(BE-TS) Triple Stack Operator Aboard Battery Extractors – Parts & Service Manual (IOP-401)

Looking for a specific replacement part? Ctrl-F (or Command-F for Mac users) brings up your browsers search panel and can search any text on the entire web page. Find parts by searching a part # or part description.

Register your equipment with BHS Optima, BHS's free app.

California Residents: WARNING: This product contains chemicals known to the State of California to cause cancer and/or reproductive harm, and birth defects or other reproductive harm. Learn more here.

Preface

TP-606 – Safety & De-Energization Procedures

General Safety

|

|

- Battery Extractor (BE) units shall only be operated by suitable persons of at least 18 years of age, who have been trained in the proper and safe operation of the BE and expressly certified/charged, in writing, by the user or their representative.

- Only one person is permitted to travel on the BE at any time.

- BE units shall only be used indoors in an industrial setting on a hard, nonslip, and level floor without defects including but not limited to holes, gouges, cracks, drains or obstacles comprised of concrete or other suitable industrial material meeting the minimum requirements specified by BHS as well as any local requirements.

- A licensed structural engineer should be consulted prior to installing a BE on any building level other than the ground floor.

- BE units are not designed to be shipped or transported after initial delivery.

- Failure to follow these instructions and warnings may result in property damage, personal injury or death.

Work Area

- Keep work area clean and well lit. Cluttered work areas and poor lighting can lead to accidents.

- Clean up/contain any fluid spills immediately to prevent slips or falls.

- Be aware of potential hazards when performing any service or maintenance to the unit.

Service & Maintenance

Service personnel shall wear Personal Protective Equipment (PPE) appropriate for the task being performed.

Operational Safety

- Only personnel trained in the proper and safe operation of BE units may operate or service the BE.

- Operators shall wear appropriate PPE suitable for working with industrial lead-acid batteries while operating the BE (See Lead-Acid Battery Explosion Hazard section).

- All data plates, warning labels, placards, etc. shall be in place and legible at all times. Contact BHS for re-placement data plates, warning labels, placards or instructions.

- All users and service personnel shall be familiar with the meaning and risks associated with all data plates, warning labels, etc.

- All operators and service personnel shall be aware of potential crush and shear points while operating or servicing the BE.

- Keep hands and arms inside the operator compartment while operating the BE.

- Remove BE from service if damaged, defective, or operating improperly (or becomes such while operating) until repairs can be made to correct any problem(s).

- All operators shall be aware of the location of the end stops in the travel path to prevent driving the BE into the end stops.

Do's and Don'ts

- DO NOT exceed the maximum capacity of the BE.

- DO NOT modify or fit the BE with attachments without prior, written approval from BHS.

- DO NOT perform any maintenance or service to the BE with a battery loaded on the BE.

- DO NOT allow anyone to ride in or on the BE.

- DO NOT operate the BE with any guard or cover removed unless required for maintenance or repair.

- Disconnect the BE from all power sources before attempting to perform service or maintenance to the unit.

- DO NOT drive the BE into the end stops.

- DO NOT operate the BE if disengaged from the guidance track.

- DO NOT allow a battery to exit the BE when a lift truck or battery stand is not present to accept the battery.

- DO NOT rotate the arm onto a battery such that any part of the extractor arm, vacuum cup or magnet contacts the top of the battery.

- DO NOT allow anyone to enter the area under the carriage without the service stands properly installed.

- DO NOT use the BE in a manner for which it is not intended. Some examples of prohibited use are but not limited to:

- To transport people

- As a vehicle jack

- To lift loads greater than its rated load capacity

- Where unintentional movement may exist

- Having direct contact with foodstuffs

- In a potentially explosive atmosphere

De-Energization

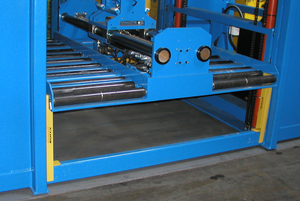

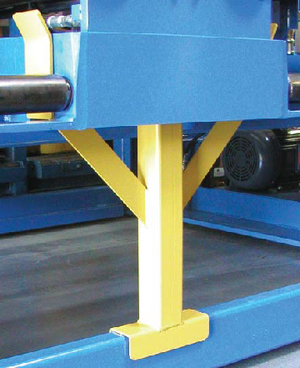

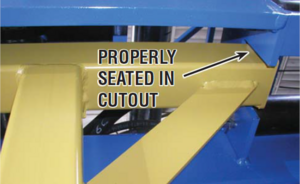

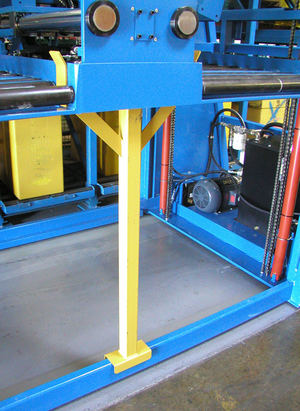

1. Fully lower the BE roller bed or position the roller bed on service stands if service requires the bed be raised. See Figures 1 & 2.

| Failure to properly support the roller bed when performing service under the BE could result in injury from the roller bed lowering unexpectedly. |

|---|

2. Turn key on dashboard to the “OFF” position. See Figure 3.

3. Disconnect power to the extractor or shut off the electrical branch circuit breaker.

| Failure to disconnect electrical power to the BE could result in electrical shock. Serious personal injury or death will occur. |

4. Actuate all hydraulic levers in both directions to re-lease any stored hydraulic pressure. See Figure 4.

Failure to release any stored hydraulic pres-sure could result in injury from:

|

Labels & Placards

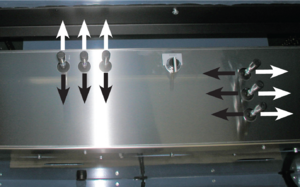

Operators should be familiar with the meaning of the following labels and placards found on the BE to ensure proper and safe operation.

|

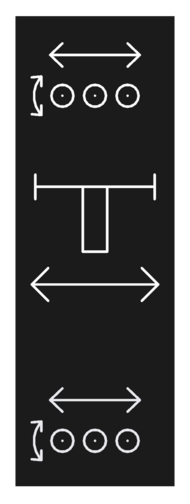

Far Power Rollers |

|---|---|

| Arm Travel | |

| Near Power Rollers |

| ||

|---|---|---|

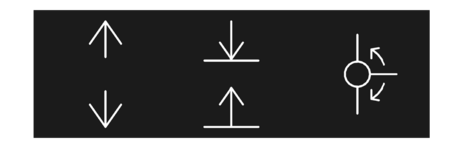

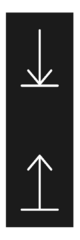

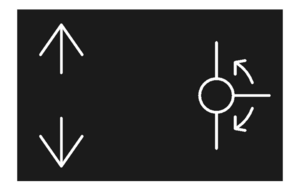

| Drive Forward/Reverse | Platform Raise/Lower | Arm Rotation Near/Far |

|

| |

|---|---|---|

| Platform Raise/Lower | Drive Foward/Reverse | Arm Rotation Near/Far |

General Information

Specification Data

| BE-24-2-TS | BE-36-2-TS | BE-42-2-TS | ||

|---|---|---|---|---|

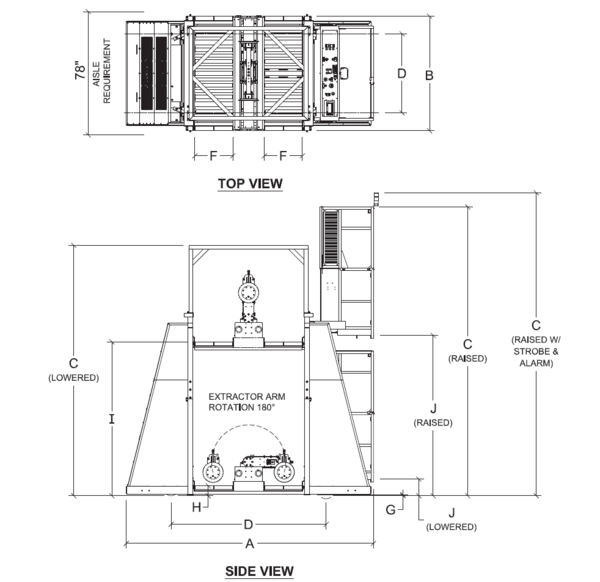

| A | Overall Length | 156.5" | 180.5" | 192.5" |

| B | Overall Width | 72" | 72" | 72" |

| C | Overall Height (Lowered) | 158.188" | 158.188" | 160.688" |

| Overall Height (Raised w/ Overhead Guard) | 182.375" | 182.375" | 182.375" | |

| Overall Height (Raised w/ Strobe & Alarm) | 191.75" | 191.75" | 191.75" | |

| D | Wheel Base | 98" | 122" | 134" |

| E | Drive Wheel Center line | 51" | 51" | 51" |

| F | Battery Compartment Width | 24" | 36" | 42" |

| G | Ground Clearance | .625" | .625" | .625" |

| H | Minimum Roller Height | 6.5" | 6.5" | 6.5" |

| I | Maximum Roller Height | 96" | 96" | 96" |

| J | Operator Platform Height (Lowered/Raised) | 11" / 103" | 11" / 103" | 11" / 103" |

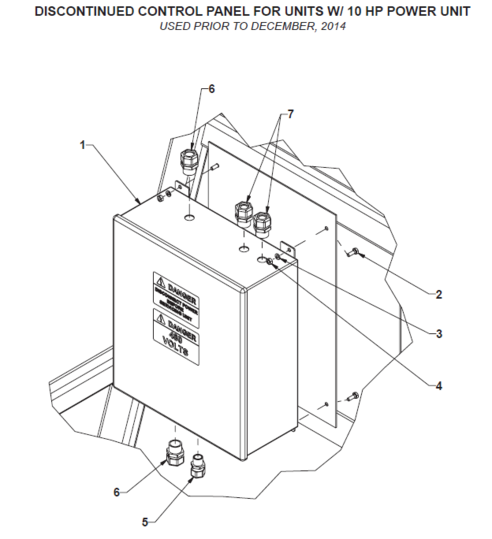

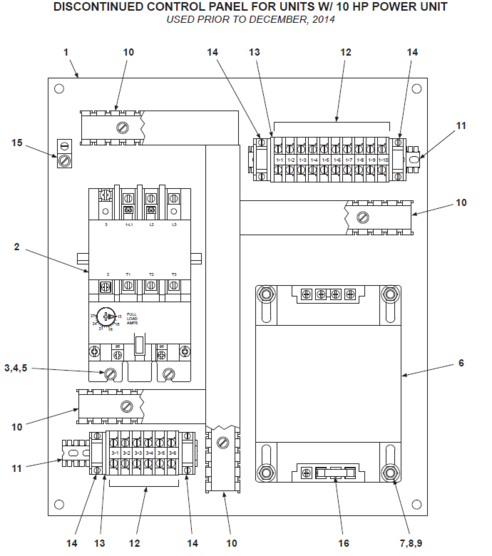

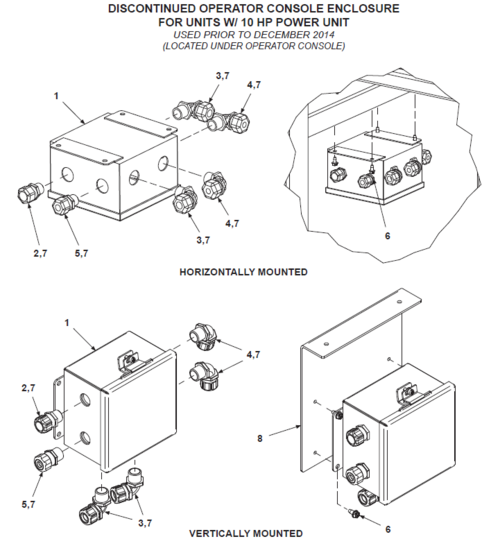

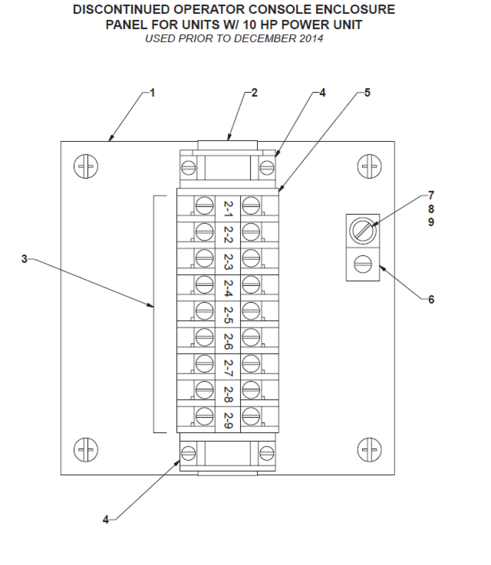

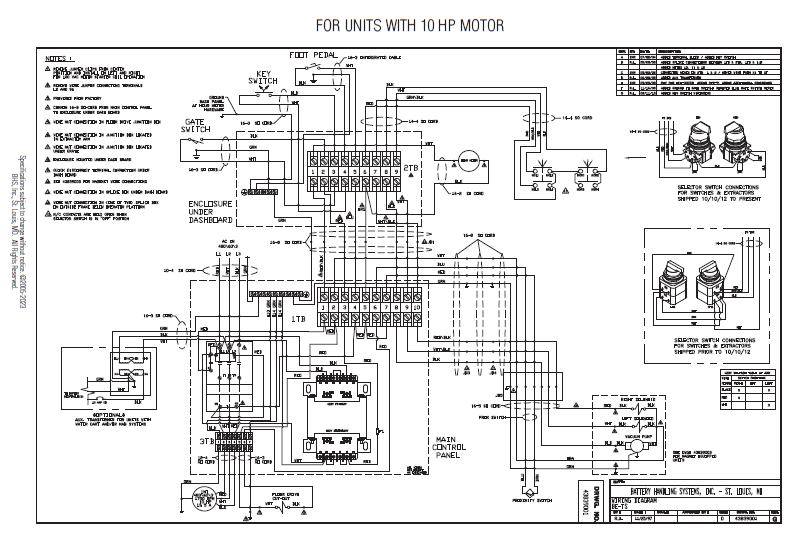

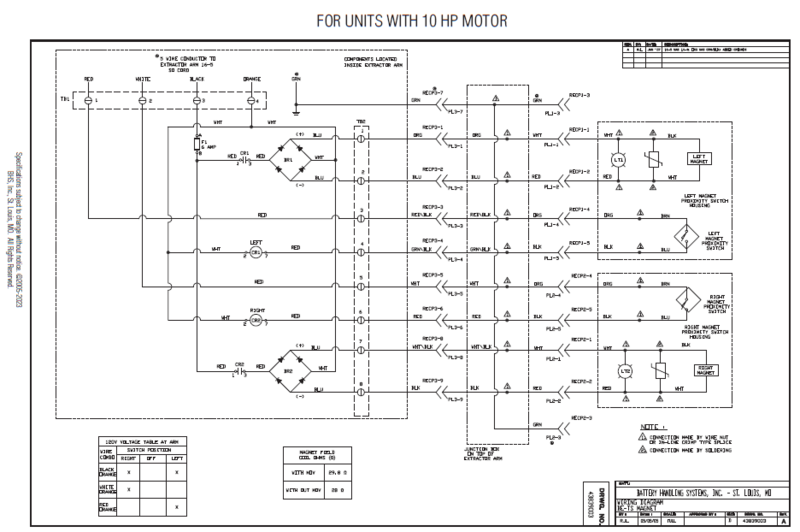

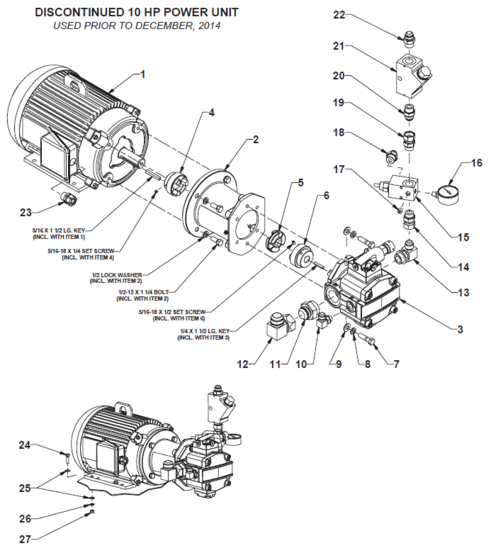

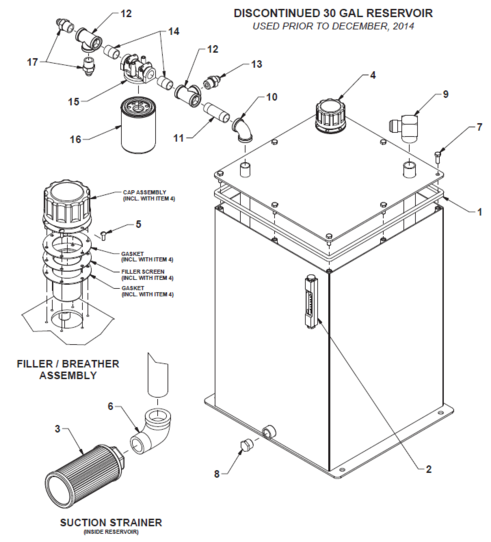

UNITS WITH 10 HP POWER UNIT USED PRIOR TO DECEMBER, 2014

| BE-24-2-TS | BE-36-2-TS | BE-42-2-TS | |

|---|---|---|---|

| Travel Speed | 0 to 190 ft/min / 0 to 0.97 m/s | 0 to 190 ft/min / 0 to 0.97 m/s | 0 to 190 ft/min / 0 to 0.97 m/s |

| Raise - Lower Speed | 0 to 26 ft/min / 0 to 0.13 m/s | 0 to 26 ft/min / 0 to 0.13 m/s | 0 to 26 ft/min / 0 to 0.13 m/s |

| Powered Roller Speed | 0 to 37 ft/min / 0 to 0.19 m/s | 0 to 37 ft/min / 0 to 0.19 m/s | 0 to 37 ft/min / 0 to 0.19 m/s |

| Arm Traverse Speed | 0 to 20 ft/min / 0 to 0.10 m/s | 0 to 20 ft/min / 0 to 0.10 m/s | 0 to 20 ft/min / 0 to 0.10 m/s |

| Arm Rotation Time | 6 s to 8 s | 6 s to 8 s | 6 s to 8 s |

| Draw Bar Pull / Vacuum

(12" / 305 mm Round Cup) |

1,000 lb / 454 kg | 1,000 lb / 454 kg | 1,000 lb / 454 kg |

| Draw Bar Pull Magnet* | 800 lb to 1,200 lb / 363 to 544 kg | 800 lb to 1,200 lb / 363 to 544 kg | 800 lb to 1,200 lb / 363 to 544 kg |

| Vacuum Attach Time | < 1 s | < 1 s | < 1 s |

| Vacuum Release Time | < 1 s | < 1 s | < 1 s |

| Input Voltage | 480 V / 3 ph / 60Hz | 480 V / 3 ph / 60Hz | 480 V / 3 ph / 60Hz |

| AC Current Draw | 16.5 A | 16.5 A | 16.5 A |

| Control Circuit Voltage | 120 V ac | 120 V ac | 120 V ac |

| Hydraulic Power Unit | 10 hp / 7.46 kW | 10 hp / 7.46 kW | 10 hp / 7.46 kW |

| Hydraulic Pump | 16 gal/min / 61 L/min | 16 gal/min / 61 L/min | 16 gal/min / 61 L/min |

| Power Unit | Hydraulic, Variable Displacement | Hydraulic, Variable Displacement | Hydraulic, Variable Displacement |

| Operating Pressure | 1,500 psi / 103 bar | 1,500 psi / 103 bar | 1,500 psi / 103 bar |

| Vacuum Pump | 1/3 hp / 0.25 kW | 1/3 hp / 0.25 kW | 1/3 hp / 0.25 kW |

| Vacuum | 21" Hg / 711 mbar | 21" Hg / 711 mbar | 21" Hg / 711 mbar |

| Full Load Capacity | 10,000 lb / 4535 kg | 10,000 lb / 4535 kg | 10,000 lb / 4535 kg |

| Weight (Empty) | 8,000 lb / 3629 kg | 8,300 lb / 3765 kg | 8,600 lb / 3901 kg |

| Total Compartment Rollers / Powered | 11/5 | 11/5 | 11/5 |

| Guide Track | 3" x 2.5" Angle

76 mm x 64 mm |

3" x 2.5" Angle

76 mm x 64 mm |

3" x 2.5" Angle

76 mm x 64 mm |

| Overall Dimensions (L x W x H) | 156.5" x 72" x 158.188"

3975 mm x 1829 mm x 4018 mm |

180.5" x 72" x 158.188"

4585 mm x 1829 mm x 4018 mm |

192.5" x 72" x 160.688"

4890 mm x 1829 mm x 4081 mm |

| Vacuum Arm Reach | 4.5" to 14" / 114 mm to 356 mm | 4.5" to 14" / 114 mm to 356 mm | 4.5" to 14" / 114 mm to 356 mm |

| Vacuum Arm Reach (Hydraulic Extension) | 9" to 23" / 229 mm to 584 mm | 9" to 23" / 229 mm to 584 mm | 9" to 23" / 229 mm to 584 mm |

| Magnet Arm Reach (Hydraulic Extension) Truck Side | 14" to 22" / 355 mm to 559 mm | 14" to 22" / 355 mm to 559 mm | 14" to 22" / 355 mm to 559 mm |

| Wheel Base | 98" / 2489 mm | 122" / 3099 mm | 134" / 3404 mm |

| Drive Wheel Center Line | 51" / 1295 mm | 51" / 1295 mm | 51" / 1295 mm |

| Battery Compartment Width | 24" / 610 mm | 36" / 915 mm | 42" / 1067 mm |

| Maximum Battery Dimensions

(L x W x H) |

48" x 23" x 34"

1219 mm x 584 mm x 864 mm |

48" x 35" x 34"

1219 mm x 889 mm x 864 mm |

48" x 41" x 34"

1219 mm x 1041 mm x 864 mm |

| Minimum Battery Width

(with vacuum / magnet) |

12" / 305 mm

6" / 152 mm |

12" / 305 mm

6" / 152 mm |

12" / 305 mm

6" / 152 mm |

| Minimum Battery Height | 17.75" / 451 mm | 17.75" / 451 mm | 17.75" / 451 mm |

| Ground Clearance | 0.63" / 16 mm | 0.63" / 16 mm | 0.63" / 16 mm |

| Roller Height | 6.5" Min / 96" Max

165 mm Min / 2438 mm Max |

6.5" Min / 96" Max

165 mm Min / 2438 mm Max |

6.5" Min / 96" Max

165 mm Min / 2438 mm Max |

| NOTES | |||

| Specifications may vary ± 5% because of temperature, floor considerations, and operator efficiency. Values represented under normal operating conditions. | |||

| * Varies with battery case thickness and condition. | |||

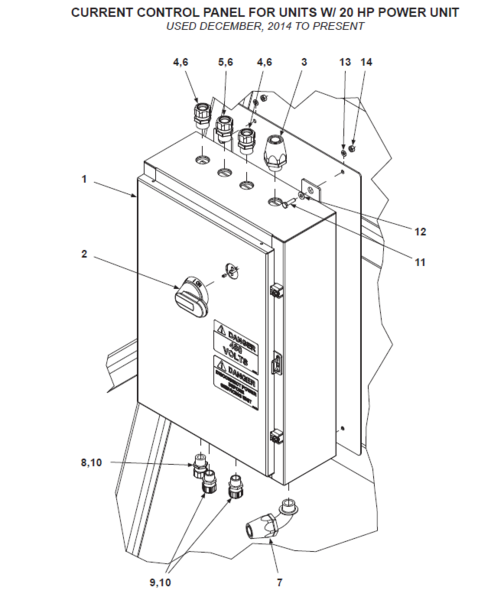

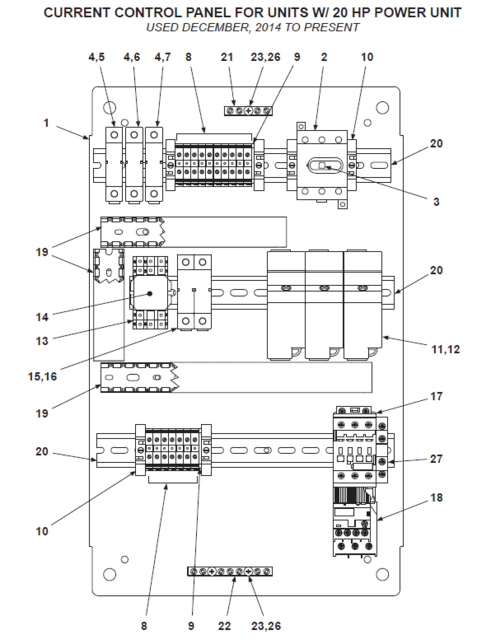

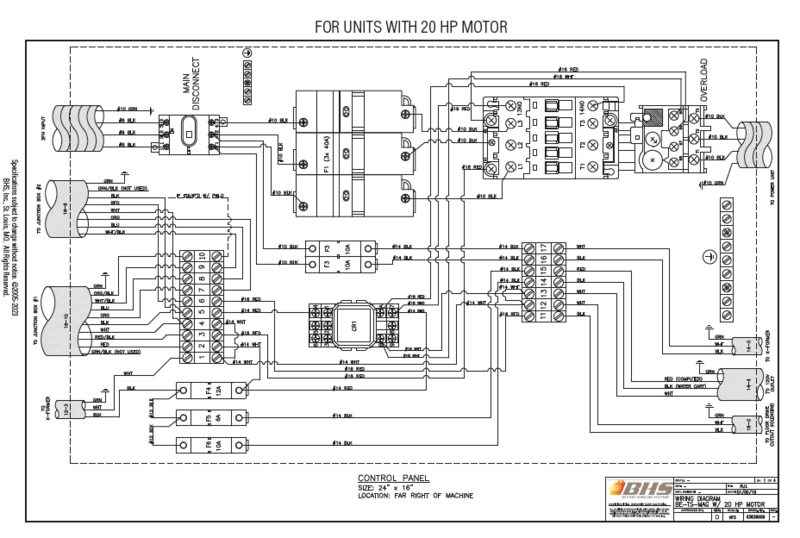

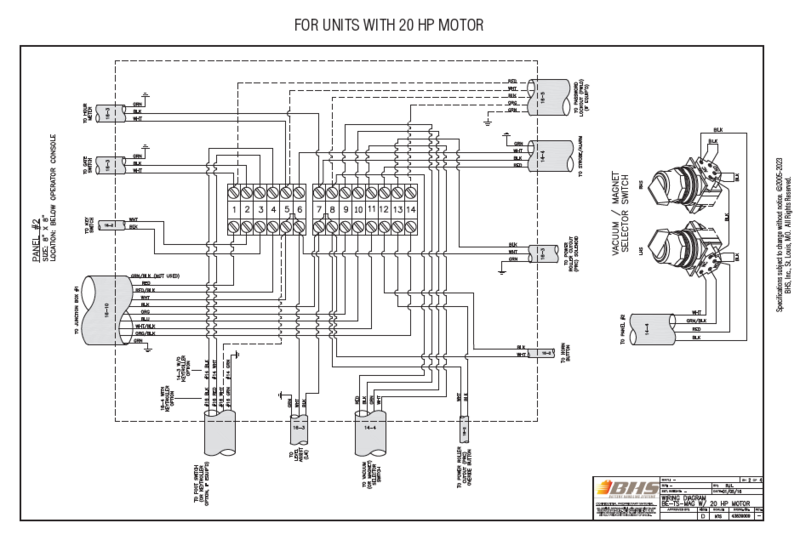

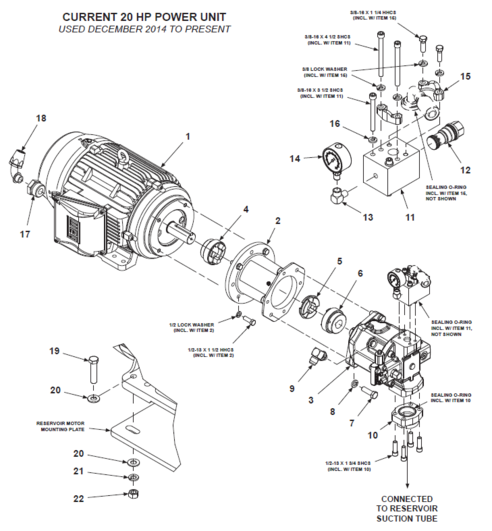

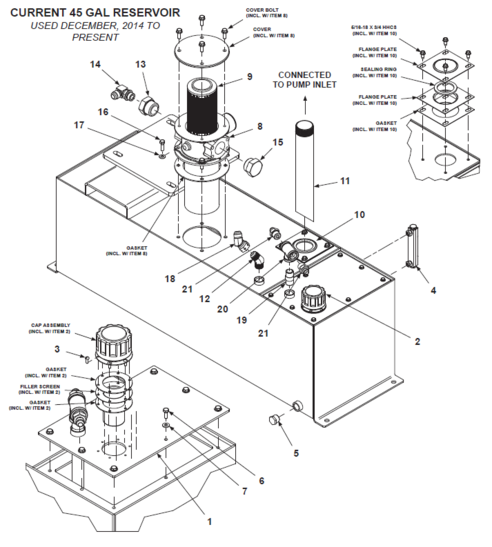

UNITS WITH 20 HP POWER UNIT USED DECEMBER, 2014 TO PRESENT

| BE-24-2-TS | BE-36-2-TS | BE-42-2-TS | |

|---|---|---|---|

| Travel Speed | 0 to 240 ft/min / 0 to 1.22 m/s | 0 to 240 ft/min / 0 to 1.22 m/s | 0 to 240 ft/min / 0 to 1.22 m/s |

| Raise - Lower Speed | 0 to 26 ft/min / 0 to 0.13 m/s | 0 to 26 ft/min / 0 to 0.13 m/s | 0 to 26 ft/min / 0 to 0.13 m/s |

| Powered Roller Speed | 0 to 37 ft/min / 0 to 0.19 m/s | 0 to 37 ft/min / 0 to 0.19 m/s | 0 to 37 ft/min / 0 to 0.19 m/s |

| Arm Traverse Speed | 0 to 20 ft/min / 0 to 0.10 m/s | 0 to 20 ft/min / 0 to 0.10 m/s | 0 to 20 ft/min / 0 to 0.10 m/s |

| Arm Rotation Time | 6 s to 8 s | 6 s to 8 s | 6 s to 8 s |

| Draw Bar Pull / Vacuum

(12" / 305 mm Round Cup) |

1,000 lb / 454 kg | 1,000 lb / 454 kg | 1,000 lb / 454 kg |

| Draw Bar Pull Magnet* | 800 lb to 1,200 lb / 363 to 544 kg | 800 lb to 1,200 lb / 363 to 544 kg | 800 lb to 1,200 lb / 363 to 544 kg |

| Vacuum Attach Time | < 1 s | < 1 s | < 1 s |

| Vacuum Release Time | < 1 s | < 1 s | < 1 s |

| Input Voltage | 480 V / 3 ph / 60Hz | 480 V / 3 ph / 60Hz | 480 V / 3 ph / 60Hz |

| AC Current Draw | 35 A | 35 A | 35 A |

| AC Current Draw w/ Electric Drive Option | 42 A | 42 A | 42 A |

| Control Circuit Voltage | 120 V ac | 120 V ac | 120 V ac |

| Hydraulic Power Unit | 20 hp / 14.9 kW | 20 hp / 14.9 kW | 20 hp / 14.9 kW |

| Hydraulic Power Unit w/ Electric Drive Option | 25 hp / 18.7 kW | 25 hp / 18.7 kW | 25 hp / 18.7 kW |

| Hydraulic Pump | 22 gal/min / 83 L/min | 22 gal/min / 83 L/min | 22 gal/min / 83 L/min |

| Power Unit | Hydraulic, Variable Displacement | Hydraulic, Variable Displacement | Hydraulic, Variable Displacement |

| Operating Pressure | 1,500 psi / 103 bar | 1,500 psi / 103 bar | 1,500 psi / 103 bar |

| Vacuum Pump | 1/3 hp / 0.25 kW | 1/3 hp / 0.25 kW | 1/3 hp / 0.25 kW |

| Vacuum | 21" Hg / 711 mbar | 21" Hg / 711 mbar | 21" Hg / 711 mbar |

| Full Load Capacity | 10,000 lb / 4535 kg | 10,000 lb / 4535 kg | 10,000 lb / 4535 kg |

| Weight (Empty) | 8,000 lb / 3629 kg | 8,300 lb / 3765 kg | 8,600 lb / 3901 kg |

| Total Compartment Rollers / Powered | 11/5 | 11/5 | 11/5 |

| Guide Track | 3" x 2.5" Angle

76 mm x 64 mm |

3" x 2.5" Angle

76 mm x 64 mm |

3" x 2.5" Angle

76 mm x 64 mm |

| Overall Dimensions (L x W x H) | 156.5" x 72" x 158.188"

3975 mm x 1829 mm x 4018 mm |

180.5" x 72" x 158.188"

4585 mm x 1829 mm x 4018 mm |

192.5" x 72" x 160.688"

4890 mm x 1829 mm x 4081 mm |

| Vacuum Arm Reach | 4.5" to 14" / 114 mm to 356 mm | 4.5" to 14" / 114 mm to 356 mm | 4.5" to 14" / 114 mm to 356 mm |

| Vacuum Arm Reach (Hydraulic Extension) | 9" to 23" / 229 mm to 584 mm | 9" to 23" / 229 mm to 584 mm | 9" to 23" / 229 mm to 584 mm |

| Magnet Arm Reach (Hydraulic Extension) Truck Side | 14" to 22" / 355 mm to 559 mm | 14" to 22" / 355 mm to 559 mm | 14" to 22" / 355 mm to 559 mm |

| Wheel Base | 98" / 2489 mm | 122" / 3099 mm | 134" / 3404 mm |

| Drive Wheel Center Line | 51" / 1295 mm | 51" / 1295 mm | 51" / 1295 mm |

| Battery Compartment Width | 24" / 610 mm | 36" / 915 mm | 42" / 1067 mm |

| Maximum Battery Dimensions

(L x W x H) |

48" x 23" x 34"

1219 mm x 584 mm x 864 mm |

48" x 35" x 34"

1219 mm x 889 mm x 864 mm |

48" x 41" x 34"

1219 mm x 1041 mm x 864 mm |

| Minimum Battery Width

(with vacuum / magnet) |

12" / 305 mm

6" / 152 mm |

12" / 305 mm

6" / 152 mm |

12" / 305 mm

6" / 152 mm |

| Minimum Battery Height | 17.75" / 451 mm | 17.75" / 451 mm | 17.75" / 451 mm |

| Ground Clearance | 0.63" / 16 mm | 0.63" / 16 mm | 0.63" / 16 mm |

| Roller Height | 6.5" Min / 96" Max

165 mm Min / 2438 mm Max |

6.5" Min / 96" Max

165 mm Min / 2438 mm Max |

6.5" Min / 96" Max

165 mm Min / 2438 mm Max |

| NOTES | |||

| Specifications may vary ± 5% because of temperature, floor considerations, and operator efficiency. Values represented under normal operating conditions. | |||

| * Varies with battery case thickness and condition. | |||

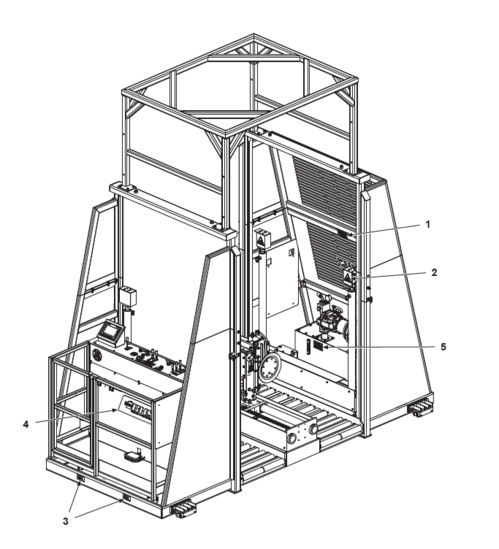

Pre-Installation Check

Floor Conditions

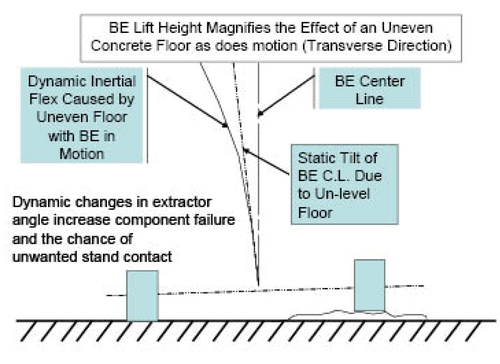

The floor is the single most critical area of the battery room. A bad floor can cause significant issues with the installation as well as downtime and maintenance problems with the extractor. The floor should be verified as to its minimum thickness and strength with user. As noted on the drawing, the specific requirement of flatness for your particular type of system is listed. Below is a chart stating floor requirements. If possible, especially on double stack and higher systems, a digital level should be used to shoot the grade for compliance with the specification. The floor should also be inspected for severe cracks or excessively wide expansion joints in the travel path of the machine. If floor drains are present, they must not have a grade to the opening that encroaches into the travel path.

F-min is a rating method used to evaluate the flatness and levelness of a floor designated as "defined travel path". For example, an F-min rating of 60 means that there is no more than .129" of variation in the transverse axis (wheels left to right) and .287" variation in the longitudinal axis (front to back) on the equipment.

To avoid potential damage to drive wheel assemblies, guide track, structural components, guide rollers and issues with the inner frame equalization the "defined travel path" of the Battery Extractor should meet or exceed the recommended F-min specification. See chart below for the model specifications.

| Model | F-Min | +/- Longitudinal | +/- Transverse | Slope Defect |

|---|---|---|---|---|

| SL, DS | 40 | .287" | .192" | .096" |

| TS | 60 | .186" | .129" | .066" |

| QS | 85 | .131" | .091" | .047" |

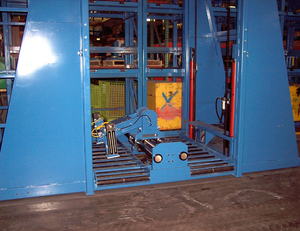

Operating Controls & Instructions

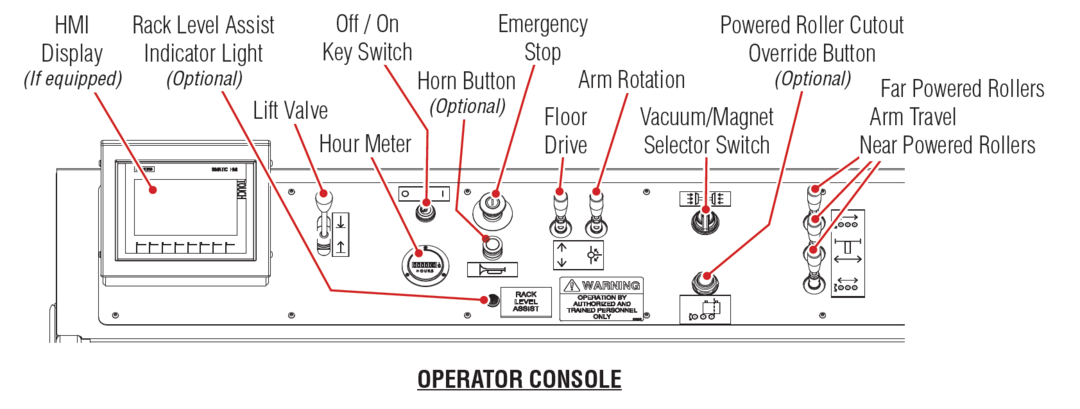

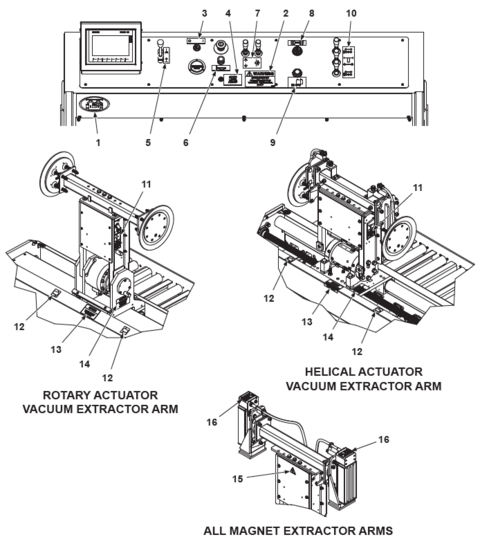

Operator Console

NOTE: Safety devices for the machine and the machine operating area SHALL NOT be rendered inoperable or misused.

Typical BE-TS operator console shown above. Position of optional controls may vary from that shown depending on age of unit and/or combination of optional controls present.

HMI display standard on units shipped after February, 2020 for Industrial Internet of Things (IIoT) package.

Safety Features

Key Switch – Located on the dash (see above). Primary on/off switch to prevent unauthorized personnel from operating the BE.

Emergency Stop – Located on the dash (see above). Will stop all functions immediately, locking all hydraulics in place. To use, press down on the red button. The machine key must be used to reset the emergency stop.

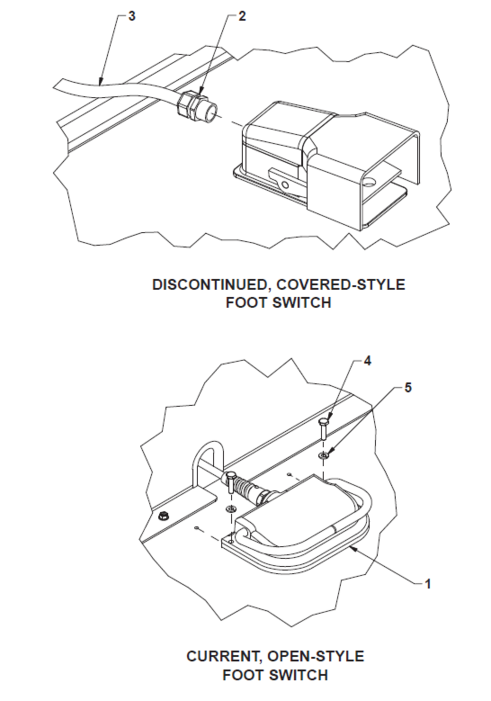

Foot Switch – Must be depressed to operate the BE. Stepping off the foot switch will stop all functions immediately, locking all hydraulics in place. To resume use, depress the foot switch.

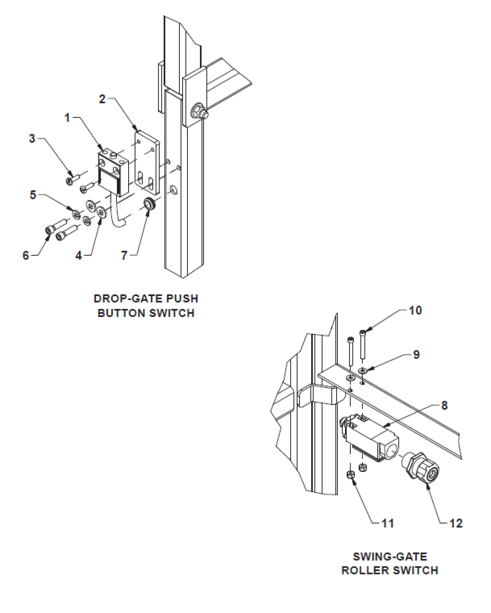

Gate Switch – The gate must be fully closed for the BE to operate.

Extractor Arm Switch – Does not permit the machine to move forward or backward unless the extractor arm is located in the center of the carriage between the indicating arrows located on the arm guard.

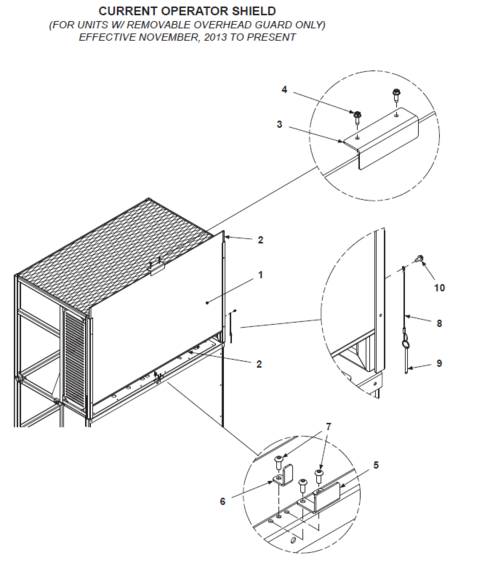

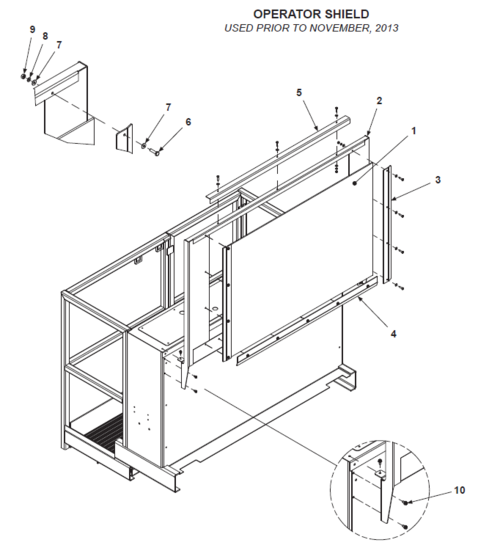

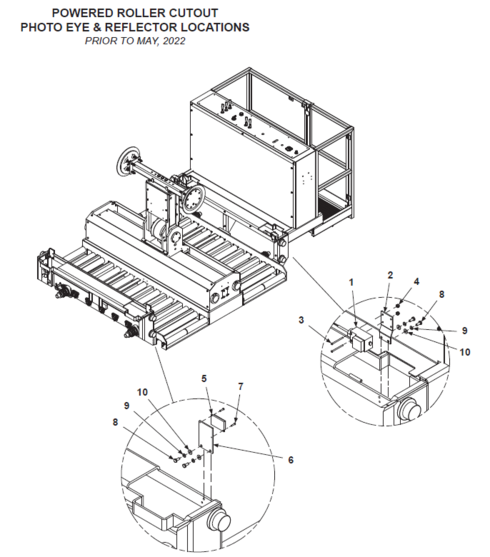

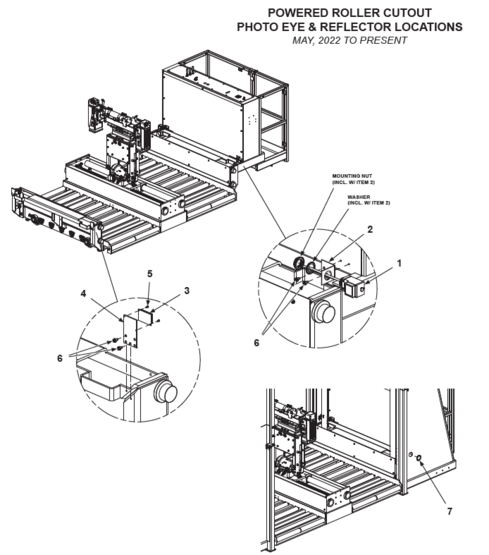

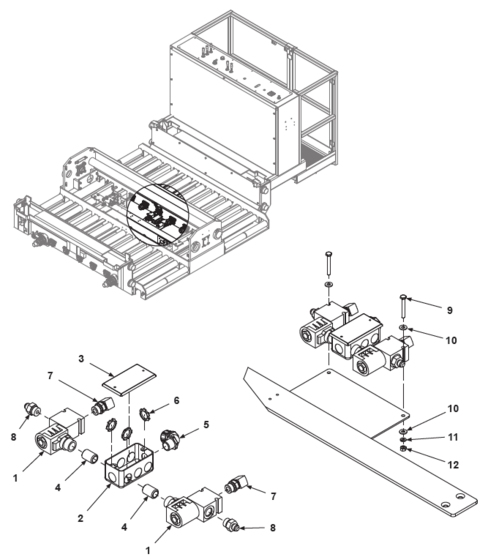

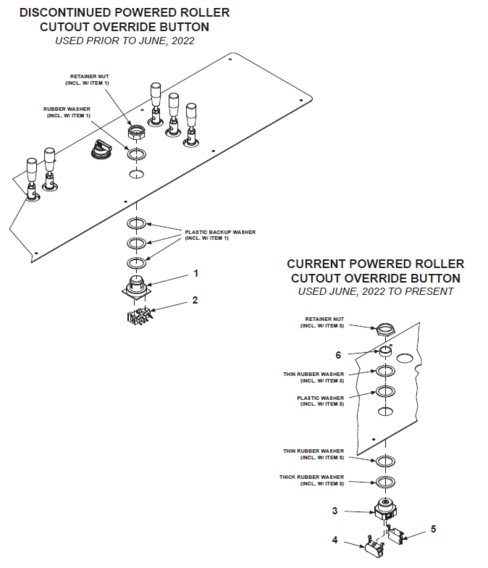

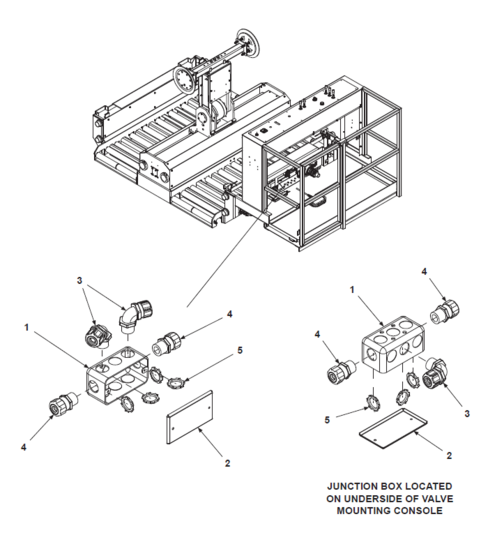

Powered Roller Cutout (PRC-1 or PRC-2) (if equipped) – Disengages the powered roller function when the photo eye positioned on the edge of the BE battery compartment is disrupted by a battery, requiring additional input from the operator. Pressing the "Power Roller Cutout" override button (see above) on the dash will resume powered roller operation when loading or unloading batteries from the BE carriage.

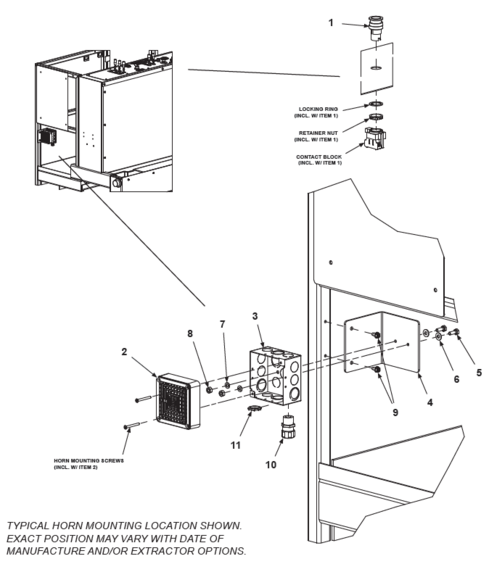

Horn (If equipped) – Button located on the dash (see above). Used to alert personnel before moving the BE.

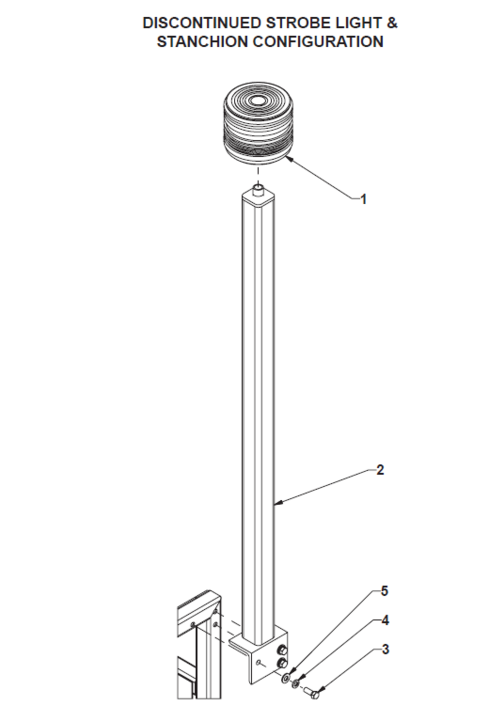

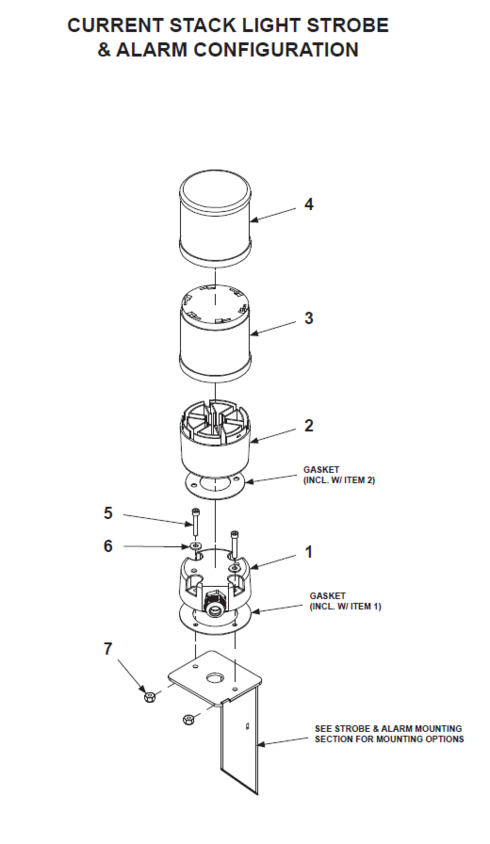

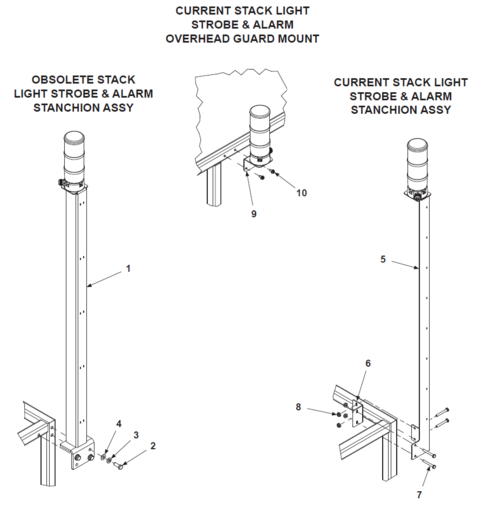

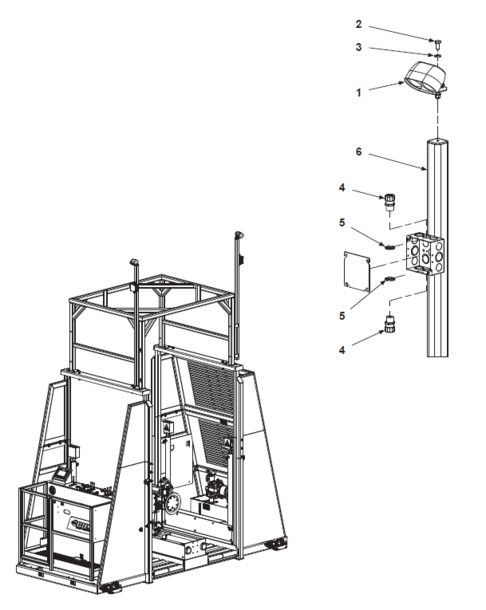

Strobe Light (If equipped) – Located on a vertical stanchion mounted to the right rear of the operator compartment. For units equipped with optional overhead guard (OHG), the beacon is located above of the operator compartment. Beacon automatically flashes when the BE is switched on to visually notify the BE is in use.

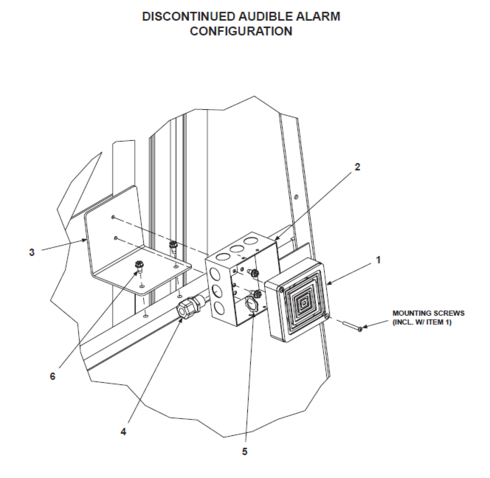

Audible Alarm (if equipped) – Mounted in the same location as the Strobe Light. Automatically sounds when the BE is switched on to notify personnel that the BE is in use.

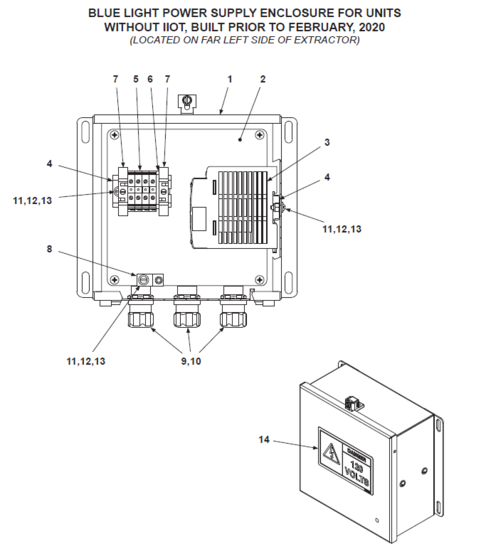

Blue Light (if equipped) - Mounted at an elevated position on either end of the extractor which project a bright, highly concentrated blue beam pattern on the ground visually alerting personnel to the direction the extractor is moving.

Operation Overview

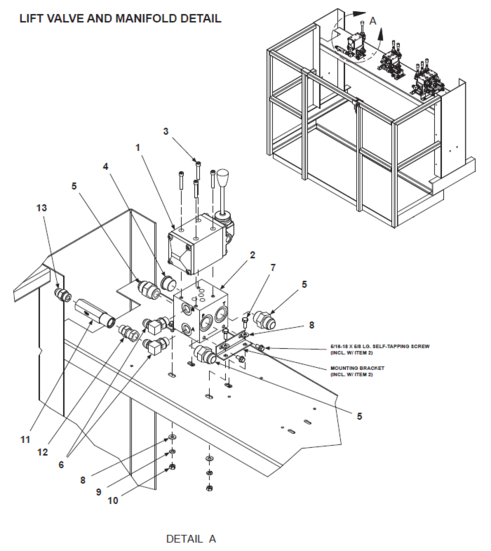

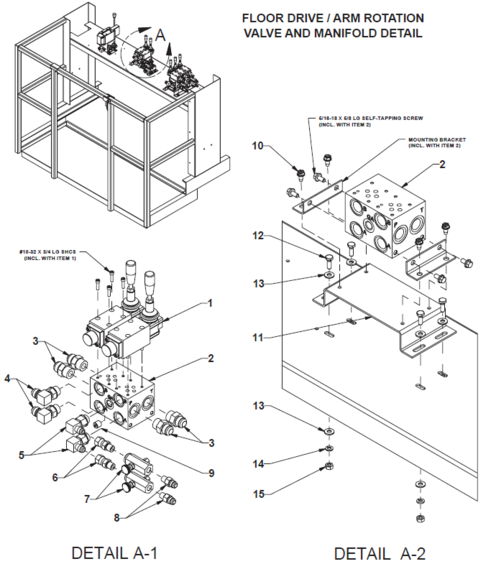

- All operators should be familiar with the operator console of the extractor before performing any battery changes. The controls of the console are simple and well marked. It consists of six, manually operated, hydraulic control valves and a three position selector switch which controls the left and right vacuum cups (or optional magnets).

- The operator shall make certain there are no persons or obstacles in the extractor path prior to traveling forward or reverse.

- All manual valves are moved in the direction of the function travel which it controls with exception of the lift/lower valve, which is pulled toward the operator for "up" and pushed away for "down."

- In the event of any failure or malfunction, step off the dead-man switch or press the E-stop button and all functions will stop immediately, locking all hydraulics in place.

- The extractor arm must be in the center of the carriage or the unit will not travel forward or reverse.

- To ensure smooth operation, all valve movements should be made in a slow, deliberate motion.

- Only one key should be provided to operate the extractor.

- When leaving the machine, the operator shall turn off the key switch, remove the key and logout out of the IIoT (if equipped) to prevent unauthorized use

- Ensure all the batteries and cables are properly stored in the battery stands prior to moving the BE.

- The BE is designed to carry only one battery in each compartment on the carriage.

- When loading the BE, position the batteries in the center of the compartments on the powered rollers to prevent any battery movement when transporting.

- Ensure there are no projections outside of the carriage before moving the BE.

Operating Instructions

Pre-Change Out Preparation

1. Position lift truck for change out in designated area.

2. Remove all battery restraints and disconnect battery cables following manufacturers guidelines. (Be sure to position battery cables so as not to be damaged by the battery during change out.)

3. Board battery extractor and close safety gate. (Gate must be fully closed or unit will not operate.)

4. Turn key switch to "ON" position.

5. Log in on the HMI display (if equipped with BE-IIoT package).

6. Depress foot pedal.

Discharged Battery Removal

1. Move extractor forward or reverse to position center of empty compartment with center of lift truck battery compartment. (Lead roller of extractor is equipped with a centering groove. Users may find it beneficial to mark center of lift truck compartment to aid in alignment.)

2. Align extractor's roller compartment height with lift truck's battery compartment.

3. Rotate extractor arm into battery compartment aligned in Step 2.

4. Move extractor arm toward battery until vacuum cup/magnet contacts battery.

![]() DO NOT force cup/magnet into battery after initial contact with battery is made.

DO NOT force cup/magnet into battery after initial contact with battery is made.

5. Energize vacuum/magnet by turning selector switch to proper direction, left or right.

6. Move extractor arm away from lift truck toward center of extractor roller bed, removing discharged battery. (Battery should be pulled past first three idler rollers onto first or second powered roller.)

7. Turn off vacuum/magnet and move extractor arm away from battery 1" to 2".

8. Rotate extractor arm out of battery compartment into opposite compartment (if empty) and center arm in carriage.

9. Move battery into center of compartment using powered rollers.

Charged Battery Retrieval

1. Locate charged battery for appropriate type of lift truck being changed.

2. Raise battery extractor roller compartment to proper level to gain access as needed to disconnect desired battery from its charger and disengage battery safety stop.

![]() ALWAYS be sure charging has been completed and charger is not still charging battery. Dangerous sparking/arcing can occur if battery is unplugged from charger while charging.

ALWAYS be sure charging has been completed and charger is not still charging battery. Dangerous sparking/arcing can occur if battery is unplugged from charger while charging.

3. Move extractor to appropriate rack position and align empty roller compartment with the center of the battery storage rack compartment. (The battery safety stop of each compartment is the center of that compartment and should be used for alignment with the groove in the lead roller of the battery extractor compartment.)

4. Rotate arm into empty compartment (if not already positioned there.)

5. Move extractor arm toward battery until vacuum cup/magnet contacts battery.

6. Energize vacuum cup/magnet by turning selector switch to proper direction, left or right.

![]() DO NOT force cup/magnet into battery after initial contact with battery is made.

DO NOT force cup/magnet into battery after initial contact with battery is made.

7. Move extractor arm away from battery rack toward center of extractor roller bed, removing charged battery. (Battery should be pulled past first three idler rollers onto first or second powered roller.)

8. Turn off vacuum/magnet and move extractor arm away from battery 1" to 2".

9. Rotate extractor arm out of battery compartment into fully vertical position.

10. Move battery into center of compartment using powered rollers.

Discharged Battery Return

1. If required, adjust extractor compartment height to battery rack level with open battery compartment. Drive extractor to align roller compartment containing discharged battery with open battery compartment.

2. Return discharged battery to battery rack using powered rollers.

NOTE: In most instances, batteries can be deposited into battery racks in one motion using only powered rollers. When this does not work, the battery may need slight assistance from extractor arm. To do this, rotate arm into compartment such as one would if removing battery from rack. If extractor is vacuum equipped, position top edge of cup slightly higher than edge of battery (or over lifting eye if so equipped) to prevent cup from adhering to battery - No vacuum/magnet is necessary for pushing. DO NOT activate vacuum/magnet switch. Slowly push battery into rack until fully into compartment.

3. Engage battery safety stop and connect battery to charger as required.

Charged Battery Installation

1. Lower extractor to fully lowered position.

2. Drive extractor back to lift truck and align roller compartment containing charged battery as performed in steps 1 and 2 of "Discharged Battery Removal".

3. Move charged battery toward lift truck compartment by using powered rollers, verifying precise battery alignment.

![]() Many batteries are a tight fit into lift truck battery compartments. Care MUST be taken to ensure alignment is precise to avoid damage to battery, lift truck, and/or battery extractor.

Many batteries are a tight fit into lift truck battery compartments. Care MUST be taken to ensure alignment is precise to avoid damage to battery, lift truck, and/or battery extractor.

4. Adjust extractor vertically as well as horizontally, if needed

5. Insert battery into lift truck as far as possible using only the powered rollers.

6. Rotate extractor arm into compartment and SLOWLY push battery into lift truck. (Be sure to watch battery cables for interference.)

7. Return extractor arm to center of roller bed and lower extractor to fully lowered position. Drive extractor out of immediate area.

8. Turn off key switch, remove key from switch, log out on the HMI display (if equipped with BE-IIoT package) and carefully exit extractor.

9. Secure newly installed battery in lift truck and reconnect battery cables.

10. Return lift truck to service

Optional Powered Roller Cutout Operation

Units equipped with optional Powered Roller Cutout, the powered roller override button must be depressed in addition to actuating the hydraulic valve when a battery disrupts the photo eye(s) at the edge of the battery compartments while using the powered rollers to transfer batteries on and off of the battery extractor.

IIoT Equipped Units

Units shipped after February, 2020 are equipped with BE-IIoT (Industrial Internet of Things) package. Operators must log in to the BE-IIoT system using the HMI (Human Machine Interface) display located on the dashboard to operate the extractor.

When finished operating the extractor, the operator should log out of the BE-IIoT to prevent unauthorized access and/or operation of the extractor.

Manual Unloading

Lockout/tagout and de-energize all equipment prior to manually unloading any battery.

In the event of power loss or an operational malfunction of the BE not allowing a battery to be unloaded using normal operating procedures, it is recommended a battery be removed from the BE using certified and approved vertical extraction methods and devices.

| Read, understand and observe all safety warnings and procedures related to the vertical extraction device(s) being used. |

Should the status of the BE not allow for safe vertical extraction (due to position in the battery aisle or level of the inner carriage), only repairs required to safely maneuver the BE to a position allowing for safe vertical extraction should be made. Once any batteries are safely unloaded, any remaining repairs can be made.

Spare Parts List

Use only BHS approved replacement parts.

Refer to the appropriate Spare Parts Kit (vacuum equipped units - Pt# BE-SPKV-TS, magnet equipped units - Pt# BE-SPKM-TS) for the list of items recommended by BHS to have on hand for BE-TS models to minimize any downtime due to minor breakdowns that may occur under normal operating conditions.

BHS offers many replacement parts kits containing relevant or related parts when replacing certain individual parts or replacing any obsolete / upgraded parts.

BHS also offers a supplement hose kit (Pt# 80342003) which contains an assortment of hoses allowing any hose on the extractor to be replaced immediately with a temporary hose of equal length or longer. After the extractor is back up and running, the failed hose can be taken to have an exact replacement made. Once the new hose is made and installed, the temporary hose can be returned to the kit for future use.

Go to www.bhs1.com and click "Parts" for all the latest parts kits and corresponding installation instructions (if applicable).

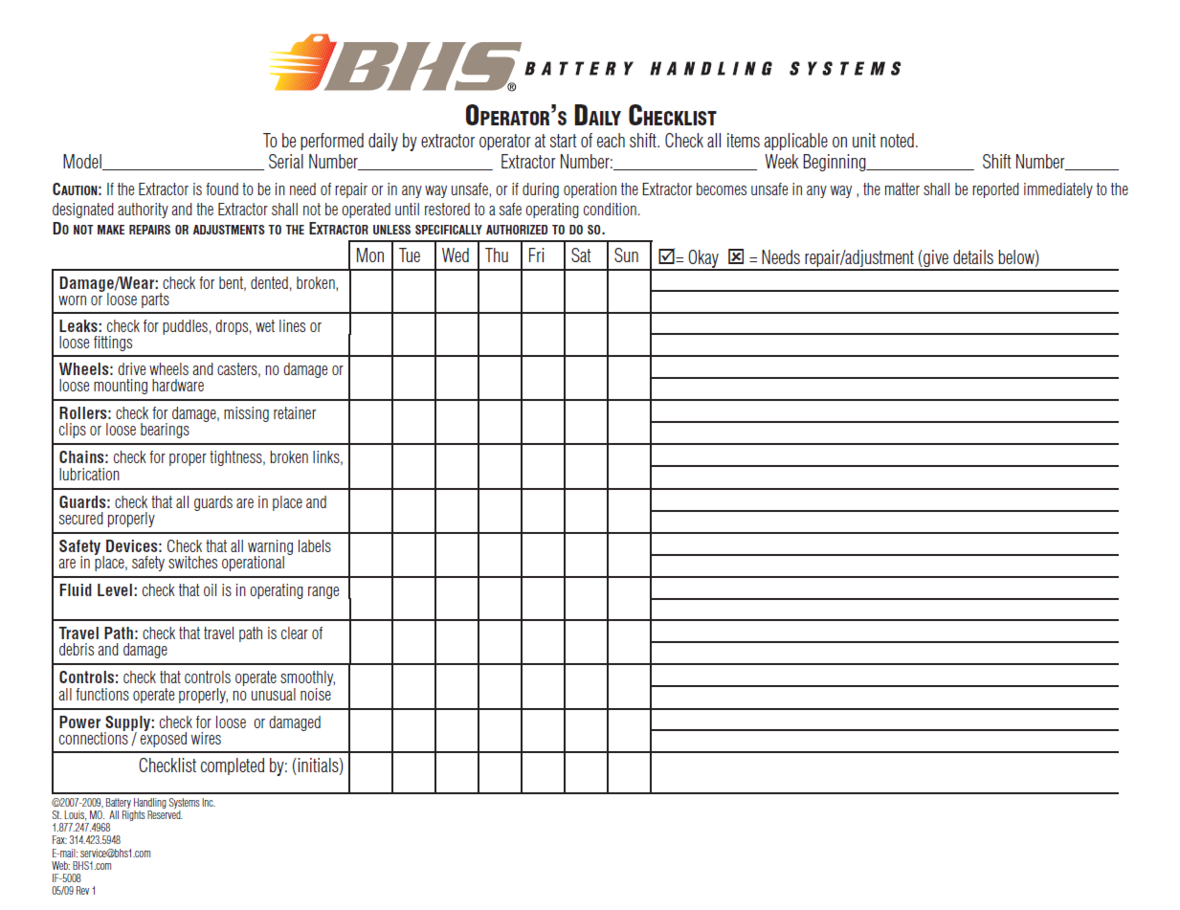

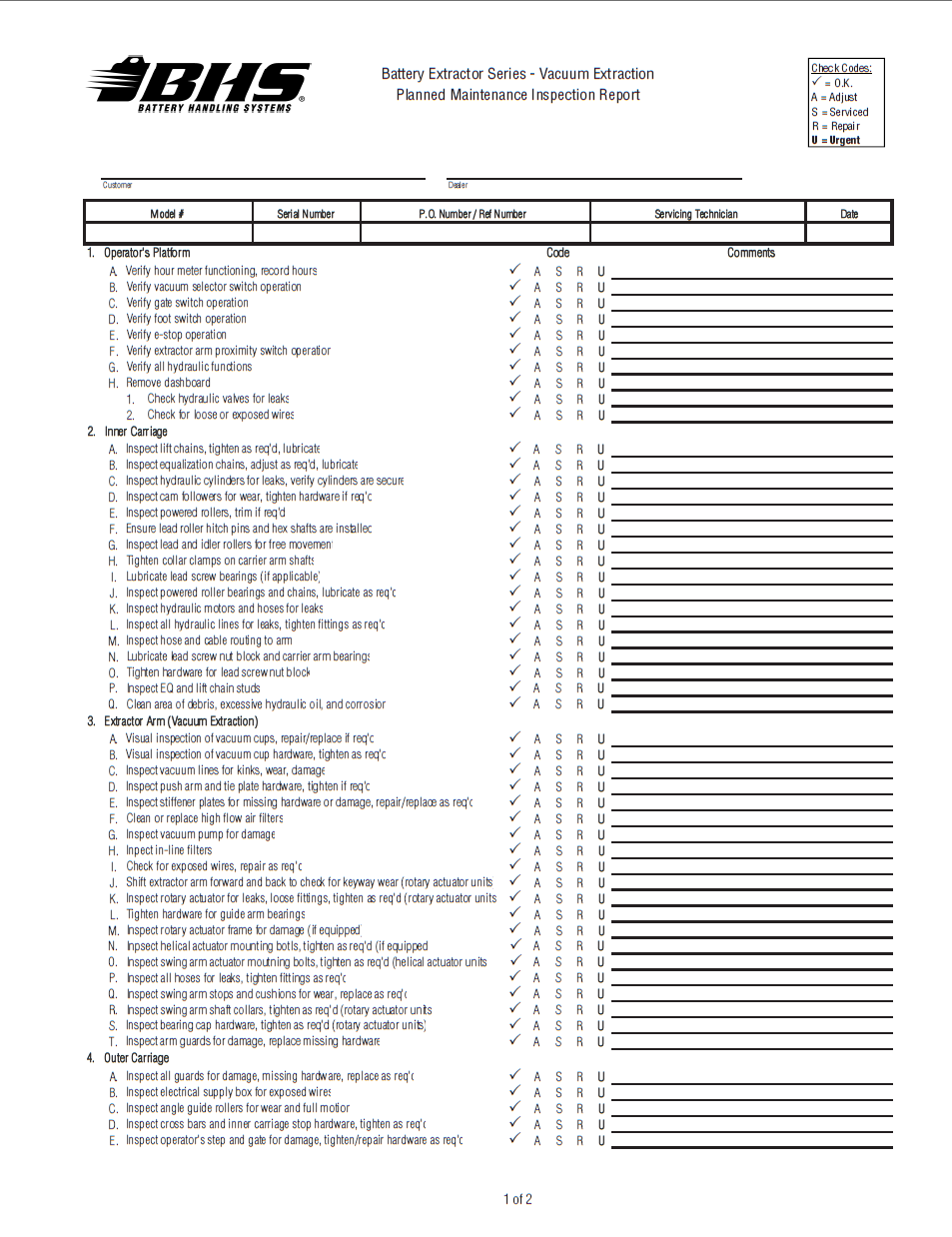

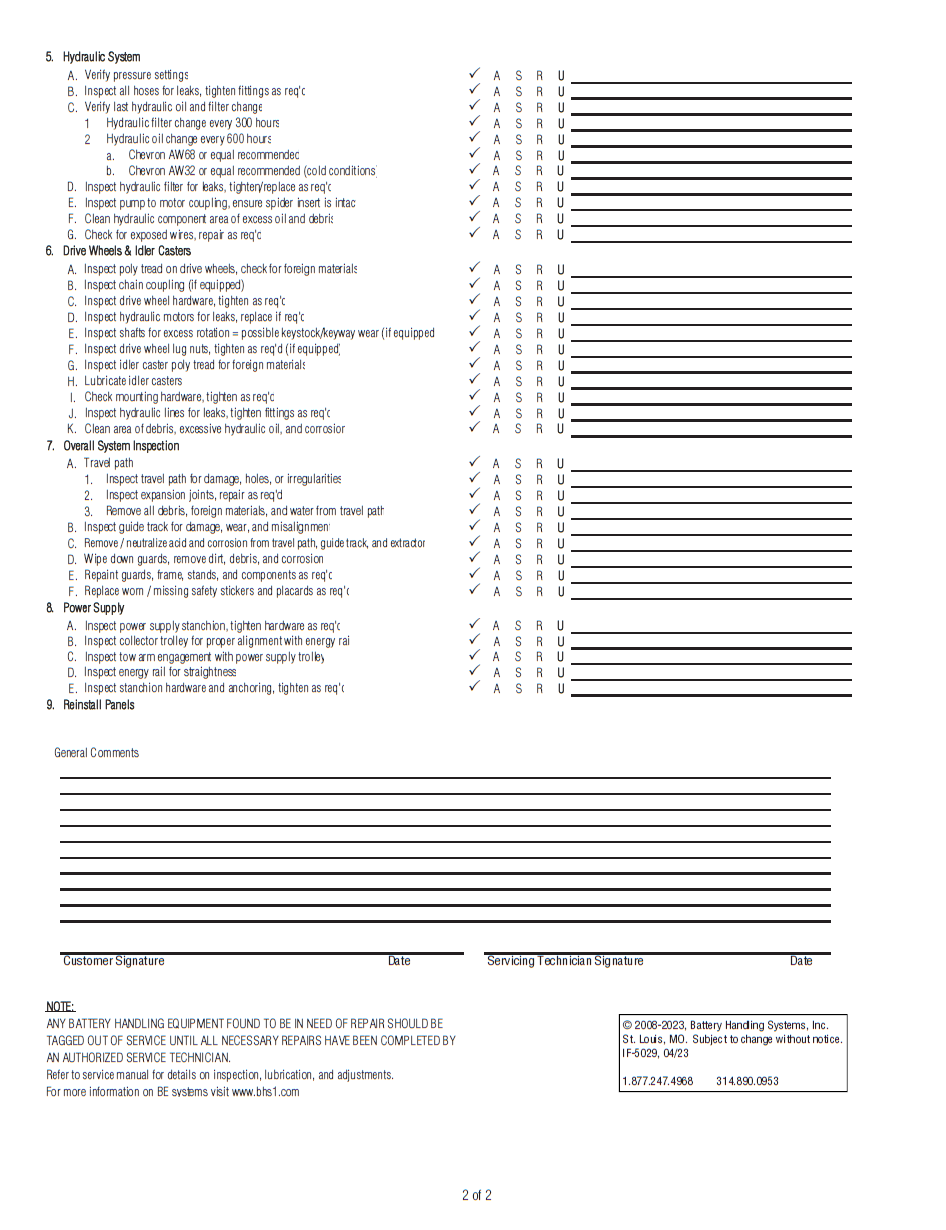

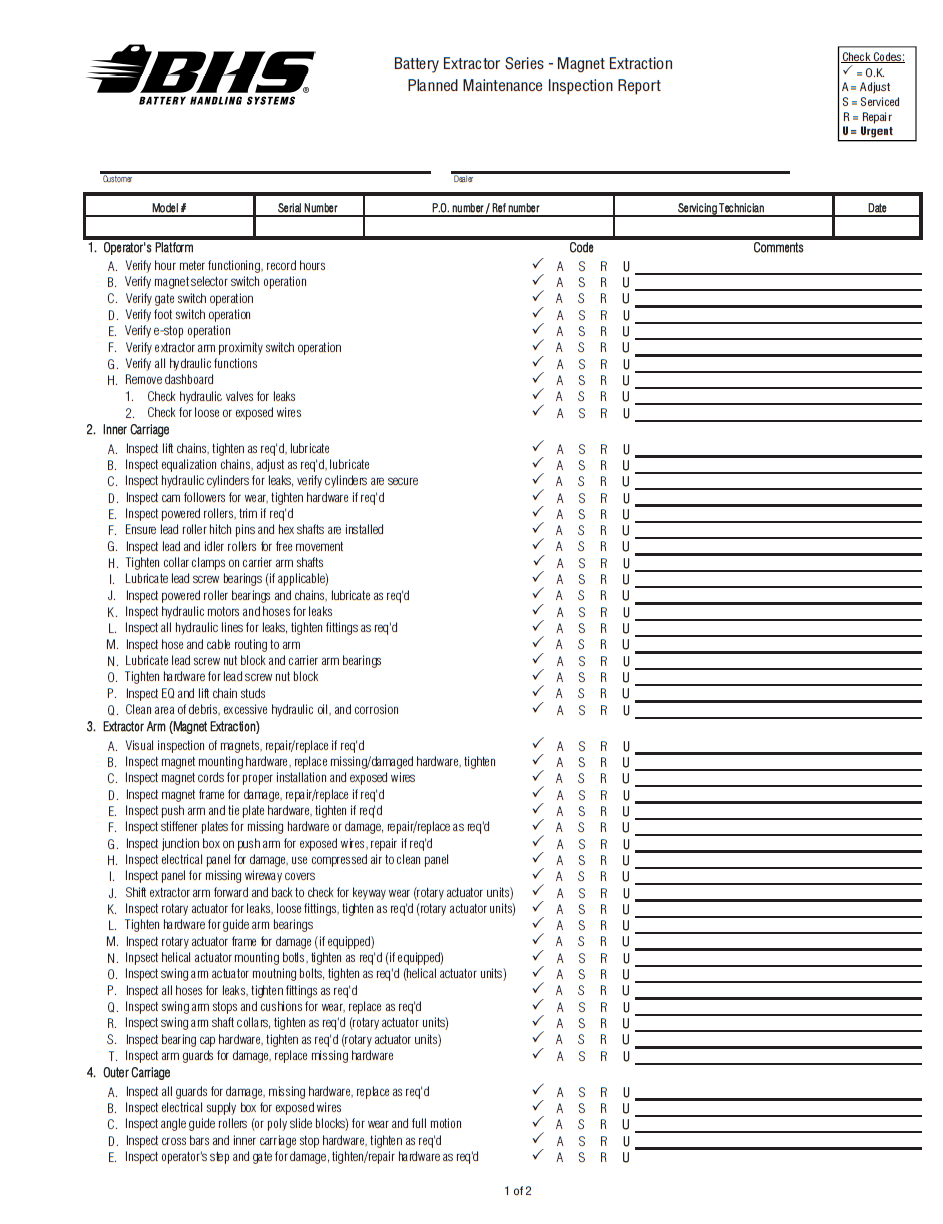

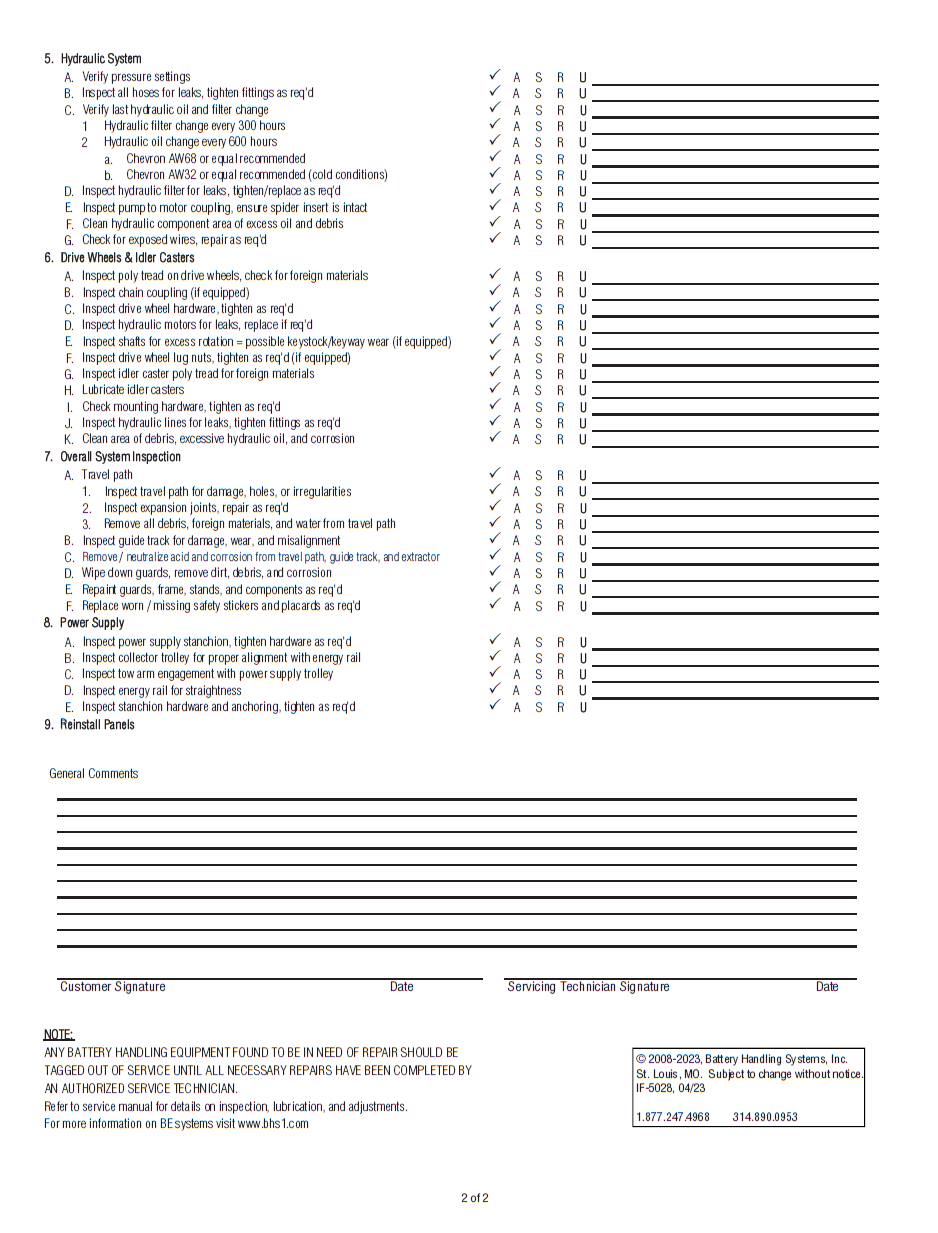

BHS recommends that a full maintenance inspection report similar to the one provided be done at least once a month.

Any parts found to be excessively worn or damaged should promptly be replaced unless said parts pose a safety risk to the operator and/or extractor, in which case the unit should be removed from service until the problem(s) are remedied (See

Operator's Daily Checklist.)

Note: Spare parts kits contain parts for the most current machine design/configuration. Due to continuous design and manufacturing updates and improvements, not all the parts in the spare parts kits may be compatible with older units. Consult factory when ordering spare or replacement parts for existing units in the field to ensure part compatibility.

Parts Sections

Chassis

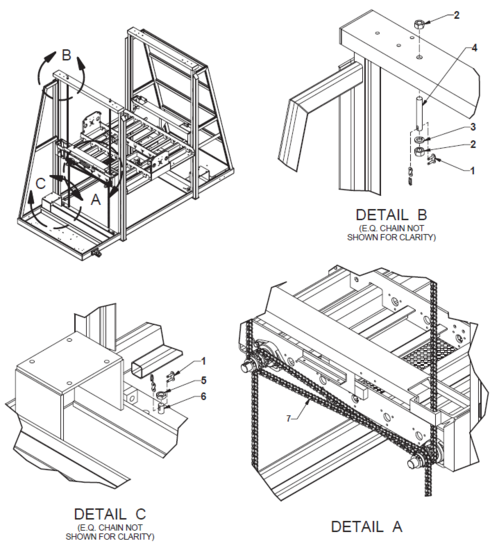

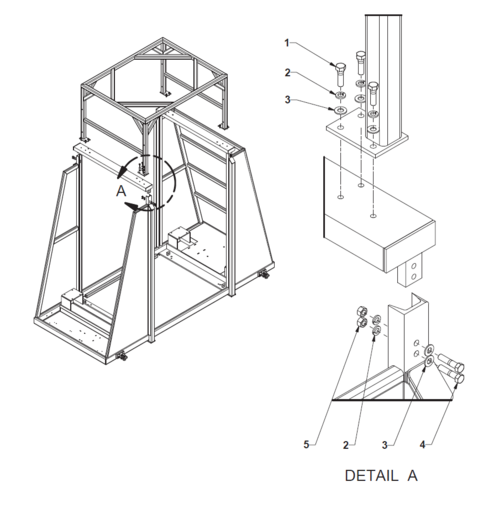

Equalization Components

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

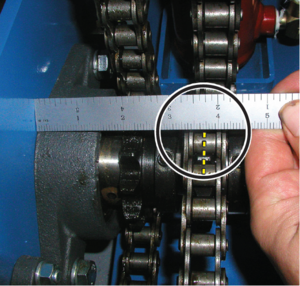

| 1 | PT0222-1 | LINK-CONNECTING-#60 | 8 | ||

| 2 | HW0017 | NUT-HEX-3/4-10 | 8 | ||

| 3 | HW0115 | WASHER-LOCK-3/4" | 4 | ||

| 4 | 43097001 | STUD-ANCHOR-5" | Upper | 4 | |

| 5 | HW0020 | NUT-JAM-3/4-10 | 4 | ||

| 6 | 43097002 | STUD-ANCHOR-2" | Lower | 4 | |

| 7 | 00158001-14 | CHAIN-ROLLER-#60 | 4 |

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | PT0416 | COLLAR-SHAFT-1 1/2" | 4 | ||

| 2 | 43097006 | KEY-3/8" X 2 3/4" | 4 | ||

| 3 | PT0224 | SPROCKET-60B12 X 1 1/2" | Keyed in line | 8 | |

| 4 | PT0405 | FLANGE BEARING-2 BOLT-1 1/2" | 4 | ||

| 5 | HW0502 | BOLT-HHCS-1/2-13 X 1 1/4" | 8 | ||

| 6 | HW0110 | WASHER-LOCK-1/2" | 8 | ||

| 7 | 43127001 | SHAFT-EQUALIZATION-81.75" | BE-24-2-TS | 2 | |

| 43327001 | SHAFT-EQUALIZATION-105.75" | BE-36-2-TS | 2 | ||

| 44327001 | SHAFT-EQUALIZATION-117.75" | BE-42-2-TS | 2 | ||

| 44527001 | SHAFT-EQUALIZATION-75.75" | BE-42-1-TS | 2 | ||

| 8 | PT0503 | BEARING-FLANGED LOAD-2 1/4" | Used after December 2003 | 8 | |

| 43026001 | BEARING-FLANGED LOAD-2 1/4" (MACHINED) | Used prior to December 2003 | 8 | ||

| 9 | HW0025 | NUT-JAM-7/8-14 | 8 | ||

| 10 | HW0117 | WASHER-LOCK-7/8" (NOT SHOWN) | Used prior to August 2002 | 8 |

Bridge & Cross Bar

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | HW0502 | BOLT-HHCS-1/2-13 X 1 1/4" | 12 | ||

| 2 | HW0110 | WASHER-LOCK-1/2" | 20 | ||

| 3 | HW0112 | WASHER-FLAT-1/2"-SAE | 20 | ||

| 4 | HW0515 | BOLT-HHCS-1/2-13 X 2" | Fully Threaded | 8 | |

| 5 | HW0007 | NUT-HEX-1/2-13 | 8 |

Lift Cylinder Connections

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 00158001-13 | CHAIN-ROLLER-#80 | 4 | ||

| 2 | HW0014 | NUT-HEX-1-8 | 8 | ||

| 3 | 43897002 | STUD-LIFT-INNER FRAME | 4 | ||

| 4 | PT0204 | LINK-CONNECTING-#80 | 8 | ||

| 5 | 43897001 | STUD-LIFT-OUTER FRAME | 4 | ||

| 6 | 43815018 | BRACKET-CYLINDER SUPPORT | 4 | ||

| 7 | SS0761 | U-BOLT-CYLINDER MOUNTING | 4 | ||

| 8 | HW0108 | WASHER-FLAT-3/8"-SAE | 12 | ||

| 9 | HW0107 | WASHER-LOCK-3/8" | 12 | ||

| 10 | HW0005 | NUT-HEX-3/8-16 | 8 | ||

| 11 | HW0514 | BOLT-HHCS-1/2-13 X 2 1/2" | Idler caster end of unit | 2 | |

| HW0504 | BOLT-HHCS-1/2-13 X 2" | Drive wheel end of unit | 2 | ||

| 12 | HW0110 | WASHER-LOCK-1/2" | 4 | ||

| 13 | HW0112 | WASHER-FLAT-1/2"-SAE | 4 | ||

| 14 | HW0402 | BOLT-HHCS-3/8-16 X 1" | 4 | ||

| 15 | 43822002 | CLEVIS ASSEMBLY | Sold as assembly only | 4 |

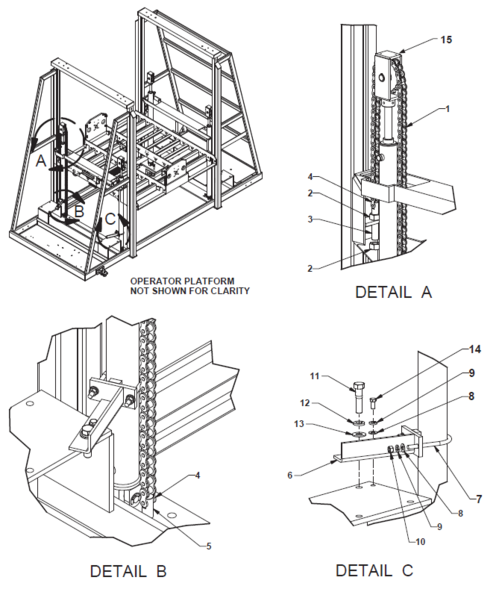

Guidance Arm

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ | |

|---|---|---|---|---|---|---|

| 1 | 43015011 | GUIDE ARM WELDMENT, 2 ROLLER | 2 | - | ||

| 2 | 43017025 | SPACER-GUIDE ARM | † 1/2" thick | 4 | - | |

| 3 | 41215204 | GUIDE ARM WELDMENT, 4 ROLLER | - | 2 | ||

| 4 | 41217274 | SPACER-GUIDE ARM | - | 4 | ||

| 5 | 43012007 | CAM ROLLER-1 3/4" | 4 | 8 | ||

| 6 | HW0115 | WASHER-LOCK-3/4" | 4 | 8 | ||

| 7 | HW0011 | NUT-HEX-3/4-16 | 4 | 8 | ||

| 8 | HW0509 | BOLT-HHCS-1/2-13 X 4-1/2" | 4 | 6 | ||

| 9 | HW0112 | WASHER-FLAT-1/2"-SAE | 4 | 6 | ||

| 10 | HW0110 | WASHER-LOCK-1/2" | 4 | 6 | ||

| 11 | HW0007 | NUT-HEX-1/2-13 | 4 | 6 | ||

| 12 | 41215234 | GUIDE ARM WELDMENT (POLY) | 2 | - | ||

| 13 | 41217317 | POLY SLIDE MOUNTING BLOCK | 4 | - | ||

| 14 | 41217318 | POLY SLIDE | 4 | - | ||

| 15 | HW0501 | BOLT-HHCS-1/2-13 X 1" | 12 | - | ||

| 16 | HW0110 | WASHER-LOCK-1/2" | 12 | - | ||

| 17 | 91253A546 | BOLT FHSCS-1/4-20 X 1-1/2" | 8 | - | ||

| 18 | HW0003 | NUT-NILN-1/4-20 | 8 | - | ||

| NOTES | ||||||

| † Older units equipped with (1) 1" thick spacer per guide arm bracket. | ||||||

| †† Multiple styles of guide arms have been utilized on extractors. Refer to the parts diagrams for correct replacement parts. | ||||||

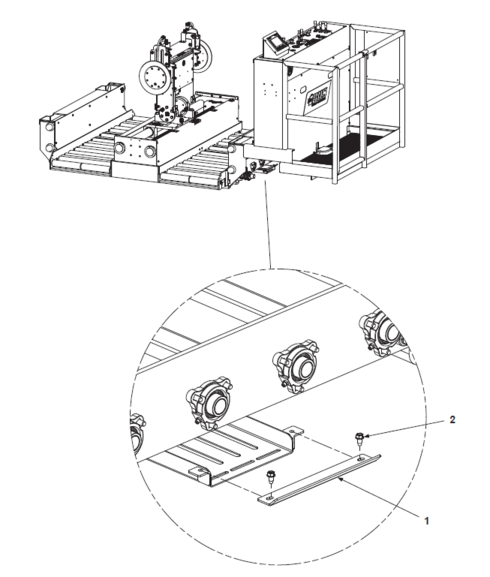

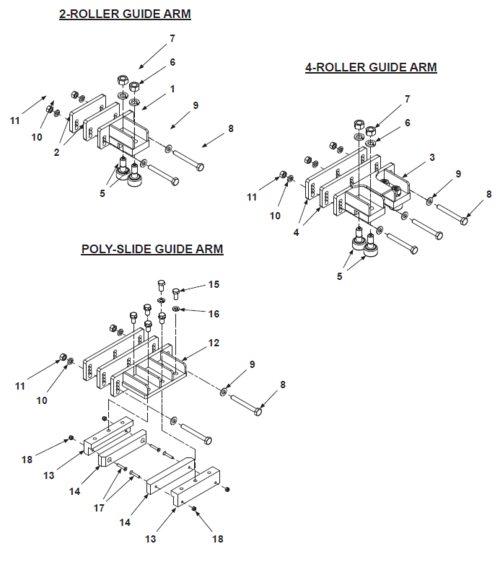

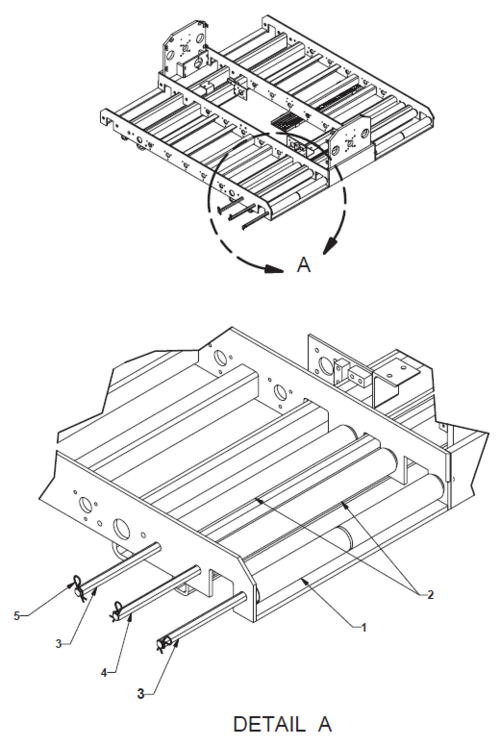

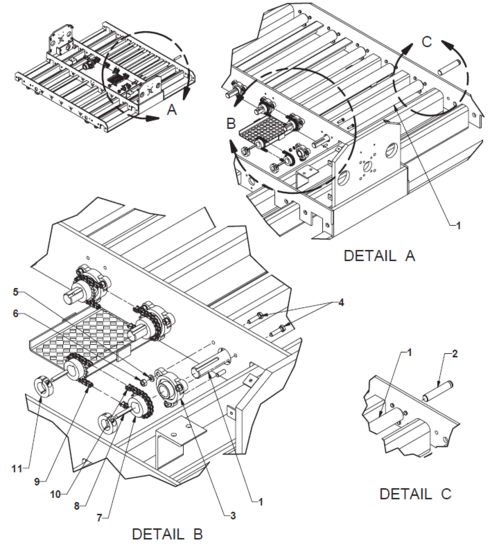

Roller Bed Componenets

Idler Rollers

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43182001 | LEAD ROLLER ASSEMBLY-24" | With alignment groove | 4 | |

| 43382001 | LEAD ROLLER ASSEMBLY-36" | With alignment groove | 4 | ||

| 43482001 | LEAD ROLLER ASSEMBLY-42" | With alignment groove | 4 | ||

| 2 | 43182002 | IDLER ROLLER ASSEMBLY-24" | 8 | ||

| 43382002 | IDLER ROLLER ASSEMBLY-36" | 8 | |||

| 43482002 | IDLER ROLLER ASSEMBLY-42" | 8 | |||

| 3 | 43187002 | SHAFT-HEX-.75" X 25.75" | 24" compartments | 8 | |

| 43387002 | SHAFT-HEX-.75" X 37.75" | 36" compartments | 8 | ||

| 43487002 | SHAFT-HEX-.75" X 43.75" | 42" compartments | 8 | ||

| 4 | 43187003 | SHAFT-HEX-.75" X 27.5" | 24" compartments | 4 | |

| 43387003 | SHAFT-HEX-.75" X 39.5" | 36" compartments | 4 | ||

| 43487003 | SHAFT-HEX-.75" X 45.5" | 42" compartments | 4 | ||

| 5 | HW1058 | PIN-HITCH | 24 |

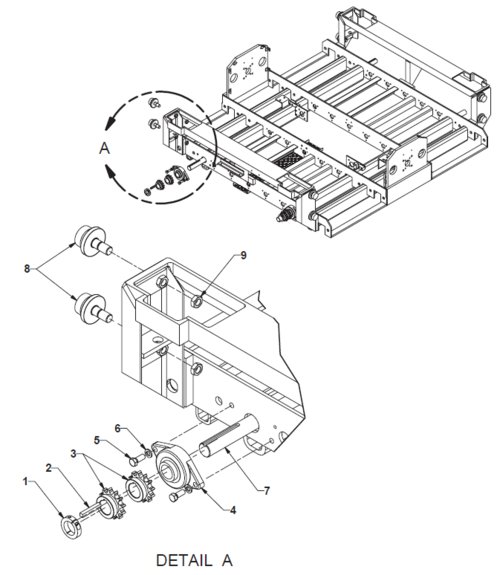

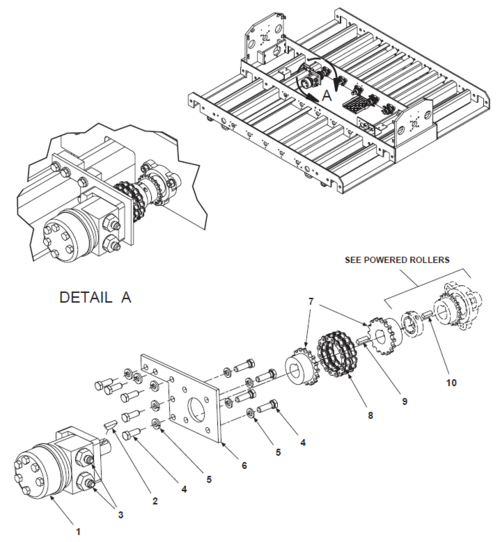

Powered Rollers

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43182003 | POWERED ROLLER-24" | 10 | ||

| 43382003 | POWERED ROLLER-36" | 10 | |||

| 43485003 | POWERED ROLLER-42" | 10 | |||

| 2 | 43087001 | JOURNAL-POWERED ROLLER | 10 | ||

| 3 | PT0404 | FLANGE BEARING-3-BOLT-1" | 20 | ||

| 4 | HW0321 | BOLT-HHCS-5/16-18 X 1 1/4" | 60 | ||

| 5 | HW0105 | WASHER-LOCK-5/16" | 60 | ||

| 6 | HW0004 | NUT-HEX-5/16-18 | 60 | ||

| 7 | PT0033 | SPROCKET-35B18 X 1" | 16 | ||

| 8 | 00197028 | KEY-1/4" X 1 1/4" | 8 | ||

| 9 | 00158001-16 | CHAIN-ROLLER-#35 | 8 | ||

| 10 | PT0031 | LINK-CONNECTING-#35 | 8 | ||

| 11 | PT0418 | COLLAR-SHAFT-1" | 10 |

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | HC0120 | MOTOR-HYDRAULIC-160CC | 2 | ||

| 2 | HW1071 | KEY-WOODRUFF-#808 STD | Supplied with Item 1 | A/R | |

| 3 | H1544 | ADAPTER-#6 JICM X #10 SAEM | 4 | ||

| 4 | HW0402 | BOLT-HHCS-3/8-16 X 1" | 18 | ||

| 5 | HW0107 | WASHER-LOCK-3/8" | 18 | ||

| 6 | 43017004 | PLATE-MOTOR MOUNTING | 2 | ||

| 7 | PT0302-1 | COUPLING BODY-#40 X 1" | 4 | ||

| 8 | PT0301 | CHAIN-COUPLING-#40 | Includes connecting pin | 2 | |

| 9 | 00197026 | KEY-1/4" X 1" | 2 | ||

| 10 | 43097003 | KEY-1/4" X 5/8" | 2 |

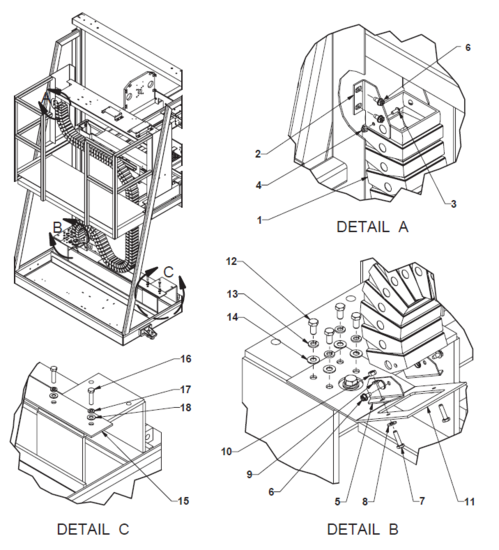

Hose Carrier

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | PT0629 | CARRIER TRACK | 81 links required | 10' | |

| 2 | PT0631 | BRACKET-UPPER MOUNTING | 1 | ||

| 3 | HW0212 | SCREW-RHMS-#10-24 X 1/2" | 2 | ||

| 4 | HW0032 | NUT-NILN-#10-24 | 2 | ||

| 5 | PT0630 | BRACKET-LOWER MOUNTING | 1 | ||

| 6 | HW0301 | BOLT-SELF TAP "F"-1/4-20 X 1/2" | 6 | ||

| 7 | HW0303 | BOLT-HHCS-1/4-20 X 1" | 2 | ||

| 8 | HW0104 | WASHER-FLAT-1/4"-SAE | 2 | ||

| 9 | HW0103 | WASHER-LOCK-1/4" | 2 | ||

| 10 | HW0002 | NUT-HEX-1/4-20 | 2 | ||

| 11 | 43817056-2 | BRACKET-CARRIER TRACK MOUNTING | 1 | ||

| 12 | HW0401 | BOLT-HHCS-3/8-16 X 3/4" | 4 | ||

| 13 | HW0107 | WASHER-LOCK-3/8" | 4 | ||

| 14 | HW0108 | WASHER-FLAT-3/8"-SAE | 4 | ||

| 15 | 43817057 | PLATE-CARRIER TRACK SUPPORT | 1 | ||

| 16 | HW0504 | BOLT-HHCS-1/2-13 X 2" | 2 | ||

| 17 | HW0110 | WASHER-LOCK-1/2" | 2 | ||

| 18 | HW0112 | WASHER-FLAT-1/2"-SAE | 2 |

Cable Retractor

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | CCR-12HD | TAKE UP REEL-CARRIER TRACK | 1 | ||

| 2 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | 2 | ||

| 3 | HW0108 | WASHER-FLAT-3/8"-SAE | 4 | ||

| 4 | HW0107 | WASHER-LOCK-3/8" | 2 | ||

| 5 | HW0005 | NUT-HEX-3/8-16 | 2 |

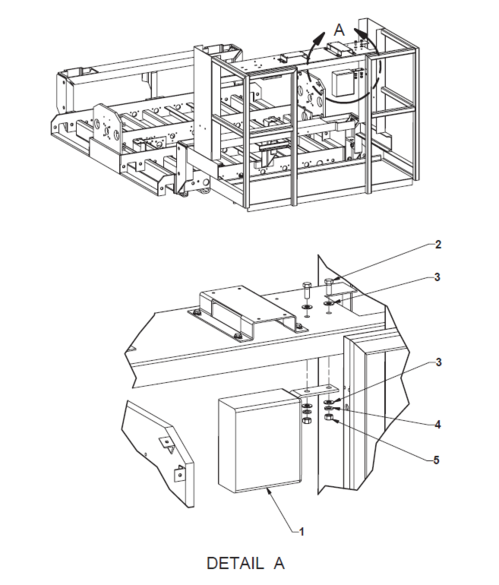

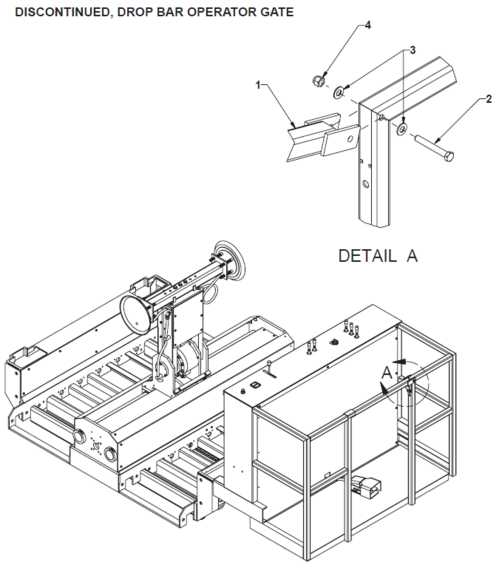

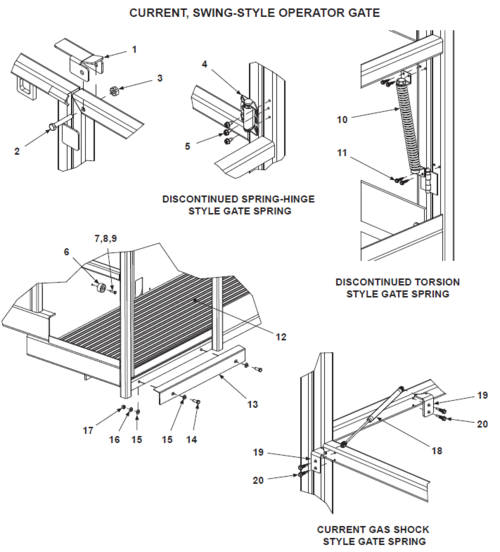

Operator Gate

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43015004 | GATE-OPERATOR | 1 | ||

| 2 | HW0407 | BOLT-HHCS-3/8-16 X 2 3/4" | 1 | ||

| 3 | HW0108 | WASHER-FLAT-3/8"-SAE | 2 | ||

| 4 | HW0006 | NUT-NILN-3/8-16 | 1 |

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43017064-2 | LATCH-SWING GATE | 1 | ||

| 2 | HW0418 | BOLT-HHCS-3/8-16 X 2 1/4" | 1 | ||

| 3 | HW0031 | NUT-LOCK-3/8-16 | 1 | ||

| 4 | N/A | HINGE-SPRING | † See notes | 1 | |

| 5 | HW0301 | BOLT-SELF TAP "F"-1/4-20 X 1/2" | 3 | ||

| 6 | HW1037 | STOP-GATE | 1 | ||

| 7 | HW0303 | BOLT-HHCS-1/4-20 X 1" | 1 | ||

| 8 | HW0104 | WASHER-FLAT-1/4"-SAE | 1 | ||

| 9 | HW0003 | NUT-NILN-1/4-20 | 1 | ||

| 10 | N/A | TORSION SPRING | † See notes | 1 | |

| 11 | HW0816 | SCREW-HHCS-SELF DRILLING-#10 X 3/4" | 4 | ||

| 12 | 43806001 | ANTI-FATIGUE MAT | 1 | ||

| 13 | 43017058-2 | THRESHOLD | 1 | ||

| 14 | HW0402 | BOLT-HHCS-3/8-16 X 1" | 2 | ||

| 15 | HW0108 | WASHER-FLAT-3/8"-SAE | 4 | ||

| 16 | HW0107 | WASHER-LOCK3/8" | 2 | ||

| 17 | HW0005 | NUT-HEX-3/8-16 | 2 | ||

| 18 | HW9002 | GAS SPRING | 80292015 | 1 | |

| 19 | 43017086-2 | BRACKET-MOUNTING-SPRING | 80292015 | 2 | |

| 20 | HW0815 | SCREW-SELF DRILLING-#12-24 X 1" T-4 | 80292015 | 4 | |

| NOTES | |||||

| † Part Discontinued. Spring Hinge and Torsion Spring must be replaced with Gas Spring Kit. | |||||

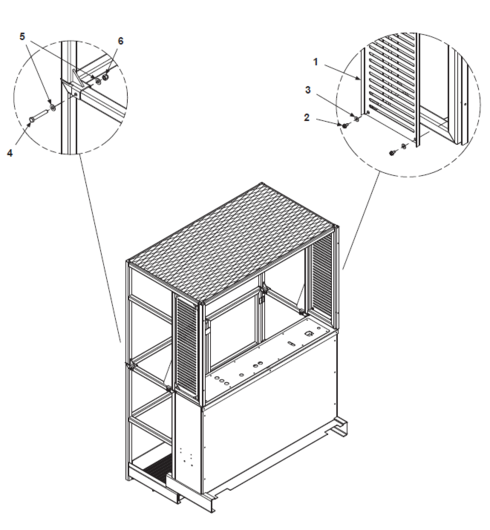

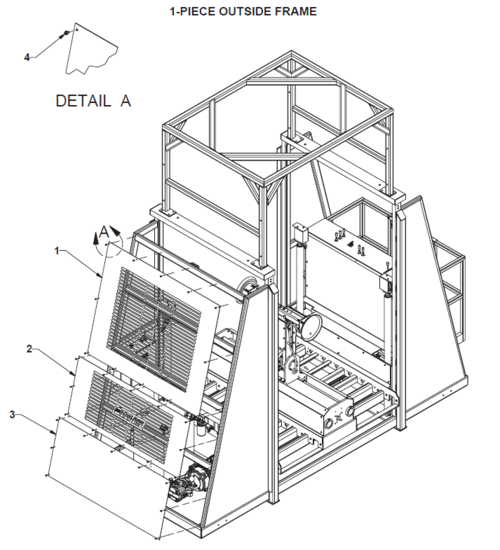

Guarding

Outer Carriage Guards

1-Piece Outside Frame Guarding

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43817038 | GUARD-FAR END-TOP | 1 | ||

| 2 | 43817037 | GUARD-FAR END-MIDDLE | 1 | ||

| 3 | 43817035 | GUARD-FAR END-BOTTOM | 1 | ||

| 4 | HW0301 | BOLT-SELF TAP "F"-1/4-20 X 1/2" | 33 |

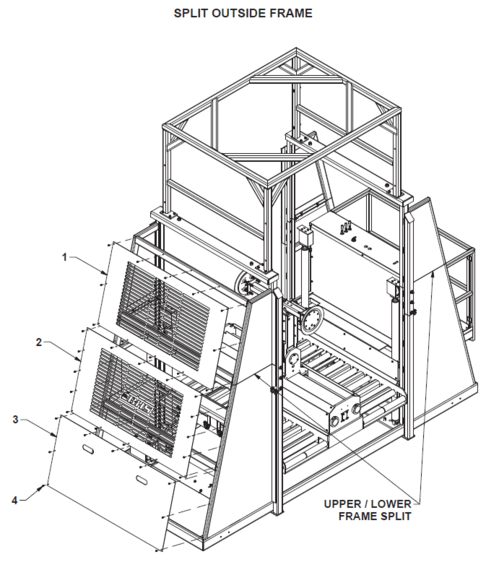

Split Outside Frame Guarding

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43817103 | GUARD-FAR END-TOP | 1 | ||

| 2 | 43817102 | GUARD-FAR END-MIDDLE | 1 | ||

| 3 | 43817101 | GUARD-FAR END-BOTTOM | 1 | ||

| 4 | HW0301 | BOLT-SELF TAP "F"-1/4-20 X 1/2" | 37 |

Inner Carriage Guards

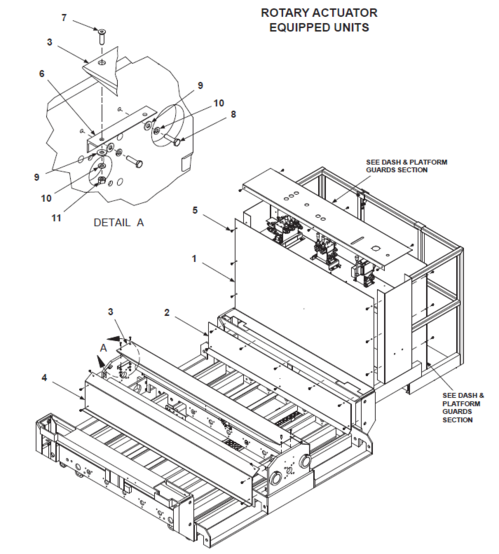

Inner Carriage Guards (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43817041-2 | GUARD-FRONT-OPERATOR CONSOLE | 1 | ||

| 2 | 43817042-2 | GUARD-INNER-FRAME | 2 | ||

| 3 | 43014006-2 | GUARD-LINEAR DRIVE SCREW | 1 | ||

| 4 | 43017010-2 | GUARD-SIDE-ARM CARRIER SHAFT | 2 | ||

| 44517002-2 | GUARD-SIDE-ARM CARRIER SHAFT | † Single compartment units only | 1 | ||

| 5 | HW0301 | BOLT-SELF TAP "F"-1/4-20 X 1/2" | 34 | ||

| 6 | 43017009-2 | BRACKET-SCREW GUARD MOUNTING | 2 | ||

| 7 | HW0306 | BOLT-FHSCS-1/4-20 X 1" | 4 | ||

| 8 | HW0303 | BOLT-HHCS-1/4-20 X 1" | 4 | ||

| 9 | HW0104 | WASHER-FLAT-1/4"-SAE | 8 | ||

| 10 | HW0103 | WASHER-LOCK-1/4" | 8 | ||

| 11 | HW0002 | NUT-HEX-1/4-20 | 4 | ||

| NOTES | |||||

| † Single Compartment Guard replaces standard, Far Side Arm Carrier Shaft Guard. | |||||

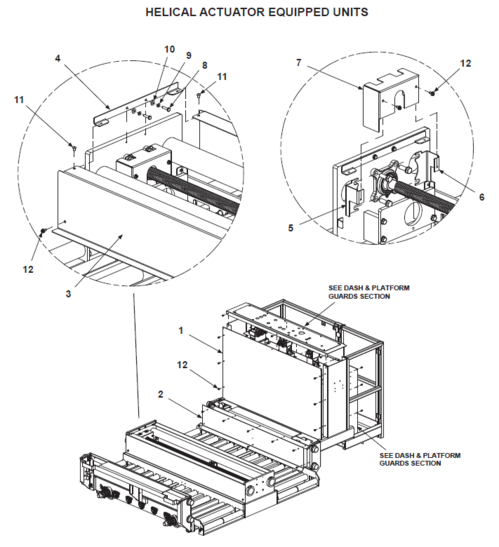

Inner Carriage Guards (Helical Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43817041-2 | GUARD-FRONT-OPERATOR CONSOLE | 1 | ||

| 2 | 43817042-2 | GUARD-INNER-FRAME | 2 | ||

| 3 | 43017081-2 | GUARD-SIDE-ARM CARRIER SHAFT | 2 | ||

| 44517003-2 | GUARD-SIDE-ARM CARRIER SHAFT | † Single compartment units only | 1 | ||

| 4 | 43017080-2 | BRACKET-SIDE GUARD MOUNTING | 2 | ||

| 5 | 43017082-3 | MOUNT-CHAIN GUARD-LEAD SCREW | 1 | ||

| 6 | 43017082-4 | MOUNT-CHAIN GUARD-LEAD SCREW | 1 | ||

| 7 | 43017083-2 | GUARD-CHAIN-LEAD SCREW | 1 | ||

| 8 | HW0303 | BOLT-HHCS-1/4-20 X 1" | 4 | ||

| 9 | HW0103 | WASHER-LOCK-1/4" | 8 | ||

| 10 | HW0104 | WASHER-FLAT-1/4"-SAE | 8 | ||

| 11 | HW0347 | BOLT-BHSCS-1/4-20 X 3/8" | 4 | ||

| 12 | HW0301 | BOLT-SELF TAP "F"-1/4-20 X 1/2" | 28 | ||

| NOTES | |||||

| † Single Compartment Guard replaces standard, Far Side Arm Carrier Shaft Guard. | |||||

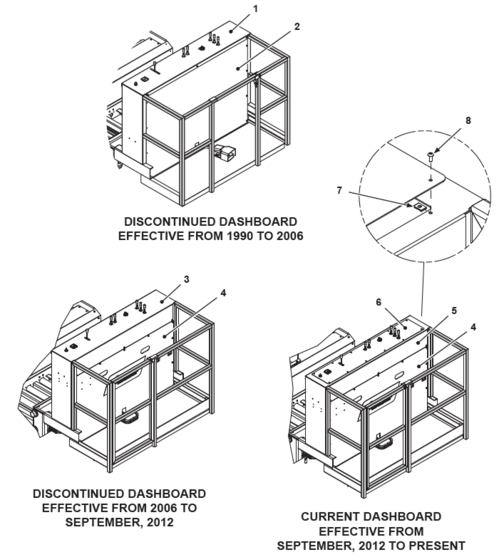

Dash & Platform Guards

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 41614004-2 | DASHBOARD-OPERATOR CONSOLE | 1 | ||

| 2 | 43817040 | KICK PLATE-OPERATOR CONSOLE | 41.5" high | 1 | |

| 3 | 43817086-2 | DASHBOARD-OPERATOR CONSOLE | 1 | ||

| 4 | 43817088 | KICK PLATE-OPERATOR CONSOLE | 33.5" high | 1 | |

| 5 | 43817110-2 | FRAME-DASHBOARD | 1 | ||

| 6 | A/R | PLATE-DASHBOARD | † See notes | 1 | |

| 7 | HW0060 | NUT-CLIP-#10-24 | 12 | ||

| 8 | SS0114 | BHSCS-#10-24 X 1/2"-SST | 12 | ||

| 9 | PL0602 | VINYL EDGING | At Foot Switch (Not shown) | 1' | |

| NOTES | |||||

| † Consult factory | |||||

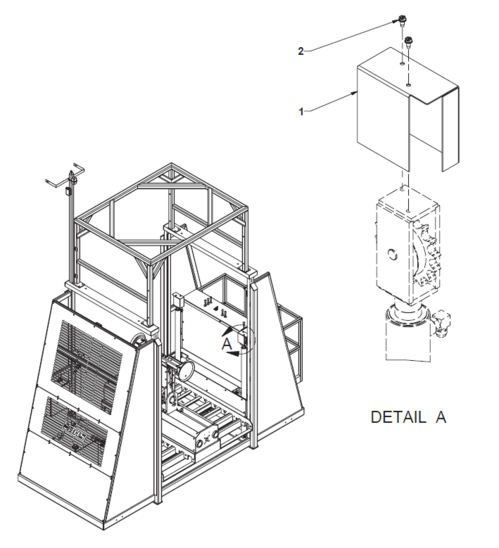

Lift Cylinder Guards

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43815016 | GUARD-CLEVIS | Operator right / Far left | 2 | |

| 43815017 | GUARD-CLEVIS | Operator left / Far right | 2 | ||

| 2 | HW0301 | BOLT-SELF TAP "F"-1/4-20 X 1/2" | 8 |

Labels & Placards

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 00196616 | LABEL-"NO RIDERS ALLOWED" | 1 | ||

| 2 | 00196210 | LABEL-WARNING-"OPERATION BY AUTHORIZED PERSONNEL ONLY" | 1 | ||

| 3 | 43696001 | PLACARD-OFF / ON | 1 | ||

| 4 | 43096018 | PLACARD-RACK LEVEL ASSIST | † If equipped | 1 | |

| 5 | 43096015 | PLACARD-PLATFORM RAISE / LOWER | 1 | ||

| 6 | 43096010 | PLACARD-HORN | † If equipped | 1 | |

| 7 | 43096016 | PLACARD-DRIVE / ARM ROTATION | 1 | ||

| 8 | 43096012 | PLACARD-VACUUM OFF / ON | Vacuum units only | 1 | |

| 43096011 | PLACARD-MAGNET OFF / ON | Magnet units only (Not shown) | 1 | ||

| 9 | 43096017 | PLACARD-POWERED ROLLER CUTOUT OVERRIDE | † If equipped | 1 | |

| 10 | 43096013 | PLACARD-POWERED ROLLERS / ARM TRAVERSE | 1 | ||

| 11 | 00196633 | LABEL-NOTICE-"IN LINE VACUUM FILTER..." | (1) per side (Vacuum units only) | 2 | |

| 12 | SM-1197 | LABEL-ARM POSITION ARROW | 2 | ||

| 13 | 00196609 | LABEL-NOTICE-"ARM MUST BE POSITIONED BETWEEN ARROWS..." | 1 | ||

| 14 | 00196602 | LABEL-NOTICE-"LUBRICATION POINTS ON UNDERSIDE" | 2 | ||

| 15 | 00196218 | LABEL-WARNING-"ELECTRICAL VOLTAGE HAZARD" | Magnet units only | 1 | |

| 16 | 00196238 | LABEL-WARNING-"STRONG MAGNETIC

FIELD/DO NOT USE WITH PACEMAKER" |

†† Magnet units only | 2 | |

| NOTES | |||||

| † Rack Level Assist (LAI), Horn and Powered Roller Cutout (PRC) are optional features. Not all units are equipped with these options. | |||||

| †† Pacemaker Warning Label takes the place of the discontinued, Triangular Magnetic Field Label. | |||||

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 00196004 | LABEL-CAUTION-"WATCH FOR BATTERY AND CHARGER CABLES IN TRAVEL PATH" | 1 | ||

| 2 | 00196216 | LABEL-WARNING-"CHAIN ENTANGLEMENT

HAZARD" |

(1) per Clevis Guard | 4 | |

| 3 | 00196622 | LABEL-LIFT POINT | (2) each end | 4 | |

| 4 | 00196700 | DECAL-BHS-24" X 7.875" | Far end (Not shown) | 2 | |

| 5 | 00196630 | LABEL-NOTICE-HYD. OIL SPEC. (AW 68) | † See notes | 1 | |

| 00196645 | LABEL-NOTICE-HYD. OIL SPEC. (AW 32) | † See notes | 1 | ||

| NOTES | |||||

| † Most units shipped prior to December 2014 require AW 68 Hydraulic Oil. Some units shipped prior to December 2014 shipped with AW 32 for low temperature applications. | |||||

Extractor Arm

Vacuum Components & Swing Arms

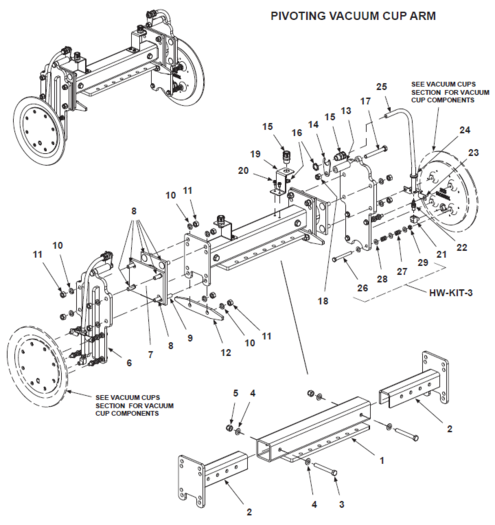

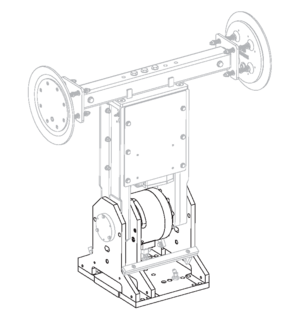

Vacuum Arms (Rotary Actuator)

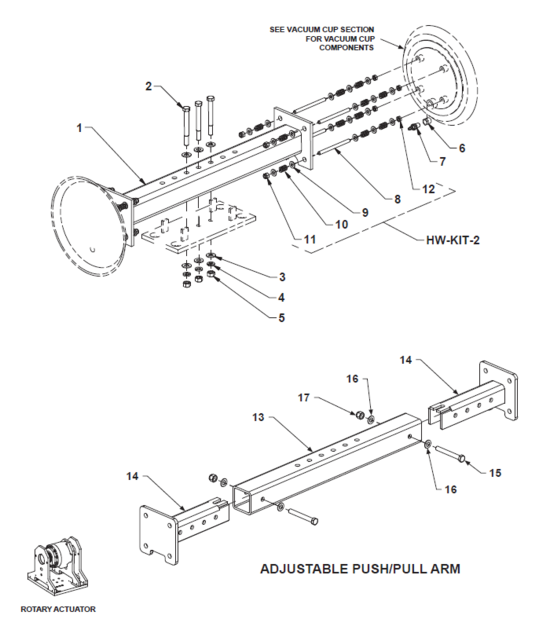

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | N/A | ARM-PUSH/PULL-30" | † Discontinued | 1 | |

| N/A | ARM-PUSH/PULL-36" | † Discontinued | 1 | ||

| 2 | HW0509 | BOLT-HHCS-1/2-13 X 4 1/2" | 3 | ||

| 3 | HW0112 | WASHER-FLAT-1/2"-SAE | 6 | ||

| 4 | HW0110 | WASHER-LOCK-1/2" | 3 | ||

| 5 | HW0007 | NUT-HEX-1/2-13 | 3 | ||

| 6 | P0505 | BUSHING-RED-#6 NPT X #4 FNPT-BRASS | 2 | ||

| 7 | P0402 | HOSE BARB-1/4 X #4 MNPT-BRASS | 2 | ||

| 8 | HW0428 | STUD-VACUUM-3/8-16 X 5" | HW-KIT-2 | 8 | |

| 9 | HW0108 | WASHER-FLAT-3/8"-SAE | HW-KIT-2 | 40 | |

| 10 | HW1001 | SPRING-3/8" | HW-KIT-2 | 24 | |

| 11 | HW0006 | NUT-NILN-3/8-16 | HW-KIT-2 | 8 | |

| 12 | HW0424 | NUT-JAM-3/8-16 | HW-KIT-2 | 8 | |

| REF | 43052006 | ADJUSTABLE PUSH/PULL ARM | Includes Items 13 through 17 | 1 | |

| 13 | 43057034 | ARM BASE | 1 | ||

| 14 | 43055008 | VACUUM CUP MOUNT | 2 | ||

| 15 | HW0523 | BOLT-HHCS-1/2-13 X 4" | 2 | ||

| 16 | HW0112 | WASHER-FLAT-1/2"-SAE | 4 | ||

| 17 | HW0008 | NUT-NILN-1/2-13 | 2 | ||

| NOTES | |||||

| † One-piece Arms no longer available. Must replace with Adjustable Arm. | |||||

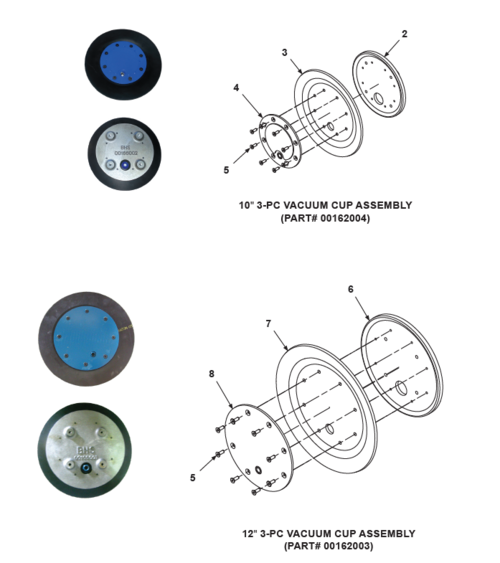

Vacuum Cups

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| A/R | 00162004 | VACUUM CUP-10" 3-PC (STANDARD) | † Includes Items 1 through 4 | A/R | |

| 00162003 | VACUUM CUP-12" 3-PC (STANDARD) | † Includes Items 4 through 7 | |||

| 00162007 | VACUUM CUP-10" 3-PC, REINFORCED | Includes Items 1,3,4 & 8 | |||

| 00162005 | VACUUM CUP-12" 3-PC, REINFORCED | Includes Items 4,5,7 & 9 | |||

| 1 | 00164006 | CASTING-10" VACUUM CUP | 10" cup only | 1 | |

| 2 | 00164004 | SEAL-RUBBER-10" | 1 | ||

| 3 | 00165002 | PLATE-FRONT-10" | 1 | ||

| 4 | HW0311 | BOLT-FHSCS-1/4-20 X 3/4" | 8 | ||

| 5 | 00166001 | CASTING-12" VACUUM CUP | 12" cup only | 1 | |

| 6 | 00164001 | SEAL-RUBBER-12" | 1 | ||

| 7 | 00165001 | PLATE-FRONT-12" | 1 | ||

| 8 | 00164007 | SEAL-RUBBER-10"-REINFORCED | A/R | ||

| 9 | 00167003 | SEAL-RUBBER-12"-REINFORCED | A/R | ||

| NOTES | |||||

| † 10" and 12" 1-Piece Cups no longer available. Must replace with 3-Piece Cup. Verify required cup size prior to ordering. | |||||

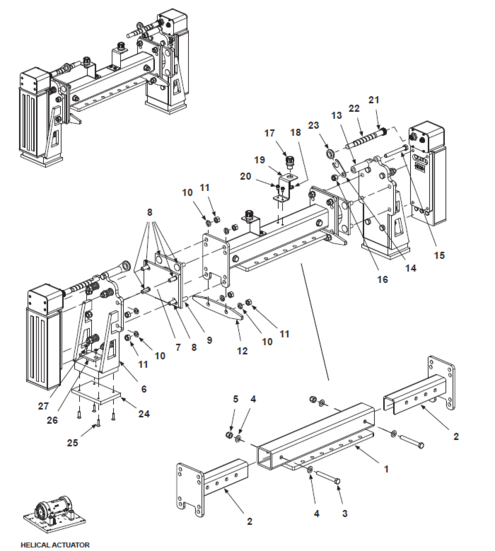

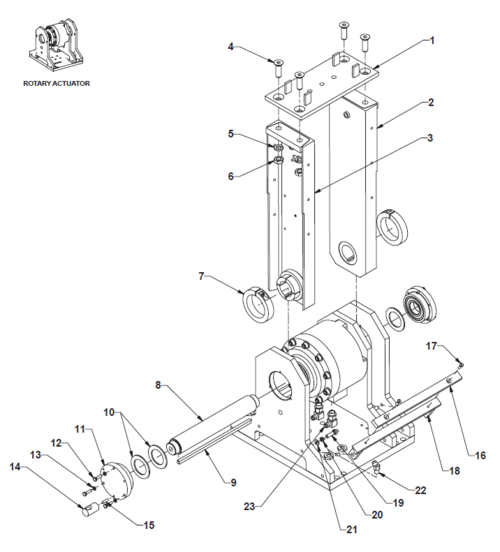

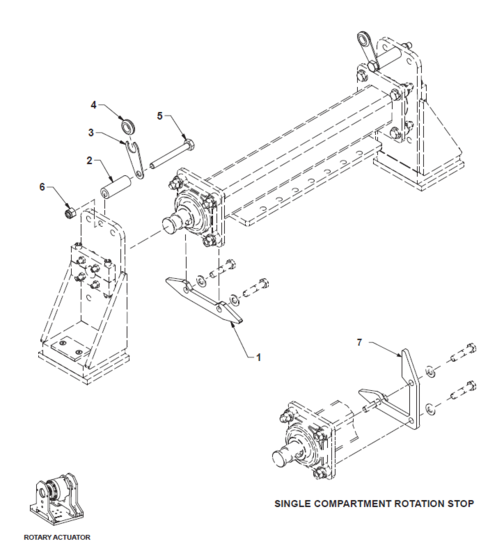

Swing Arms (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

| 1 | 45055001 | TIE PLATE-SWING ARM | BE-24-2-TS | 1 | |

| 45255001 | TIE PLATE-SWING ARM | BE-36-2-TS (NOT SHOWN) | 1 | ||

| 45355001 | TIE PLATE-SWING ARM | BE-42-2-TS (NOT SHOWN) | 1 | ||

| 2 | 43055004 | SWING ARM-RHS | † | NOT SOLD INDIVIDUALLY | 1 |

| 3 | 43055002 | SWING ARM-LHS | † | NOT SOLD INDIVIDUALLY | 1 |

| 4 | HW0603 | BOLT-FHSCS-5/8-11 X 2" | 4 | ||

| 5 | HW0113 | WASHER-LOCK-5/8" | 4 | ||

| 6 | HW0010 | NUT-JAM-5/8-11 | 4 | ||

| 7 | PT0413 | COLLAR-SHAFT-3" | 80252001 | 2 | |

| 8 | 43027001 | SHAFT-ROTARY ACTUATOR | 80252001 | 1 | |

| 9 | HW1013 | KEY-3/8" X 12" | 80252001 | 1 | |

| 10 | PT0419 | BEARING-SAE 841-2" I.D., 3" OD, 1/8" THICK | 80252001 | 3 | |

| 11 | 43052005 | CAP-BEARING | INCLUDES BEARING | 2 | |

| 12 | HW0303 | BOLT-HHCS-1/4-20 X 1" | 6 | ||

| 13 | HW0103 | WASHER-LOCK-1/4" | 6 | ||

| 14 | 43057014 | STANDOFF-WIRE | 1 | ||

| 15 | HW0312 | SCREW-SHSS-1/4-20 X 1"-CUP POINT | 1 | ||

| 16 | 43057003 | CUSHION-SWING ARM | 2 | ||

| 17 | HW0306 | BOLT-FHSCS-1/4-20 X 1" | 4 | ||

| 18 | 43055001 | STOP-SWING ARM | 2 | ||

| 19 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | 4 | ||

| 20 | HW0107 | WASHER-LOCK-3/8" | 4 | ||

| 21 | HW0108 | WASHER-FLAT-3/8"-SAE | 4 | ||

| 22 | H1565 | ADAPTER-45 DEG-#6 JICM X #4 MNPT | 2 | ||

| 23 | H1600 | ADAPTER-90 DEG-#6 JICM X #8 SAEM | 2 | ||

| NOTES | |||||

|---|---|---|---|---|---|

| † Included in multiple kits. | |||||

| See Single Compartment Swing Arm Stop for the the Single Compartment Swing Arm Stop. | |||||

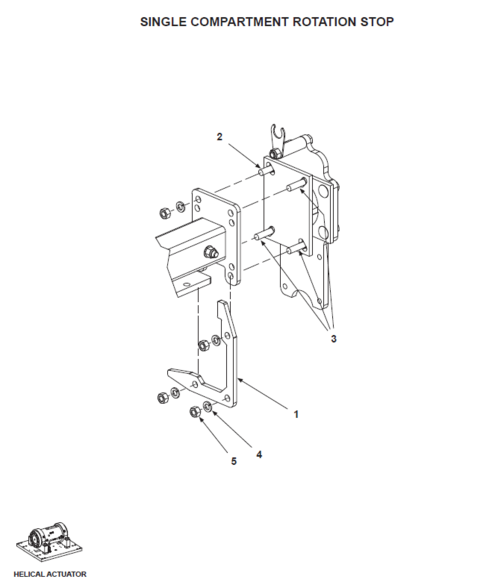

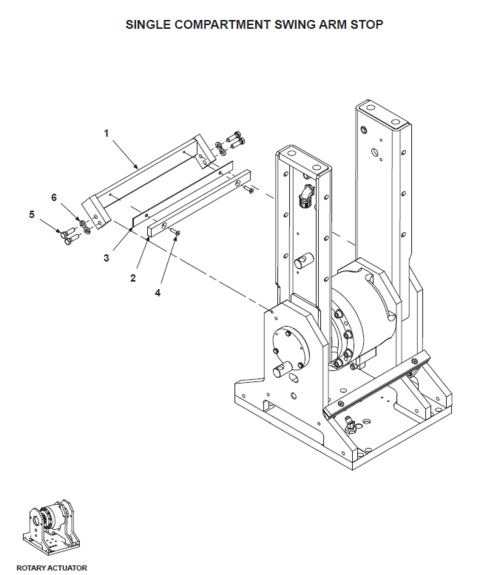

Vacuum Swing Arm Stop (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 44555001 | STOP-SWING ARM | 1 | ||

| 2 | 43057003 | CUSHION-SWING ARM | 1 | ||

| 3 | 43057008 | SPACER-SWING ARM STOP | 1 | ||

| 4 | HW0306 | BOLT-FHSCS-1/4-20 X 1" | 2 | ||

| 5 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | 4 | ||

| 6 | HW0107 | WASHER-LOCK-3/8" | 4 |

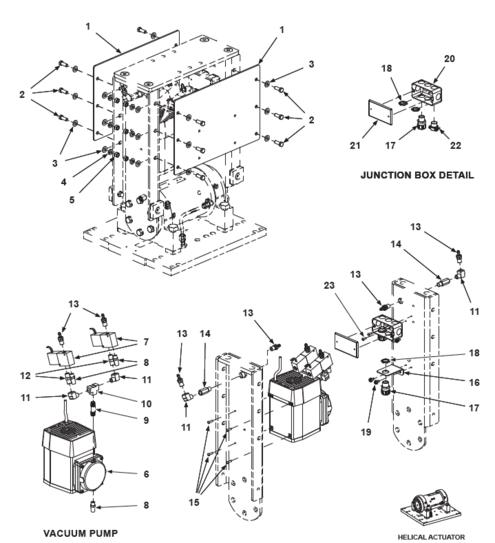

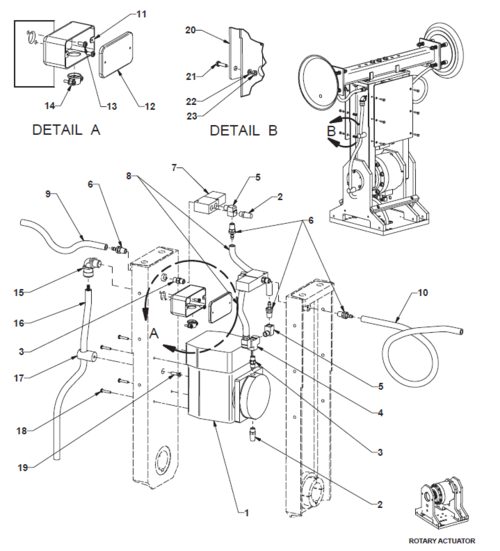

Vacuum Pump (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | P0005 | PUMP-VACUUM | 1 | ||

| 2 | P0208 | FILTER-HI FLOW | 3 | ||

| 3 | P0503 | NIPPLE-#4 NPT-BRASS | 3 | ||

| 4 | P0502 | TEE-#4 FNPT-BRASS | 1 | ||

| 5 | P0506 | ELBOW-STR-90 DEG-#4 NPT-BRASS | 4 | ||

| 6 | P0402 | HOSE BARB-1/4 X #4 NPTM-BRASS | 6 | ||

| 7 | P0207 | VALVE-VACUUM RELEASE | 2 | ||

| 8 | P0302 | HOSE-VACUUM-1/4" I.D. | Two 6" pieces | 1' | |

| 9 | P0302 | HOSE-VACUUM-1/4" I.D. | Short Arm side | 1' | |

| 10 | P0302 | HOSE-VACUUM-1/4" I.D. | Long Arm side | 2' | |

| 11 | E0611 | JUNCTION BOX-4" X 2" X 2" | 1 | ||

| 12 | E0612 | COVER-JUNCTION BOX | 1 | ||

| 13 | HW0212 | SCREW-RHMS-#10-24 X 1/2" | 2 | ||

| 14 | E0624 | CONNECTOR-1/2" | 1 | ||

| 15 | E0608-1 | RESTRAINT-1/2"-90 DEG | Grip size .450" to .560" | 1 | |

| 15a | E0617 | LOCKNUT-CONDUIT-1/2" | Not shown | 2 | |

| 16 | E0501 | CORD-14-4 SW/SOW | Withtout Ground Connection in Arm | 15' | |

| E0514 | CORD-16-5 SW/SOW | ||||

| 17 | 43057014 | STANDOFF-CABLE | 1 | ||

| 18 | HW0206 | SCREW-RHMS-#10-32 X 3/4" | 4 | ||

| 19 | HW0306 | BOLT-FHSCS-1/4-20 X 1" | 1 | ||

| 20 | 43057021 | PLATE-STIFFENER | † | 2 | |

| 21 | HW0402 | BOLT-HHCS-3/8-16 X 1" | † | 12 | |

| 22 | HW0107 | WASHER-LOCK-3/8" | † | 12 | |

| 23 | HW0005 | NUT-HEX-3/8-16 | † | 12 | |

| 24 | HW0108 | WASHER-FLAT-3/8"-SAE | † | Not shown | 24 |

| 25 | P0111 | FILTER-VACUUM-INLINE | Not shown | 2 | |

| NOTES | |||||

| † Included in multiple kits. | |||||

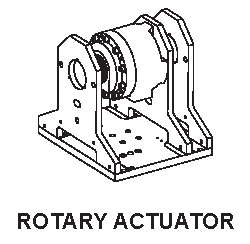

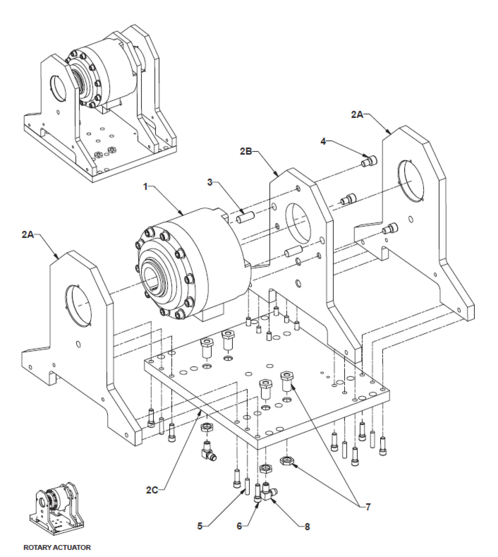

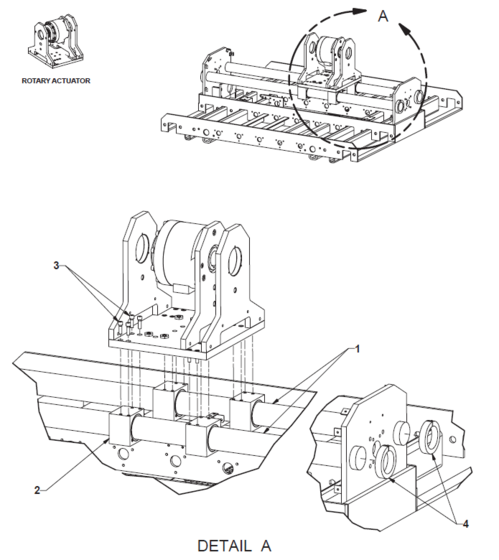

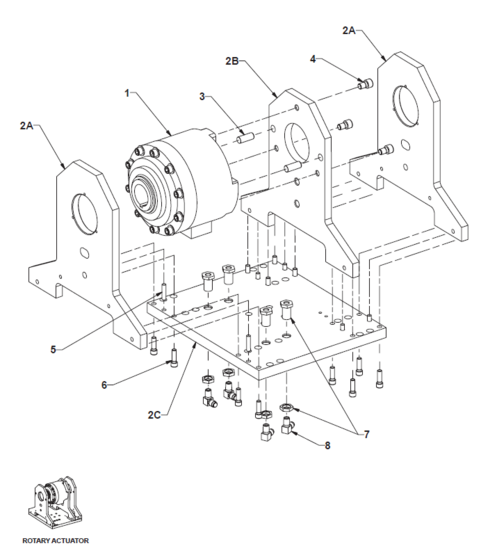

Rotary Actuator

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43046001 | ROTARY ACTUATOR | 1 | ||

| 2 | 80000002 | ROTARY ACTUATOR BASE ASSEMBLY | Without Actuator | 1 | |

| 2A | N/A | VERTICAL CARRIER PLATE-OUTER | Included with 80000002 | 2 | |

| 2B | N/A | VERTICAL CARRIER PLATE-INNER | Included with 80000002 | 1 | |

| 2C | N/A | CARRIER BASE PLATE | Included with 80000002 | 1 | |

| 3 | HW1070 | PIN-PULL DOWEL-5/8" X 1 1/2" | 2 | ||

| 4 | HW0508 | BOLT-SHCS-1/2-13 X 3/4" | 3 | ||

| 5 | HW1045 | PIN-PULL DOWEL-3/8" X 1 1/2" | Included with 80000002 | 6 | |

| 6 | HW0412 | BOLT-SHCS-3/8-16 X 1 1/4" | Included with 80000002 | 12 | |

| 7 | H0010 | FITTING-BULKHEAD-3/4-16 X #4 FNPT | 4 | ||

| 8 | H1579 | ADAPTER-90 DEG-#6 JICM X #4 NPTM | 2 |

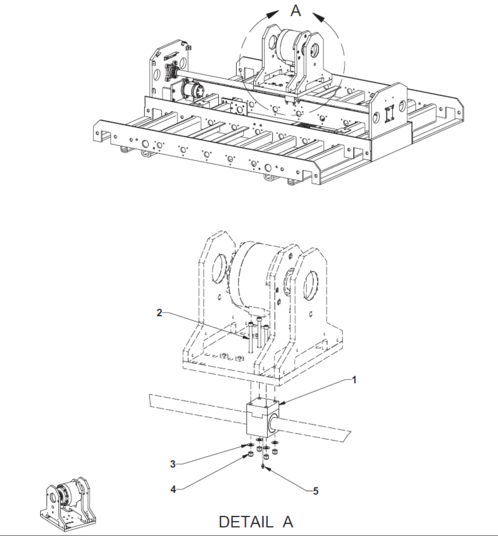

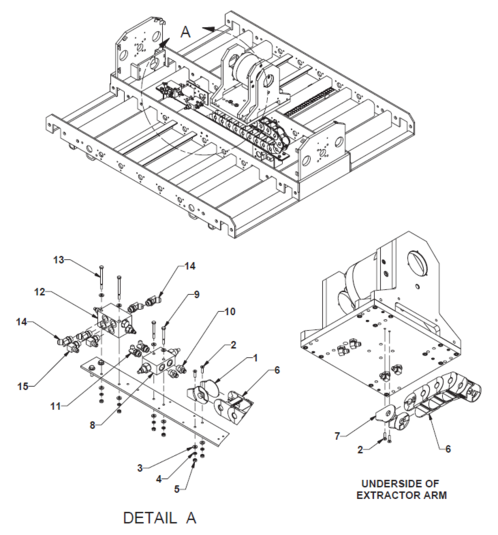

Carrier Shafts & Bearings (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43057045 | CARRIER SHAFT-EXTRACTOR ARM | † See notes | 2 | |

| 2 | 43054007 | BEARING-EXTRACTOR ARM CARRIER | 80252002 | †† See notes | 4 |

| 3 | HW0412 | BOLT-SHCS-3/8-16 X 1 1/4" | 80252002 | 16 | |

| 4 | PT0413 | COLLAR-SHAFT-3" | 4 | ||

| 5 | PT0624 | FITTING-ZERK | 80252002 | Not shown | 4 |

| NOTES | |||||

| † See Vacuum Extended Reach (Rotary Actuator) section for Extended Reach equipped units. | |||||

| †† See Carrier Shafts & Bearings (Helical Actuator) section for Helical Actuator equipped units. | |||||

Drive Screw Components (Rotary Actuator)

Drive Nut Assembly (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43054006 | DRIVE NUT ASSEMBLY | 80252003 | † See notes | 1 |

| 2 | HW0426 | BOLT-SHCS-3/8-16 X 5 1/2" | 80252003 | †† See notes | 4 |

| 3 | HW0108 | WASHER-FLAT-3/8"-SAE | 80252003 | †† See notes | 4 |

| 4 | HW0006 | NUT-NILN-3/8-16 | 80252003 | †† See notes | 4 |

| 5 | PT0624 | FITTING-ZERK | 80252003 | 1 | |

| NOTES | |||||

| † See Drive Nut Assembly (Helical Actuator) section for Helical Actuator equipped units. | |||||

| †† It is recommended to replace mounting hardware when replacing Drive Nut Assembly. | |||||

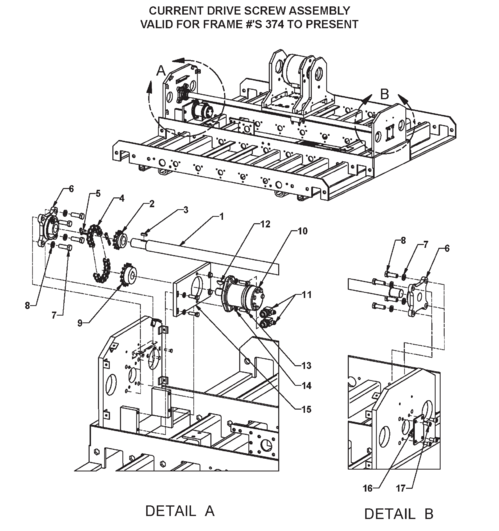

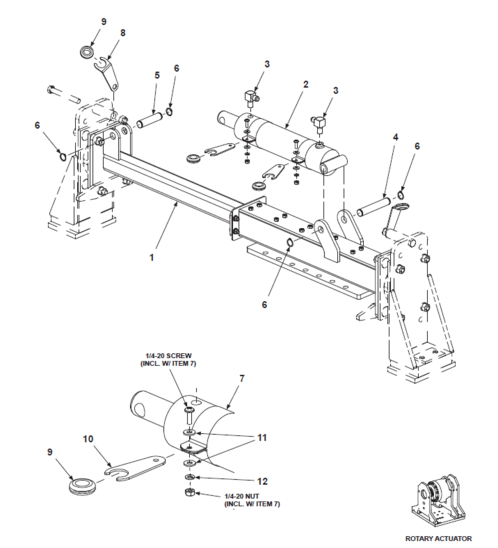

Drive Screw

[Current] Drive Screw Assembly (Frame #'s 374 to Present)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43024001 | SCREW-LINEAR DRIVE | 1 | ||

| 2 | PT0119 | SPROCKET-50B15 X 1 3/16" | 1 | ||

| 3 | 43097004 | KEY-1/4 X 7/8" | 1 | ||

| 4 | 00158001-15 | CHAIN-ROLLER-#50 | 1 | ||

| 5 | PT0102 | LINK-CONNECTING-#50 | 1 | ||

| 6 | PT0406 | FLANGE BEARING-4 BOLT-1 3/16" | Alloy casting | 2 | |

| 7 | HW0503 | BOLT-HHCS-1/2-13 X 1 1/2" | 8 | ||

| 8 | HW0110 | WASHER-LOCK-1/2" | 8 | ||

| 9 | PT0107 | SPROCKET-50B15 X 1" | 1 | ||

| 10 | HC0121 | MOTOR-HYDRAULIC-100CC | SAE 2-Bolt mount | 1 | |

| 11 | H1605 | ADAPTER-90 DEG-#6 JICM X #10 SAEM | 2 | ||

| 12 | HW1071 | KEY-WOODRUFF-#808 STD | Supplied with Item 10 | A/R | |

| 13 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | 6 | ||

| 14 | HW0107 | WASHER-LOCK-3/8" | 6 | ||

| 15 | 43017007 | PLATE-MOUNTING-SCREW DRIVE MOTOR | 1 | ||

| 16 | 43057019 | PLATE-COVER | 2 | ||

| 17 | HW0415 | BOLT-SHCS-3/8-16 X 3/4" | 8 |

| ITEMS BELOW ARE REQUIRED FOR REPLACING THE LINEAR DRIVE

SCREW ON UNITS WITH FRAME #'S OF 373 AND EARLIER | |||||

|---|---|---|---|---|---|

| LINEAR DRIVE SCREW UPDATE KIT | |||||

| REF | 80252011 | UPGRADE KIT | 1 | ||

| 1 | 43024001 | SCREW-LINEAR DRIVE | 1 | ||

| 2 | PT0119 | SPROCKET-50B15 X 1 3/16" | 1 | ||

| 3 | 43097004 | KEY-1/4" X 7/8" | 1 | ||

| 6 | PT0406 | FLANGE BEARING-4 BOLT-1 3/16" | Alloy casting | 2 | |

| 7 | HW0503 | BOLT-HHCS-1/2-13 X 1 1/2" | 8 | ||

| 8 | HW0110 | WASHER-LOCK-1/2" | 8 | ||

| 16 | 43057019 | PLATE-COVER | 2 | ||

| - | 43057022 | SHIM-18GA | May not be required - (Not shown) | 2 | |

| - | 43057018 | TEMPLATE-BEARING MOUNT PATTERN | (Not shown) | 1 | |

| - | 43057020 | SPACER PLATE | (Not shown) | 2 | |

| - | 80000015 | INSTRUCTION DETAIL | (Not shown) | REF | |

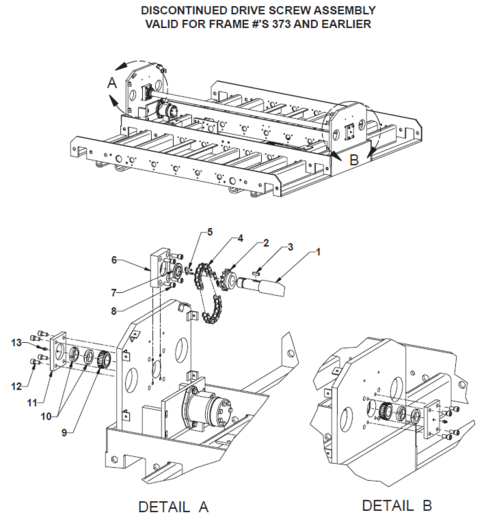

[Discontinued] Drive Screw Assembly (Frame #'s 373 and Earlier)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | N/A | SCREW-LINEAR DRIVE (DISCONTINUED) | See 80252011 Upgrade Kit | 1 | |

| 2 | PT0118 | SPROCKET-50B12 X 1 3/16" | 1 | ||

| 3 | 43097004 | KEY-1/4" X 7/8" | 1 | ||

| 4 | 00158001-15 | CHAIN-ROLLER-#50 | 1 | ||

| 5 | PT0102 | LINK-CONNECTING-#50 | 1 | ||

| 6 | 43057016 | BLOCK-BEARING RETAINER | 2 | ||

| 6a | PT0414 | RACE-TAPERED ROLLER BEARING | Included with 43057016 | 2 | |

| 7 | PT0623 | SEAL-GREASE | 2 | ||

| 8 | HW0416 | BOLT-SHCS-3/8-16 X 1" | 8 | ||

| 9 | PT0415 | BEARING-TAPERED ROLLER | 2 | ||

| 10 | HW1050 | NUT-LOCK | 4 | ||

| 11 | 43057017 | PLATE-COVER | 2 | ||

| 12 | HW0415 | BOLT-SHCS-3/8-16 X 3/4" | 8 | ||

| 13 | PT0624 | FITTING-ZERK | 2 |

Hose Carrier Plate

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43915018 | PLATE-HOSE CARRIER | 1 | ||

| 2 | PT0618 | BRACKET-FIXED END | 1 | ||

| 3 | HW0301 | BOLT-SELF TAP "F"-1/4-20 X 1/2" | 2 | ||

| 4 | PT0617 | HOSE CARRIER | 20 links required | 3 FT | |

| 5 | PT0619 | BRACKET-MOVING END | 1 | ||

| 6 | HW0303 | BOLT-HHCS-1/4-20 X 1" | 2 | ||

| 7 | HW0103 | WASHER-LOCK-1/4" | 2 | ||

| 8 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | † See notes | 2 | |

| 9 | HW0108 | WASHER-FLAT-3/8"-SAE | 6 | ||

| 10 | HW0107 | WASHER-LOCK-3/8" | 4 | ||

| 11 | HW0005 | NUT-HEX-3/8-16 | 4 | ||

| 12 | HC0262 | VALVE-CROSS PORT RELIEF | Includes cartridges | 1 | |

| 12a | 43846002 | REPLACEMENT CARTRIDGE | †† For Item 12 (Not shown) | 2 | |

| 13 | HW0308 | BOLT-HHCS-1/4-20 X 2 1/2" | 2 | ||

| 14 | HW0104 | WASHER-FLAT-1/4"-SAE | 2 | ||

| 15 | HW0103 | WASHER-LOCK-1/4" | 2 | ||

| 16 | HW0002 | NUT-HEX-1/4-20 | 2 | ||

| 17 | H1560 | ADAPTER-45 DEG-#8 JICM X #8 SAEM | 4 | ||

| 18 | E1329 | JUNCTION BOX-4" X 4" X 2" | PVC - Includes cover | 1 | |

| 19 | HW0212 | SCREW-RHMS-#10-24 X 1/2" | 4 | ||

| 20 | HW0102 | WASHER-FLAT-#10-SAE | 4 | ||

| 21 | E0623 | RESTRAINT-1/2"-90 DEG | Grip size .250" to .375" | 2 | |

| 22 | E0622 | RESTRAINT-1/2" | Grip size .450" to .560" | 1 | |

| 23 | E0617 | LOCKNUT-CONDUIT-1/2" | For Items 21 & 22 (Not shown) | 3 | |

| 24 | HW1076 | BOLT-FHSCS-3/8-16 X 1" | † See notes | 2 | |

| NOTES | |||||

| † Units built prior to February 2014 without extended reach option use (4) HW0403 mounting bolts.

†† Cartridges are for replacement only. | |||||

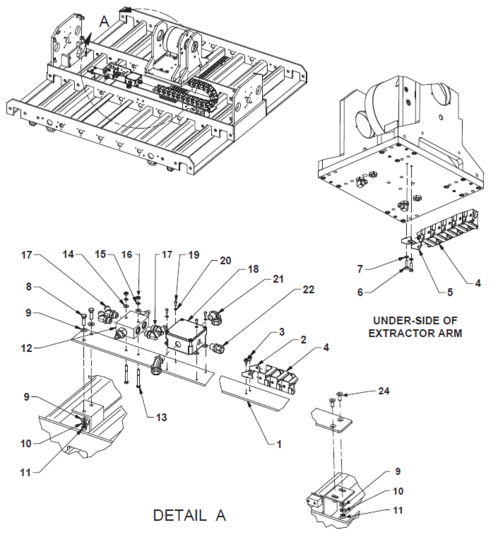

Magnet Components (Rotary Actuator)

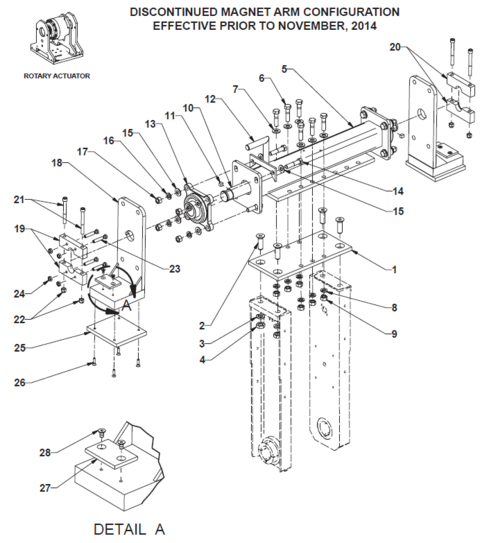

[Discontinued] Magnet Arm Configuration

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 41257014 | TIE PLATE-SWING ARM | All units | 1 | |

| - | 41655008 | EXTENSION-ARM | BE-36 only (Not shown) | 1 | |

| - | 43455001 | EXTENSION-ARM | BE-42 only (Not shown) | 1 | |

| 2 | HW0603 | BOLT-FHSCS-5/8-11 X 2" | 4 | ||

| 3 | HW0113 | WASHER-LOCK-5/8" | 4 | ||

| 4 | HW0010 | NUT-JAM-5/8-11 | 4 | ||

| 5 | 41655001 | CARRIER TUBE-MAGNET SWING SHAFT | 1 | ||

| 6 | HW0504 | BOLT-HHCS-1/2-13 X 2" | 6 | ||

| 7 | HW0112 | WASHER-FLAT-1/2"-SAE | 6 | ||

| 8 | HW0110 | WASHER-LOCK-1/2" | 6 | ||

| 9 | HW0007 | NUT-HEX-1/2-13 | 6 | ||

| 10 | 41657006 | SHAFT-MAGNET SWING | 1 | ||

| 11 | 41698001 | KEY-3/8" X 7/16" | 2 | ||

| 12 | N/A | STOP-MAGNET SWING | † Dicontinued | 1 | |

| 13 | PT0430 | FLANGE BEARING-4 BOLT-1 1/2" | 2 | ||

| 14 | HW0513 | BOLT-HHCS-1/2-13 X 2 1/4" | 8 | ||

| 15 | HW0112 | WASHER-FLAT-1/2"-SAE | 16 | ||

| 16 | HW0110 | WASHER-LOCK-1/2" | 8 | ||

| 17 | HW0007 | NUT-HEX-1/2-13 | 8 | ||

| 18 | 41655002 | PLATE-MAGNET MOUNTING | 2 | ||

| 19 | 41257015 | BLOCK-TIGHTENER | 2-piece item | 1 | |

| 20 | 41257016 | BLOCK-FIXED | 2-piece item | 1 | |

| 21 | HW0423 | BOLT-SHCS-3/8-16 X 3 1/2" | 4 | ||

| 22 | HW0006 | NUT-NILN-3/8-16 | 4 | ||

| 23 | HW0806 | SET SCREW-3/8-16 X 2" | Replaces Swivel Head | 4 | |

| 24 | HW0424 | NUT-JAM-3/8-16 | 4 | ||

| 25 | 41657017 | INSULATOR-MAGNET MOUNT | 2 | ||

| 26 | HW0306 | BOLT-FHSCS-1/4-20 X 1" | 8 | ||

| 27 | 41657008 | PAD-MAGNET SLIDE | 2 | ||

| 28 | HW0314 | BOLT-FHSCS-1/4-20 X 1/2" | 4 | ||

| NOTES | |||||

| † Refer to [Current] Magnet Arm Configuration (Rotary Actuator) section for replacement / upgrade parts. | |||||

Magnet Pivot Stop (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | N/A | MAGNET PUSH/PULL ARM | † See notes | 1 | |

| 2 | 43055010 | MAGNET MOUNT | 2 | ||

| 3 | PT0470 | BEARING-MAGNET PIVOT | 2 | ||

| 4 | HW0525 | BOLT-CARRIAGE-1/2-13 X 1 1/2" | 12 | ||

| 5 | HW0524 | BOLT-CARRIAGE-1/2-13 X 2" | †† Stop Plate location | 4 | |

| 6 | HW0110 | WASHER-LOCK-1/2" | 16 | ||

| 7 | HW0007 | NUT-HEX-1/2-13 | 16 | ||

| 8 | 43058009 | PLATE-ROTATION STOP | 2 | ||

| 9 | 43058003 | SLEEVE-STOP | 2 | ||

| 10 | 43058010 | SUPPORT-CABLE | 2 | ||

| 11 | PL0501 | GROMMET-1/2" | 2 | ||

| 12 | HW0523 | BOLT-HHCS-1/2-13 X 4" | 2 | ||

| 13 | HW0008 | NUT-NILN-1/2-13 | 2 | ||

| 14 | 43057037 | INSULATOR-BOTTOM | 2 | ||

| 15 | HW0306 | BOLT-FHSCS-1/4-20 X 1" | 8 | ||

| 16 | 41657008 | SLIDE-MAGNET | 2 | ||

| 17 | HW0314 | BOLT-FHSCS-1/4-20 X 1/2" | 4 | ||

| 18 | 44558001 | PLATE-ROTATION STOP | †† Single compartment units only | 2 | |

| REF | 43052014 | ADJUSTABLE PUSH-PULL ARM | Includes Items 19-23 | A/R | |

| 19 | 43055018 | ARM BASE | 1 | ||

| 20 | 43055019 | MAGNET MOUNT | 2 | ||

| 21 | HW0523 | BOLT-HHCS-1/2-13 X 4" | 2 | ||

| 22 | HW0112 | WASHER-FLAT-1/2"-SAE | 4 | ||

| 23 | HW0008 | NUT-NILN-1/2-13 | 2 | ||

| NOTES | |||||

| † 1-Piece Arm no longer available. Must be replaced with Adjustable Arm. | |||||

| †† Single compartment Stop Plates require (1) additional 2" long Carriage Bolt each | |||||

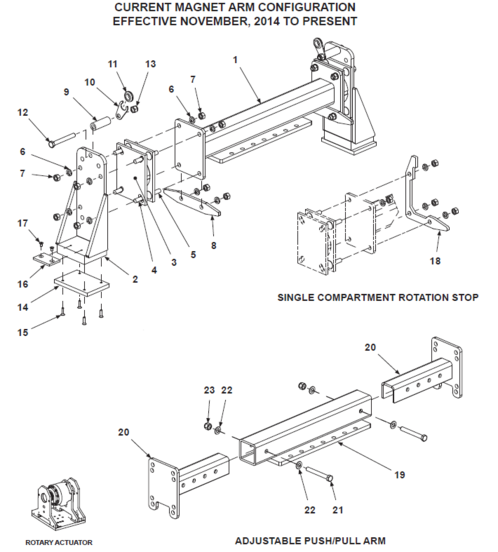

[Current] Magnet Arm Configuration (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| REF | 80252012 | MAGNET SWING STOP KIT | Includes Items 1 through 6 | A/R | |

| 1 | 43057029 | PLATE-STOP | 1 | ||

| 2 | 43058003 | SLEEVE-STOP | 2 | ||

| 3 | 43057030 | SUPPORT-CABLE | 2 | ||

| 4 | PL0501 | GROMMET-1/2" | 2 | ||

| 5 | HW0509 | BOLT-HHCS-1/2-13 X 4 1/2" | 2 | ||

| 6 | HW0008 | NUT-NILN-1/2-13 | 2 | ||

| 7 | 44557003 | PLATE-STOP | † Single compartment units only | 1 | |

| NOTES | |||||

| † For units equipped with Pivot Shaft. See [Current] Magnet Arm Configuration (Rotary Actuator) for units with Independent Magnet Pivot Bearings. | |||||

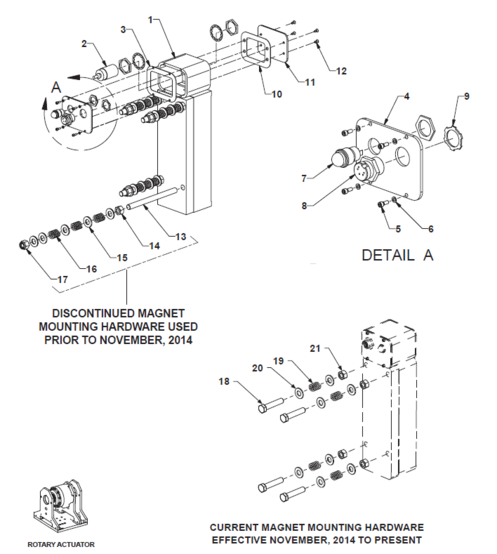

Magnet Mounting Hardware (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| REF | 43032009 | MAGNET ASSEMBLY | Includes Items 1 through 12 | A/R | |

| 1 | N/A | ELECTROMAGNET-95VDC | 2 | ||

| 2 | E0314 | SENSOR-PROXIMITY-30MM | 2 | ||

| 3 | N/A | GASKET-REAR | Discontinued - Not used | 2 | |

| 4 | 41657002 | COVER-PROXIMITY SENSOR HOUSING | Rear | 2 | |

| 5 | HW1065 | SCREW-SHCS-#6-32 X 3/8" | 8 | ||

| 6 | HW1066 | WASHER-LOCK-#6 | 8 | ||

| 7 | E0376 | INDICATOR LIGHT | † See notes | 2 | |

| 8 | E0335 | RECEPTACLE-5 PIN MALE | With 12" lead | 2 | |

| 9 | E0617 | LOCKNUT-CONDUIT-1/2" | 2 | ||

| 10 | N/A | GASKET-FRONT | Discontinued - Not used | 2 | |

| 11 | 41657003 | COVER-PROXIMITY SENSOR HOUSING | 80252015 | Front | 2 |

| 12 | HW0138 | SCREW-FHSCS-#8-32 X 3/8" | 80252015 | 8 | |

| 13 | HW0433 | STUD-1/2-13 X 5" | 80252006 | For units with Magnet Pivot Shaft only.

See [Discontinued] Magnet Arm Configuration for units built prior to 11/01/14 |

8 |

| 14 | HW0007 | NUT-HEX-1/2-13 | 80252006 | 8 | |

| 15 | HW0112 | WASHER-FLAT-1/2"-SAE | 80252006 | 40 | |

| 16 | HW1002 | SPRING-1/2" | 80252006 | 24 | |

| 17 | HW0008 | NUT-NILN-1/2-13 | 80252006 | 8 | |

| 18 | HW0514 | BOLT-HHCS-1/2-13 X 2 1/2" | 80252014 | For units with independent Pivot Bearings only.

See [Current] Magnet Arm Configuration for units built 11/01/14 to present) |

4 |

| 19 | HW1002 | SPRING-1/2" | 80252014 | 4 | |

| 20 | HW0112 | WASHER-FLAT-1/2"-SAE | 80252014 | 8 | |

| 21 | HW0007 | NUT-HEX-1/2-13 | 80252014 | 4 | |

| NOTES | |||||

| † Extractors built or replacement magnets shipped prior to October 2021 used multi-piece indicator lights with replaceable bulb and lens and are no longer available. Current indicator light is a 1-piece LED assembly. Replacement of any multi-piece component requires replacing entire assembly with current, 1-piece indicator light. | |||||

Magnet Cords (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | E1105 | JUNCTION BOX-4" X 2" X 2" | Weather proof box | 1 | |

| 2 | HW0301 | BOLT-SELF TAP "F"-1/4-20 X 1/2" | 2 | ||

| 3 | E1106 | COVER-JUNCTION BOX | Weather proof with gasket | 1 | |

| 4 | E0333 | RECEPTACLE-9 PIN MALE | With 12" lead | 1 | |

| 5 | E0608-1 | RESTRAINT-1/2"-90 DEG | Grip size .450" to .560" | 2 | |

| 6 | E0617 | LOCKNUT-CONDUIT-1/2" | 3 | ||

| 7 | E0334 | CORD-5 PIN FEMALE | With 36" lead | 2 | |

| 8 | E0332 | CORD-9 PIN FEMALE-90 DEG | With 36" lead | 1 | |

| 9 | PL0501 | GROMMET-1/2" | 1 | ||

| 10 | 41657013-2 | PLATE-PANEL MOUNTING | With single cable hole | 1 | |

| 11 | E0334-6 | CORD-5 PIN FEMALE | With 72" lead | 2 | |

| 12 | 43057038-2 | PLATE-PANEL MOUNTING | With dual cable holes | 1 |

Magnet Panel Mounting (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43057021 | PLATE-STIFFENER | 1 | ||

| 2 | HW0402 | BOLT-HHCS-3/8-16 X 1" | 12 | ||

| 3 | HW0108 | WASHER-FLAT-3/8"-SAE | Not shown | 24 | |

| 4 | HW0107 | WASHER-LOCK-3/8" | 12 | ||

| 5 | HW0005 | NUT-HEX-3/8-16 | 12 | ||

| 6 | 41637001 | PANEL-COMPONENT MOUNTING | 1 | ||

| 7 | HW0325 | BOLT-5/16-18 X 1 3/4"-PAN HEAD | 4 | ||

| 8 | N/A | INSULATOR-THREADED FEMALE | Discontinued | 4 | |

| 9 | HW0106 | WASHER-FLAT-5/16"-SAE | 8 | ||

| 10 | HW0326 | NUT-NILN-5/16-18 | 8 | ||

| 11 | E1016 | FUSE HOLDER | 1 | ||

| 12 | HW0130 | SCREW-RHMS-#8-32 X 1/2" | 1 | ||

| 13 | HW0133 | WASHER-FLAT-#8-SAE | 1 | ||

| 14 | HW0132 | NUT-NILN-#8-32 | 1 | ||

| 15 | E0325 | FUSE-7AMP-250VAC | FLM-7 or FNM-7 | 1 | |

| 16 | PL0307 | INSULATOR-MALE STUD | 4 |

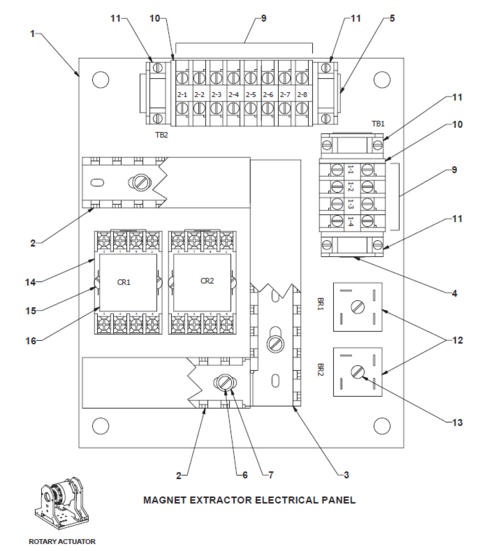

Magnet Extractor Electrical Panel (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 41637001 | PANEL-COMPONENT MOUNTING | 1 | ||

| 2 | 41637002 | WIRE WAY | 2 | ||

| 3 | 41637003 | WIRE WAY | 1 | ||

| 4 | 41637004 | TRACK-TERMINAL BLOCK MOUNTING | 1 | ||

| 5 | 41637005 | TRACK-TERMINAL BLOCK MOUNTING | 1 | ||

| 6 | HW0130 | SCREW-RHMS-#8-32 X 1/2" | 10 | ||

| 7 | HW0132 | WASHER-FLAT-#8-SAE | 10 | ||

| 8 | HW0133 | NUT-NILN-#8-32 | Not shown | 16 | |

| 9 | E1020 | TERMINAL BLOCK | 12 | ||

| 10 | E1040 | END BARRIER | 2 | ||

| 11 | E1330 | END ANCHOR | 4 | ||

| 12 | E1009 | RECTIFIER-FULL WAVE BRIDGE | 2 | ||

| 13 | HW0135 | SCREW-RHMS-#8-32 X 3/4" | 2 | ||

| 14 | E1313 | SOCKET-RELAY-8 PIN | 2 | ||

| 15 | HW0139 | SCREW-RHMS-#8-32 X 1 1/4" | 4 | ||

| 16 | E0331 | RELAY-DPDT-110VAC | with Indicator Light | 2 |

Swing Arm Stop (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43055007 | MOUNT-STOP-SWING ARM | † See notes | 2 | |

| 2 | 43057024 | STOP-SWING ARM | BE-24 | 4 | |

| 43057023 | STOP-SWING ARM | BE-36 & BE-42 | 4 | ||

| 3 | HW0304 | BOLT-HHCS-1/4-20 X 1 1/2" | 4 | ||

| 4 | HW0104 | WASHER-FLAT-1/4"-SAE | 8 | ||

| 5 | HW0103 | WASHER-LOCK-1/4" | 4 | ||

| 6 | HW0002 | NUT-HEX-1/4-20 | 4 | ||

| 7 | HW0403 | BOLT-HHCS-3/8-16 X 1 1/4" | 4 | ||

| 8 | HW0107 | WASHER-LOCK-3/8" | 4 | ||

| 9 | HW0108 | WASHER-FLAT-3/8"-SAE | 4 | ||

| NOTES | |||||

| † See Vacuum Swing Arm Stop (Rotary Actuator) section for single compartment stop mount and stop. | |||||

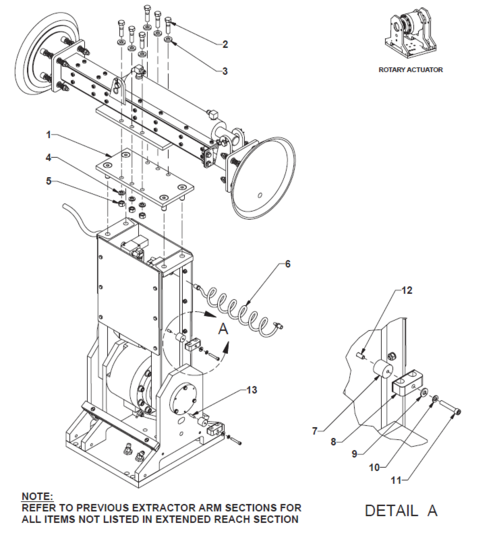

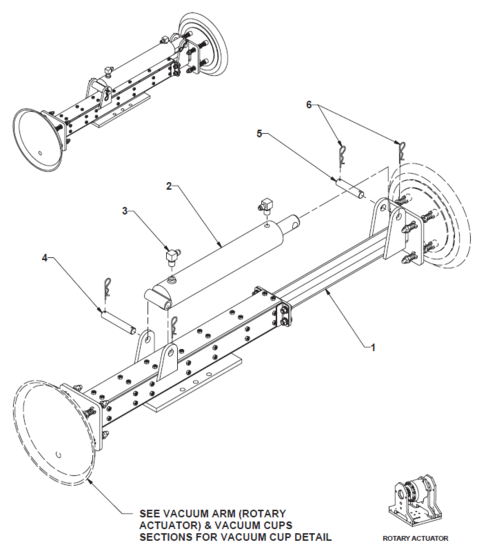

Vacuum Extended Reach (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 41257014 | TIE PLATE-SWING ARM | All units | 1 | |

| - | 41655008 | EXTENSION-ARM | BE-36 only (Not shown) | 1 | |

| - | 43455001 | EXTENSION-ARM | BE-42 only (Not shown) | 1 | |

| 2 | HW0504 | BOLT-HHCS-1/2-13 X 2" | 6 | ||

| 3 | HW0112 | WASHER-FLAT-1/2"-SAE | 6 | ||

| 4 | HW0110 | WASHER-LOCK-1/2" | 6 | ||

| 5 | HW0007 | NUT-HEX-1/2-13 | 6 | ||

| 6 | P0301-1 | HOSE-COIL-VACUUM | 1 | ||

| 7 | 41257035 | STANDOFF | 2 | ||

| 8 | HW1072 | RESTRAINT-HOSE | 2 | ||

| 9 | HW0104 | WASHER-FLAT-1/4"-SAE | 2 | ||

| 10 | HW0103 | WASHER-LOCK-1/4" | 2 | ||

| 11 | HW0318 | BOLT-SHCS-1/4-20 X 1 1/2" | 2 | ||

| 12 | HW0302 | BOLT-HHCS-1/4-20 X 3/4" | 1 | ||

| 13 | HW0312 | SCREW-SHSS-1/4-20 X 1"-CUP POINT | 1 |

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 41255005 | ARM-EXTENSION-VACUUM | 1 | ||

| 2 | HC0416 | CYLINDER-EXTENDED REACH-VACUUM | 2 1/2" X 12" Cylinder | 1 | |

| 3 | H1578 | ADAPTER-90 DEG-#6 JICM X #6 MNPT | 2 | ||

| 4 | 41257031 | PIN-CLEVIS END | 1 | ||

| 5 | 00197036 | PIN-ROD END | 1 | ||

| 6 | HW1058 | PIN-HITCH | 4 |

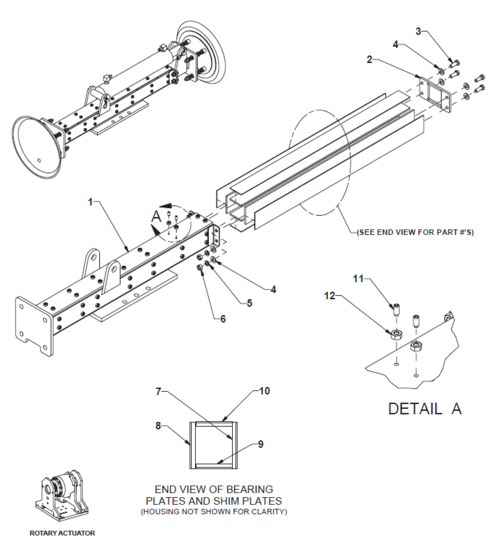

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 41255004 | HOUSING-EXTENDED REACH-VACUUM | 1 | ||

| 2 | 41257030 | PLATE-END | 1 | ||

| 3 | HW0402 | BOLT-HHCS-3/8-16 X 1" | 4 | ||

| 4 | HW0108 | WASHER-FLAT-3/8"-SAE | 8 | ||

| 5 | HW0107 | WASHER-LOCK-3/8" | 4 | ||

| 6 | HW0005 | NUT-HEX-3/8-16 | 4 | ||

| 7 | 41258002 | PLATE-BEARING | 80258001 | Side | 2 |

| 8 | 41258005 | PLATE-SHIM | 80258001 | Side | 2 |

| 9 | 41258003 | PLATE-BEARING | 80258001 | Upper / lower | 2 |

| 10 | 41258004 | PLATE-SHIM | 80258001 | Upper / lower | 2 |

| 11 | HW0812 | SCREW-SHSS-1/4-20 X 5/8"-HALF DOG | 28 | ||

| 12 | HW0002 | NUT-HEX-1/4-20 | 28 |

Extended Reach (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43046001 | ROTARY ACTUATOR | 1 | ||

| 2 | 80000002 | ROTARY ACTUATOR BASE ASSEMBLY | Without Actuator | 1 | |

| 2A | N/A | VERTICAL CARRIER PLATE-OUTER | Included with 80000002 | 2 | |

| 2B | N/A | VERTICAL CARRIER PLATE-INNER | Included with 80000002 | 1 | |

| 2C | N/A | CARRIER BASE PLATE | Included with 80000002 | 1 | |

| 3 | HW1070 | PIN-PULL DOWEL-5/8" X 1 1/2" | 2 | ||

| 4 | HW0508 | BOLT-SHCS-1/2-13 X 3/4" | 3 | ||

| 5 | HW1045 | PIN-PULL DOWEL-3/8" X 1 1/2" | Included with 80000002 | 6 | |

| 6 | HW0412 | BOLT-SHCS-3/8-16 X 1 1/4" | Included with 80000002 | 12 | |

| 7 | H0010 | FITTING-BULKHEAD-3/4-16 X #4 FNPT | 4 | ||

| 8 | H1579 | ADAPTER-90 DEG-#6 JICM X #4 MNPT | 4 |

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | PT0634 | BRACKET-MALE END | Sols as a set | 1 | |

| 2 | HW0306 | BOLT-FHSCS-1/4-20 X 1" | 4 | ||

| 3 | HW0104 | WASHER-FLAT-1/4"-SAE | 10 | ||

| 4 | HW0103 | WASHER-LOCK-1/4" | 6 | ||

| 5 | HW0002 | NUT-HEX-1/4-20 | 6 | ||

| 6 | PT0627 | HOSE CARRIER | 14 links required | 39" | |

| 7 | PT0634 | BRACKET-FEMALE END | Sols as a set | 1 | |

| 8 | HC0262 | VALVE-CROSS PORT RELIEF | 1 | ||

| 8a | 43046003 | REPLACEMENT CARTRIDGE | † For Item 8 (Not shown) | 2 | |

| 9 | HW0308 | BOLT-HHCS-1/4-20 X 2 1/2" | 2 | ||

| 10 | H1546 | ADAPTER-#6 JICM X #8 SAEM | 2 | ||

| 11 | H1617 | ADAPTER-45 DEG-#6 JICM X #8 SAEM | 2 | ||

| 12 | HC0237 | VALVE-SEQUENCING | 1 | ||

| 12a | 43046005 | REPLACEMENT CARTRIDGE | † For Item 12 (Not shown) | A/R | |

| 13 | HW0317 | BOLT-HHCS-1/4-20 X 3 1/2" | 2 | ||

| 14 | H1560 | ADAPTER-45 DEG-#8 JICM X #8 SAEM | 4 | ||

| 15 | H1600 | ADAPTER-90 DEG-#6 JICM X #8 SAEM | 2 | ||

| NOTES | |||||

| † Cartridges are for replacement only | |||||

Magnet Extended Reach (Rotary Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43055011 | ARM-EXTENSION-MAGNET | 1 | ||

| 2 | HC0415 | CYLINDER-EXTENDED REACH-MAGNET | 2 1/2" X 8" Cylinder | 1 | |

| 3 | H1578 | ADAPTER-90 DEG-#6 JICM X #6 MNPT | 2 | ||

| 4 | 43057042 | PIN-CLEVIS END | 1 | ||

| 5 | 43057043 | PIN-ROD END | 1 | ||

| 6 | HW1132 | RETAINING RING-EXTERNAL-3/4" I.D. | 4 | ||

| 7 | HW1043 | CLAMP-CYLINDER | 2 | ||

| 8 | 43057044-2 | SUPPORT-CABLE | 2 | ||

| 9 | PL0501 | GROMMET-1/2" I.D. | 4 | ||

| 10 | 43058019 | SUPPORT-CABLE-BAND CLAMP | 2 | ||

| 11 | HW0104 | WASHER-FLAT-1/4"-SAE | 4 | ||

| 12 | HW0103 | WASHER-LOCK-1/4" | 2 |

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43055012 | HOUSING-EXTENDED REACH-MAGNET | 1 | ||

| 2 | 50057008 | PLATE-END | 1 | ||

| 3 | HW0402 | BOLT-HHCS-3/8-16 X 1" | 4 | ||

| 4 | HW0108 | WASHER-FLAT-3/8"-SAE | 8 | ||

| 5 | HW0107 | WASHER-LOCK-3/8" | 4 | ||

| 6 | HW0005 | NUT-HEX-3/8-16 | 4 | ||

| 7 | 43058013 | PLATE-BEARING-SIDE | 2 | ||

| 8 | 43058016 | PLATE-SHIM-SIDE | 2 | ||

| 9 | 43058014 | PLATE-BEARING-UPPER/LOWER | 2 | ||

| 10 | 43058015 | PLATE-SHIM-UPPER/LOWER | 2 | ||

| 11 | HW0812 | SCREW-SHSS-1/4-20 X 5/8"-HALF DOG | 24 | ||

| 12 | HW0002 | NUT-HEX-1/4-20 | 24 |

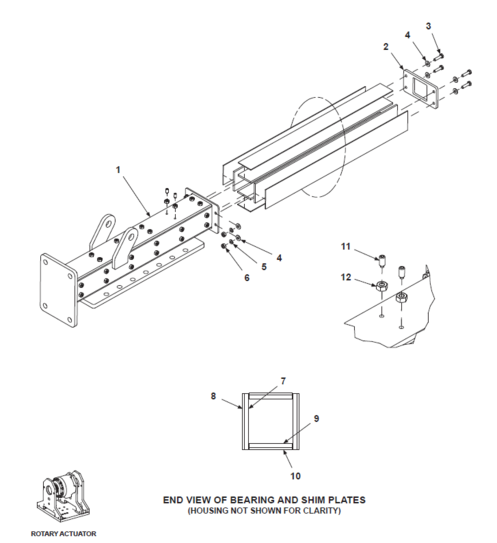

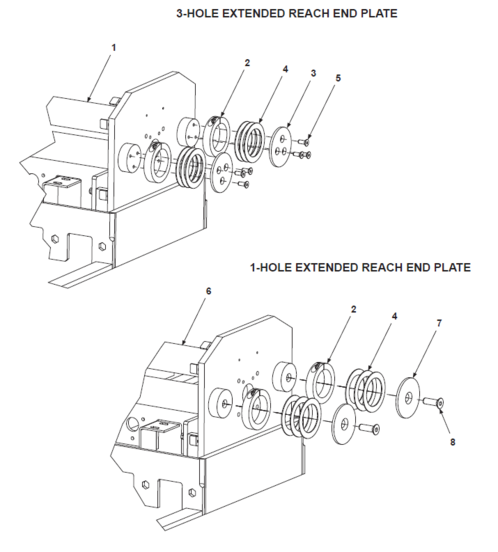

Extended Reach End Plate

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | N/A | CARRIER SHAFT-EXTRACTOR ARM | † 3-Hole version | A/R | |

| 2 | PT0413 | COLLAR-SHAFT-3" | 4 | ||

| 3 | 50057009 | PLATE-END-3 HOLE | Replacement part only | 4 | |

| 4 | 50057010 | SHIM-END PLATE | †† See notes | A/R | |

| 5 | HW1076 | BOLT-FHSCS-3/8-16 X 1" | 12 | ||

| 6 | 43057045 | CARRIER SHAFT-EXTRACTOR ARM | 1-Hole version | 2 | |

| 7 | 43017076 | PLATE-END-1 HOLE | 4 | ||

| 8 | HW0603 | BOLT-FHSCS-5/8-11 X 2" | 4 | ||

| NOTES | |||||

| † 3-Hole Carrier Shaft no longer available. Must replace 3-Hole shaft with current, 1-Hole version along with new ennd plates & hardware. | |||||

| †† Shim quantity varies due to manufacturing tolerances. | |||||

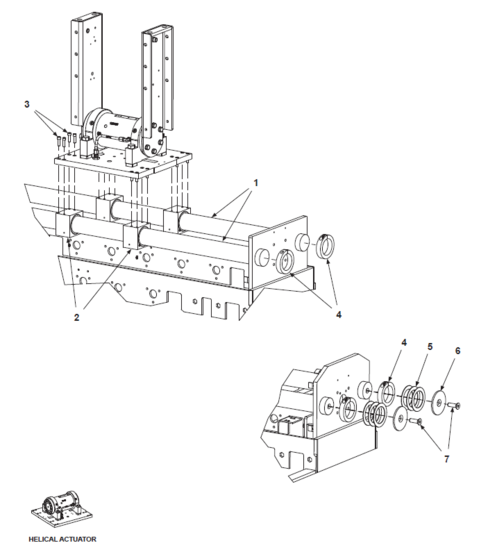

Carrier Shafts & Bearings

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43057045 | CARRIER SHAFT-EXTRACTOR ARM | † See notes | 2 | |

| 2 | 43054007 | BEARING-EXTRACTOR ARM CARRIER | 80252002 | 4 | |

| 3 | HW0412 | BOLT-SHCS-3/8-16 X 1 1/4" | 80252002 | 16 | |

| 4 | PT0413 | COLLAR-SHAFT-3" | 4 | ||

| 5 | 50057010 | SHIM-END PLATE | A/R | ||

| 6 | 43017076 | PLATE-END-1 HOLE | 4 | ||

| 7 | HW0603 | BOLT-FHSCS-5/8-11 X 2" | 4 | ||

| 8 | PT0624 | FITTING-ZERK | 80252002 | Not shown | 4 |

| NOTES | |||||

| † See Extended Reach End Plate section for Extended Reach equipped units. | |||||

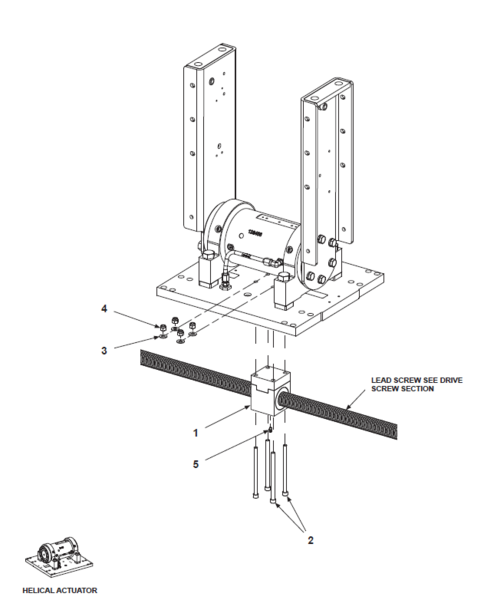

Drive Nut Assembly (Helical Actuator)

| ITEM | BHS PART NUMBER | DESCRIPTION | REF. KIT NO. | NOTES | NO. REQ |

|---|---|---|---|---|---|

| 1 | 43054006 | DRIVE NUT ASSEMBLY | 80252003 | 1 | |

| 2 | HW0426 | BOLT-SHCS-3/8-16 X 5 1/2" | 80252003 | † See notes | 4 |

| 3 | HW0108 | WASHER-FLAT-3/8"-SAE | 80252003 | † See notes | 4 |

| 4 | HW0006 | NUT-NILN-3/8-16 | 80252003 | † See notes | 4 |

| 5 | PT0624 | FITTING-ZERK | 80252003 | 1 | |

| NOTES | |||||