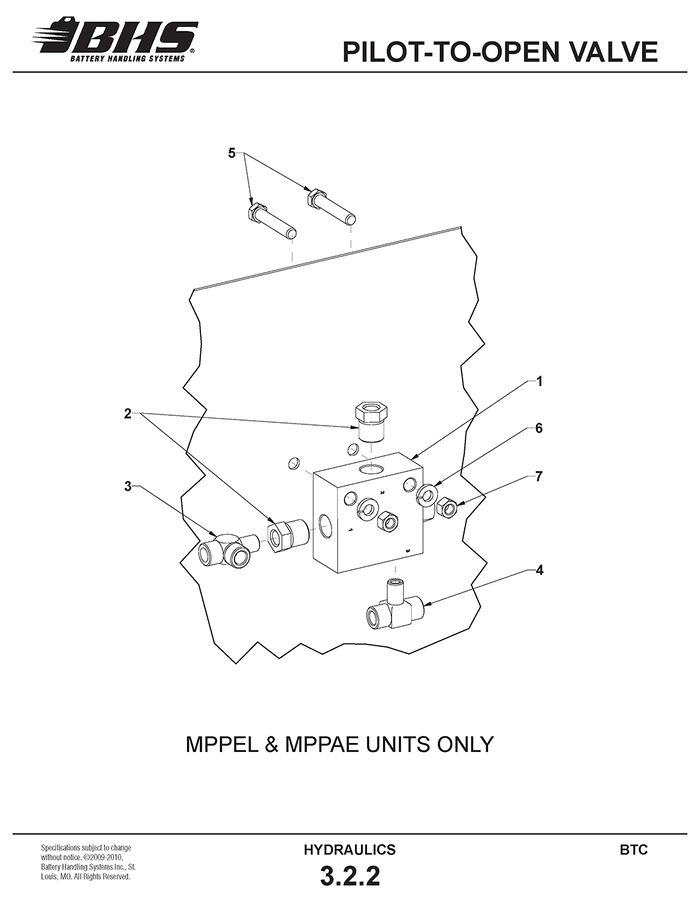

PILOT-TO-OPEN VALVE

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0209 | VALVE-PTO | 1 | ||

2 | H0201 | BUSHING-RED-#8 MNPT X #4 FNPT | 2 | ||

3 | H0600 | TEE-MALE RUN-#4 NPT | 1 | ||

4 | H0700 | TEE-BRANCH-#4 NPT | 1 | ||

5 | HW0405 | BOLT-HHCS-3/8-16 X 2" | 2 | ||

6 | HW0107 | WASHER-LOCK-3/8" | 2 | ||

7 | HW0005 | NUT-HEX-3/8-16 | 2 |

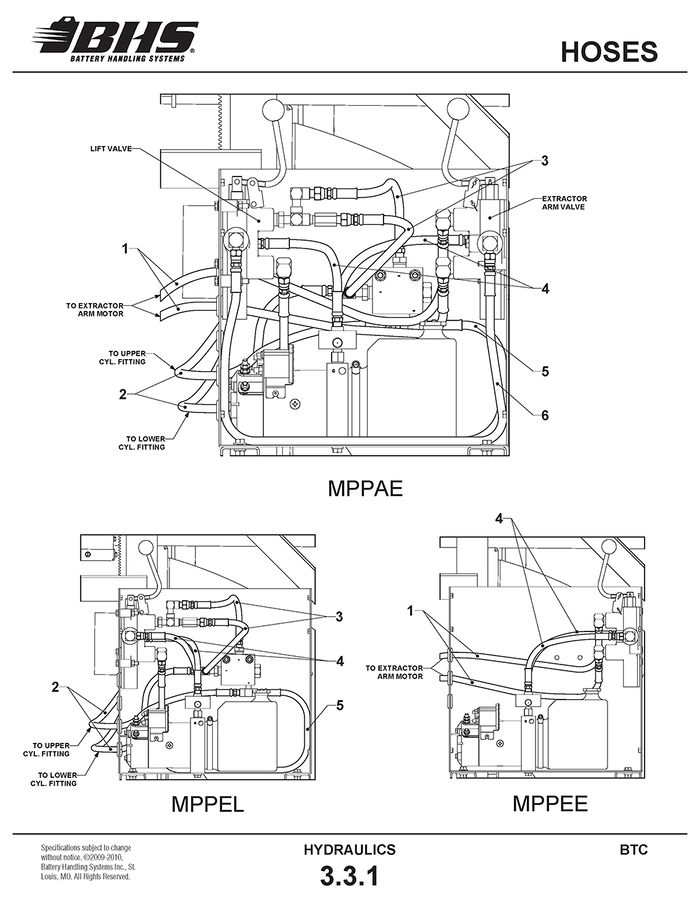

HOSES

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 00142001-87 | HOSE-HYDRAULIC-54"-JICSW X MNPTSW | MPPEE & MPPAE | 2 | |

2 | 00142001-27 | HOSE-HYDRAULIC-40"-MNPT X MNPTSW | MPPEL & MPPAE | 2 | |

3 | 00142001-85 | HOSE-HYDRAULIC-13"-MNPT X MNPTSW | MPPEL & MPPAE | 2 | |

4 | 00142001-86 | HOSE-HYDRAULIC-13"-JICSW X MNPT | ALL | 2 | |

5 | 00142001-17 | HOSE-HYDRAULIC-30"-JICSW X MNPT | MPPEL & MPPAE | 1 | |

6 | 00142001-24 | HOSE-HYDRAULIC-36"-JICSW X JICSW | MPPAE ONLY | 1 |

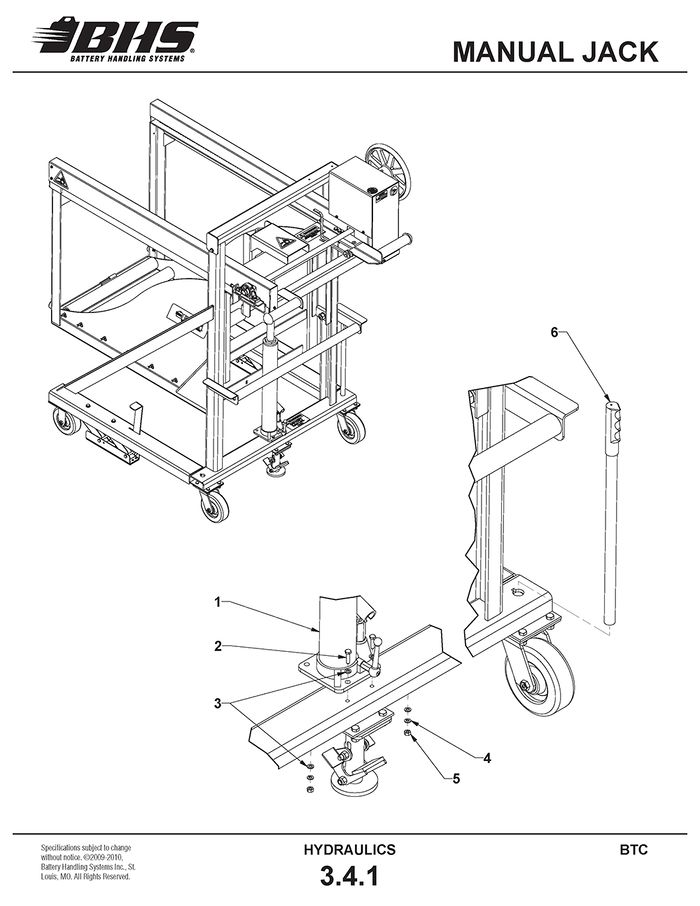

MANUAL JACK

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 05046003 | MANUAL JACK | HANDLE SOLD SEPARATELY | 1 | |

2 | HW0303 | BOLT-HHCS-1/4-20 X 1" | 2 | ||

3 | HW0104 | WASHER-FLAT-1/4"-SAE | 4 | ||

4 | HW0103 | WASHER-LOCK-1/4" | 2 | ||

5 | HW0002 | NUT-HEX-1/4-20 | 2 | ||

6 | HC0414 | JACK HANDLE | 1 |

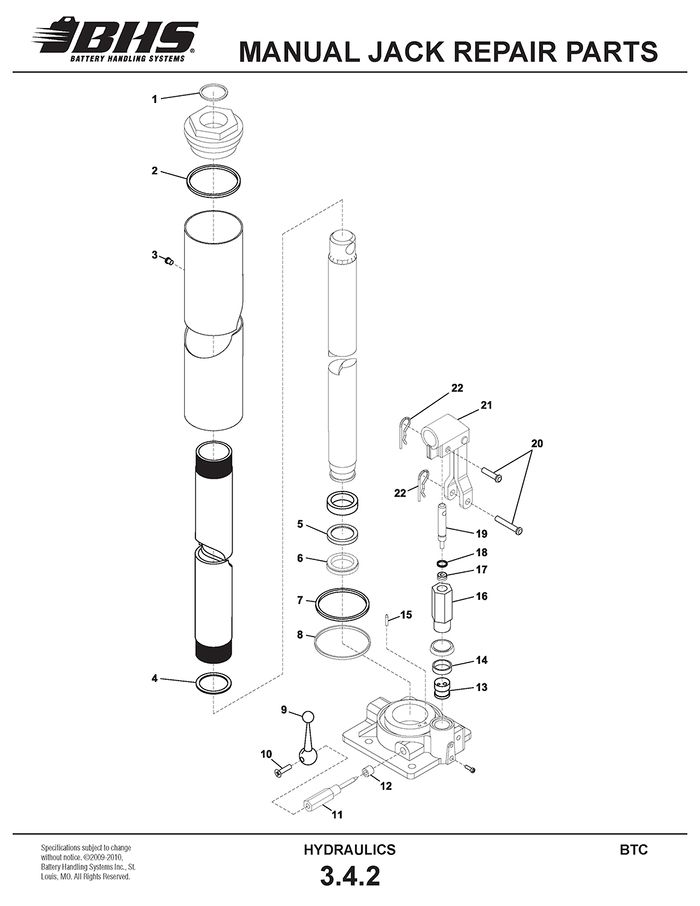

MANUAL JACK REPAIR PARTS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | - | O-RING | AVAILABLE IN REPAIR KIT ONLY | 1 | |

2 | - | O-RING | AVAILABLE IN REPAIR KIT ONLY | 1 | |

3 | - | FILLER PLUG | AVAILABLE IN REPAIR KIT ONLY | 1 | |

4 | - | GASKET | AVAILABLE IN REPAIR KIT ONLY | 1 | |

5 | - | BACK-UP RING | AVAILABLE IN REPAIR KIT ONLY | 1 | |

6 | - | U-CUP | AVAILABLE IN REPAIR KIT ONLY | 1 | |

7 | - | BACK-UP RING | AVAILABLE IN REPAIR KIT ONLY | 1 | |

8 | - | O-RING | AVAILABLE IN REPAIR KIT ONLY | 1 | |

9 | HC0412 | RELEASE HANDLE | 1 | ||

10 | HC0413 | SCREW-RELEASE HANDLE | 1 | ||

11 | HC0411 | RELEASE VALVE | 1 | ||

12 | - | SEAL | AVAILABLE IN REPAIR KIT ONLY | 1 | |

13 | HC0519 | CARTRIDGE | 1 | ||

14 | - | SEAL | AVAILABLE IN REPAIR KIT ONLY | 1 | |

15 | HC0522 | FILTER | 1 | ||

16 | HC0406 | PUMP CYLINDER | 1 | ||

17 | - | SEAL | AVAILABLE IN REPAIR KIT ONLY | 1 | |

18 | - | O-RING | AVAILABLE IN REPAIR KIT ONLY | 1 | |

19 | HC0525 | PUMP PISTON | 1 | ||

20 | HC0526 | PIN | 2 | ||

21 | HC0528 | HANDLE SOCKET | 1 | ||

22 | HC0529 | RETAINING PIN | 2 | ||

REF | HC0405 | REPAIR KIT | A/R |

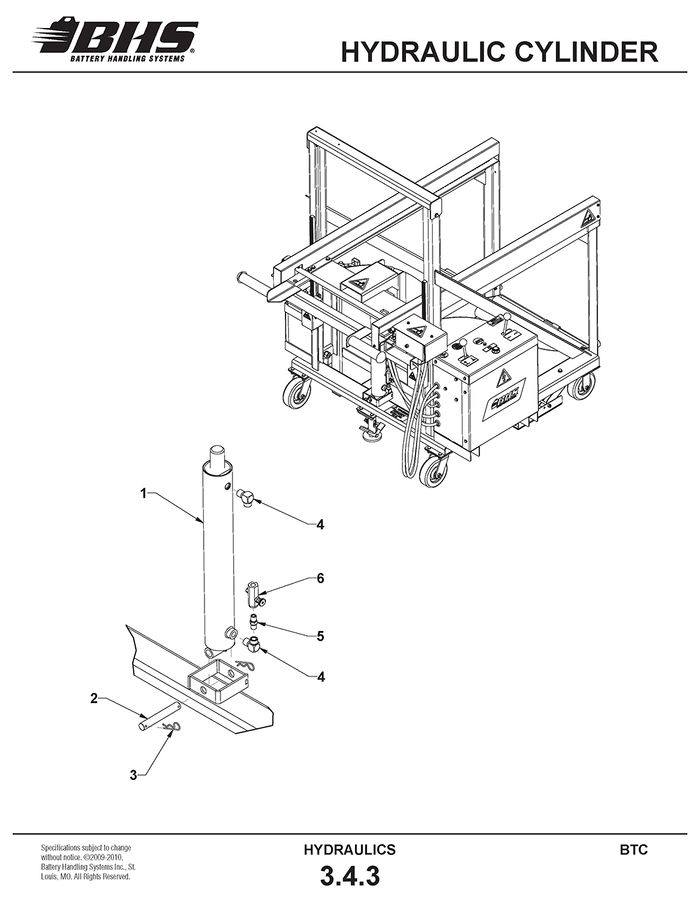

HYDRAULIC CYLINDER

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HC0402 | CYLINDER-LIFT | 1 | ||

2 | 00197035 | PIN-CYLINDER | 1 | ||

3 | HW1058 | PIN-HITCH | 2 | ||

4 | H0303 | ELBOW-STR-90 DEG-#6 NPTM X #4 FNPT | 2 | ||

5 | H0001 | NIPPLE-#4 NPT | 1 | ||

6 | HC0211 | VALVE-ADJUSTABLE FLOW CONTROL | 1 |

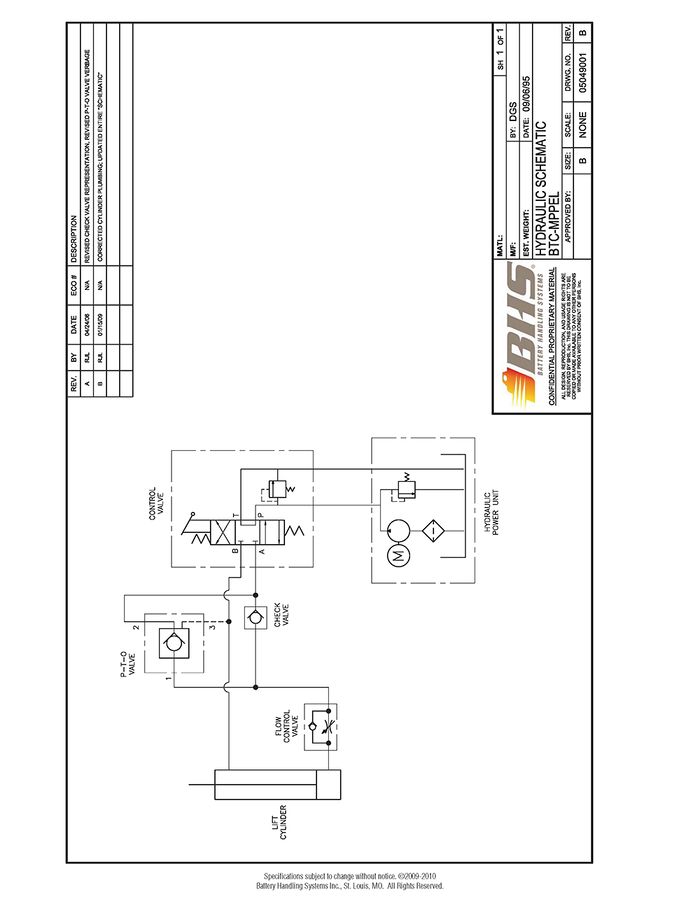

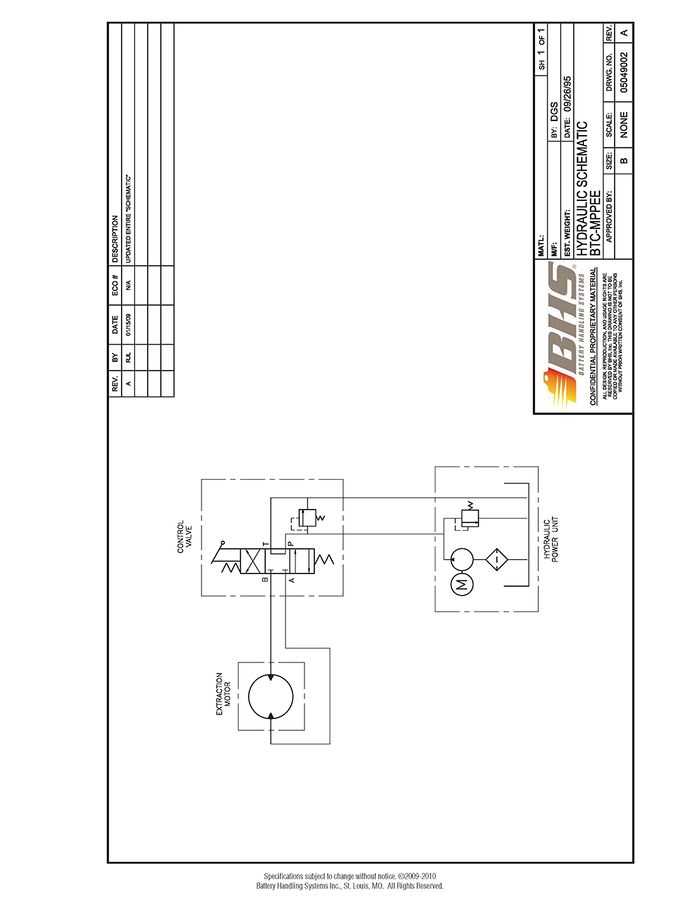

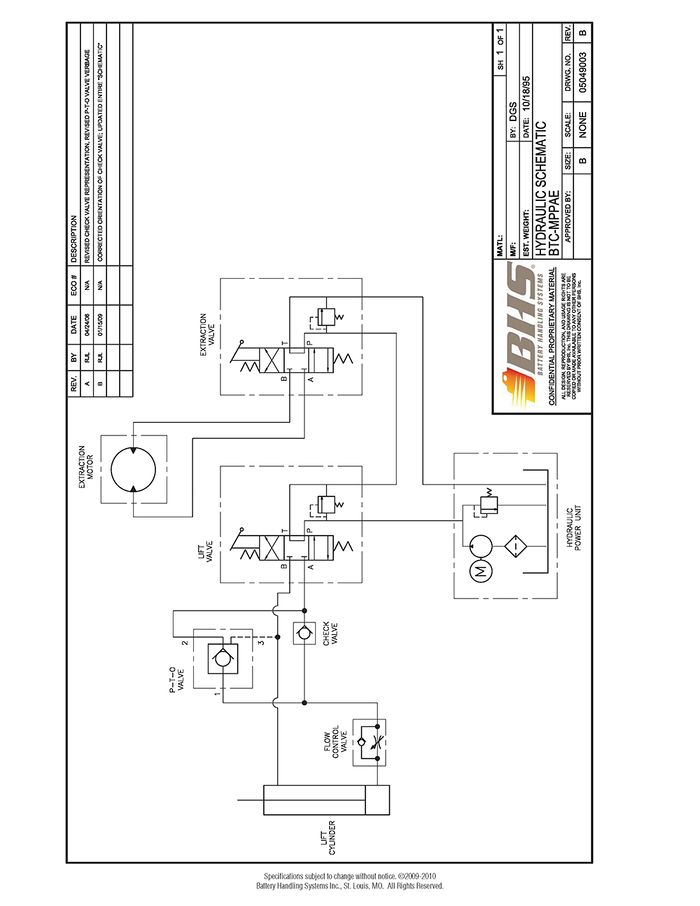

HYDRAULIC SCHEMATICS

ELECTRICAL

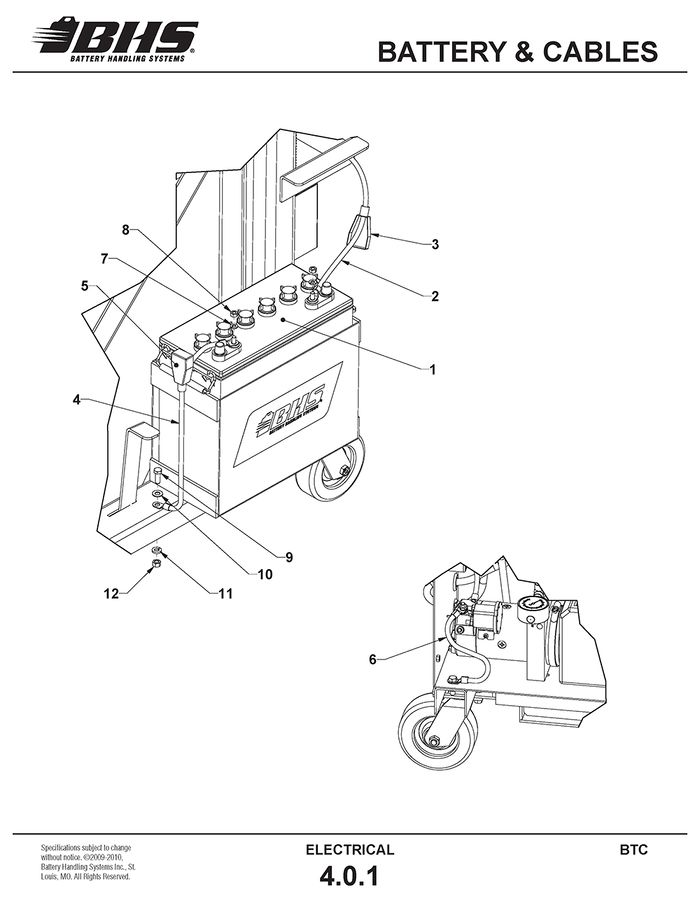

BATTERY & CABLES

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E0416 | BATTERY-12VDC | 1 | ||

2 | 05032003 | CABLE-BATTERY-76" | BTC-18 & 24 | 1 | |

05032004 | CABLE-BATTERY-84" | BTC-30 | |||

3 | E1103-1 | COVER-TERMINAL-RED | 1 | ||

4 | 05032005 | CABLE-GROUND-BATTERY | 1 | ||

5 | E1104-1 | COVER-TERMINAL-BLACK | 1 | ||

6 | 05032006 | CABLE-GROUND-POWER UNIT | 1 | ||

7 | HW0105 | WASHER-LOCK-5/16" | 2 | ||

8 | HW0004 | NUT-HEX-5/16-18 | 2 | ||

9 | HW0402 | BOLT-HHCS-3/8-16 X 1" | 1 | ||

10 | HW0108 | WASHER-FLAT-3/8"-SAE | 1 | ||

11 | HW0107 | WASHER-LOCK-3/8" | 1 | ||

12 | HW0005 | NUT-HEX-3/8-16 | 1 |

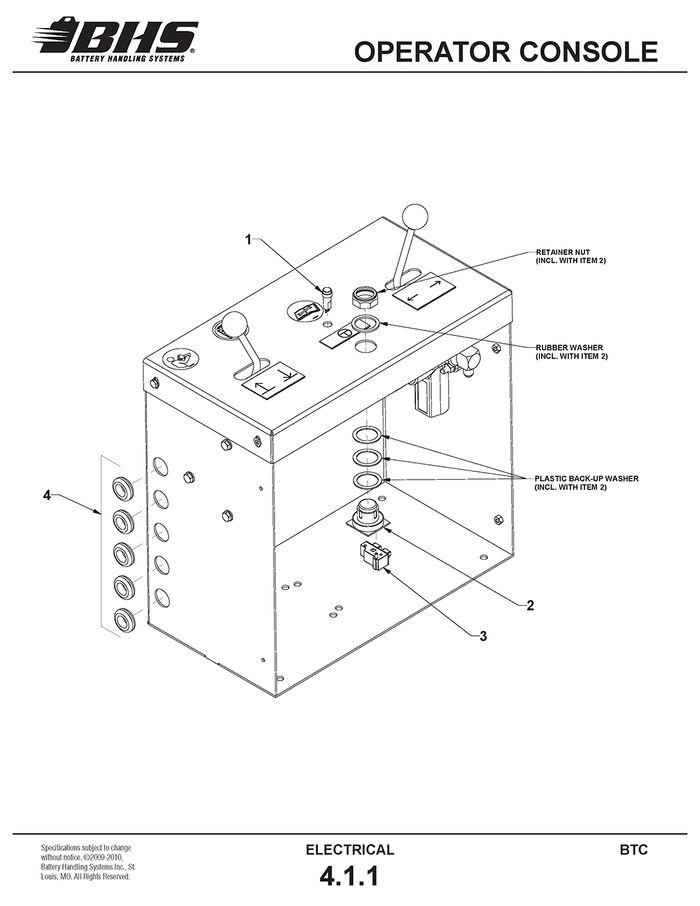

OPERATOR CONSOLE

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E1361 | LIGHT-INDICATOR-12VDC | 1 | ||

2 | E0308 | ACTUATOR-PUSH BUTTON | 80032001 | 1 | |

3 | E0307 | CONTACT BLOCK-N/O | 80032001 | 1 | |

4 | PL0501 | GROMMET-1/2" I.D. | A/R |

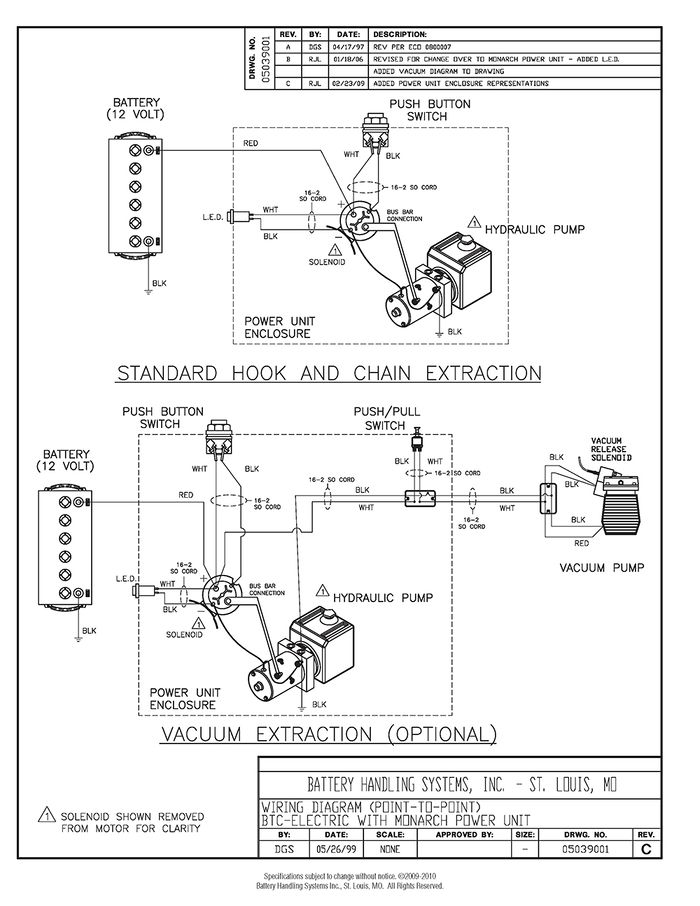

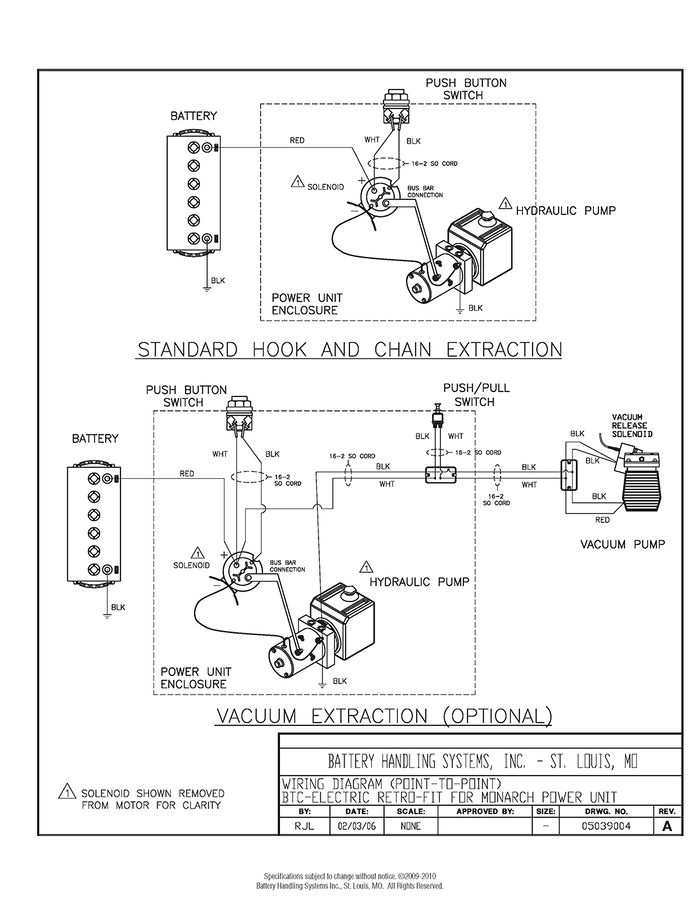

ELECTRICAL SCHEMATICS

STANDARD OPTIONS

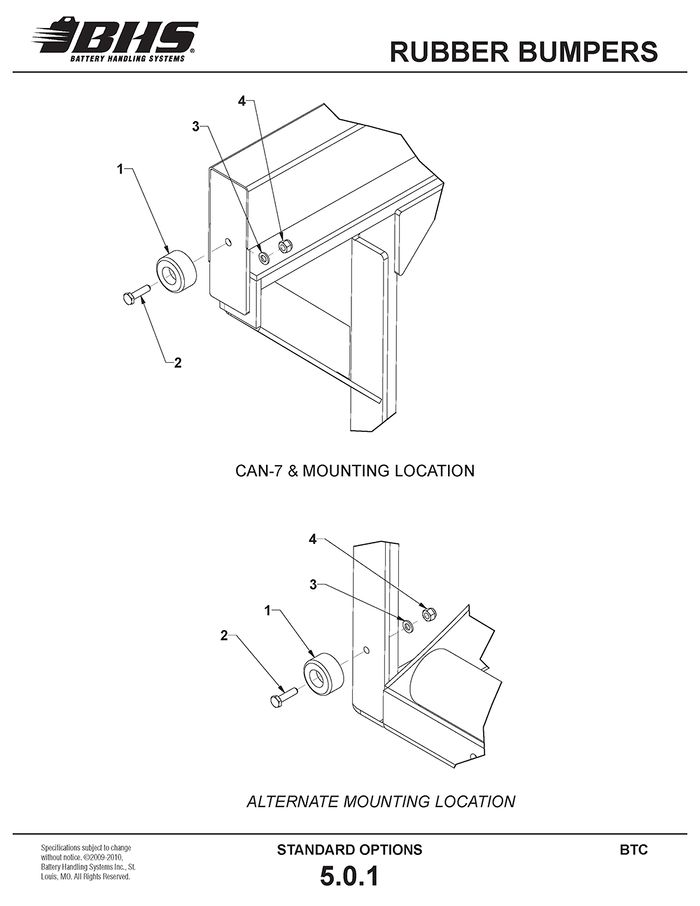

RUBBER BUMPERS

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | HW1037 | BUMPER-RUBBER-RECESSED | 80092001 | 2 | |

2 | HW0303 | BOLT-HHCS-1/4-20 X 1" | 80092001 | 2 | |

3 | HW0104 | WASHER-FLAT-1/4"-SAE | 80092001 | 2 | |

4 | HW0003 | NUT-NILN-1/4-20 | 80092001 | 2 |

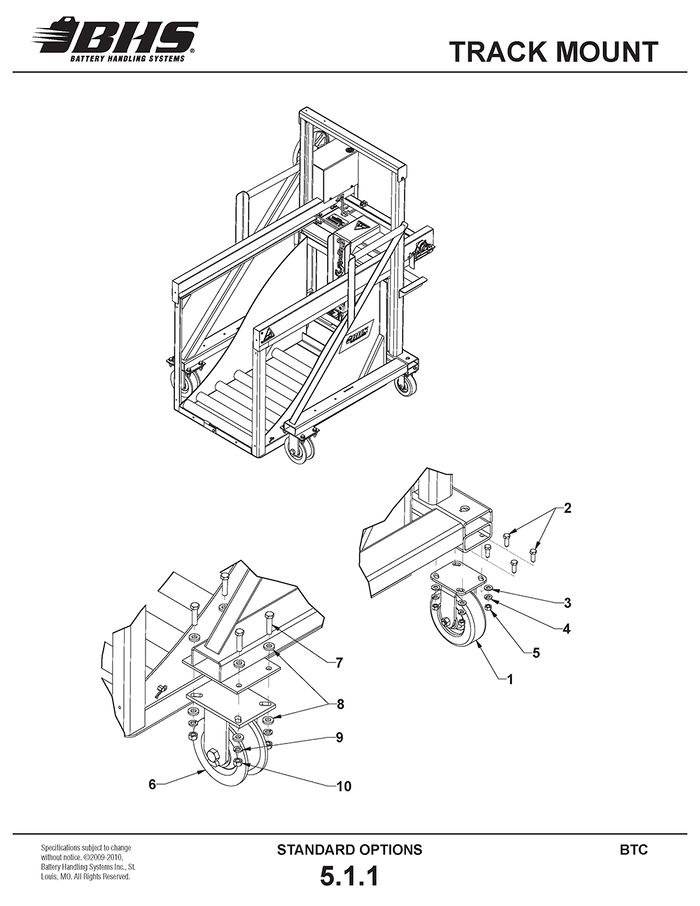

TRACK MOUNT

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | C0015 | CASTER-6" X 2"-RIGID | 2 | ||

2 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | 8 | ||

3 | HW0108 | WASHER-FLAT-3/8"-SAE | 8 | ||

4 | HW0107 | WASHER-LOCK-3/8" | 8 | ||

5 | HW0005 | NUT-HEX-3/8-16 | 8 | ||

6 | C0080 | CASTER-6" X 3"-DUAL FLANGED | 2 | ||

7 | HW0504 | BOLT-HHCS-1/2-13 X 2" | 8 | ||

8 | HW0112 | WASHER-FLAT-1/2"-SAE | 16 | ||

9 | HW0110 | WASHER-LOCK-1/2" | 8 | ||

10 | HW0007 | NUT-HEX-1/2" | 8 |

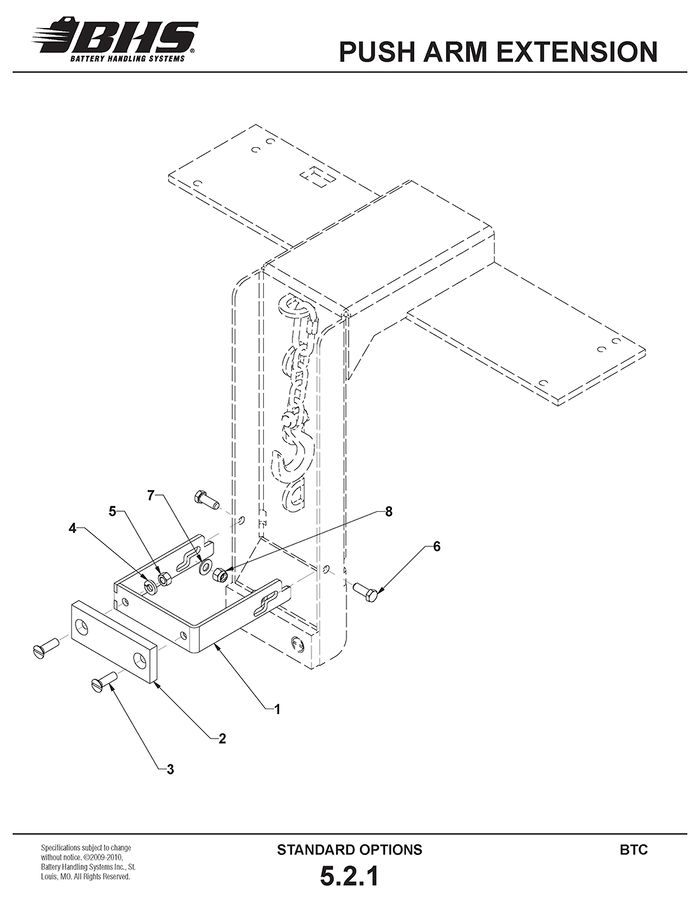

PUSH ARM EXTENSION

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 05015036 | EXTENSION-PUSH PAD | 1 | ||

2 | 05057010 | PAD-PUSH | 1 | ||

3 | HW0413 | BOLT-FHSMS-3/8-16 X 1 1/4" | 2 | ||

4 | HW0107 | WASHER-LOCK-3/8" | 2 | ||

5 | HW0005 | NUT-HEX-3/8-16 | 2 | ||

6 | HW0402 | BOLT-HHCS-3/8-16 X 1" | 2 | ||

7 | HW0108 | WASHER-FLAT-3/8"-SAE | 2 | ||

8 | HW0006 | NUT-NILN-3/8-16 | 2 |

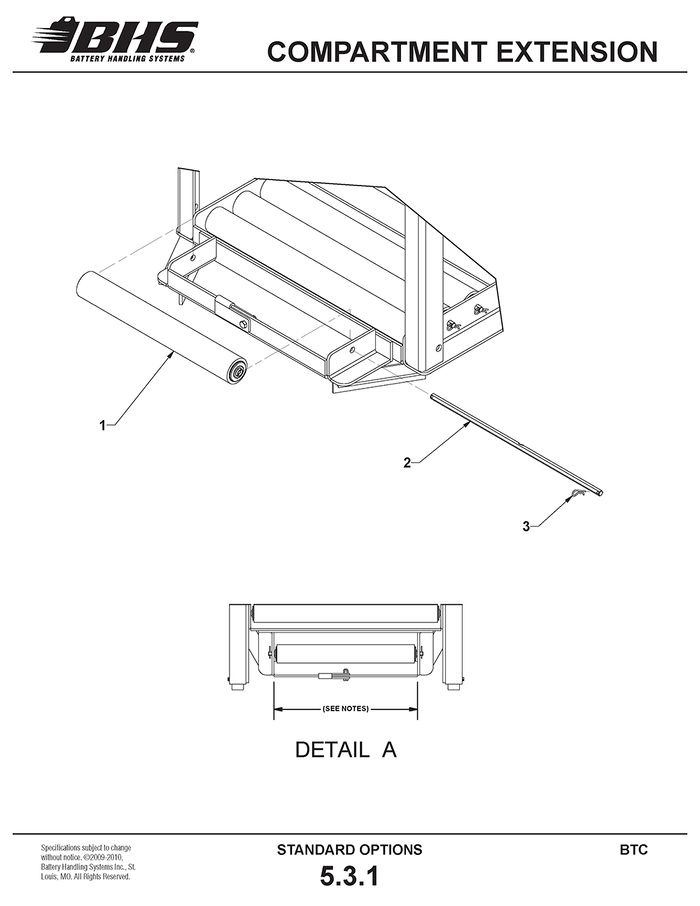

COMPARTMENT EXTENSION

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1a | 00182007 | ROLLER ASSEMBLY-14.563" | † | 1 | |

1b | 00182003 | ROLLER ASSEMBLY-18.563" | † | ||

1c | 43182002 | ROLLER ASSEMBLY-23.875" | † | ||

2a | 00187012 | SHAFT-HEX-.438" X 16.125" | †† | 1 | |

2b | 00187044 | SHAFT-HEX-.438" X 20" | †† | ||

2c | 43187002 | SHAFT-HEX-.75" X 25.75" | †† | ||

3 | HW1014-1 | PIN-HITCH | FOR USE WITH .438" HEX SHAFT | 2 | |

HW1058 | PIN-HITCH | FOR USE WITH .75" HEX SHAFT |

† THE ROLLERS LISTED ABOVE ARE THE MOST COMMON ROLLERS USED IN COMPARTMENT EXTENSIONS. IF YOUR UNIT IS EQUIPPED WITH A ROLLER OTHER THAN THOSE LISTED, MEASURE THE INSIDE WIDTH OF THE COMPARTMENT EXTENSION (SEE DETAIL A) AND CONSULT THE FACTORY.

†† HEX SHAFT LETTER “a” IS TO BE USED WITH ROLLER “a”, HEX SHAFT “b” WITH ROLLER “b” ETC

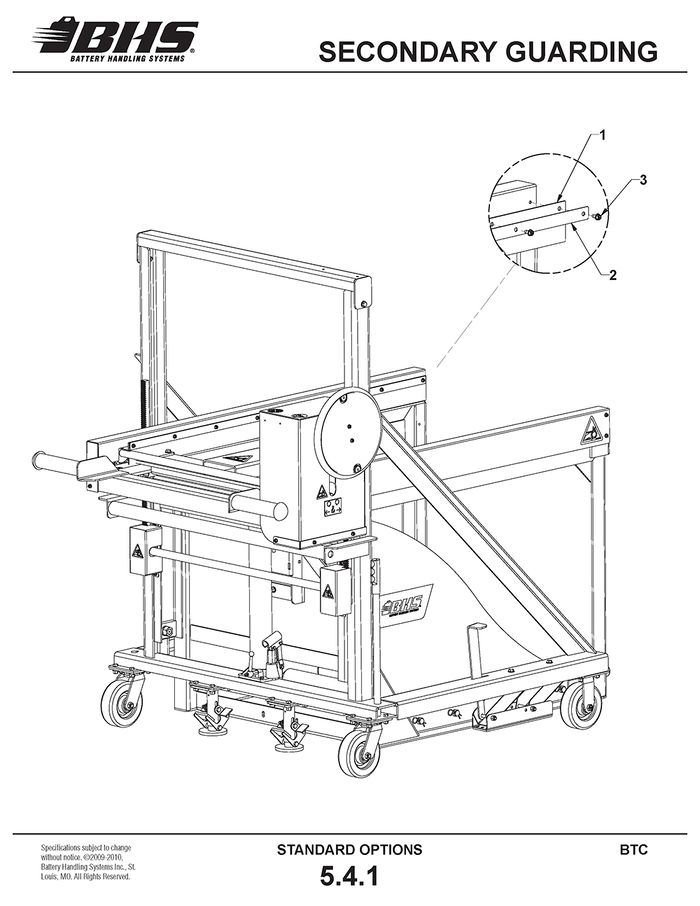

SECONDARY GUARDING

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | 05317156 | GUARD-CHAIN-RUBBER | STANDARD BTC | 2 | |

05017103 | GUARD-CHAIN-RUBBER | BTC-CAN-7 | |||

05017105 | GUARD-CHAIN-RUBBER | BTC-CAN-14 | |||

2 | 05317155 | RETAINER-RUBBER GUARD | STANDARD BTC | 2 | |

05017102 | RETAINER-RUBBER GUARD | BTC-CAN-7 | |||

05017104 | RETAINER-RUBBER GUARD | BTC-CAN-14 | |||

3 | HW0301 | BOLT-SELF-TAP "F"-1/4-20 X 1/2" | 16 |

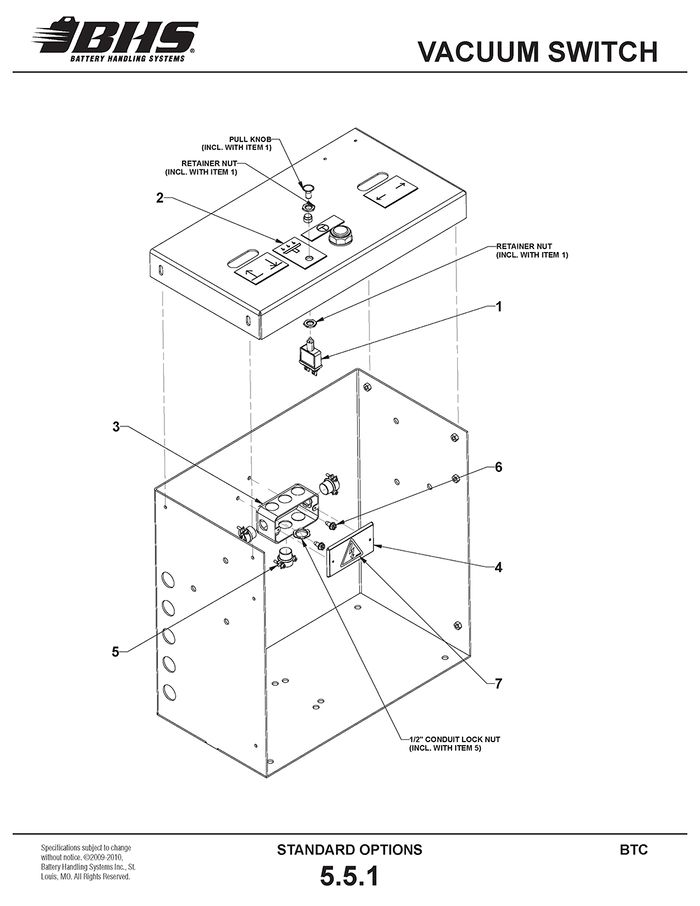

VACUUM SWITCH

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E0302 | SWITCH-PULL | 6-28VDC, 75 AMP | 1 | |

2 | 08096005 | PLACARD-VACUUM-ON/OFF | 1 | ||

3 | E0611 | JUNCTION BOX-4" X 2" X 2" | 1 | ||

4 | E0612 | COVER-JUNCTION BOX | 1 | ||

5 | E0624 | CONNECTOR-1/2" | INCLUDES LOCK NUT | 3 | |

6 | HW0301 | BOLT-SELF-TAP "F"-1/4-20 X 1/2" | 2 | ||

7 | 00196218 | LABEL-WARNING-"ELECTRICAL VOLTAGE HAZARD" | 1 |

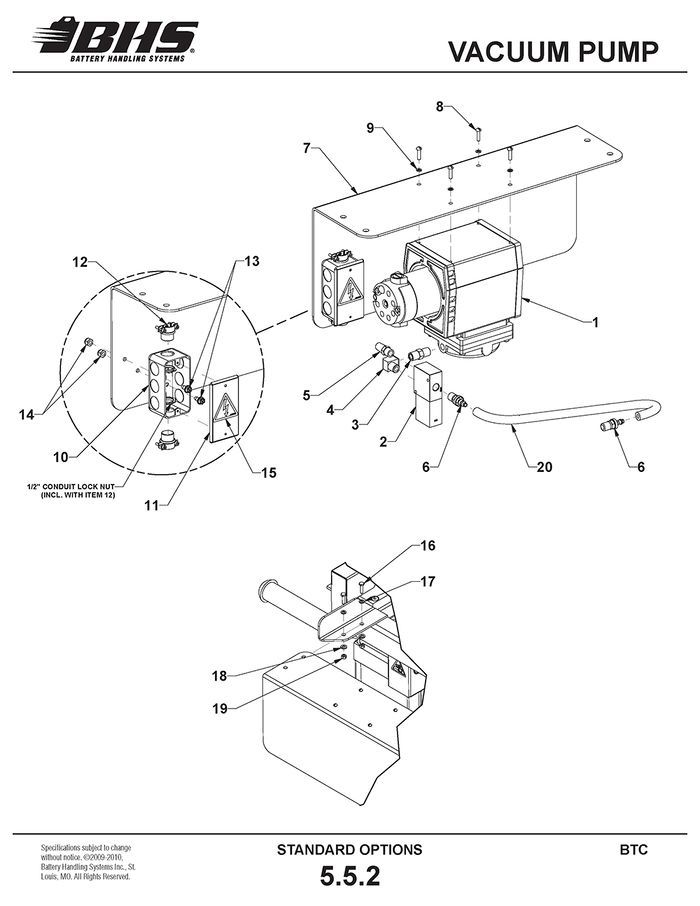

VACUUM PUMP

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | P0001 | PUMP-VACUUM-12VDC | 80062001 | 1 | |

2 | P0205 | VALVE-VACUUM RELEASE-12VDC | 80062001 | 1 | |

3 | P0503 | NIPPLE-#4 NPT-BRASS | 80062001 | 1 | |

4 | P0506 | ELBOW-STR-90 DEG-#4 NPT-BRASS | 80062001 | 1 | |

5 | P0208 | FILTER-HIGH FLOW | 80062001 | 1 | |

6 | P0402 | HOSE BARB-1/4" X #4 NPT-BRASS | 2 | ||

7 | 05167001-2 | MOUNT-VACUUM PUMP | 1 | ||

8 | HW0206 | SCREW-RHMS-#10-32 X 3/4" | 4 | ||

9 | HW0101 | WASHER-LOCK-#10 | 4 | ||

10 | E0611 | JUNCTION BOX-4" X 2" X 2" | 1 | ||

11 | E0612 | COVER-JUNCTION BOX | 1 | ||

12 | E0624 | CONNECTOR-1/2" | INCLUDES LOCK NUT | 2 | |

13 | HW0301 | BOLT-SELF-TAP "F"-1/4-20 X 1/2" | 2 | ||

14 | HW0003 | NUT-NILN-1/4-20 | 2 | ||

15 | 00196218 | LABEL-WARNING-"ELECTRICAL VOLTAGE HAZARD" | 1 | ||

16 | HW0303 | BOLT-HHCS-1/4-20 X 1" | 4 | ||

17 | HW0104 | WASHER-FLAT-1/4"-SAE | 4 | ||

18 | HW0105 | WASHER-LOCK-1/4" | 4 | ||

19 | HW0002 | NUT-HEX-1/4-20 | 4 | ||

20 | P0302 | HOSE-VACUUM -1/4" I.D. | SOLD BY LENGTH | A/R |

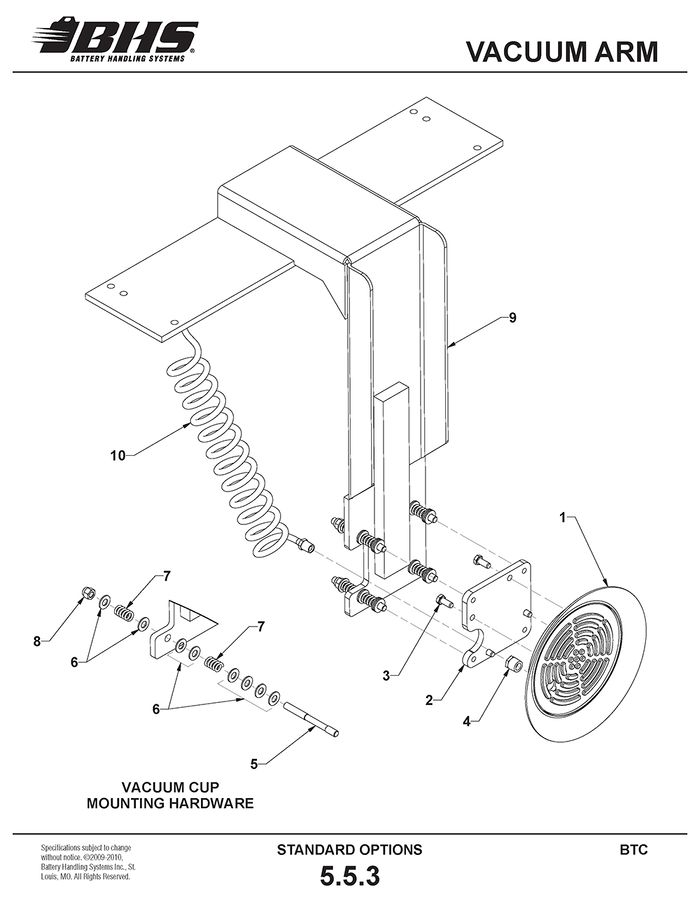

VACUUM ARM

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | N/A | VACUUM CUP-250 mm | 00162001 | AVAILABLE IN KIT ONLY | 1 |

2 | 00117059 | PLATE-VACUUM CUP ADAPTER | 00162001 | 1 | |

3 | HW0328 | BOLT-HHCS-5/16-18 X 3/4" | 00162001 | 4 | |

4 | P0505 | BUSHING-RED-#6 NPT X #4 FNPT-BRASS | 00162001 | 1 | |

5 | HW0427 | STUD-VACUUM-3/8-16 X 4" | HW-KIT-1 | 4 | |

6 | HW0108 | WASHER-FLAT-3/8"-SAE | HW-KIT-1 | 32 | |

7 | HW1001 | SPRING-3/8" | HW-KIT-1 | 8 | |

8 | HW0006 | NUT-NILN-3/8-16 | HW-KIT-1 | 4 | |

9 | 05055002 | EXTRACTOR ARM-BTC-18 | 1 | ||

05155002 | EXTRACTOR ARM-BTC-24 | ||||

05255001 | EXTRACTOR ARM-BTC-30 | ||||

10 | P0301-1 | HOSE-COIL-VACUUM | 1 |

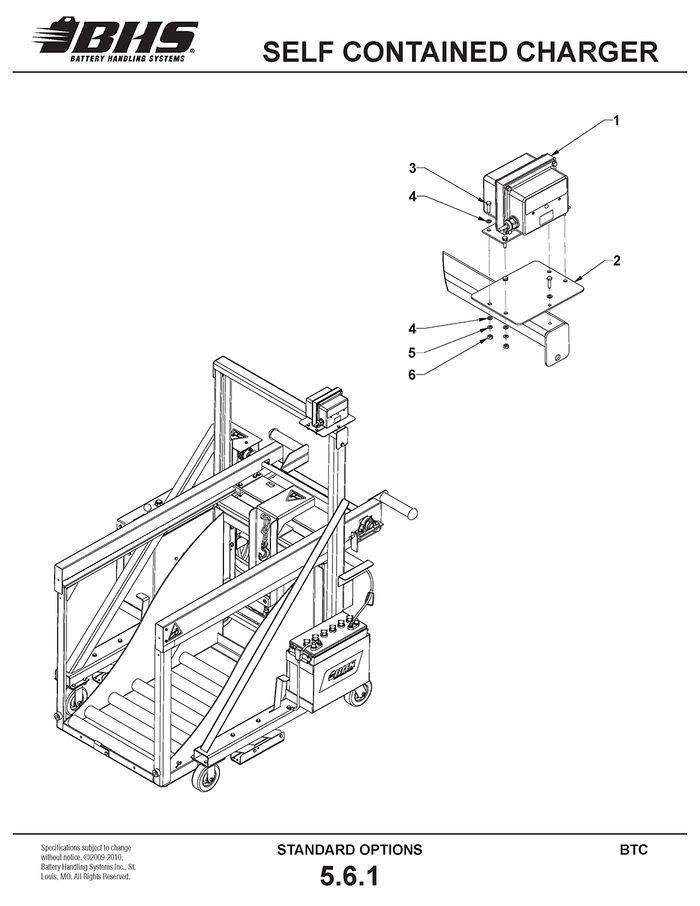

SELF CONTAINED CHARGER

ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

1 | E0209 | CHARGER-12VDC / 25A | 1 | ||

2 | 05217007 | MOUNT-CHARGER | 1 | ||

3 | HW0303 | BOLT-HHCS-1/4-20 X 1" | 6 | ||

4 | HW0104 | WASHER-FLAT-1/4"-SAE | 12 | ||

5 | HW0103 | WASHER-LOCK-1/4" | 6 | ||

6 | HW0002 | NUT-HEX-1/4-20 | 6 |

PARTS KITS

BTC-18, BTC-24 CASTER KIT

P/N: 80122001

QTY |

PART# |

DESCRIPTION |

2 | C0015 | CASTER-6" X 2"-RIGID |

2 | C0020 | CASTER-6" X 2"-SWIVEL |

1 | C0010-1 | FLOOR LOCK |

20 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" |

20 | HW0005 | NUT-HEX-3/8-16 |

20 | HW0107 | WASHER-LOCK-3/8" |

20 | HW0108 | WASHER-FLAT-3/8"-SAE |

BTC-30 CASTER KIT

P/N: 80122002

QTY |

PART# |

DESCRIPTION |

2 | C0015 | CASTER-6" X 2"-RIGID |

2 | C0020 | CASTER-6" X 2"-SWIVEL |

2 | C0010-1 | FLOOR LOCK |

24 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" |

24 | HW0005 | NUT-HEX-3/8-16 |

24 | HW0107 | WASHER-LOCK-3/8" |

24 | HW0108 | WASHER-FLAT-3/8"-SAE |

BTC VECTOR BRAKE REPLACEMENT KIT

P/N: 80112001

QTY |

PART# |

DESCRIPTION |

1 | 05012004-B | BRAKE PAD ASSEMBLY (BLUE) |

1 | 05017023-2B | MOUNT-VECTOR BRAKE (BLUE) |

2 | 05017025-2B | ARM-VECTOR BRAKE (BLUE) |

4 | HW1007 | CLIP RING-STAR-3/8" |

2 | 05018010 | PIN-PIVOT |

1 | HW1008 | BOLT-SHOULDER-3/8-16 X 1/2" |

2 | HW0408 | BOLT-HHCS-3/8-16 X 3 1/4" |

2 | HW0006 | NUT-NILN-3/8-16 |

1 | HW1003 | SPRING-TORSION |

1 | 05017026 | CLASP-VECTOR BRAKE |

BTC HANDWHEEL AND SHAFT KIT

P/N: 80152002

QTY |

PART# |

DESCRIPTION |

1 | 05026001 | HANDWHEEL |

1 | 05027002 | SHAFT-HANDWHEEL |

1 | HW0104 | WASHER-FLAT-1/4" |

1 | HW0003 | NUT-NILN-1/4-20 |

1 | 00197017 | KEY-3/16" X 1" |

1 | HW0317 | BOLT-HHCS-1/4-20 X 3 1/2" |

1 | 05017045 | HANDWHEEL COVER |

2 | HW0301 | BOLT-SELF TAP “F”-1/4-20 X 1/2 |

ATC / BTC / WTC

SLIDE BLOCK KIT

P/N: 80052005

QTY |

PART# |

DESCRIPTION |

2 | 05056002 | SLIDE BLOCK |

2 | 05057004 | RETAINER PLATE-BOTTOM |

8 | HW0006 | NUT-NILN-3/8-16 |

2 | HW0409 | BOLT-FHSCS-3/8-16 X 2” |

6 | HW0407 | BOLT-HHCS-3/8-16 X 2 3/4” |

16 | HW0108 | WASHER-FLAT-3/8”-SAE |

ATC / BTC / WTC

PULL BLOCK REPLACEMENT KIT

P/N: 80052002

QTY |

PART# |

DESCRIPTION |

2 | 05057005 | PULL BLOCK |

4 | HW0307 | BOLT-SHCS-1/4-20 X 1" |

4 | HW0103 | WASHER-LOCK-1/4” |

BATTERY STOP KIT

P/N: 80812001

QTY |

PART# |

DESCRIPTION |

1 | 00194001 | STOP-BATTERY |

1 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" |

1 | HW0006 | NUT-NILN-3/8-16 |

1 | HW0108 | WASHER-FLAT-3/8"-SAE |

RUBBER BUMPER KIT

P/N: 80092001

QTY |

PART# |

DESCRIPTION |

1 | HW1037 | BUMPER-RUBBER-RECESSED |

2 | HW0104 | WASHER-FLAT-1/4”-SAE |

1 | HW0003 | NUT-NILN-1/4-20 |

1 | HW0303 | BOLT-HHCS-1/4-20 X 1” |

ATC / BTC

MODIFIED LEVER VALVE KIT

P/N: 08046001

QTY |

PART# |

DESCRIPTION |

1 | HC0234-1 | HANDLE KIT (INCLUDES MODIFIED HANDLE) |

1 | HW0804 | SCREW-SHSS-3/8-16 X 1” |

1 | HW1004 | NUT-COUPLING-3/8-16 |

ATC / BTC

MANUAL VALVE KIT

P/N: 80042002

QTY |

PART# |

DESCRIPTION |

1 | 08046001 | MODIFIED LEVER VALVE KIT |

1 | HC0201 | MANUAL VALVE |

4 | H1303 | ADAPTER-90-DEG-#6 JIC X #8 NPT |

1 | HW0804 | SCREW-SHSS-3/8-16 X 1" |

1 | HW1004 | NUT-COUPLING-3/8-16 |

2 | HW0001 | NUT-HEX-#10-24 |

1 | HW0204 | SCREW-RHMS-#10-24 X 1" |

ATC / BTC

PUSH BUTTON KIT

P/N: 80032001

|

QTY |

PART# |

DESCRIPTION |

|

1 |

E0308 |

ACTUATOR-PUSH BUTTON |

1 |

E0307 |

CONTACT BLOCK-N/O |

10" VACUUM CUP ASSEMBLY

P/N: 00162001

|

QTY |

PART# |

DESCRIPTION |

|

1 |

N/A |

10" VACUUM CUP |

1 |

00117059 |

PLATE-ADAPTER-VACUUM CUP |

4 |

HW0328 |

BOLT-HHCS-5/16-18 X 3/4" |

1 |

P0505 |

BUSHING-RED-#6 NPT X #4 FNPT-BRASS |

1 |

P0506 |

ELBOW-STR-90 DEG-#4 NPT-BRASS |

1 |

P0401 |

ELBOW-#4 NPTM X 1/4" BARB-BRASS |

24 |

HW0108 |

WASHER-FLAT-3/8"-SAE |

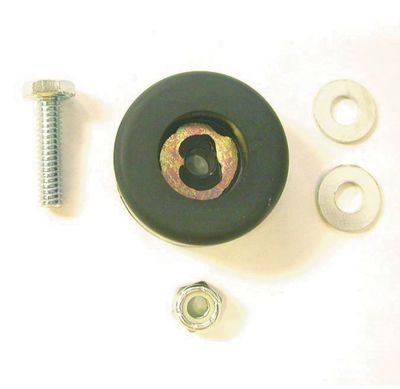

ATC / BTC VACUUM STUD SPRING KIT

P/N: HW-KIT-1

QTY |

PART# |

DESCRIPTION |

4 | HW0006 | NUT-NILN-3/8-16 |

16 | HW0108 | WASHER-FLAT-3/8"-SAE |

4 | HW0427 | STUD-3/8-16 X 4" |

8 | HW1001 | SPRING-3/8" |

ATC / BTC

VACUUM PUMP KIT (12V)

P/N: 80062001

QTY |

PART# |

DESCRIPTION |

1 | P0503 | NIPPLE-#4 NPT-BRASS |

1 | P0506 | ELBOW-STR-90 DEG-#4 NPT-BRASS |

1 | P0208 | FILTER |

1 | P0205 | SOLENOID-12V |

1 | P0001 | VACUUM PUMP-12V |

STATEMENT OF WARRANTY

Statement of Warranty

Click here for details on BHS' Statement of Warranty.